Thread: Build thread 37 Dodge PU

-

06-08-2016 06:55 PM #211

".....Are you going to use relays on your headlights?......"

I really hadn't even considered it until I read your post. I probably won't on the 37, but it is something to consider on the Ram 50 and El Camino (the ones I'm most likely to take cross country).

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

06-08-2016 08:12 PM #212

I used 2 of these on the Vette and I have 2 more I'm going to put on the Mustang I gave my grandson. I changed the wires around some and used the black wires for ground.

12 Volt Relay Socket Car Alarm 40 30 Amp 40A 30A 12V Automotive Ships from US | eBayKen Thomas

NoT FaDe AwaY and the music didn't die

The simplest road is usually the last one sought

Wild Willie & AA/FA's The greatest show in drag racing

-

06-10-2016 05:11 PM #213

With the radiator in hand I was able to get some actual measurements and figure out how I’m going to build the mounting brackets. From the looks of it I’ll be able to run a mechanical fan (my first choice). The mechanical fan means I also want to use a fan shroud. The radiator is set up for an original style shroud, so I took the easy way out and ordered a new reproduction (which are readily available and cheap).

While I’m waiting on the shroud to get here I went ahead and got the grill shell wired. I’ve always enjoyed building my own harness. It’s probably not a whole lot cheaper than buying a ready made harness but like I said I enjoy doing it. Of course when I checked my box of terminals I needed to restock that and I only had about half of the colors and gauges of wire I needed.

I was actually planning on using the headlights that were on the truck but my luck was holding true and it turns out they were 6 volt. Knowing that the truck is going to be taken apart for paint and body at some point I decided to go ahead and use plugs for everything so the harness won’t have to be cut and spliced back together to get the lights out.

The harness itself was fairly simple (headlight, turn signals, parking lights and horn) and really didn’t take that long to build. I terminated the harness with a 6 circuit plug just a little bit past the grill shell so that if I ever need to take the grill shell out it’s just unplug the one plug.

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

06-12-2016 05:38 AM #214

[QUOTE=Mike P;558109]

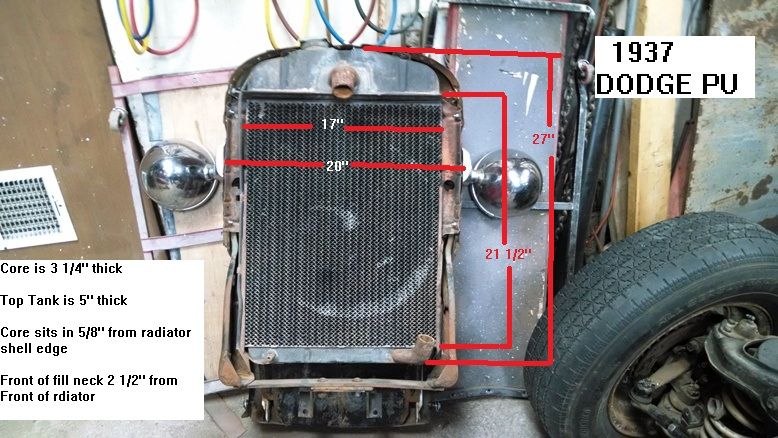

I happened to still have the original radiator for the truck, so getting measurements and seeing how it was originally mounted was where I started.

Nobody lists a replacement radiator for a 37 Dodge so it was more time spent doing a computer search for something that would work. I wasn’t having much luck finding anything that would fit or was affordable. After an hours or so looking at various radiators I remembered the post here on the site from a couple of months ago from the guy who had used a first generation Mustang radiator in his 37. The width is right but it could stand to be a few inches taller. I really debated about whether to keep looking for something bigger or to go ahead and order one. I eventually ended up deciding to take a chance on a 2 row (1 inch tubes) and see how it does. My thinking is the engine is only 341 cubic inches, it will have open hood sides and it will not have AC (and without the AC it will stay in the garage on those 100 degree days we have ).

).

Are you planning to build a shroud? I ask cause my car has a hood only, no side curtains, pretty much open.

Sitting in traffic the water temp would climb towards 200+ . Get moving it would drop rather quickly to 185-190. The water temp was unstable as hell, put up with it for a few years cause it never got seriously hot. But I found myself fixated on the temp gauge.

Got a wild hair and pieced together a shroud ...... I can attest to this, it totally stabilized the water temp I can feel the air blasting all the way back on the firewall.I have two brains, one is lost and the other is out looking for it

-

06-12-2016 06:32 AM #215

".....Are you planning to build a shroud?....."

Definitely!

"......With the radiator in hand I was able to get some actual measurements and figure out how I’m going to build the mounting brackets. From the looks of it I’ll be able to run a mechanical fan (my first choice). The mechanical fan means I also want to use a fan shroud. The radiator is set up for an original style shroud, so I took the easy way out and ordered a new reproduction (which are readily available and cheap)....."

With any luck the shroud should be here Tuesday or Wednesday. I figure I'll get into town tomorrow and pick up the steel I need to build the radiator brackets and maybe by the end of the week have the radiator in.

You did a nice job on your shroud Pepi! It also looks like your using the same fan that will be going on mine.

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

06-12-2016 09:10 AM #216

Very nice job!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

06-20-2016 04:26 PM #217

The radiator and fan shroud got in so I spent the last few days getting the cooling system done.

I was pleasantly surprised when the shroud came in to find out it was metal (I was pretty much expecting fiberglass). It fit the radiator well and except for having about a 1 ½” gap at the top (which was easily remedied with a strip of metal riveted in ) couldn’t have been better for the project.

I got the grill out and was working at a pretty good clip on Saturday afternoon.

Then the electrical substation up the road decided to go out. It was 103 degrees outside when the lights and coolers went down. Fortunately the last time the power went out for any length of time a couple of years ago I got around and wired my generators in. This time it was just hook up a battery to the generator throw a couple of switches and I had power again. My generator is enough to power the house but a little too light for the welder and compressor so I just kicked back in the house for the next 14 hours until the power came back on.

The radiator and shroud is a tight fit in the grill shell, but it does fit, along with the transmission cooler.

It would have gone a bit quicker (and would be a bit easy to service if I have to in the future) if I had set the engine back a couple of inches further or used the short BB Chevy water pump instead of the long one, but it is what it is. I’ve got enough room to get to everything and I’m very happy with the depth of the fan in the shroud.

There is a lot of room between the top of the radiator and the grill shell (that I wish I could have found a taller radiator). When I get some time I will probably find or build an overflow tank to fit up there.

I’ll probably get around and order the controller for the transmission later this week so I can go ahead and do the wiring next.Last edited by Mike P; 06-22-2016 at 02:57 AM.

I've NEVER seen a car come from the factory that couldn't be improved.....

-

06-20-2016 04:54 PM #218

Lookin' good there Mike. And an expansion tank on top should be an ideal piece!!

-

06-20-2016 06:15 PM #219

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,300

- Blog Entries

- 1

Nice work Mike! I might be able to give you some feed back on the compushift mini in a couple of weeks. My trans works in my 72 now and I'm trying to drive it on July 2nd. The compushift is one of the things i'm going to check off my list before I drive it.

Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

06-24-2016 05:49 PM #220

Thanks Ryan, I’d appreciate any of your insights and opinions about how you like it. I got started on my electrical a couple of days ago, and pretty quickly figured out that that I needed to have the Compushift unit on hand so I could incorporate that wiring into the harness I’m building and figure out exactly where to mount the controller.

I also pulled the trigger on an Autometer electronic speedometer as long as I had the card out. When I initially set the dash up a few years ago I bought a mechanical speedometer……I could still run a cable and use that, but was running into problems finding the recommend driven gear for the 4.56s (and knowing that the recommended one would probably still be a tooth or two off to actually get the speedometer to read correctly). The electronic speedometer I put in the ram 50 kind of spoiled as far as calibrating the speedometer by just pushing a button.

I’ve got the components outside the cab installed (lights, horn, senders, relays etc) so I’ve been plugging away at some of the wiring. The work bench currently looks like a bomb went off, but I got a couple of minor changes made to the fuse box to make it compatible with the Chevy turn signal switch in the steering column and all the wires labeled. I also got some of the wiring on the turn signal plug done.

I decided a while back that I would mount the fuse box, ignition box and transmission controller inside the glove box to make it more convenient. There was no glove box liner in the 37 when I bought it but surprisingly they are being reproduced. The original style glove box liners are extremely deep however and they wouldn’t clear the heater I installed. My solution is to make a liner out of some old stainless I had left over from doing the floor.

Hopefully I’ll have the liner built this weekend and at least some more of the wiring done before the transmission controller and speedometer get in next week.

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

06-24-2016 06:08 PM #221

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,300

- Blog Entries

- 1

Nice work! Sounds like you're making great progress on it for sure!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

07-04-2016 05:01 PM #222

I spent the last couple of days getting most of the wiring taken care of before I go into surgery. Knowing that I’ll be taking the truck completely apart at some point I made it so the wiring looms could be unplugged for easy removal and reinstall. Having just 2 plugs to undo to get the gauge cluster out will be especially nice.

I ordered the Compushift mini to control the lockup and overdrive and also got the electronic speedometer in……cause you know what’s a few more wires.

Actually the hookup on that was pretty straight forward. The only minor issue I had was getting the three pin plug that goes into transmission to go in. When I contacted the company I was told the correct plug is no longer available and they supply a GM plug (I did some checking for the correct plug and couldn’t find a source either…… and my buddy at the tranny shop didn’t have one and couldn’t source one for me either). Anyway I finally wiggled it just right and it did go in.

The Compushift also uses a throttle position sensor (in my case cable operated). I was able to find room under the dash to mount that and connect the cable to the gas pedal instead if adding one more thing to the carburetor linkage.

In the back of my mind I figured this one would be pretty simple to wire (and relatively speaking I guess it was). Jut the handful of circuits I needed to run still ending up being a pretty good size pile of wires by the time I got everything pulled into the cab.

The glove box I built turned out to be quite bit shallower that I had planned in order to clear the heater. There was still enough room to mount the ignition control box in it but I elected to mount that on the inside of the firewall up under the dash (it’s still relatively easy to get to). At least getting to the fuses and the control box for the Compushift will be a snap.

I’ve still got to get the fuel pumps mounted (the wiring is already there and switch installed) and hook up the alternator and ignition but that’s pretty much just 4 or 5 wires that are already run.

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

07-05-2016 08:27 AM #223

Looks nice Mike.

Well thought out and reasonably neat.

-

07-05-2016 09:48 AM #224

Nicely done, I like the ease of quick disconnects to get to things like the speedometer, and behind dash area. Really like the fuse in glove box design. Was planning to put an old Blaupunkt pull out stereo in dash and locate fuse panel on back fire wall or under seat. But in retrospect, the dash box is a perfect location for fuse box, and pull out radio could go under seat!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

07-05-2016 11:55 AM #225

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,300

- Blog Entries

- 1

Great work Mike! I put my compushift on the top of a control center I made, but I may change my mind and Velcro it to the side. I haven't decided yet. Hopefully I can get it installed and test drive it in the next couple of weeks.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

432Likes

432Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

And then a newer model....

Montana Mail Runner