Thread: 55 Wagon Progress

Hybrid View

-

11-08-2021 06:47 PM #1

It's beautiful, but clearly not stock.

Kudos..

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

11-21-2021 07:19 AM #2

Thanks guys!

Wagon progress! So Jared has been tackling the fun task of prepping interior trim pieces, getting them ready for another round of epoxy..

Another modification we're undertaking, the air cleaner, when mocked up on the engine, showed a tight proximity to the back of the AC compressor. Looking at the clearance we had to the firewall, moving backward 1" will give us much needed breathing room for the AC lines. So out with the old ....

And to move rearward, the mounting hole is moved forward one inch..

Next in store is a new bottom for the air cleaner..

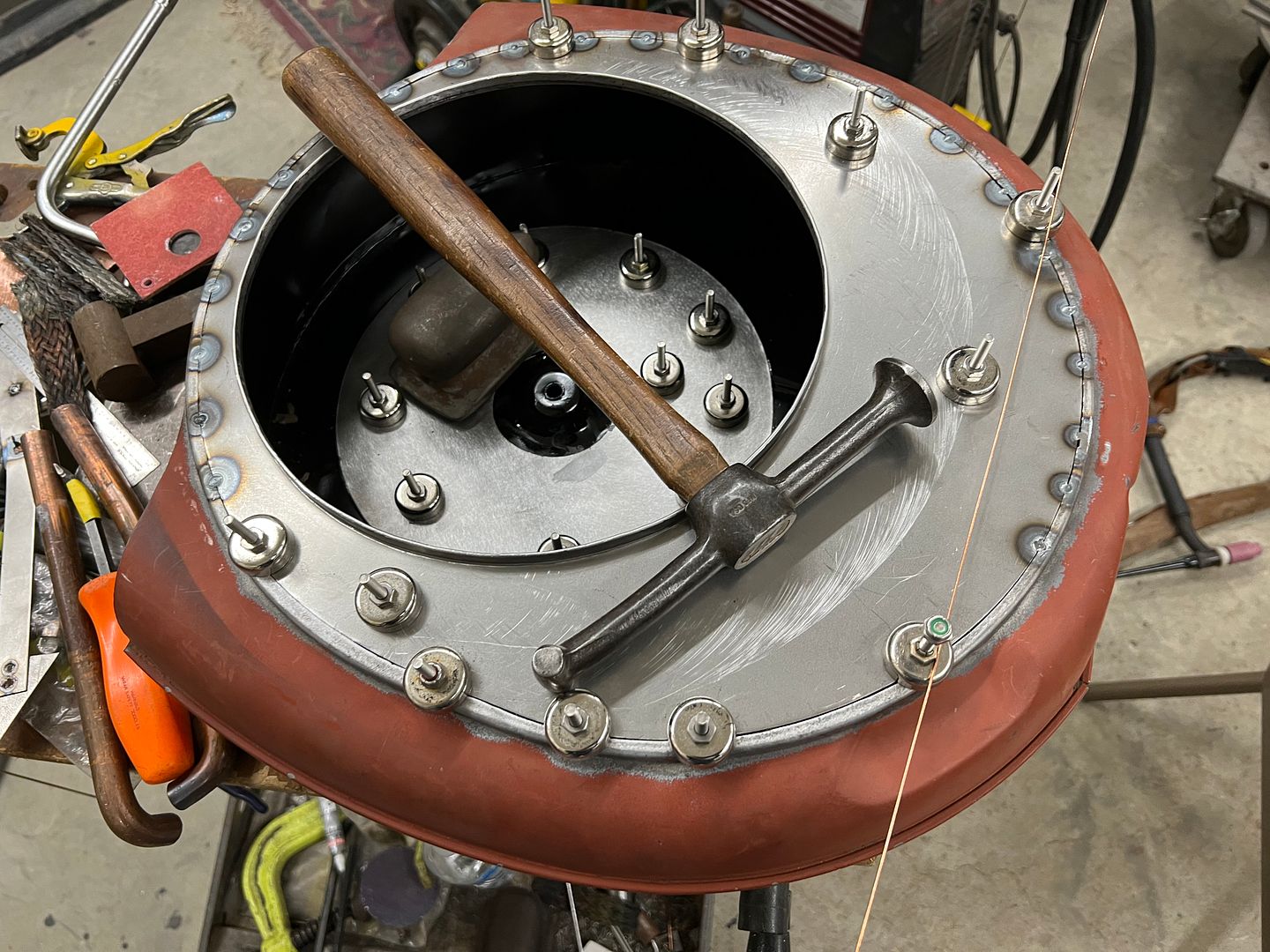

A hammerform is used to give us a folded lip out the bottom

https://youtu.be/QPLDGIxJAYk

https://youtu.be/Zm6TIkxDDUA

Robert

-

11-21-2021 07:40 AM #3

At this point we need to hem the flange so the bottom isn't quite so sharp..

A 1/2 x 1/2 aluminum angle is used as a height gauge so we can use the roloc sander to get our flange to a consistent height. This will allow us to use a tipping die in the bead roller to fold the hem..

Then the part is re-installed in the hammer form to hammer the hem flat..

https://youtu.be/eScyS2lkfOU

Robert

-

11-22-2021 05:13 AM #4

So I've had some questions as to why this or that with modifying the air cleaner. I was going to hold out with the REAL reason, but here goes.... This firewall is just too clean that I can't bring myself to clutter it up (or the wheelwell) by mounting an ignition coil and then being forced into using an overly long coil wire..

So as shown here.... this will be the approximate location as we fabricate a sealed cavity from the bottom side of the air cleaner to mount the coil. This should put the coil wire about two inches in front of the distributor...

So this should give us a nice clean look and keep the firewall as open as we can...Robert

-

11-23-2021 09:49 PM #5

Time for some welding.. TIG used to tack the new bottom in place.....

I thought my eyesight was going.... time to replace these..

Next, we'll work on the base plate....Robert

-

11-26-2021 09:27 PM #6

More work on the Caddy air cleaner, time to fabricate the pocket for the coil. Our radius brake that is bolted to the front of the shear is used to bend some 18ga into a horseshoe. One side is trimmed short and the other is left long to bend and form the bottom in the magnetic brake.

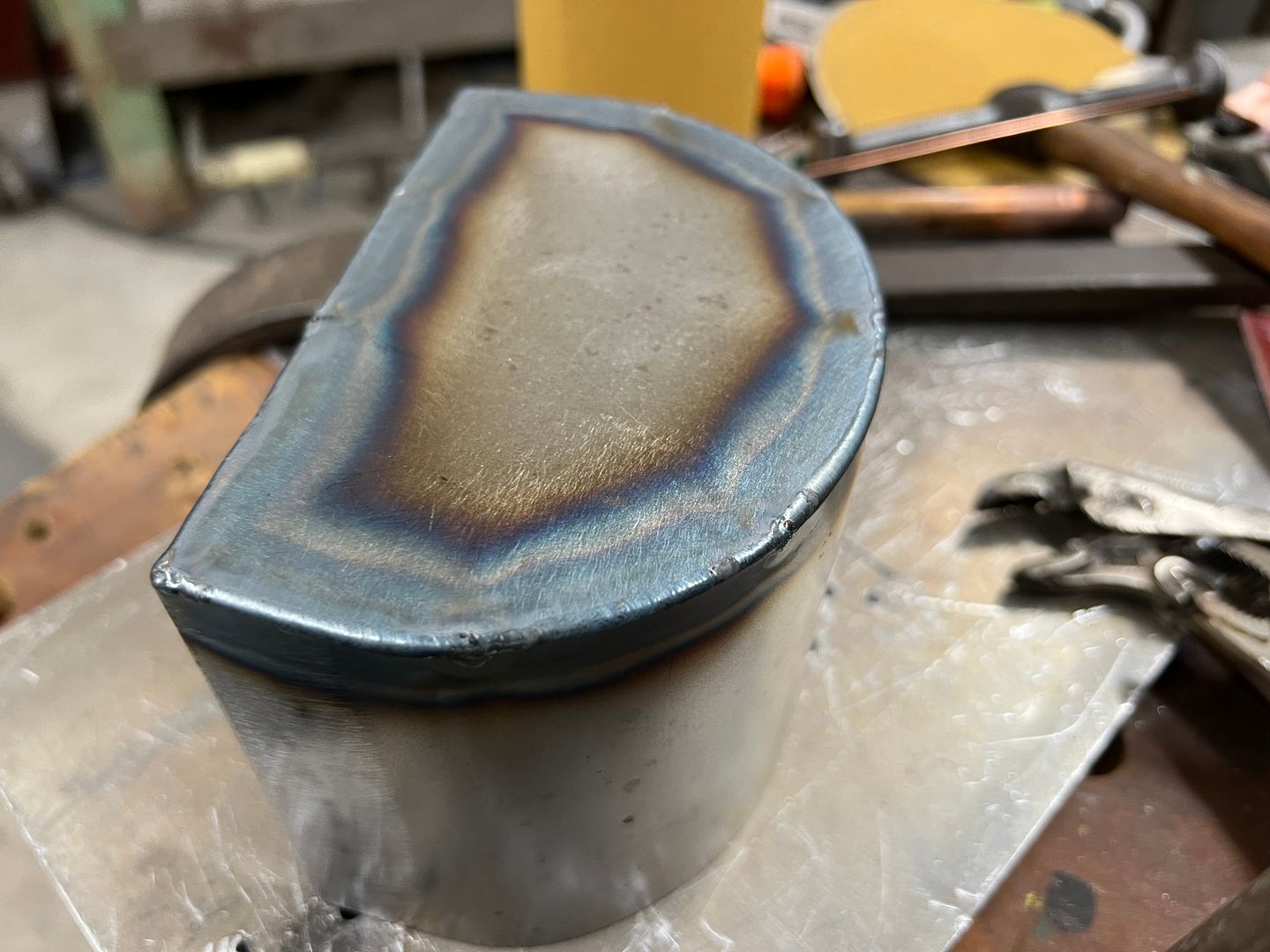

And end plate is cut out to seal off the void from the rest of the air cleaner innards. This gets tacked in place and then fusion welded using the TIG.

A holesaw is used to get the hole started and offset Wiss snips to trim out the hole in both the housing and the mounting flange. TIG tacked and fusion welding on the flange, and it then gets trimmed to fit inside the air cleaner housing.

Yup, that's what I was looking for...Robert

-

11-27-2021 04:33 AM #7

As always. your (and the crews) work is out of this world.. do you anticipate the weight of the coil causing any flex in the housing?

Just curious how rigid it's become.

-

11-27-2021 05:39 AM #8

When it was made we put some crown in the bottom panel to provide such support. So it should stay put. :fingerscrossed:Robert

-

11-27-2021 06:24 AM #9

I continue to be amazed! Those fusion welds are a thing of beauty! Excellent, and great use of space too!Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

11-27-2021 07:44 PM #10

johnboy

Mountain man. (Retired.)

Some mistakes are too much fun to be made only once.

I don't know everything about anything, and I don't know anything about lots of things.

'47 Ford sedan. 350 -- 350, Jaguar irs + ifs.

'49 Morris Minor. Datsun 1500cc, 5sp manual, Marina front axle, Nissan rear axle.

'51 Ford school bus. Chev 400 ci Vortec 5 sp manual + Gearvendors 2sp, 2000 Chev lwb dually chassis and axles.

'64 A.C. Cobra replica. Ford 429, C6 auto, Torana ifs, Jaguar irs.

-

11-27-2021 08:33 PM #11

Thanks fellas.. Keeping fingers crossed that this thing works as planned..

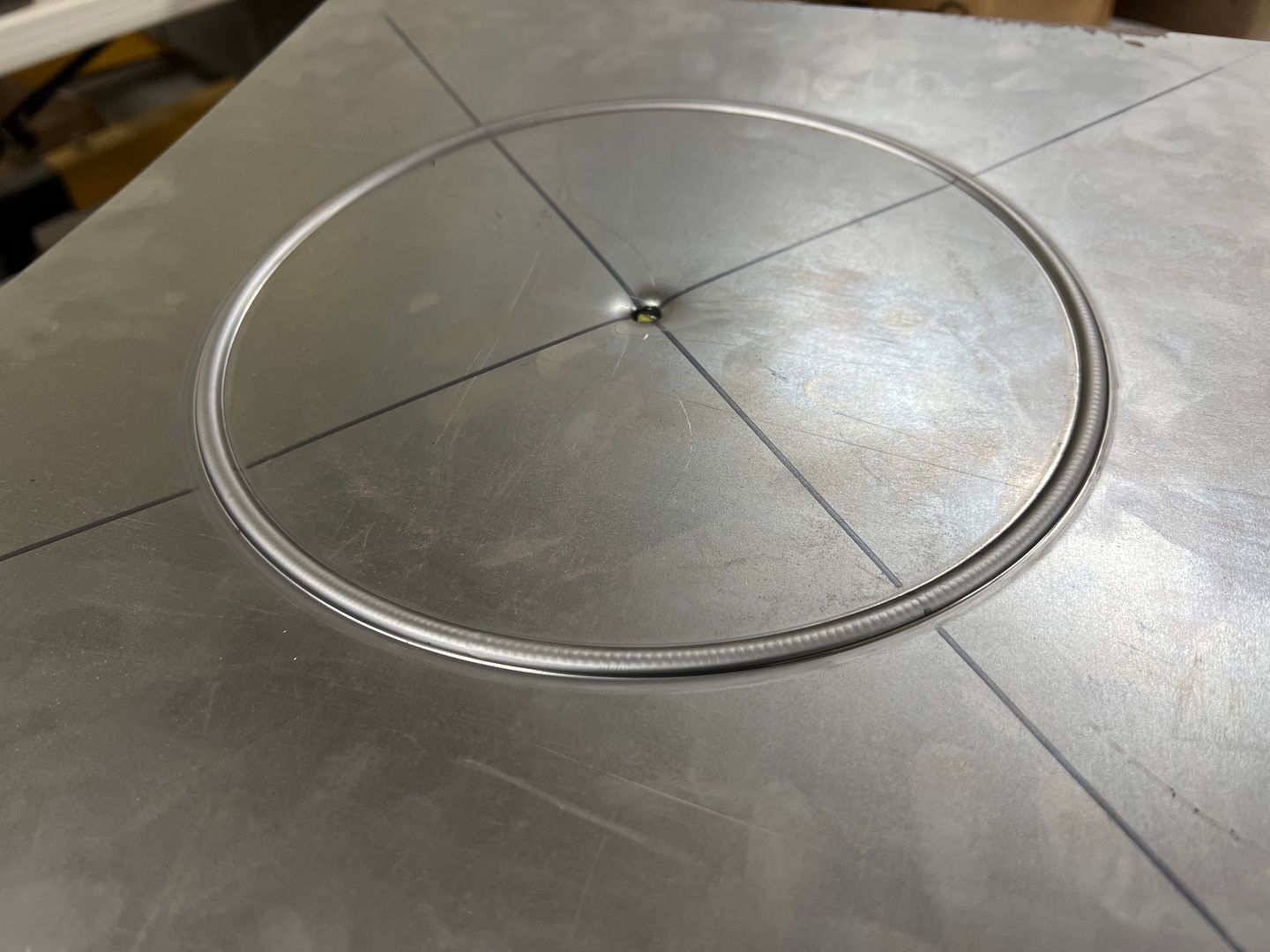

Now for our bottom plate for the air cleaner.. In order to keep the filter located properly (keep it from moving around) we decided to add a bead to the bottom of the plate.

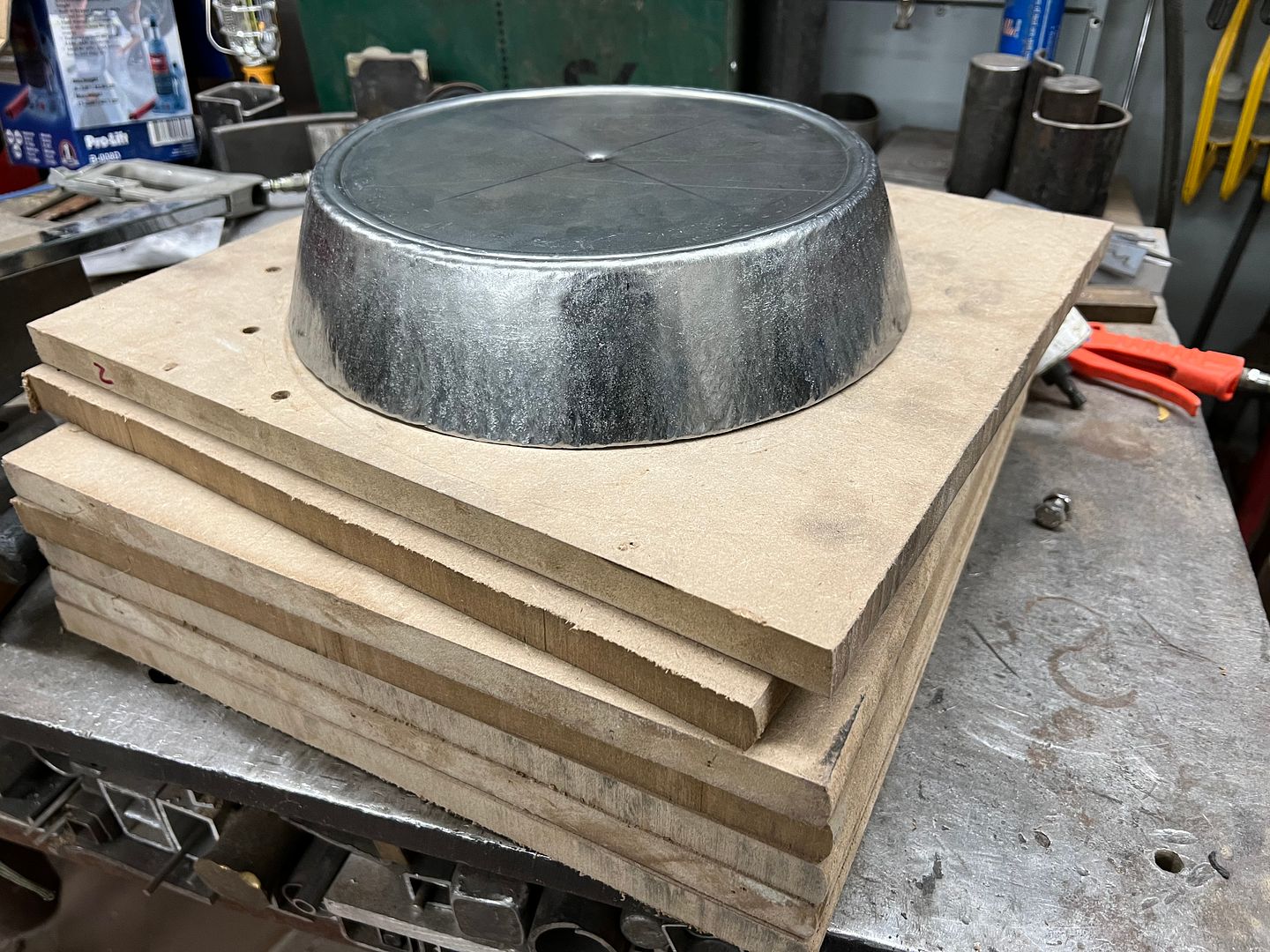

Then the plate is trimmed to a circle, and the thumbnail dies in the Lennox used to start the shrinking process around the edge.

https://youtu.be/Vy30NeziryY

We then jumped on the Erco kick shrinker to flatten the uneven surface..

https://youtu.be/B1Jg_9BfDNc

https://youtu.be/Xlu2LsUNcj0

And repeat. Repeatedly. We have two or three more rounds to go and we can start tipping and stretching.

Robert

-

12-01-2021 06:22 AM #12

Last night we changed out the thumbnail shrinking dies for linear stretch dies in the Lennox TE250 in order to tip the flange back horizontal again. We have a backstop / fence that had been notched for tooling and this did a nice job of getting the flange depth consistent.

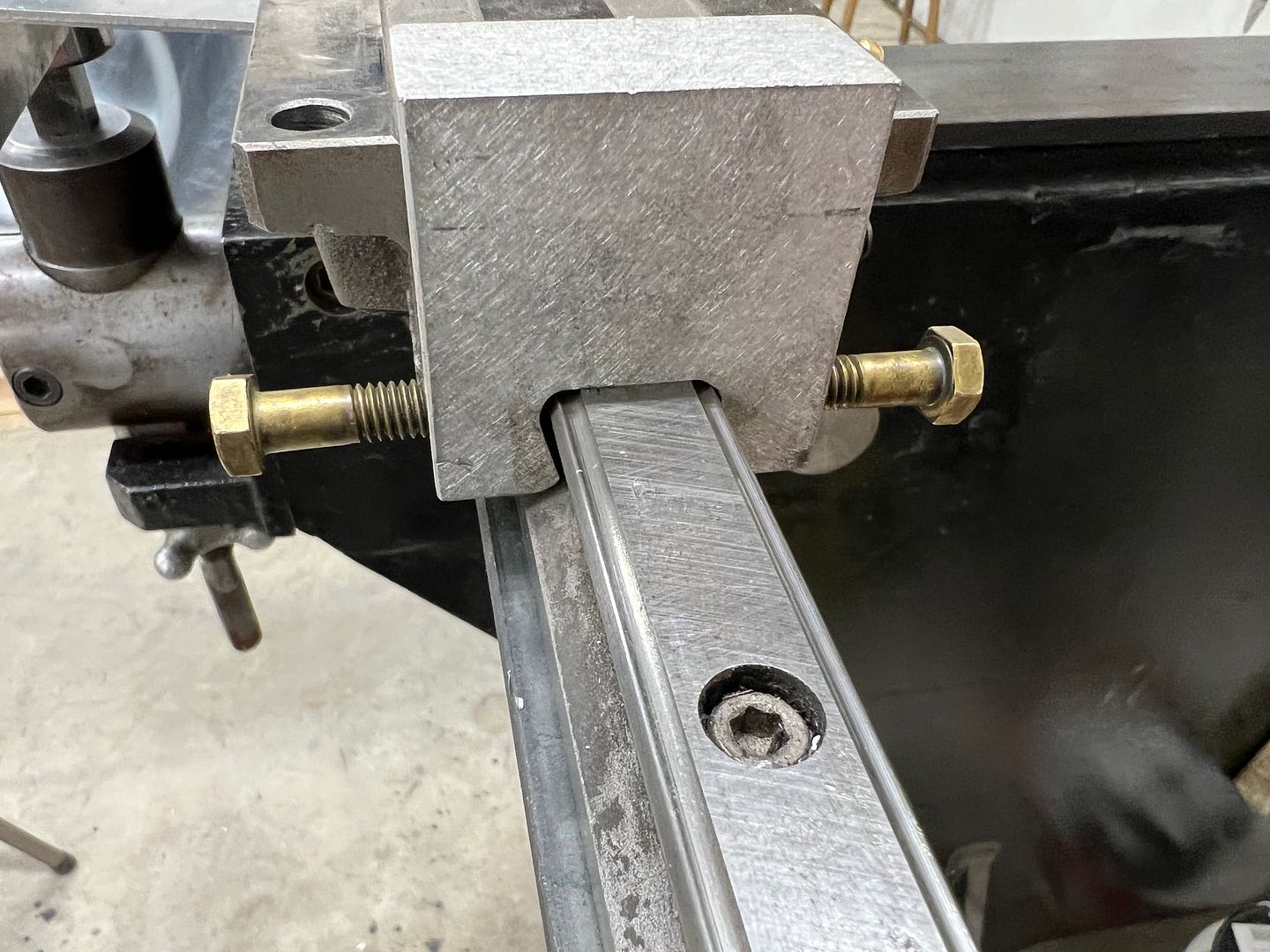

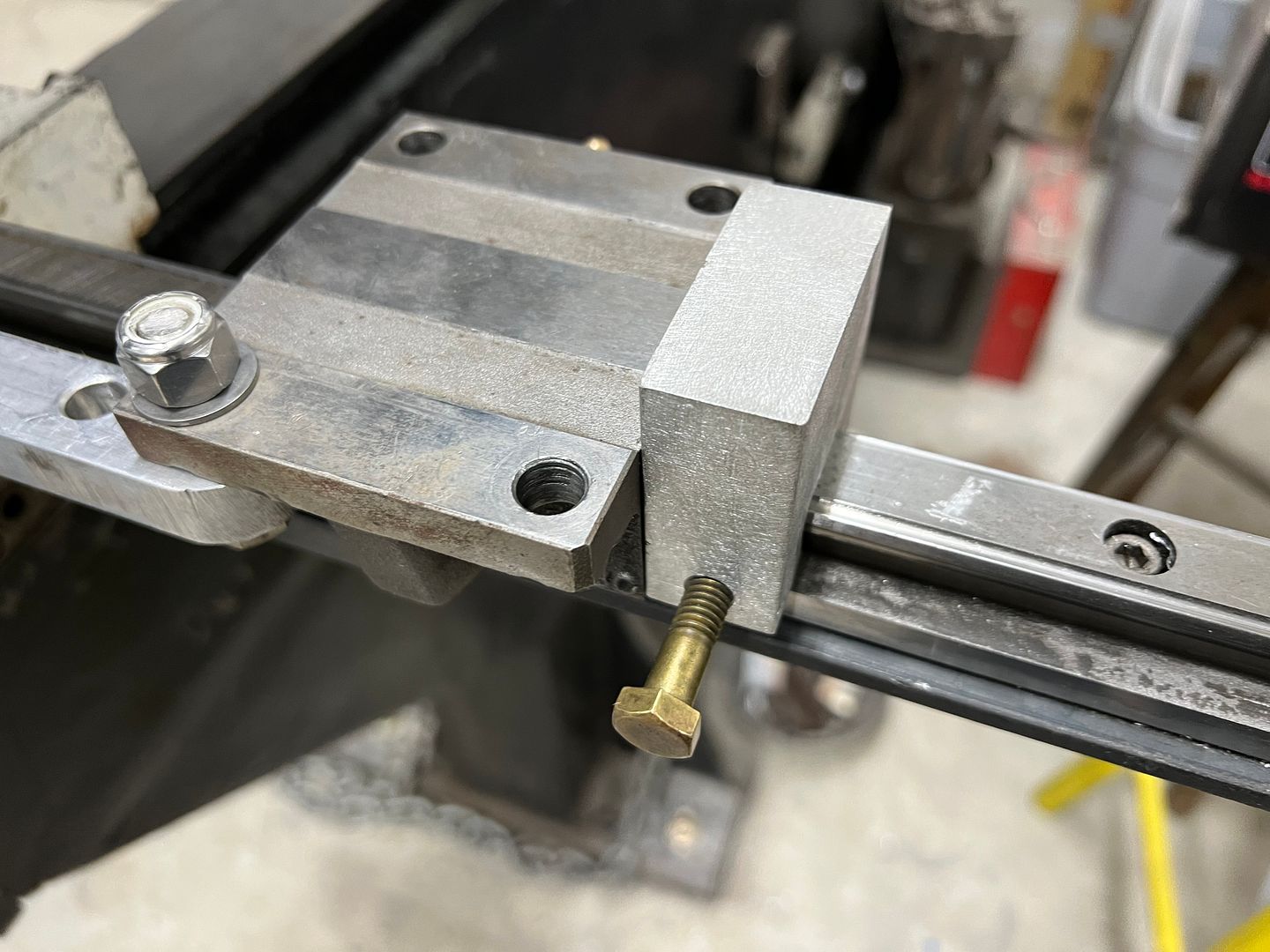

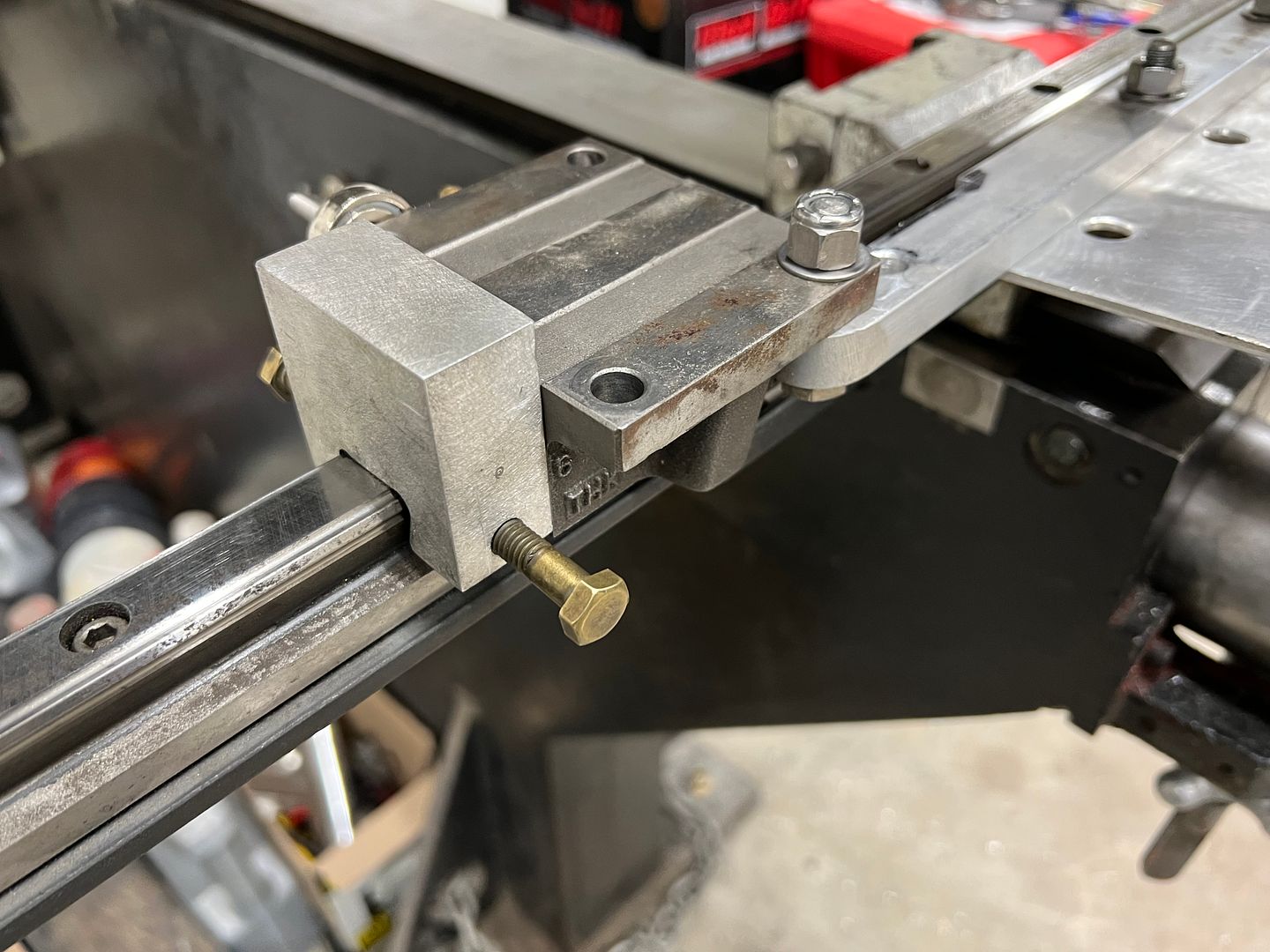

As this gets bolted to our linear slide and we'll need that to remain stationary, some Cerutti built clamp blocks are added.

Linear stretch dies in action:

https://www.youtube.com/watch?v=-euPrCTj9zI

Next, we had been having issue with the Skat Blast cabinet, and given the sale going on this week at TP Tools, ordered a new high volume cabinet gun and nozzle, some high flow fittings, and while we're at it, how about some fresh glass..

Amazing....we can see!

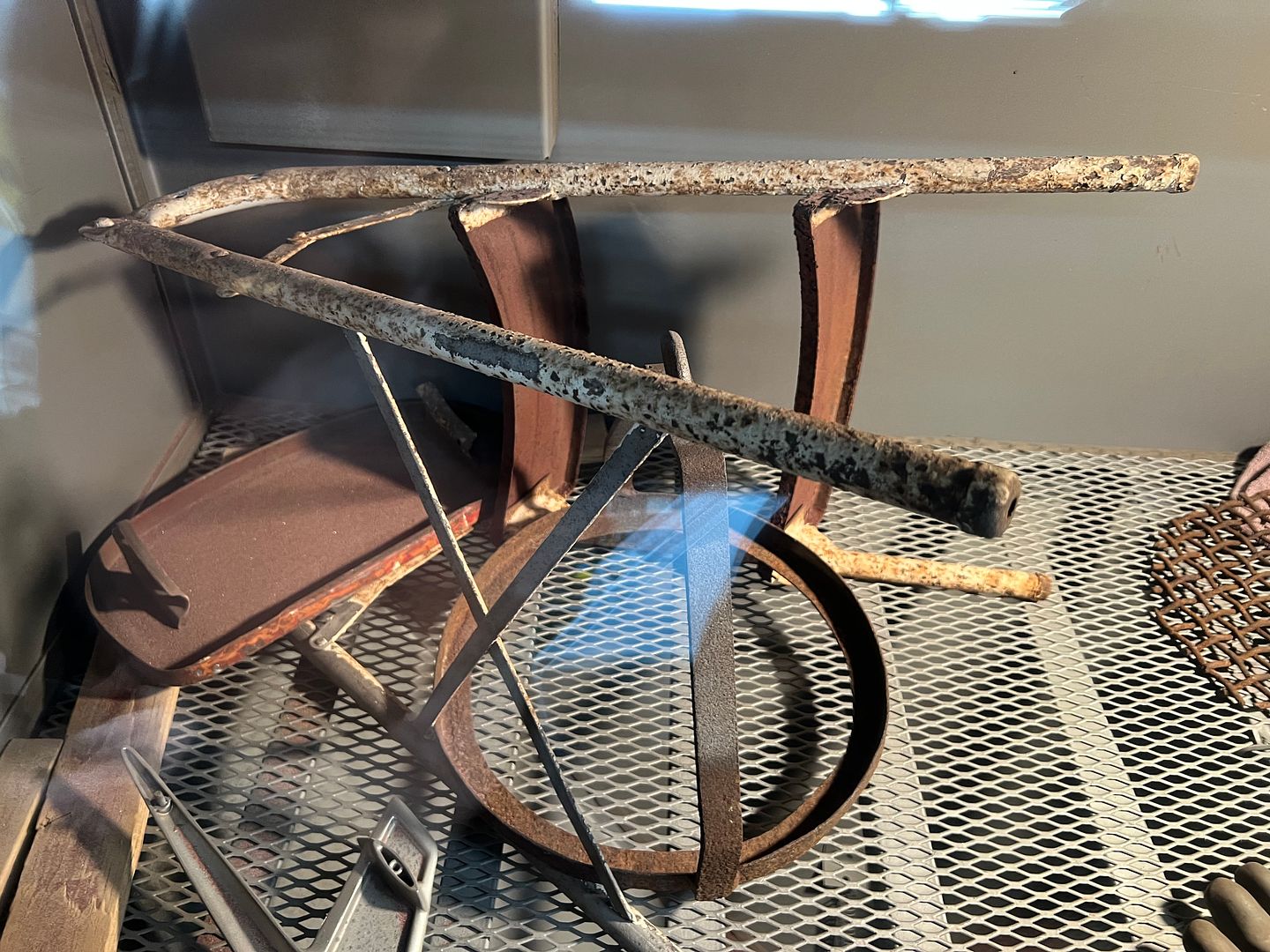

But alas, all the new parts did not fix the losing media about 5-10 seconds in. So we figured this was a blockage with the suction tube, which requires removing the expanded metal deck inside. Which has sealant along front and rear edge. So a handy utility knife was employed, along with this fancy tool we had made up for removing tiles in raised flooring, as it did well in pulling up the expanded metal.

The screen was tipped up out of the way and a large magnet holds it in place...

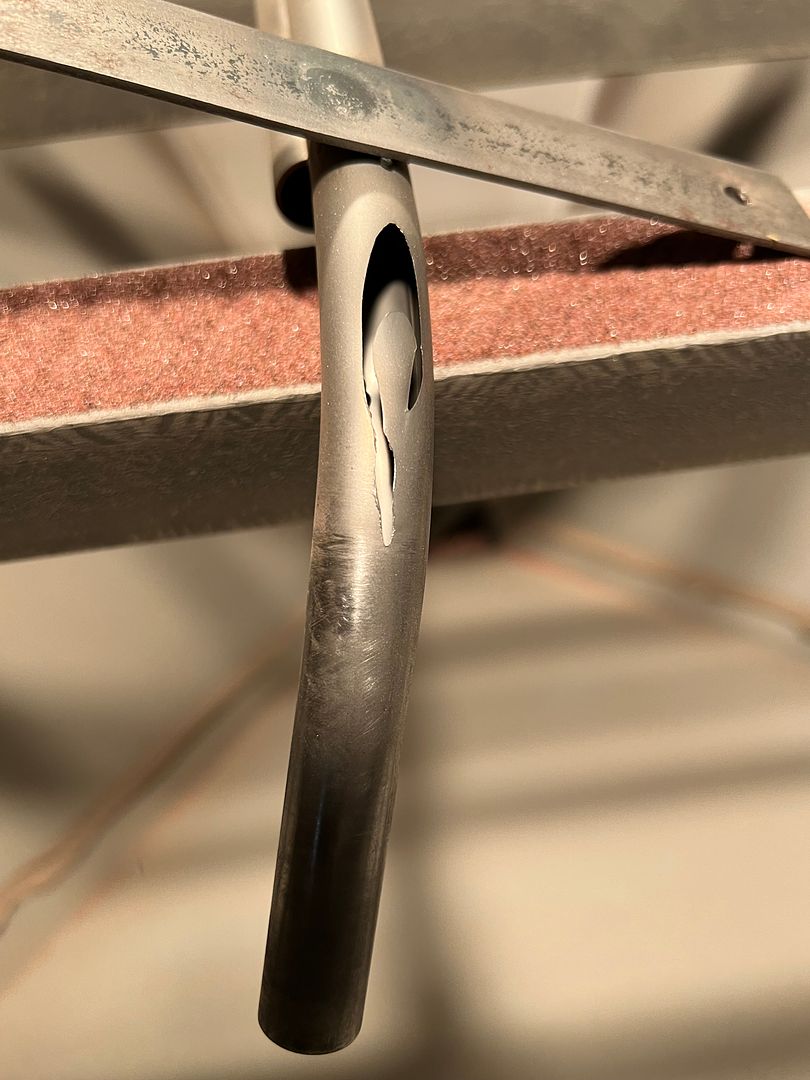

Once we had access to the pickup tube, we noticed a hole in the inside corner that didn't belong.

Once we removed the tube, we noticed it was more widespread...

Well, I guess we have found the suction/media issue, and now have a used High flow gun/nozzle for sale. Luckily the sale is still going on, ordered the replacement tube last night..Last edited by MP&C; 12-01-2021 at 09:33 AM.

Robert

-

12-01-2021 07:32 AM #13

-

12-01-2021 06:50 PM #14

johnboy

Mountain man. (Retired.)

Some mistakes are too much fun to be made only once.

I don't know everything about anything, and I don't know anything about lots of things.

'47 Ford sedan. 350 -- 350, Jaguar irs + ifs.

'49 Morris Minor. Datsun 1500cc, 5sp manual, Marina front axle, Nissan rear axle.

'51 Ford school bus. Chev 400 ci Vortec 5 sp manual + Gearvendors 2sp, 2000 Chev lwb dually chassis and axles.

'64 A.C. Cobra replica. Ford 429, C6 auto, Torana ifs, Jaguar irs.

-

12-01-2021 08:50 AM #15

I did price materials... The replacement was too cheap and it has lasted the past 20 years...Robert

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

.JPG)

.JPG)

_IMG_1775.JPG)

My grandfather, mom's side, drove a 39 Plymouth coupe when I was about 4 or 5 and I thought it was pretty cool and I loved the tail fins on the 49 Cadillac. I drew cars when I was in the 5th and 6th...

How did you get hooked on cars?