Thread: 55 Wagon Progress

Hybrid View

-

12-24-2015 02:46 PM #1

Thanks guys!

The frame had some slight pitting so the sides were hit with the DA to flatten things out a bit, and some Evercoat 416 used to address some of our plug weld grinding marks on the frame plates...

Here's the "winter" heating method for spraying in cold temps. 170,000 BTU aimed at the air return, and the air handler fan turned on constant to circulate the heat. Open window for air intake..

After three coats of primer, the sides of the frame are looking much better than before...

Also got some more primer on these parts as well, should be ready for blocking in a few days.

Robert

-

12-25-2015 09:41 AM #2

Robert, from that last pic are you saying you block sand interior panels too?

What painstaking attention to detail.

What painstaking attention to detail.

Jack.Last edited by Jack F; 12-31-2015 at 04:28 PM.

www.clubhotrod.com/forums/showthread.php?t=44081

-

12-29-2015 08:49 PM #3

-

12-25-2015 10:13 AM #4

Nice work. i LIKE THE HEATER TOO!

"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

12-27-2015 04:04 PM #5

In the winter weather, the booth fan will evacuate the heat in short order, the torpedo heater does a good job of keeping the temps up to par.

The other day when we primed the frame a second time we also did the front side of the trailer wheels..

and today I mixed up some Centari that has been sitting on the shelf a few years.. It sprayed pretty decent...

And more blocking.....

Last edited by MP&C; 12-27-2015 at 04:14 PM.

Robert

-

12-27-2015 04:46 PM #6

great color for the wheels! I'd like to see my car that color I think...

-

12-29-2015 08:45 PM #7

They would see you coming for sure!!

Made another trip to the car wash tonight. Tire soak, high pressure soap, and a rinse...

While Kyle was media blasting, I used the 36" AFS to block the tail gate.

This had been blocked a couple times before and never seemed to come out right. Of course, I was using a shorter block as well. The 36 really did the trick in getting things nice and flat...

.....and getting things ready for another epoxy session...

Moved these out of the way, closer to the door so we can get tires on this weekend. Order trim rings today, now for some baby moons that fit... I swear they get brighter every time I look at them..

Robert

-

12-30-2015 02:41 AM #8

-

01-01-2016 11:18 AM #9

johnboy

Mountain man. (Retired.)

Some mistakes are too much fun to be made only once.

I don't know everything about anything, and I don't know anything about lots of things.

'47 Ford sedan. 350 -- 350, Jaguar irs + ifs.

'49 Morris Minor. Datsun 1500cc, 5sp manual, Marina front axle, Nissan rear axle.

'51 Ford school bus. Chev 400 ci Vortec 5 sp manual + Gearvendors 2sp, 2000 Chev lwb dually chassis and axles.

'64 A.C. Cobra replica. Ford 429, C6 auto, Torana ifs, Jaguar irs.

-

01-01-2016 05:50 PM #10

Uh-oh... here we go....

Picked up some 400 grit PSA paper yesterday, used it this evening to get the tail gate finished to 400 grit, next week we'll wet sand to 600 grit.

Nephew Chris came over and helped Kyle and I get the frame off the rotisserie and back on the floor..

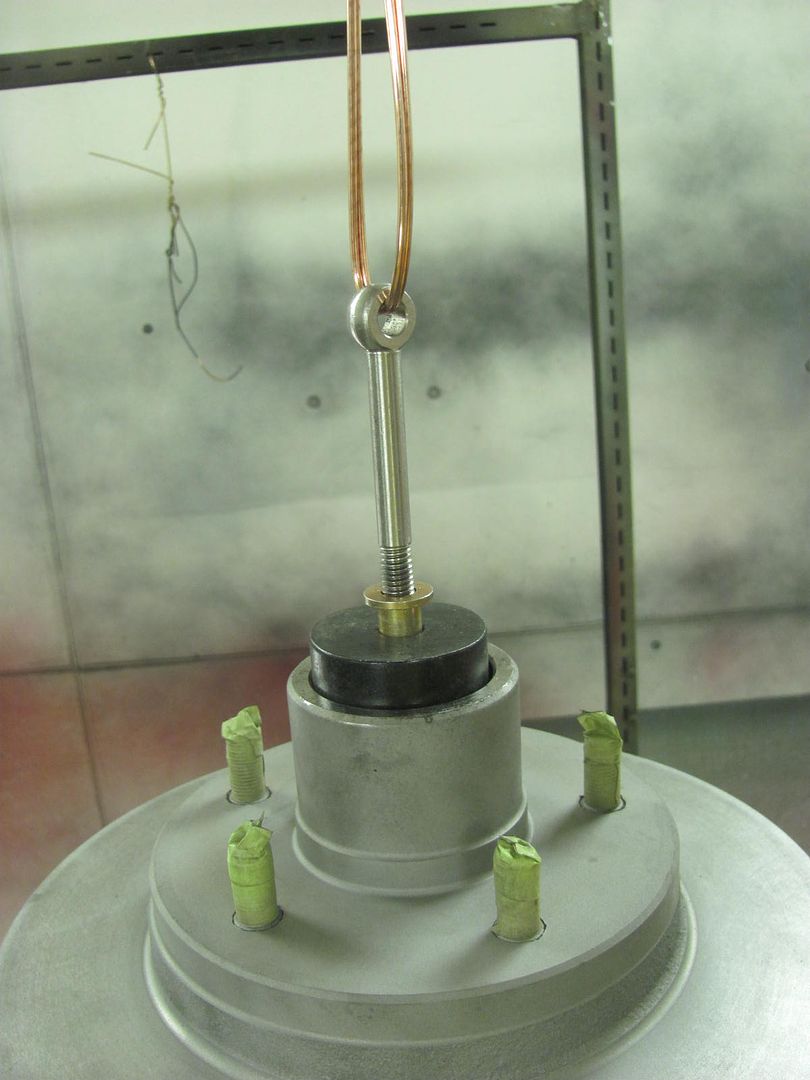

With the rotisserie freed up, we now have a new paint fixture...

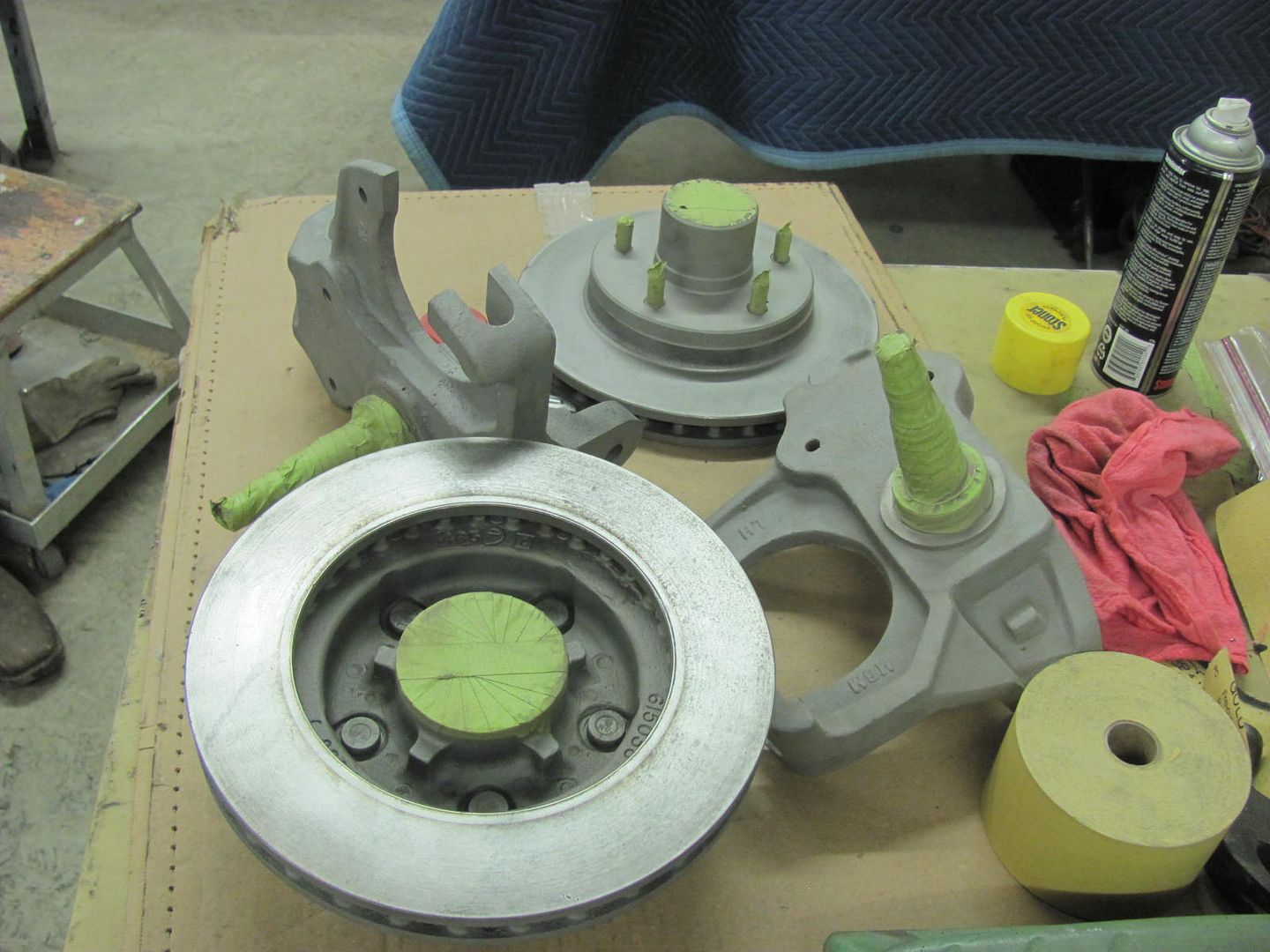

Parts prepped for epoxy primer tomorrow...

While I was getting these parts taped off, Kyle started blowing apart the rear end for media blasting..

Robert

-

12-30-2015 01:07 PM #11

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,299

- Blog Entries

- 1

Great work and nice fixtures to hold things!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

01-02-2016 08:21 PM #12

Today Kyle worked on getting the axle pads welded on....

.....while I was spraying some SPI epoxy....

.....and while I had some epoxy mixed, we poured some inside the tailgate to seal the inner and outer skins ..

Axle pads done, then heated the opposite side to counter the weld shrinking...

It's real close, just a little more straightening to do...

other parts from the booth today....

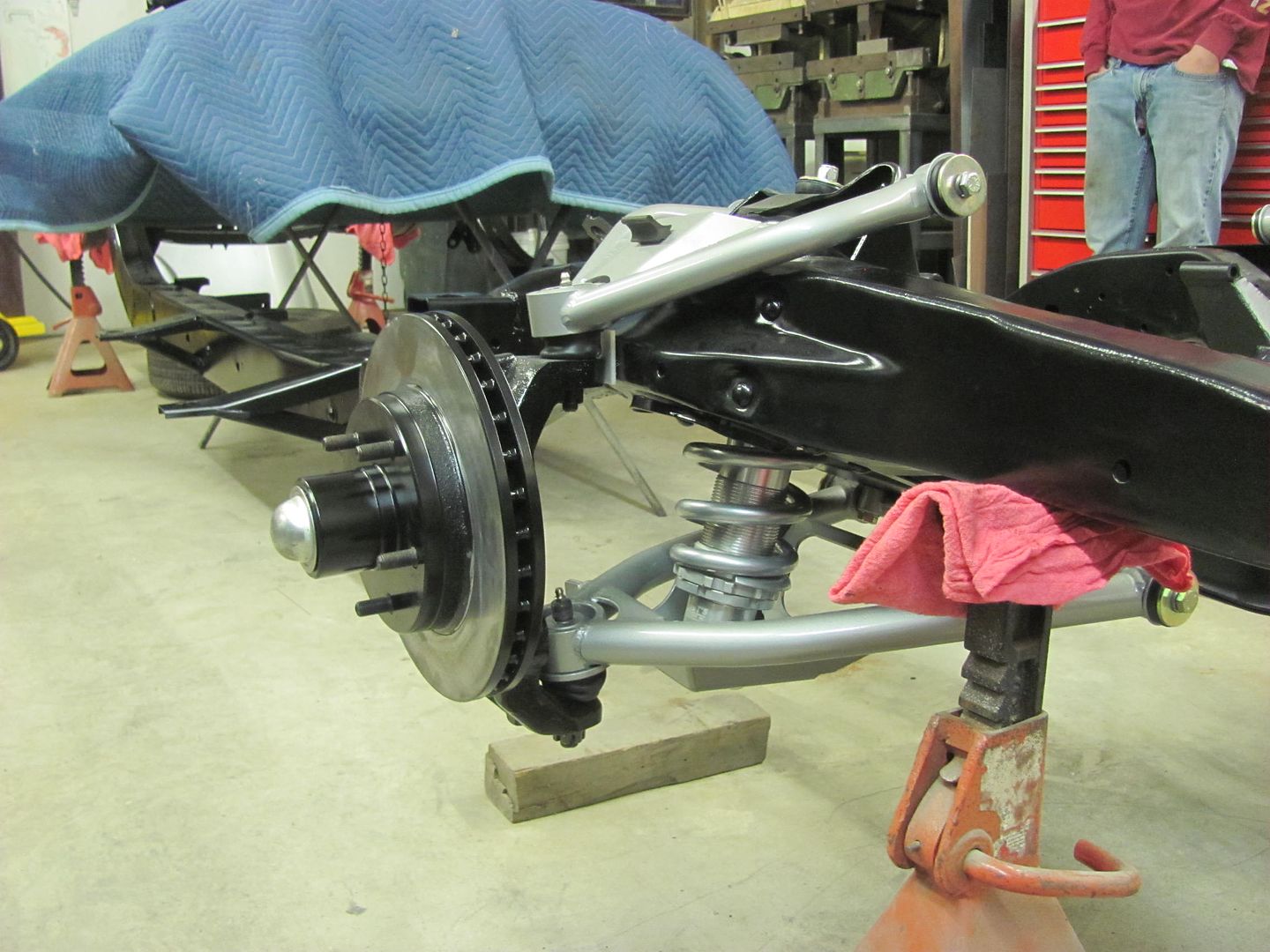

....and then sprayed some silver metallic Imron on the A-arms..

Robert

-

01-05-2016 08:32 PM #13

Well tonight we worked on getting the parts out of the booth so we can get the next load of parts ready for epoxy, and in between spent some more time on straightening the rear. In measuring at the bead of the 18" wheels, we had a +/- .020 on the passenger side and a +/- .035 on the drivers side.

....and more heat applied for some shrink..

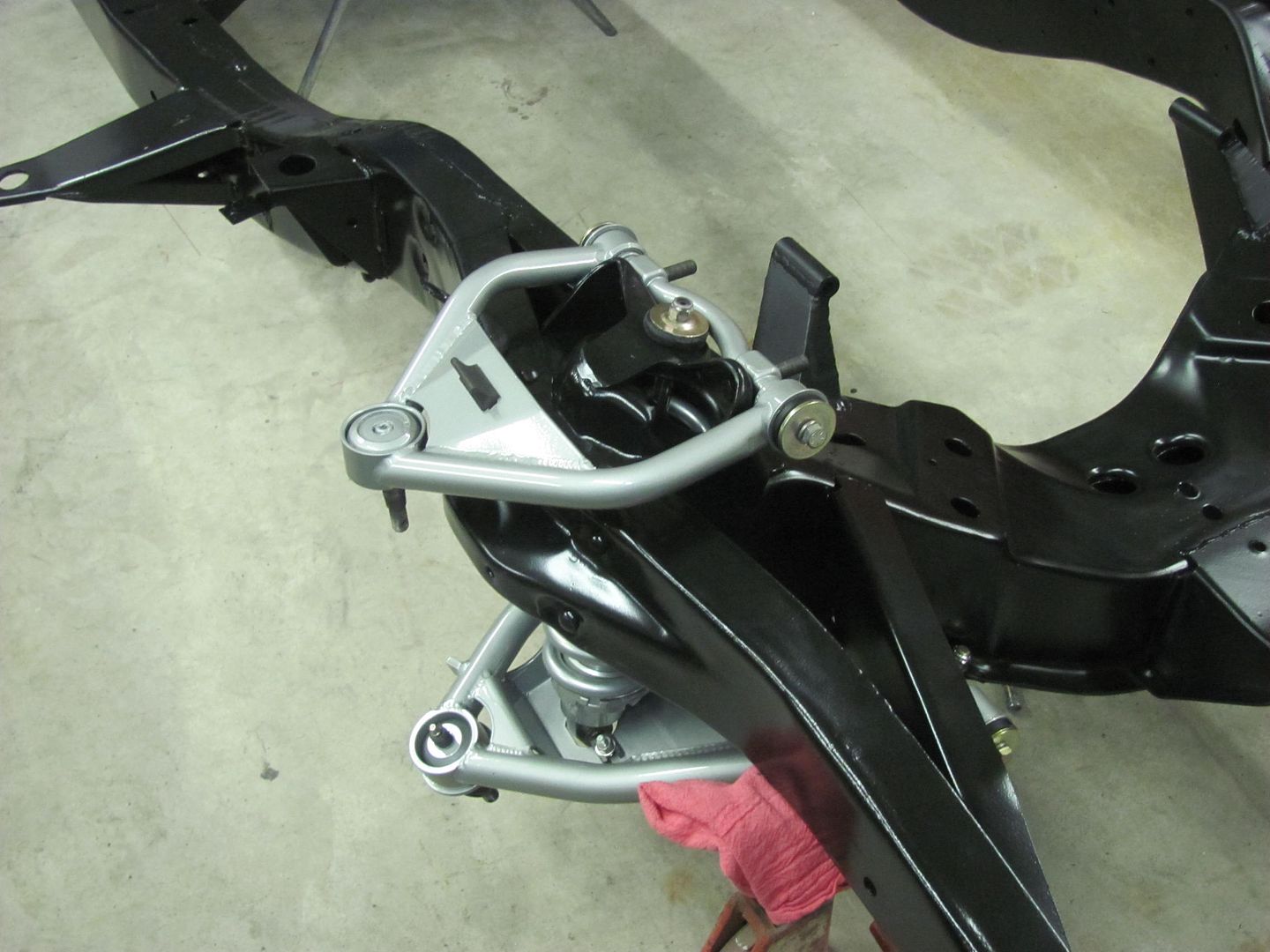

We'll let that cool and get some of the front end parts bolted up..

Robert

-

01-09-2016 09:58 PM #14

Getting the front end put together...

....and more blocking and hanging parts in prep for the next round of epoxy...

The doors are getting real close to needing wet sanding..

Robert

-

01-10-2016 08:30 AM #15

Here's a video taken yesterday using the 36" AFS sander. Note how the sander is grasped and the fact that this promotes letting the sandpaper do the work without "leaning" on it. Applying downward force through your palm to get the job done more quickly runs the risk of deflecting the sander downward at that point, causing low spots...

Robert

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Just in case......Happy Birthday Richard. .

Happy Birthday techinspector1