Thread: Grandkids Coaster Car build.

-

11-06-2012 02:16 PM #106

Good to see this one back up again - - - - KUDOS to Grandpa and Co..

" I'm drinking from my saucer, 'cause my cup is overflowed ! "

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

11-07-2012 10:34 AM #107

Just lovin it,Mike...As others have said..''wish you were my grandpa''..Color's kool,,flames n everything.. ..Awesome..

..Awesome..

Micah 6:8

If we aren't supposed to have midnight snacks,,,WHY is there a light in the refrigerator???

Robin.

-

11-07-2012 01:24 PM #108

Your going to need a reverse on that.....Just so you know

Charlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

11-07-2012 02:27 PM #109

Really nice, Mike. Thanks for keeping everybody informed of your progress.

I briefly considered showing some of my efforts for my kids ..... until you showed us yours.

Jim

-

05-19-2013 07:59 PM #110

I haven’t posted much in a while, but thought I’d go ahead and update this thread. We got the little 2 cycle motor running…..kind of. To get it to really run the way it should is probably going to take some new rings and reed valves. As the motor was discontinued over 50 years ago, finding parts will likely take a bit of research and time. Cade seems to be going thru a growth spurt so we came up with plan B to get the car moving under its own power while he can still fit in it.

Plan B is to use an electric motor to power it. I had read where some people had good luck using old Ford starter motors on homemade golf carts and as I happened to have one on the shelf that was our starting point.

As some people had had issues with the motors getting too hot and burning out, I decided to remove the brush cover, drill vent holes in the front housing and add a small fan a shroud to help this one cool. We’ll cross our fingers and see how long it lasts.

As shown on page 4 of this thread we had made the rear section of the floor removable and already mocked up the transaxle so we went ahead and made the new section of floor for the motor unit and then started bolting the parts on.

Today was spent diagramming out how we would run the wiring. Cade kind of surprised me a bit, he had already had some electric stuff in science class and really understood what all the circuits would be doing. Then it was on to removing the rear floor from the car.

Were hoping to finish the install next weekend and with luck we might have time to get the wiring in and it moving under its own power.

I was a bit disappointed we couldn’t get the gas engine running well (I firmly believe all cars should burn dead dinosaurs) but it wasn’t a total waste of time as at least Cade started getting the basics of internal combustion engines.I've NEVER seen a car come from the factory that couldn't be improved.....

-

05-19-2013 10:07 PM #111

That's a clever idea with the fan and shroud...good thinking that man!johnboy

Mountain man. (Retired.)

Some mistakes are too much fun to be made only once.

I don't know everything about anything, and I don't know anything about lots of things.

'47 Ford sedan. 350 -- 350, Jaguar irs + ifs.

'49 Morris Minor. Datsun 1500cc, 5sp manual, Marina front axle, Nissan rear axle.

'51 Ford school bus. Chev 400 ci Vortec 5 sp manual + Gearvendors 2sp, 2000 Chev lwb dually chassis and axles.

'64 A.C. Cobra replica. Ford 429, C6 auto, Torana ifs, Jaguar irs.

-

05-19-2013 10:37 PM #112

I'd think the reeds would be easy enough to fabricate from some stainless shim stock.

I once read a story of a guy in Cuba whom cut piston rings on a lathe from cast iron sewer pipe..

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

05-20-2013 05:28 AM #113

Some good work on the starter! Should be a hoot for the kids. Won't be too long before Cade straps a second battery in, wired in series to pump 24V through for faster times

Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

05-20-2013 09:03 AM #114

Then a field weakening coil. Electric hotrodCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

05-20-2013 09:24 AM #115

Jim might be of some help here as he runs several electric cars in Electracthon events. I believe he did a complete Electric car build thread a while back. I imagine the biggest problem is regulating the 12volt flow for speed control, and longer battery life. Jim's thread is below:

Electrathon - A Different Kind of "Hotrod"

Anyway cool solution for the mean time, and thanks for the update."  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

05-20-2013 04:59 PM #116

That's Boss!!

-

05-21-2013 04:20 AM #117

Glad to see this thread back up again. Mike, your creativity is amazing.

I started my son driving Quarter Midgets when he was 5; I think it made him a better driver when he got older. We race electric cars together now (Electrathon America); he's 38, I'm 65. I'm waiting for my grandson to get old enough for me to get into mischief with him...

Jim

Racing! - Because football, basketball, baseball, and golf require only ONE BALL!

-

05-26-2013 06:51 PM #118

I got word a few days ago that my Mom back in Illinois is not doing so well and I may have to make a trip back there so I went ahead and did some of the assembly without Cade during the week so we could actually get the car done this Sunday.

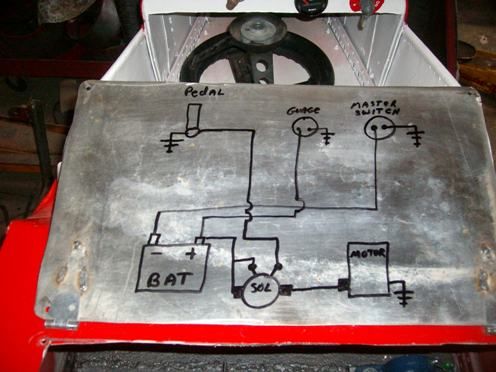

Cade and I had figured out the wiring last Sunday and this is what we came up with. In order to cut down the amount of wire we had the amount of wire we had to run we are running the switches on the ground side of the circuits. To make life easier if we have to trouble shoot down the road we put the circuit diagram on the bottom side of access cover.

The “gas pedal” was something I had been mulling over for some time. With the different length of the kids legs I figured the pedal would need to be moved so everybody could drive it. In order to make it simple and quick (and the kids be able to do it themselves) I decided to make the pedal assembly slide in a slot with a clench bolt to tighten it down. For the switch itself I used one of the old Chevy style switches that bolt to the starter and are activated from cab with a push rod.

It was kind of amusing when I went to buy the switch. I went to the only “real” parts store we still have left in town. It’s mostly young guys there now, but I waited for the guy who’s about my age to wait on me (I really didn’t what go thru the whole “what’s the application” game). I explained what I needed, he said “OK” and without looking it up walked back to the shelf and pulled the correct dusty old box out.

As usual with something like this it took a lot longer to figure out what I would do than it actually took to build the darn thing.

Cade and I did some finish-up work on it t and then it was time for its maiden voyage. The transaxle works well (it goes just as fast backwards and it does forward) and the kids pretty much spent the rest of the afternoon driving the wheels off of it. Here are a couple of Video links.

Car 2 - YouTube

Car 3 - YouTube

Car 4 - YouTube

Cade’s growing so fast he probably won’t be able to fit in it much longer, but he sure is enjoying while he can.I've NEVER seen a car come from the factory that couldn't be improved.....

-

05-26-2013 08:00 PM #119

Kewl test drives there Mike!!!!! Didn't the kids let you have a turn, or didn't anyone film it??Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

05-26-2013 08:01 PM #120

That is too cool and am glad you all were able to finish it. If you need to head to Illinois, have a safe trip and hope everything works out with your mom.

113Likes

113Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

He definitely moves around! A MIA Happy Birthday, Tech!

Happy Birthday techinspector1