Thread: Shop truck build

Hybrid View

-

02-11-2012 08:21 PM #1

Finished loosening all the brackets from the bus frame rails, they will be clamped and used as a template on the F7 frame.

My 10 year old daughter came out in the shop to help, polished fingernails and all... Who was I to stop her......

Then the rear was coaxed outside to make room for the truck...

Now most of the bolts holding the rears have been there since the early 50's. They were all fine thread bolts, most were double nutted, and most were in the top flange where it was inaccessible with an impact. Needless to say, we had a workout.

For the rear removal, I had to enlist my buddy Scott's help, he owns the motorcycle shop down the road that I do painting for every now and then... Here's the JD rear removal tool in use:

Looking bare...

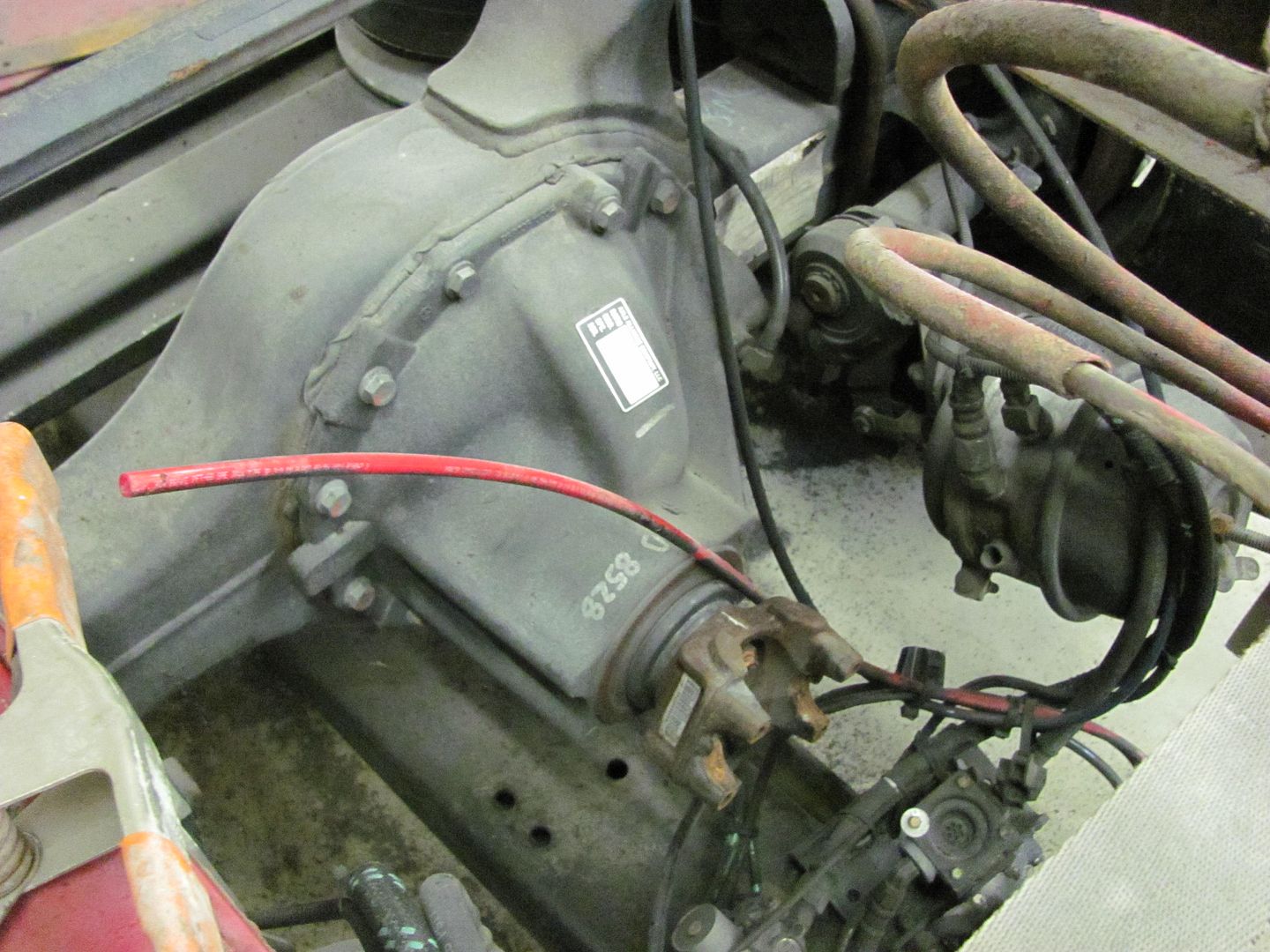

We got the new rear pushed up in place..

-

02-11-2012 08:25 PM #2

My next big hurdle is going to be getting the rear located and bolted up so all the air tanks and plumbing can be installed. The target location is for a 10' C-A dimension, although I do have some flexibility. At this point, I think I'm going to get the new driveshaft built first, and locate the rear around that. The White auxilliary trans has a bolt on yoke and incorporated the parking brake drum on its output. As the parking brake feature will not be needed with the modern air brakes, the drum will be removed and the yoke bolted up direct. All of the old u-joints were Spicer 1610 series with the bolt on caps...

As the aux trans is fixed and its yoke has no provision for suspension travel, the old driveshaft had a slip yoke at the front, which we'll need for the new one as well...

The rear is out of a 2007 Peterbilt school bus chassis, and uses a Spicer SPL90 series u-joint, so the new driveshaft will need a mix of u-joints to get all these parts working together.

So until the driveshaft is done......

10Likes

10Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

this is all to common now days. i've lost a lot of people this year. we're all getting long in the tooth so it is a given. RIP people in N Texas lost a great trans man. Mike Mcgee of Trick Shift...

We Lost a Good One