Thread: My 67XR7GT Build

Hybrid View

-

03-08-2014 05:53 PM #1

Awesome car! Looks really solid, too.1 Corinthians 1:27

-

03-06-2014 07:26 PM #2

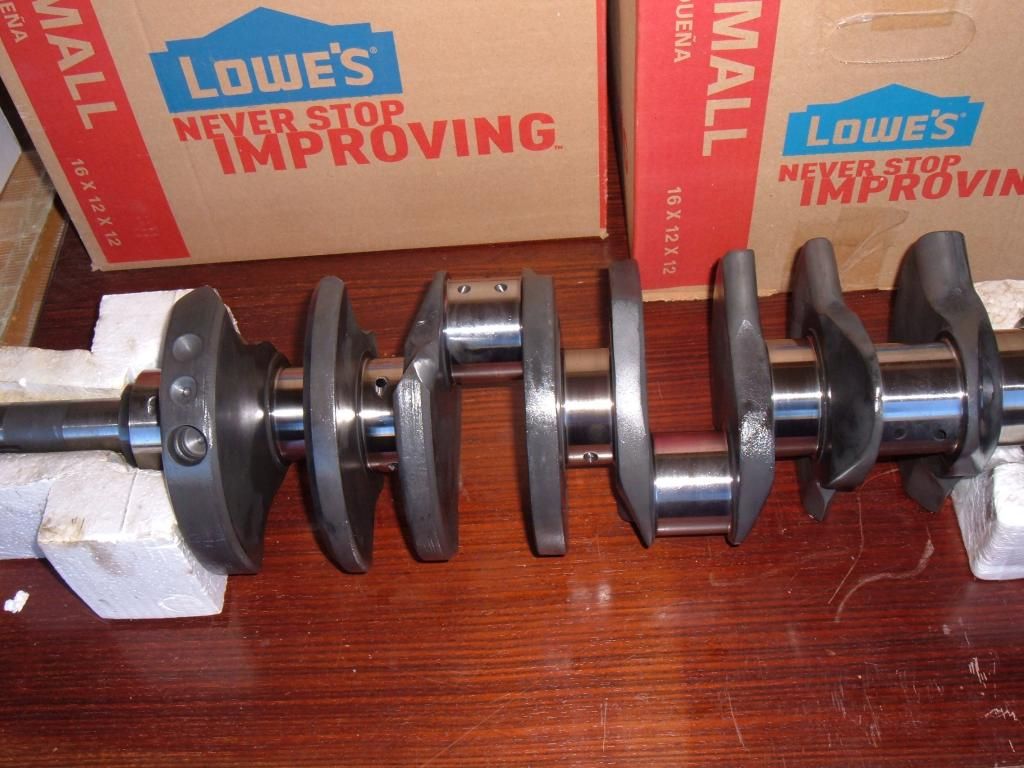

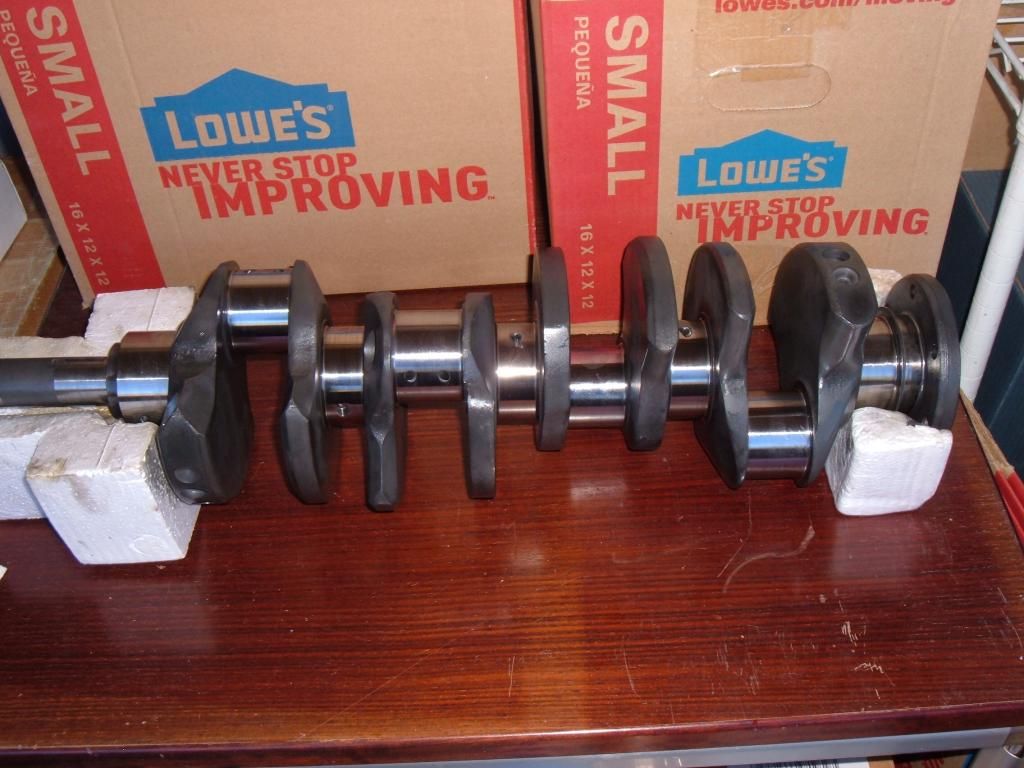

Yes a Cobra replica, the guy I bought the crank from builds them. The funny thing is I 've owned this crank for over 5 months, and have not seen it other than a few pics I got from the guy.

I gave up the storage units last year I had this car & other stuff in, that I've paid for over 30 years, and the money I was paying for the storage is now paying to put the Cougar back on the road.Richard

-

03-06-2014 10:17 PM #3

Love the cougar, are you going to try and use nascar heads as well? It would be sweet if you turned this it to a turn grabbber, or is this just going to be a qtr mile runner?

-

03-06-2014 11:56 PM #4

I had thought about some HR heads for all of .5 seconds, but they won't fit under the hood. But I have always had a thing for Tunnel Port heads.

I am not building for big HP numbers, I'll go for an easy 450 to 500 HP. I am staying close to stock cubic inches, even at this HP & Torque level the car will have a problem hooking up, if ever...

Today, John at Costa Mesa R&D was telling me about a new Auto Cross SCCA class called "CAM" (Classic American Muscle) that would be fun playing around in. And I've been going out to the SCCA sponsored Auto Cross at the Old El Toro Marine Base for some time with my Porsche 914 friends.

SoloMatters.com - Introducing - Classic American Muscle (CAM)Last edited by 1967 XR7 GT; 03-07-2014 at 08:54 PM.

Richard

-

03-07-2014 07:08 AM #5

Over the long history of the FE engines, I have ran many with grooved cranks, grooved bearings--in every thing from race cars to the tow trucks----------altho the nerd heads say that grooving a bearing will cut the load carrying ability into quarters ending up with just 50 % of load ability that a non grooved has, the importance of the better oil flow to the rods for both lube and cooling by far surpasses the reduced load capacity of the main--------

-

03-08-2014 10:00 AM #6

Richard

-

03-08-2014 10:31 AM #7

How much did you cut the caps???I was early on told by an old timer that it takes .007 to be able to get almost a complete new circle--and my experience has verified that----any amount less and the pattern doesn't clean up at the dividing lines------

Also---be advised that the Cleveland bearing is .032 shorter than the fe main ---then also subtract the width of the groove--you are loosing a sig amount of surface-----------

-

03-08-2014 04:31 PM #8

I didn't cut the caps, I got the machine shop too. I am just doing the mock ups & assembly to expedite the machine work.

What do you mean the Cleveland bearing is .032" shorter than the FE mains ? You talking length or bearing width ? With the Cleveland bearings it's the top bearing is the side that's grooved the bottom side has no groove and is why I went with them to use with a grooved crank, since I had some what of limited options on .020" mains 1/2 grooved.

Ford FE main bearing bore size range: 2.9417" - 29425"

351 Cleveland main bearing bore size range: 2.9415" - 2.9425"

Now I had found where one of the known FE engine builders, likes to go as tight as 2.9412" on the bores for extra bearing crush, then measures the bearing clearances, then has the crank ground for a specific clearance.

Now my machine shop likes to go on the tight side, and will go tighter should I say. And I'll ask my crank grinder's recommendation as he's has some knowledge of the FE.

So thanks for your advice & suggestions, all advice is welcome.Richard

-

03-08-2014 08:09 PM #9

Well, actually its the width of the bearing ---the old bearing books list it as length as they are looking at direction of front to rear of the engine-----

and that's why I asked-----a narrower bearing, minus the suface over the crank groove results in signifintely less bearing area, especially in the Ford engines where the mains and rod bearings are a lot narrower than gm or mopar stuff--------

-

11-04-2014 11:39 AM #10

-

11-04-2014 12:06 PM #11

so did you replace the crank or weld the main grooves???????

-

11-04-2014 12:38 PM #12

Same crank, since it is a fairly rare item with the extra counterweights.

The machinist recommended welding them up, so I went ahead and had

it done since it was cheap enough.Richard

-

11-26-2015 11:10 AM #13

I was finally able to get the car it in the garage and on jack stands, I got the headers off which was a lot of work, I had forgot some of the bolts can be only turned a 1/4 turn at a time to get in or out, which includes lifting each side of the motor to reach some.

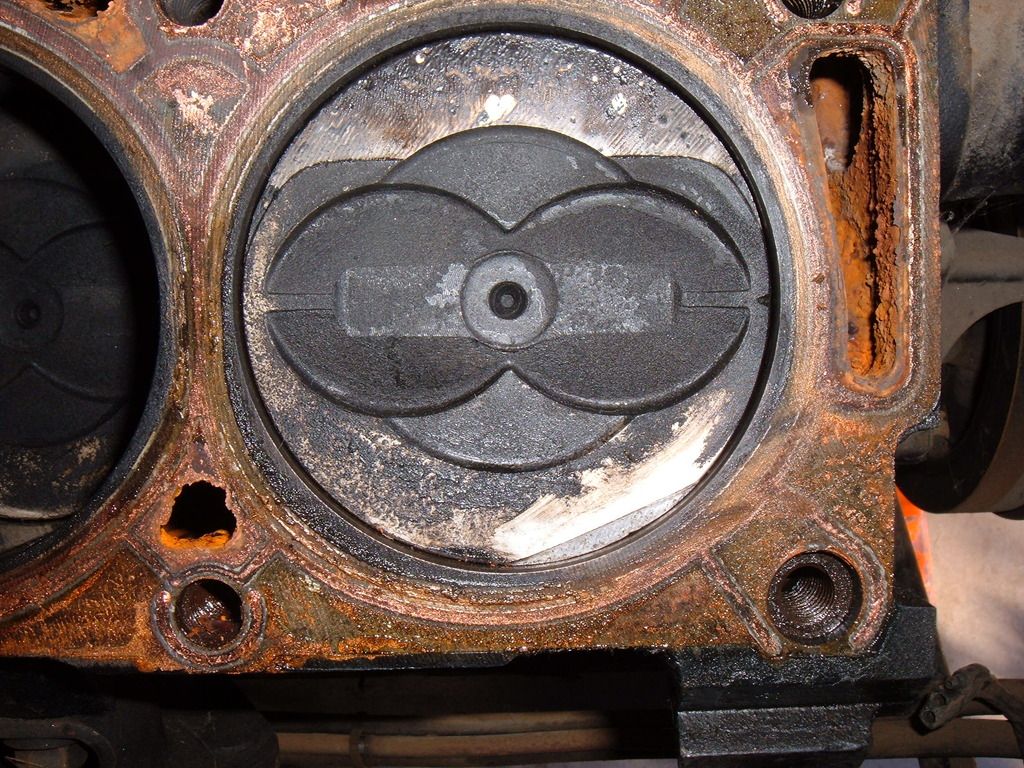

I pulled the heads, and you can see on No.1 the clean spot where the piston was hitting the head, so I found which rod bearing I lost. Cyl's 5&6 you can see rust on top of the pistons from pulling coolant from where the int was leaking on the head, apparently I didn't seal the water jackets well enough.

Richard

-

08-18-2017 05:39 PM #14

This was a Dbl PostLast edited by Type 4 Unleashe; 08-20-2017 at 11:36 AM. Reason: DBL POST

Richard

Stupid Is As Stupid Does

And You Can't Fix Stupid...

-

08-18-2017 05:45 PM #15

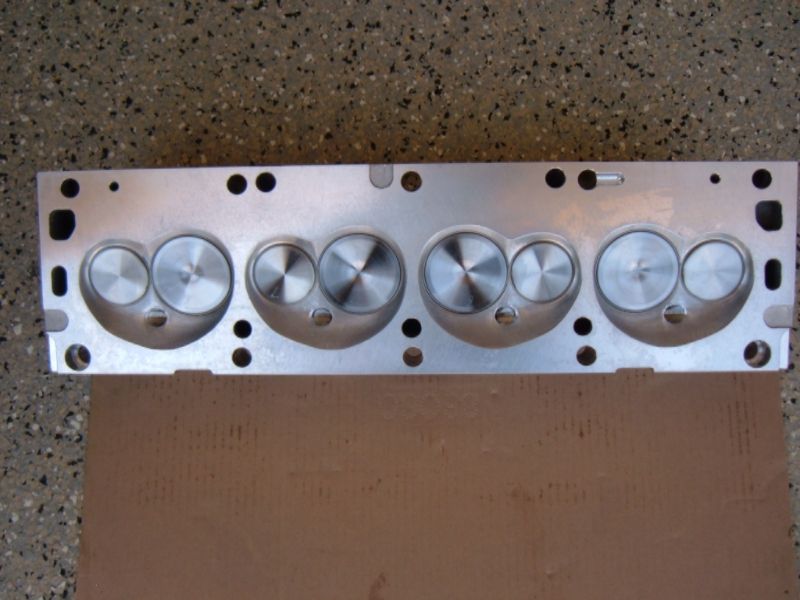

I had to save quite a while for these big ticket items

I've finally had these items just show up at my door. Heads are the NHRA legal casting CNCed Edelbrock Pro Ports, with stock location exh. Shock Towers made it necessary to go with stock location exh, due to how tight the 2 1/8" adjustable headers were, I couldn't take the chance with having the headers re-flanged to fit a re-located exhaust port, then dealing with fitment issues.

Then I had my "J" Sidewinder matched ported

Flow numbers @ .600" lift cam, which is what I am running: 330 Int & 232 exh with no pipe.

Intake valve 2.200 BP spec Ferrea

Exh. valve 1.650 BP spec Ferrea

There's this guy on one of the Ford Forums that has a program that from engine and car spec's, allows the program with a fair degree of accuracy

to determine an engines Torque & HP and how the car would run in the 1/8 & 1/4 mile, including a 60 ft.

Spec's: 67 Cougar, C6 3500 stall, 4:57 locker

427 @ 429 ci. flat tops @ 10.5 CR with Pro Ports, matched ported Sidewinder with an 850 Holley

Crower cam: 604/618 lift & 263/272 @ .050", with 108 LS - 104 IC

Exhaust 2 1/8 adjustable Hookers

Engine & Car Ratings:

427 car

Torq 560 at 4600

Powr 594 at 6100

1.60

7.18 at 96.7

11.22 at 121.1

Richard

Stupid Is As Stupid Does

And You Can't Fix Stupid...

15Likes

15Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

In our neighborhood, 2 blocks down the hill was a gas station that (to me) all the cool car guys hung out there. 32 coupes, 33 & 34 Fords as well, a sweet 56 Ford Beach wagon that was setup gasser...

How did you get hooked on cars?