Thread: 454 head questions

-

02-12-2005 06:38 AM #1

454 head questions

OK gentlemen here what I am doing. 454 block .030 over. TRW forged pistions, L2349F I think was the # which is an LS6 duplicate I believe. To give you as much info as possible to help me choose I will be running a hydraulic cam, th400 trans with 2500-3000 converter, and approx a 3.37;1 rear. Choosing heads now:

I have 781 open chambers that came with block 118CC which will need all the work, valves etc.

I am looking at Edelbrocks 118 cc rectangular port performer RPM aluminum heads.

Also looking at Brodix Race ready aluminum 118cc oval ports with the 271cc runners.

All of these heads with 118-119cc should put me at about 9.5-9.75:1 compression so I can run on pump gas. Which do you recommend. Motor is going into a 66 Chevelle for mostly street but occasional track use and will be a weekend driver. My thoughts are stock heads are decent but the coin required to get them up to snuff will be quite large. The aluminums are kinda pricey but the extra weight and performace over the irons I figured was worth it. Now I think I like the Brodix the best with the small runners (271cc)and oval ports to keep the torque up. They have 2.25 intakes and 1.88 exhaust. They are like $1850. in Summit. The Edelbrocks are about $1750. in summit and have 315cc runners and are rectangular with 2.19 intakes and 1.88 exhaust valves. So what would you guys choose?

Then again World has a big block iron 118cc head for about 1500.

Opinions please!

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

02-12-2005 11:17 AM #2

heads

I like the Edelbrock Performer R.P.M. heads ,they are high quality pieces and the rec. port will give you all the flow you need .The price is also pretty reasonable. I like alum. over cast iron hand's down.Especially on a rat motor!!!

-

02-17-2005 02:42 PM #3

C'Mon TECHINSPECTOR, RIFLE and you guru's out there with all the experience help me out here on this question. Anyone with experience with heads. Please.

-

02-21-2005 03:23 AM #4

Hey! I'll try this one on

Aluminum vs. iron heads, I guess that's your primary question.

I'm not speaking from personal experience, and maybe that's a bad thing; but, from what I've read... aluminum heads are fairly hard to seal to the block with conventional head gaskets. Aluminum has a fairly high coefficient of expansion, so when it heats up it moves a lot in respect to iron, and when it cools down it does it again. Apparently all this squirming around on the block compromises the head gasket's abliity to hold a seal. and that is bad news.

Now, this from experience, aluminum corrodes like the dickens if you have anything less than straight antifreeze in the block. I messed up the water passages on a really nice smallblock Torker intake by running 50/50 water/antifreeze for less that a year, and that antifreeze was the good Prestone stuff.

I used to think, yeah man, I'm gonna build me a L-88 with the aluminum heads and all that good hardware. No iron head L--72 for me, I can't stand the extra 100? lbs on the front end of my already overweight 1/2 ton GMC. Well, I got over that after I grew up some, and decided to shave the weight elsewhere, as if it really mattered on a pickup. I just did not want the corrosion problems associated with aluminum, and ruining a set of aluminum heads is a lot more traumatic than ruining a manifold.

And now to that head gasket problem, about 5 years ago, I blew a head gasket on a 350 Chevy about 3 miles out of town. By the time I had shut it down, the head (iron) was cracked and the block was cracked in the same place. So a bad head gasket ruined a perfectly good 4-bolt main 350 block in about as much time as it took to write this paragraph. If this can happen with a mild iron-headed smallblock, it can certainly happen with a high-powered aluminum-headed big block. I simply would not take the chance of ruining a block from a head gasket failure if I could avoid it. If you're going to be on the street with your ride, I would strongly recommend iron heads, because I dont think you'll ever see a difference due to the extra weight. If you're gonna race it, and use the aluminum heads, I would retorque those babies after every run, and replace the head gaskets after every 10 runs. The only sure-fire way to seal aluminum heads to an iron block and have a worry free ride, is probably to o-ring the block, and that is indeed an expensive proposition.

Randy

-

02-21-2005 10:19 AM #5

I respectfully disagree with just about everything in the last post except for the part about the kind of damage a blown head gasket will do. No disrespect, Randy, but I've used aluminum heads extensively.

Edelbrock' performer heads are terrific parts. They have taken the time to match all of their components for maximum performance, and matching parts is what engine building is all about.

First, aluminum heads seal perfectly fine if you use the right gaskets. If you buy Edelbrock's heads, ask them what gaskets to use. If you follow their specs and torque them properly, you won't have any problems. After all, the auto manufacturers have been using aluminum heads on iron blocks for years now.

Second, the aluminum heads let you run a higher compression ratio without detonation.

Third, modern antifrezes are formulated for aluminum heads and engines. Double check the label and make sure it meets the GM1825M specs (like Texaco Dex-Cool). I've got 120k miles on my aluminum head LT-1 Vette. No problems. Do NOT run 100% antifreze.

Assuming I had to buy heads, I'm not sure I'd ever run another set of iron heads on a performance engine.

Something else to think about. You stated that your engine was mostly for street use, with an occasional trip down the quarter mile. Depending on the cam, carb and intake you use, these heads may come in at a higher RPM than you would like on the street - especially with a 3.37 gear.

In your shoes, I'd check with Edelbrock's tech department in addition to what you might discover here.Jack

Gone to Texas

-

02-22-2005 07:46 AM #6

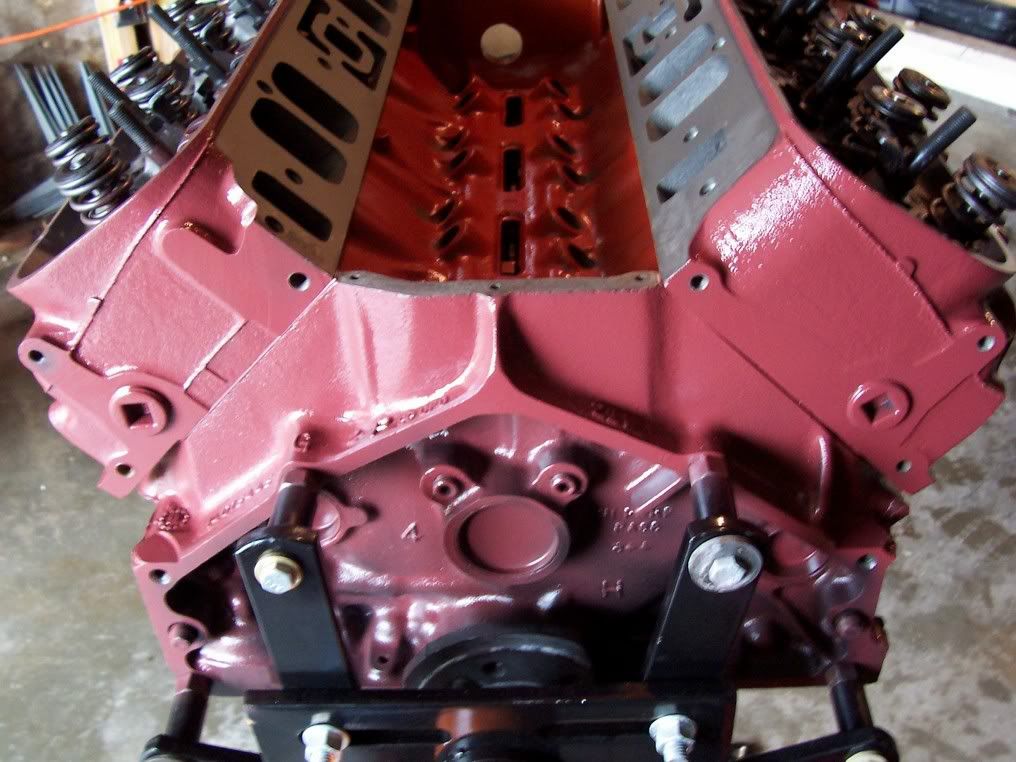

ok, i know im young, but i have built alot of engines.i am doing a similar project as you.sorry bout the photo size but...

and there she is, i went with the Ls7 cast iron heads, and i think you should do the same. with a big block....cast iron hands down.

-

02-22-2005 08:54 AM #7

Good pictures, and a nice job on the engine. However, I'm wondering what conclusions about iron vs aluminum heads can be drawn from a series of photos. You said that it's iron heads on a big block "hands down." What reasons are you putting forth?

Here's a photo of a big block with aluminum heads, but without some background on performance, etc., it doesn't say much except that someone built one.

I'm not doubting that you built a heck of an engine there, or that your recommendation isn't valid. I just don't see any backup except for the photos.Jack

Gone to Texas

-

02-22-2005 09:12 AM #8

Henry , that is very nice looking PLEASE, Dont tell me it's a 1000 h.p. I don't think I can take it twice in one day.

-

02-22-2005 09:13 AM #9

Let's do the smell test:

GM builds real crate engines that they extensively test and attach a warranty to those engines. They have access to resources that the common man couldnt begin to have. The GM 12498827 engine is 572 ci at 12:1. It has an advertised HP of 720@6250 and a TQ of 685@4500. This aint Leroy's Crate Engine Shop down the street either. They make a low compression model too.

Given that GM tests/designs/develops/manufactures heads in both iron and aluminum (and some stuff we arent told about), doesnt it smell right that they would choose a head that maximizes performance? Maybe not emissions or gas mileage on this part number but certainly performance. If an iron head made more power, they would have used it. If there was a lhint of a ongevity issue with aluminum in a 12:1 motor, they would have used iron.

mike in tucson

-

02-22-2005 02:49 PM #10

So riverhorse im not the only one smelling something wrong with that story!!!!hehe

I tried to be sensible about it in another post (check it out). Gotta love my dads motor haha

what rockers are those?? you know the $$$$$$$ ones.

-

02-22-2005 02:53 PM #11

Riverhorse,Originally posted by riverhorse59

Henry , that is very nice looking PLEASE, Dont tell me it's a 1000 h.p. I don't think I can take it twice in one day.

It's only 550, so I guess you'd need two.

Jack

Gone to Texas

-

02-22-2005 03:35 PM #12

Originally posted by 71nova

So riverhorse im not the only one smelling something wrong with that story!!!!hehe

I tried to be sensible about it in another post (check it out). Gotta love my dads motor haha

what rockers are those?? you know the $$$$$$$ ones.

so i dont remember every brand name in the freegin universe, shoot me. why would i post an engine on here, and do all this talkin about it, if it wasnt mine? what will prove to you that this is my engine?

-

02-22-2005 07:13 PM #13

Uhhh . . . Since it's not mine, I couldn't care less who owns it.what will prove to you that this is my engine? But back to the original question. Since it's "cast iron hands down," I'm still wondering why, and how do a half dozen photographs support that point?and i think you should do the same. with a big block....cast iron hands down.

But back to the original question. Since it's "cast iron hands down," I'm still wondering why, and how do a half dozen photographs support that point?and i think you should do the same. with a big block....cast iron hands down.

Or perhaps the only purpose is for us to "feast our eyes" on this purty motor?

Jack

Gone to Texas

-

02-23-2005 11:44 AM #14

I was just teasing bout your dads motor, BUT 1000 horse just gave me quite a chuckle with what i see done to it. Its a very nice looking motor though i give you that.

Where did you get your blow through carb at?

-

02-26-2005 05:44 PM #15

Back to 30A rider, I dont know what machine work is in your area, but I had a set of 049 heads done last year...milled to 113 cc chambers, larger valves (2.19/1.88) , teflon seals, set up with the springs I supplied, all ready to bolt on...and he also supplied the valves, I told him to get what he usually uses...they cost me 675.00 complete, ready to bolt on and go. That's lots less than any aluminum heads, and they flow like crazy. Small intake runners so they're good for low end torque like you want (same as your 781's) If it's primarily a street car, I wouldnt be concerned about the weight savings, especially for that extra money. Also, the fact that you can run a higher CR with aluminum (true) does not apply here, cause you're only looking at under 10/1 anyway. So I would definitely go with the iron heads...just my opinion. Also, respectfully speaking, vertok's post, as Henry said, is nonsense.When your dreams turn to dust, Vacuum!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

You're welcome Mike, glad it worked out for you. Roger, it's taken a few years but my inventory of excess parts has shrunk a fair bit from 1 1/2 garage stalls to about an eight by eight space. ...

1968 Plymouth Valiant 1st Gen HEMI