Thread: Build thread 37 Dodge PU

-

04-06-2016 04:49 PM #166

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,300

- Blog Entries

- 1

Mike, make sure the trans you are getting has lock up and over drive. 518's only have over drive. More great work too!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

04-06-2016 07:27 PM #167

".....Still got the "eye" for adaptability, Mike! ....."

Yeah, I guess so Roger. I was thinking about that this morning while I was writing the post. I know I can actually buy almost everything to build this from places like Speedway. Summit, Jegs etc, and actually looked at a lot of it in the catalogs. I just still get a kick out of adapting stuff on my own....it's not so the much the cost or availability of stuff like it was when I was younger it's the challenge of figuring things out.

".......518's only have over drive....."

You are correct Ryan, I misspoke, they are building a 46RH. I've been thru the old 727s and 904s before but am having a heck of a time keeping up with all the "new" numbering Mopar is using. I did come a cross a good post on another site that helped explain it a bit for me. In case anybody else is interested I saved the info.

"......

518's have no lockup and use the single wrap rear band.

46rh has lockup and single wrap rear band.

46re has lockup and gov solenoind, single wrap rear band

47rh has lockup and triple wrap band with smaller piston

47re has lockup and gov solenoid, triple wrap rear band with smaller piston.

48re has lockup and gov solenoid, upgraded pump, 6 pinion steel planetaries, and triple wrap rear band with smaller piston

......."

Fortunately the guy at the tranny shop is giving me what I want rather than what I ask for LOL.

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

04-09-2016 06:54 PM #168

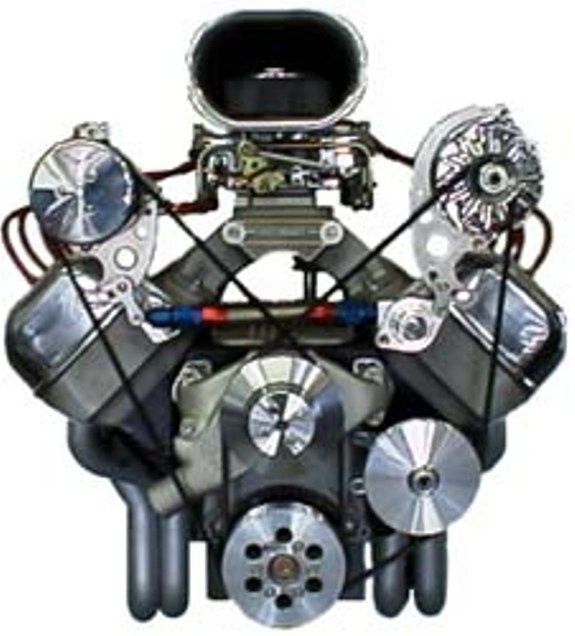

I knew 13 years ago that this day would eventually come………and I kept putting it off, hoping the problem would go away, maybe even a simple solution would come along…..but the day is finally here, I have no more time and have to do something!!!! Yes it’s time to finally bite the bullet and figure out how to hang a power steering pump on the old HEMI. Sorting out brackets has never been one of my favorite jobs hence the 13 years of this being a “roundtoit” job, I even considered just throwing a manual rack under the truck and calling it good. Anyway with my hand and wrist possibly not getting a lot better, I figured if I’m going to drive it I’s better be able to turn the steering wheel.

I’ve spent a couple of days searching the internet to see what’s for sale and what other people have been doing to mount the pumps. From what I’m seeing Hot Hemi Heads looks to be about the only game in town. March does offer a set up for the 392 (tall deck) Hemi but it's pretty pricey to experiment with. PAW used to offer some brackets, but that's pretty much gone now.

Now the Hotheads stuff is nice quality and a solution to a problem, I know firsthand because I’m running their timing cover, lower pulleys and AC bracket on the 57 Plymouth. That being said, there are a few issues I have with their setup.

The first thing is the amount of belt wrap around the water pump pulley. The small contact patch works OK as long as you are running AC along with the Alternator as the 2 belts (one on each side WP pulley) provide sufficient friction to spin the WP and fan without slipping. However without the 2nd belt it can be problematic to keep the WP and fan (HD Clutch and 7 Blade) turning without slipping. It also ends up requiring a pretty long belt which in my experience is much more likely to come off at high RPM. Finally the Hotheads brackets also limits you to using a Saginaw pump (more on that later).

While I used the Hotheads pulleys and brackets on the 354 Hemi in the Plymouth, when I set the 331 up for the 37 Dodge I took a different route and used a stock 4 groove BB Mopar lower pulley, stock Hemi Timing cover, modified Chevy alternator bracket, 2 groove upper water pump pulley (of unknown origin…..hey it fit and lines up), and long BB Chevy Water pump. In order to use the Hotheads PS pump bracket I would need not only the bracket but their; timing cover, lower pulley, WP pulley, PS bracket and alternator bracket. Additionally I would also end up having to change over to the more expensive short BB Chevy water pump.

It would cost me over $500 in parts to convert to the Hotheads system (which I suppose isn't all that horrible) but I would still end up with marginal belt wrap on the water pump and power steering pulleys and an even longer belt. The Hotheads stuff IS an option, but I decided to see if I could come up with something better.

A lot of people are aware that the Mustang II power steering rack is designed to work at a lower pressure than the commonly used Saginaw power steering pump produces. The over pressure can cause the steering to be “twitchy” which most people either learn to live with or correct by reducing the pressure of the Saginaw pump. Our own Techinspector made a comment here a while back that really stuck with me about this problem “……. why not just use a Mustang II PS pump if you’re going to make/modify brackets anyway…..” As I was going to be starting from scratch anyway…..and just happen to have a couple of the Ford Mustang II PS pumps laying in the pile I figured why not. “Why not” turned out to be quickly evident when I actually looked at the pump…..it’s long and besides the pump body the pressure lines connects to back of the pump requiring even more room. Moving the pump down and out away from the block a bit would create interference with the motor mounts and front header tube. The latter plastic body Ford pump might be shorter, but I didn’t have one to look at. So I figured back to plan B (a Saginaw pump) and headed for my core pile again.

While I was rooting around for a Saginaw pump and brackets to use for mockup I came across a couple of old Federal/Mopar PS pumps I had saved. They actually looked like they might be able to be adapted to the Hemi. I looked up the operating pressure and even though they are still a bit higher than the Ford pump they are less than the Saginaw pump, so I figured why not.

Using the stock Mopar brackets as a starting point I began seeing what I could do to mount the pump. The first issue I found was that groove in the lower pulley it lined up best with was the grove already currently being used for the water pump belt. So I started playing around with what could be moved fore or aft to get clearance. While going thru this the light came on and I recalled something I had run into while building the 500 Cadillac engine for the El Camino.

From the late 60’s thru the mid 70’s Cadillac’s 472 and 500 ci engines used a belt from the crank pulley around the WP pulley and tensioned with the smog pump to turn the water pump. They then spun the alternator with a belt running from a separate groove on the water pump pulley to the alternator. The result was good belt wrap on the pulleys and the use of 2 short belts instead of 1 long one. Never being one not to rob a good idea from someone else, I settled on doing basically the same thing on the Hemi.

This solution actually worked out very well for me. The water pump already had a 2 groove water pump pulley with the inner grove not being used. The alternator bracket I built had been spaced out to line up with the out groove of the WP pulley, so to line it up with the rear groove only required the removal of the spacers.

Modifying the stock Mopar brackets to fit the boss on the water pump was pretty straight forward.

Then the other thing I needed to do was build a bracket to lock the pump in place.

Actually modifying/building the brackets took less than 45 minutes. Figuring out what to build and modify plus test fitting things numerous times pretty much turn this into an all day job.

Aligning the alternator to the rear groove on the water pump pulley was about the simplest part. When I set the pulleys and alternator originally, I had to space the alternator out, so all I had to do there was remove the spacers.

With the engine in the stand it’s hard to get good pictures of the new setup, but I’m pretty happy with everything. The belt alignment is good and I have really good belt wrap on the pulleys.

The pump that’s on there now is just for mockup, I’ve got a rebuilt coming in that should be here Monday, but at least now the major work that I had been putting off is finally done.

.Last edited by Mike P; 04-10-2016 at 03:53 AM.

I've NEVER seen a car come from the factory that couldn't be improved.....

-

04-10-2016 05:06 AM #169

Looks like it was always there, Mike! Another lesson on adapting things ya' got vs simply ordering and waiting for the BBT to bring boxes. Thanks for the details, and hope the exercise on the hand/arm wasn't a bad thing.Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

04-10-2016 05:18 AM #170

Don't know if you guys have tried these yet, in a skillsaw these blades cut 1/4" flat stock like butter, very smooth cut edge.

Diablo 7-1/4 in. x 38-Tooth Steel Demon Ferrous Metal Cutting Saw Blade-D0738F - The Home Depot

Sorry for the thread diversion...

-

04-10-2016 06:49 AM #171

Kudos Mike, hot rodding at its best. Really nice work...

.PLANET EARTH, INSANE ASYLUM FOR THE UNIVERSE.

-

04-10-2016 07:09 PM #172

-

04-13-2016 07:01 AM #173

A nice side effect about getting the Dodge back into the shop is itís making me clear some other stuff out. I sold the engine run stand I built for the 283 to my friend who runs the machine shop (Dave, (69bee) who also just registered here). Dave is also the one who I traded my mockup engine and transmission to and Iíll be loaning him the manual transmission adapter, flywheel and bellhousing so he can test run the mockup hemi after he gets it built.

I also got around to taking my HEMI off the big run stand and on to the cart.

When I thought about it a bit I realized that the engine has been on that stand for at least the last 9 years. It needs to be wiped down good to get the accumulated dust and grit off of it and the paint is a bit faded now, but Iíll wait to detail it until I blow the truck apart for paint and body work (if I live that long ) Actually the faded paint on the engine should look right at home with the paint that is currently covering the truck.

) Actually the faded paint on the engine should look right at home with the paint that is currently covering the truck.

With the engine off the run stand that let me move the stand to the back shed and frees up enough room to put fenders and grill when we do the engine swap.

The big plan right now is to actually move the 37 into the shop on Saturday (after a quick stop at a small car show their having here in town). With any luck Iíll have my favorite helper Cade along with me.

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

04-13-2016 03:56 PM #174

I'm a bit jealous of you having a grandson to turn wrenches with. I thought I would be turning wrenches with my nephew Toad, but he's just too far away..

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

04-14-2016 01:51 PM #175

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,300

- Blog Entries

- 1

Your ps pump bracket solution is very similar to what I'm going to do on my 354. I can't justify that kind of coin for pullies and brackets for a long while since the entire car needs so much. Great work! I also want to add that your early hemi info has helped me a bunch too!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

04-15-2016 09:10 AM #176

Great work, Mike! Good to see the 37 out of the shadows again.1 Corinthians 1:27

-

04-16-2016 05:30 PM #177

Well it turned out to be a great Saturday. The wife and I took the 57 Plymouth to breakfast and met up with the kids and grandkids. Afterward Cade and I went over to the small car show a couple of blocks away. After wandering around for a bit we headed to my shop to start on the 37 Dodge. After we got to Dodge moved from the back shed to the shop I started off by having Cade blow off a years accumulation of dust.

From there it getting the front sheetmetal off and the mockup engine and tranny out and tearing down the mockup engine to get it over to Dave on Monday. Dave did stop by for a bit while we were getting the engine out so I was able to send a few of the parts with him today (and lighten the load I have to take over).

Cade has turned out to be a pretty good helper:

It took up about 4 hours to get it all apart, which I didn’t figure was too bad for an old man with a bad hand and his 13 year old grandson.

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

04-16-2016 07:08 PM #178

Always enjoy your family threads Mike. Nothing like Quality family time"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

04-17-2016 03:17 AM #179

Mike P., can I be your grandson too???

-

04-17-2016 03:55 AM #180

432Likes

432Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Borrowed from a FB post... Bubba loved to hunt, and every Friday after work he would fire up his grill and stoke up his smoker for the weekend and cook venison steaks, roasts and an occasional...

the Official CHR joke page duel