Thread: 41 New Yorker Coupe

-

05-25-2011 04:23 PM #46

You're welcome Dave.

No problem Rick.

Anytime Dan.

The Engine Analyzer is nice.

I've ran it twice for free trials. Once at work and once at home.

I'm out of IP addresses to run it anymore.

If I remember correctly, its a little over 4 bills. Too rich for my blood.

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

05-25-2011 04:32 PM #47

Thanks Steve.

All these details are taking forever.

I was out tapping on the front metal on the weekend and man am I having a hard time.

I tacked everything together before I should have and I'm paying the piper now.

The shape is way off and its gonna be pretty hard lifting the whole car onto the English wheel to smooth out all the knock dings I've put into it.

Well, there's always high build primer and bondo I guess.

-

05-25-2011 04:51 PM #48

After figuring out the pivot points I started on the sleeves for the ball joints.

I found some nice steel screw in style sleeves for the upper arms at the local speed shop.

As I wanted stainless finish, I welded some schedule 80 pipe around the sleeves to weld the arm to.

For the lowers, I got stock Cobra ball joints.

These were a little trickier as they are press in

I used two pieces of schedule 80 pipe for these. I had to cut a sliver out and reweld to the correct size to fit the balljoint. The weld seams ended up under the connection point of the arm to the sleeve to lock everything up for sure.

The pic below shows the fit of the ball joint after it was pressed out.

-

05-25-2011 05:05 PM #49

Here's a beauty move.

Nice looking lower control arm going together.....

It would be good if it was going on a train and the wheels didn't have to turn....DOH!

-

05-25-2011 05:21 PM #50

I cut the obtrusive pipe off and started on the upper arm to get the wheel turning and to figure out how to get out of the lower arm mess.

Jigged the upper arms up to weld the sleeves on.

Got the uppers done and the bushings and sleeves made up.

I screwed the ball joints in to check things out.

-

05-28-2011 05:30 AM #51

I got the lower control arm mess sorted out and finished the coilover mounts and Delrin bushings.

Of coarse a couple of grease fittings for good measure.

Last edited by 123pugsy; 05-28-2011 at 05:32 AM.

-

05-28-2011 05:40 AM #52

I cut all the pieces for the crossmember and the front kickups and welded them up.

-

05-28-2011 05:51 AM #53

I got the 1'' diameter solid sleeves with 5/8 fine threaded tapped ends tacked in place.

These are for the steering rack and lower control arms.

Over the sleeves that protrude are pieces of 1-1/2'' pipe with end caps to stiffen things up some more.

Everything was chamfered before welding for strength.

I also got the upper coilover mounts ready and did a little mock up here.

-

05-28-2011 06:07 AM #54

I got the crossmember and coilover mounts welded and polished up.

I then made up the upper control arm mounts.

My first thought was to use different amount of shims behind the front and rear of the plate to achieve camber and castor. This was a mistake as the plate is solid and shims will need to be applied evenly.

I had slots milled in the plate and made up some eccentric washers to be able to adjust castor. I got this idea from the bolts used on the Ford upper arms of the IRS.

Shims behind will adjust camber.

Last edited by 123pugsy; 05-28-2011 at 06:18 AM.

-

05-28-2011 09:21 AM #55

Wow Pugsy it looks great. Nice custom work."  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

05-28-2011 03:52 PM #56

Thanks Steve.

I got the chassis rolling and pushed it outside for the first time.

-

05-28-2011 04:01 PM #57

Next thing was to make up some motor mounts to hold up the big block Chevy.

Then a crossmember for the tranny.

Its actually going to hold up the Gearvendors overdrive unit so I will be able to weld it in and still be able to pull the tranny no problem.

The exhaust pipes will run thru the 4'' holes.

-

05-28-2011 04:15 PM #58

Man nice work ..You still have snow on the ground and I was (am) complaining about rainCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

05-28-2011 04:20 PM #59

Remember, Freedom isn't Free, thousands have paid the price so you can enjoy what you have today.

Duct tape is like 'The Force.' It has a light side and a dark side, and it holds the universe together.

-

05-28-2011 04:25 PM #60

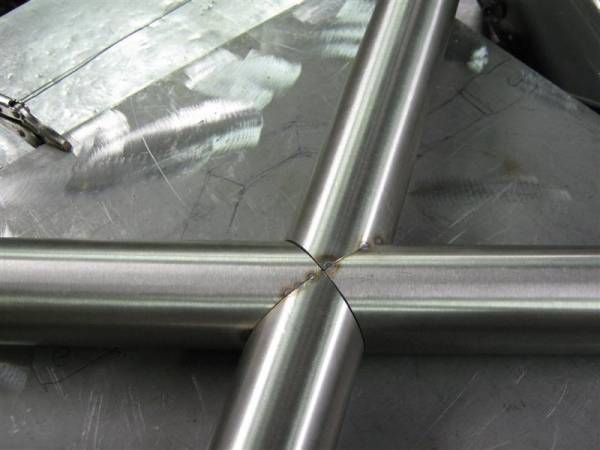

Next thing to do was to start the exhaust system.

I started with 4 pcs of 3'' dia stainless for the X pipe.

Then some elbows were added at the front and back.

I'm using Dynamax Ultraflow Welded mufflers. I hope its not too loud.

9Likes

9Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

It was SWMBO's little dog. .

the Official CHR joke page duel