Thread: Build thread 37 Dodge PU

-

04-17-2016 05:45 AM #181

You can never have too many grandchildren!

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

04-17-2016 07:47 AM #182

Cade's gettin' tall enough to wash the roof...........................good sign..........Your Uncle Bob, Senior Geezer Curmudgeon

It's much easier to promise someone a "free" ride on the wagon than to urge them to pull it.

Luck occurs when preparation and opportunity converge.

-

04-17-2016 01:19 PM #183

-

04-17-2016 02:39 PM #184

And she comes packin' her own lunch too, hope there is enough for everybody in that chest ?

I too enjoy your family photo's and yes, Cade will be wanting the keys of the truck before you know it Mike.I maybe a little crazy but it stops me going insane.

Isaiah 48: 17,18.

Mark.

-

04-17-2016 03:59 PM #185

Actually guys that's my other grandSON Austin.....just before a haircut (although it's still a bit longish). The "lunch box" is actually his first tool box......a handfull of cheap wrenches, a crescent wrench and pair of safety glasses. Right now that box is enough for him, but I have a smaller roller chest that needs refurbished set aside for him when he outgrows it.

I usually babysit him for a few hours a couple days a week while his mom is taking college (and grandma's working). I'm a firm believer you can't start them too young.

https://www.youtube.com/watch?v=ATR-Uxj0p4I

Whiplash as far as Cade getting the keys to the truck, he's already asked about the little 87 Ram 50 I put the small block in

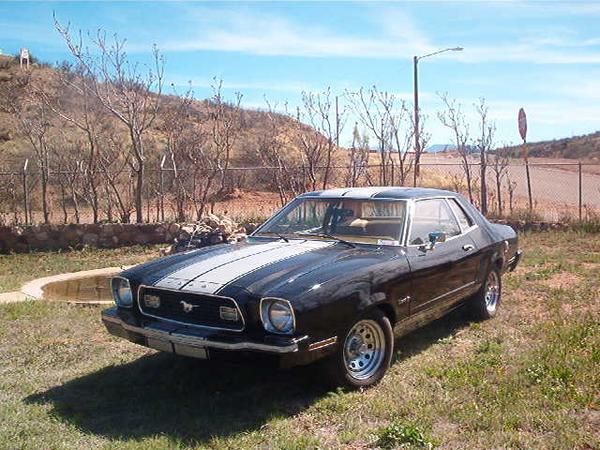

I think he things the 37 is too far away from being driveable . I may have headed that off though. We talked yesterday about the possibility of starting on the 74 Mustang II his grandma used to drive (it got parked with a tired engine a few years ago) this summer. It's got a 2.3 that shouldn't be too bad to go thru and we would probably pull the automatic out and put the 4 speed back in. Basically a drive train I would trust a 16 year old with

. I may have headed that off though. We talked yesterday about the possibility of starting on the 74 Mustang II his grandma used to drive (it got parked with a tired engine a few years ago) this summer. It's got a 2.3 that shouldn't be too bad to go thru and we would probably pull the automatic out and put the 4 speed back in. Basically a drive train I would trust a 16 year old with  Of course that would be dependent on his grades which at this point could stand a bit of improvement.

Of course that would be dependent on his grades which at this point could stand a bit of improvement.

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

04-17-2016 04:55 PM #186

My apologies to Austin!

Good idea on the M2 also..

-

04-17-2016 06:15 PM #187

No apologies needed from anyone, I can see how it could happen.

There are a lot of personality differences between Cade and Austin. Cade is the one that I see as being a pretty responsible driver by the time he reaches 16. Austin is the fearless one and I see a lot of broken parts in his future (something like me at that age ).

).

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

04-17-2016 08:17 PM #188

Weird how brothers and sisters differ so much. William is quiet, reserved and afraid of heights. Charlotte would wing-walk if you'd let her.

.PLANET EARTH, INSANE ASYLUM FOR THE UNIVERSE.

-

04-22-2016 07:09 PM #189

Well, 3 days after I started on the 20 minuet job of changing the rack out, the new rack is finally in.

It turns out the rack not coming with the correct fitting and having to source adapters was the least of the problems. Although this rack looks a lot like an original Ford rack, I now suspect it’s probably an overseas copy (big surprise). There were several subtle differences between this and a Ford rack that turned it into a real PIA to install. The pressure lines on the back of the rack were set farther out than the original (and couldn’t be interchanged because the Ford rack lines and fitting are SAE and the replacement uses metric. The Pinion shaft also was about ½” longer……. just enough to have to shorten one of the steering shaft and have the flats milled longer (thanks Dave). It also changed the angle of the joint causing it to bind and shaft to rub on the frame. By the time all was said and done I had to notch and box a place on the crossmember and one on the frame, plus realign the steering shafts.

If I had know all that I would have to go thru, I would have just sent the rack that was in it out to be rebuilt……but because of the unknowns with my hand and how long I’ll be laid up It was quicker to basically set the steering up all over again.

Oh well at least it’s done now.

.Last edited by Mike P; 04-23-2016 at 07:58 PM.

I've NEVER seen a car come from the factory that couldn't be improved.....

-

04-22-2016 07:18 PM #190

I also got the engine and transmission mated together today.

20 Years ago I would have muscled it into place then being as how it’s Friday gone out and had a few beers this evening. Now it’s the chain hoist, alignment dowels and the recliner.

There are a few tricks to the Hot Heads adapter, so I wrote that up and put it in the general Hemi info thread.

General Hemi Info part 3

.

.Last edited by Mike P; 04-22-2016 at 08:27 PM.

I've NEVER seen a car come from the factory that couldn't be improved.....

-

04-23-2016 05:50 PM #191

I’m shooting to set the engine and transmission in the truck tomorrow, so I figured I’d get the cable kickdown sorted out this afternoon. I order the El cheapo kickdown kit off E Bay and basically got a bag-o-parts with a cable and a handful of brackets……instructions would probably been usless for my application but it would have been nice to receive some.

For the carburetor end I modified one of the supplied brackets to hold the cable end of the cable and then fabricated a bracket to attach to the center carburetor. I made the carb bracket with several adjustment holes to ensure I would have enough adjustment when it came time to fine tune the kickdown. The bracket is functional, works well, and is easy to get to, but not very pretty.

The reason I didn’t spend a lot of time on the bracket is that once the kickdown is dialed and I’m happy with the adjustment it will be a simple matter to change the 2 center carburetors side to side and the brackets and cable will be hidden between the 2 rows of carbs.

The transmission end of the cable was pretty simple, just one small bracket to build to hold the cable end. I did install the mechanical end of the shift linkage to make sure there wouldn’t be any interference issues with the kickdown and shift linkage.

I’m glad I got the cable installed while the transmission and engine are still on the stand. Once the cooler lines, electrical wiring and shift cable are added it’s going to be a little crowded on that side of the transmission…..and not a lot of fun to work on from underneath.

.Last edited by Mike P; 04-23-2016 at 05:53 PM.

I've NEVER seen a car come from the factory that couldn't be improved.....

-

04-24-2016 02:45 PM #192

Well this was the 3rd and hopefully last time for me swinging an engine and transmission into the 37 Dodge. I’ve lost count of the number of times I’ve had engines and transmissions hanging from that chain hoist but I still get a little nervous when there is a HEMI and transmission hanging up there. It sure is easier and safer than using a cherry picker though.

There are still parts to buy/make and everything to hook up but it’s getting closer.

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

04-25-2016 10:29 AM #193

-

04-25-2016 11:27 AM #194

I'll just give them a link to this thread

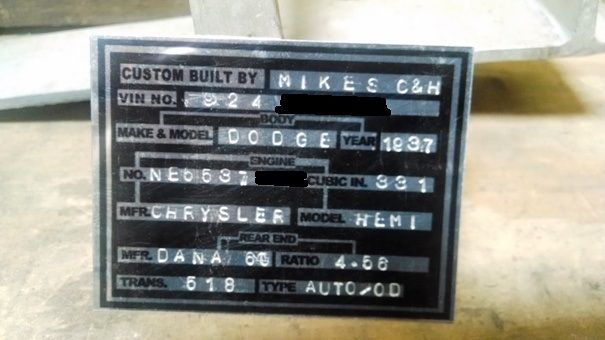

Actually, a few years back I picked up one of these that will be riveted somewhere on the truck, which covers the major components.

I also keep a running record of the parts (with application/part number) on things like molded radiator hoses, belts, brakes and bearings (especially on ones like this that will have Granada Rotors, GM Calipers, hoses off who knows what and the correct bearings and seal to put them on Mustang II spindles). On parts that won't be seen I usually mark them with a paint pen/permanent marker (you might have noticed the writing on the transmission) I also write the U Joint numbers in paint pen on the ends of the drive shaft, especially when I use conversion joints.

I also make a wiring diagram if I've done any major wiring changes/additions.

I usually end up keeping the things I build for at least a few years, and it does make life easier when replacement parts are needed.

.Last edited by Mike P; 04-25-2016 at 11:34 AM.

I've NEVER seen a car come from the factory that couldn't be improved.....

-

04-25-2016 11:44 AM #195

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,299

- Blog Entries

- 1

Mike, very nice work! Your adapter looks nicer than the one I decided to go with. Which torque converter did you end up going with? I think I'm going to use one from a 1500 pick up because it's suppose to be a little higher stall. Very nice work. Seeing the engine and trans in your truck makes me want to get mine in. (I may have to change plans for my vacation next week)

Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

432Likes

432Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

I didn't know him but followed his posts. True hotrodder, he will be missed. RIP 34_40 MIKE. Condolence to the Mrs. Nolan

We Lost a Good One