Thread: Glued in patch panels??.

-

11-13-2012 02:57 PM #1

Glued in patch panels??.

I'm working on replacing the rusted out floor boards on the driver's side floor board on my Astro project.They are spot welded and I don't have that kind of welding equipment.The only two things I could do is to drill small holes in the patch panel and weld them up to what is the body frame work and what is good metal remaining in the floor boards or you guys spoke if gluing patch panels and glue the patch panel to the body's frame work.

I need a source for the glue and alittle more info about gluing panels.I will add pictures to this thread once I get them.Last edited by 1gary; 11-13-2012 at 02:59 PM.

Good Bye

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

11-13-2012 03:17 PM #2

What you want is produced by 3M, they call it a two part panel adhesive.

3M two part bonding in a tube

3m Panel bonding in a roll (adhesive film)

Basic instructionsInstead of being part of the problem, be part of a successful solution.

-

11-13-2012 08:10 PM #3

Obviously welding a nice new section would be best however; have you considered a thin fiberglass laminate over top and bottom of the entire assembly? Seals it nicely and will definitely hold the patch panels in place. When all dried it can be painted black and you're good to go."Where the people fear the government you have tyranny. Where the government fears the people you have liberty." John Basil Barnhil

-

11-13-2012 10:45 PM #4

Thanks for the ref Bill.

-

11-13-2012 11:03 PM #5

Two things,as I understand it that brought the end of production of Astro/Safari's,was it failed the frontal cash from the National Safety Counsel because the foot area for the driver's side and passenger side crushed and because the vans didn't come with side air bags.

While I have the floor board off in the drivers side,I want to try to reinforce it with a combination of welding to what ever solid floor board is there and glue to the body frame work,weld from the bottom the patch panel to the body frame work I can get to,(that up weld has got me thinking about getting welder's leathers again so I don't get tattooed with slag again and a auto darkening welders helmet).

I'm going to the shop tomorrow to get some photo's and will try to post them so you guys see what I am dealing with.

-

11-13-2012 11:23 PM #6

like glen said if no big holes fiber glass resin with cloth or mat works very good fixed many floors this way as well with fiber gel with cloth or mat. if you not welding the steel patch in or using pop rivets/screws to hold fit up then glass will have a better fit up has the glass will lay flat were fixing the metal patch down may be very hard if you do not use some screws or poprivets to hold it down to help hold fit up so why stop ?at that point why wast good money on panle bond ? heavy duty seam sealer and blind pop riverts can do a ok repair and when done you can hold a doly over the head and get someone from the other side to flatten the end of the rivets some what if you do not like the end not flush. be the key here is to use the rivet with a short reachLast edited by pat mccarthy; 11-13-2012 at 11:45 PM.

Irish Diplomacy ..the ability to tell someone to go to Hell ,,So that they will look forward to to the trip

-

11-13-2012 11:41 PM #7

all astro van s if hit hard the front tire can end up in the foot well .air bag or not . i fixed may share of them vans. when i work at the body shops. there good vans but do not use panle bond were you need to weld parts back on if part of your fix fails it could not fail the way it was made to. someone could get hurt far worseIrish Diplomacy ..the ability to tell someone to go to Hell ,,So that they will look forward to to the trip

-

11-14-2012 06:35 AM #8

I got it up in the air pretty high so I should be able to get under it to get a better idea what I'm dealing with.

And yes a rotisserie sure would be great for this repair and for clean up.My 110 mig isn't up to the task to weld metal as thick as a rotisserie would need.That has been a stumbling block for a number of things I want to build.

I'll have to see what I can reach from the bottom today.The sub frame was planned to be dropped off with the current 4.3/tranny because I have a second sub frame stripped to the bare frame for the 383 build up.I have been putting that off in case I was forced to drive the van because of troubles of a daily driver and because I didn't want to make the van immobile in the shop.This repair very well might force me removing the sub frame now.

-

11-14-2012 06:40 AM #9

Pat-in your opinion how much of the floor pan can I remove before I have to worry about the body structure and need to temporarily weld in brace it??.

-

11-15-2012 12:50 AM #10

-

11-15-2012 07:23 AM #11

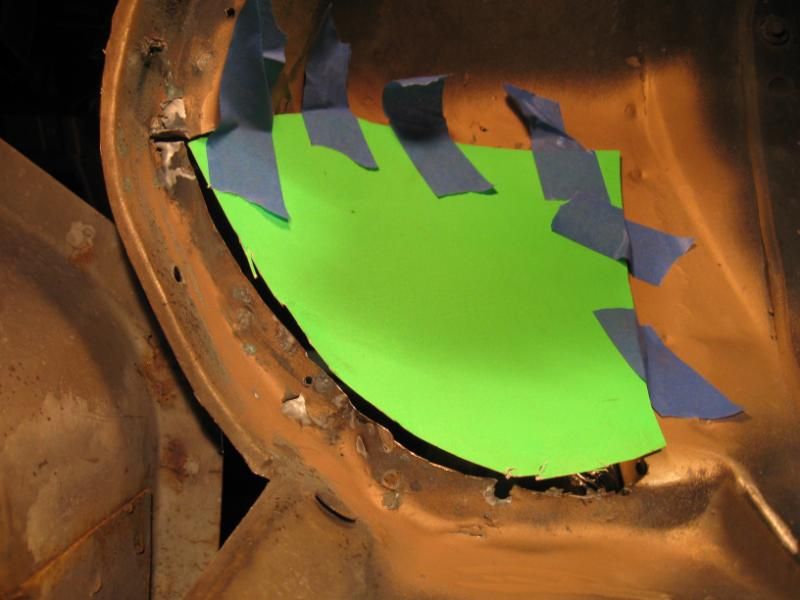

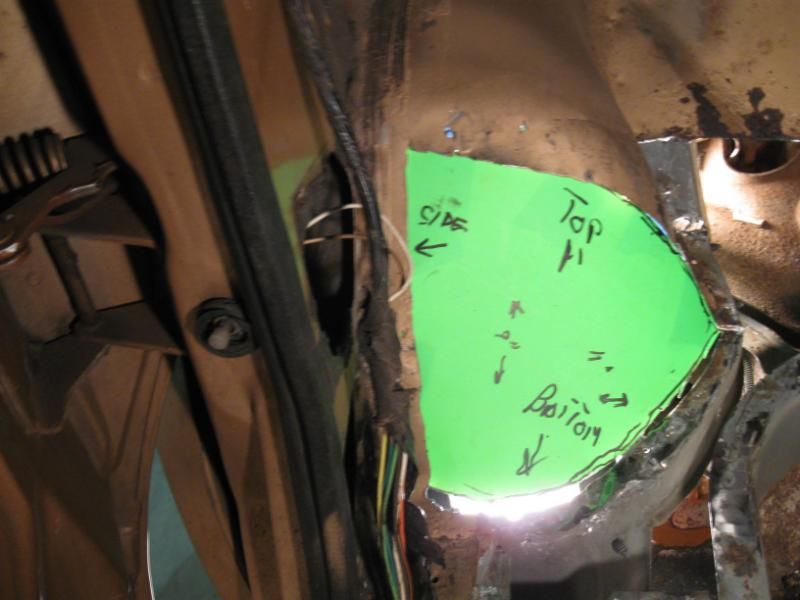

I think I'm going to be ok once I remove the sub frame.I should be able to weld to the body frame from the bottom.The view from the top inside:

The view from the bottom:

The construction paper template in the actual wheel well:

I'm trying to avoid cutting out the wide bead rolled section because I don't have a bead roller.The wheel well patch has some weird angles given it is curved.Sure am trying to cut it so it will be a tight seamed butt weld.

-

07-06-2013 08:25 AM #12

glueing has it place, we like it on door skins and some area's where the heat from welding will warp the panel, but for most rockers and floors and major items welding is the correct method, alos some of the paint guys can comment on the effects of painting over a glued seam

the ems guy

1Likes

1Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

To the top

Where is everybody?