Thread: 55 Wagon Progress

Hybrid View

-

07-03-2022 11:15 AM #1

Very nice, probably better than new!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

07-03-2022 01:13 PM #2

So I've been rather lax on the updates as we've had a distraction here at the shop. Someone had a mishap in returning home on Memorial day (about midnight) from one of the local watering holes. Let's call him "Dale Jr"

Seems he was coming in a bit hot in the final turn where his left tires were out in the grass in the opposite lane..

Which, when combined with over-correction....

Here, I guess not wanting to go a lap down, he took the nearest path back to the "track", completely ignoring pit road to his right....

The remnants left behind suggested the drivers window broke out, likely when this gem flew out of the vehicle...

So we've been rebuilding from that the past few weeks in spare time, pre-painting pickets to limit June/July sun exposure.....

and we finished off here yesterday around noon...

Still have one more coat of paint to apply, but this will hold it until cooler days or the next mishap at the track..Robert

-

07-04-2022 04:28 AM #3

So, with Dale Jr's plate and phone.. were the "authorities" able to connect with them?

At least to pay restitution! Lumber & Paint is no longer inexpensive.. not to mention the labor.

Enquiring minds need to know... well.... me and Cosmo anyway!

-

07-04-2022 07:58 AM #4

Police were on scene and left incident report with all pertinent info. His insurance is covering repairsRobert

-

07-05-2022 06:11 AM #5

Glad to hear it. Some things should be made right every once in awhile. 8-)

-

07-14-2022 05:54 AM #6

With fence repair duties out of the way we can get back to some progress on the wagon. Finally got the correct clips for the beltline molding...

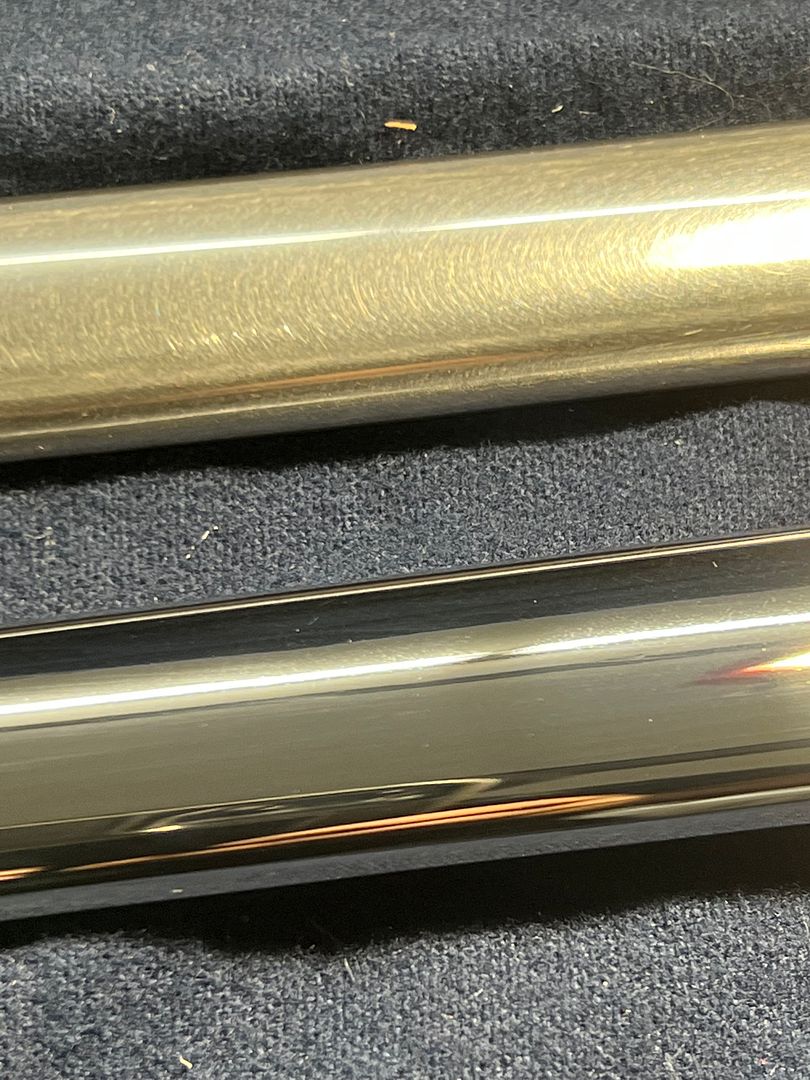

We had been attempting to polish up some of the stainless trim but always seems to find 67 years worth of scratches difficult to remove. So we opted to give Trizact a try, starting with 1500, then 3000, 5000, and finally 8000.. The edge of the 3000 and up seemed to bear the brunt of the polishing duties, and wore off much sooner than the center. In an effort to get more life out of the trizact pads, we purchased a 5" Dynabrade where we could cut the outer (worn) portion off the pads and continue to use.. The Trizact did well on the stainless, a much easier task at the polishing stage...

We also have been working on the wiring, and getting it run inside some protective loom. To keep things tidy and knot free, we opted for some heat shrink tubing spaced at regular intervals.. Where I've seen electrical tape used in similar situations, the tape seems to turn into a sticky mess in short order so we'll give this a try. Jared has some re-wiring to do on his 39 coupe so this is good practice (learning curve) for him.. This section is from the fuse box to the rear of the body, the tan wire pulled out is for the fuel sending unit.

These clips are just about the right size for this harness "portion", we got them to run along the frame rail behind the rear axle, but found use for them in a couple other locations. Corvette part.

Here Jared made a protective channel where the wire passes under the rear seat frame.

Robert

-

07-14-2022 08:01 AM #7

That trim looks beautiful. Very nice work on the wiring too.

-

07-14-2022 09:30 AM #8

Top notch!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

07-21-2022 03:13 PM #9

You always amaze with craftmanship and knowhow

-

08-10-2022 05:12 AM #10

Thanks guys!

More progress on the wagon, we're getting some of our wiring run to the back of the car...

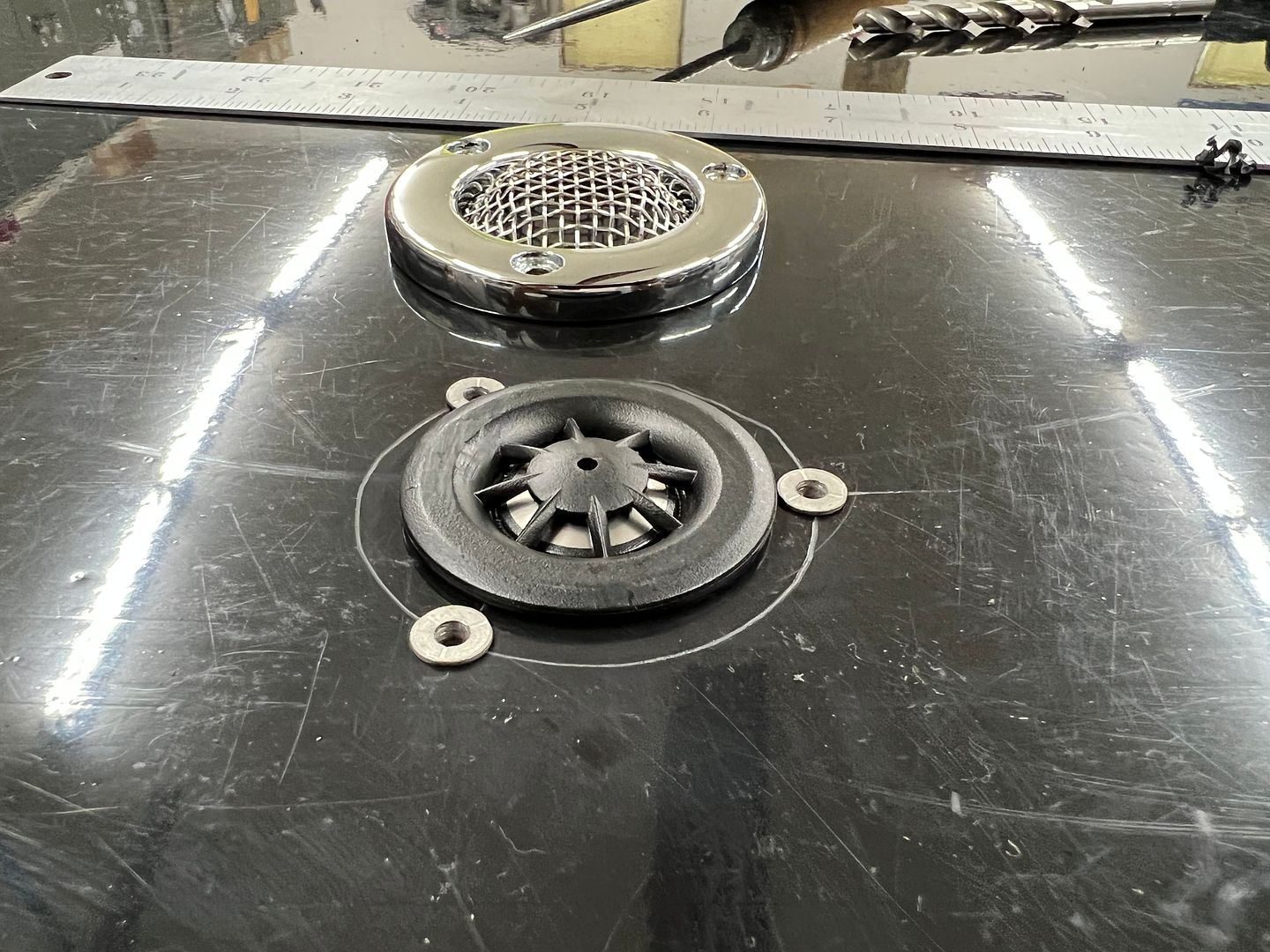

In cutting out door panels our upholsterer cut out the speakers a bit too large for how we were mounting them. I don't think I had conveyed those details as I had planned on doing the speaker cutouts portion.. So to keep him from having to do that work over again, we offered to cut them out this time around.

6-32 Riv-nuts used to hold the tweeter grill in place...

8-32 machine screws were sharpened to transfer the hole pattern onto the panel, then our speaker spacers matched to those for cutting out the center hole.

Next, holes drilled for our stainless trim that we had welded the impaling pins on prior....

The stainless trim would be needed for upholstery, so we got to polishing.. A board was drilled to accept the impaling pins and better hold the trim piece for our prep stage of removing 67 years worth of scratches. Also worked well in holding things steady at the buffer..

We used 3M Trizact on the DA, starting with 1500 grit and finishing with 8000 grit. This process cuts out the first two buffing stages, and seems to polish out nicer. Buffing process was using green rouge on sewn wheel and final was grey rouge on loose wheel.

https://youtu.be/REH9gLXxaco

This is after 3000 Trizact:

This is after 8000 Trizact:

This is after buffing:

That'll do pig, that'll do.Robert

-

08-10-2022 05:58 AM #11

As always,such nice work..

-

08-10-2022 09:48 PM #12

johnboy

Mountain man. (Retired.)

Some mistakes are too much fun to be made only once.

I don't know everything about anything, and I don't know anything about lots of things.

'47 Ford sedan. 350 -- 350, Jaguar irs + ifs.

'49 Morris Minor. Datsun 1500cc, 5sp manual, Marina front axle, Nissan rear axle.

'51 Ford school bus. Chev 400 ci Vortec 5 sp manual + Gearvendors 2sp, 2000 Chev lwb dually chassis and axles.

'64 A.C. Cobra replica. Ford 429, C6 auto, Torana ifs, Jaguar irs.

-

09-07-2022 09:12 PM #13

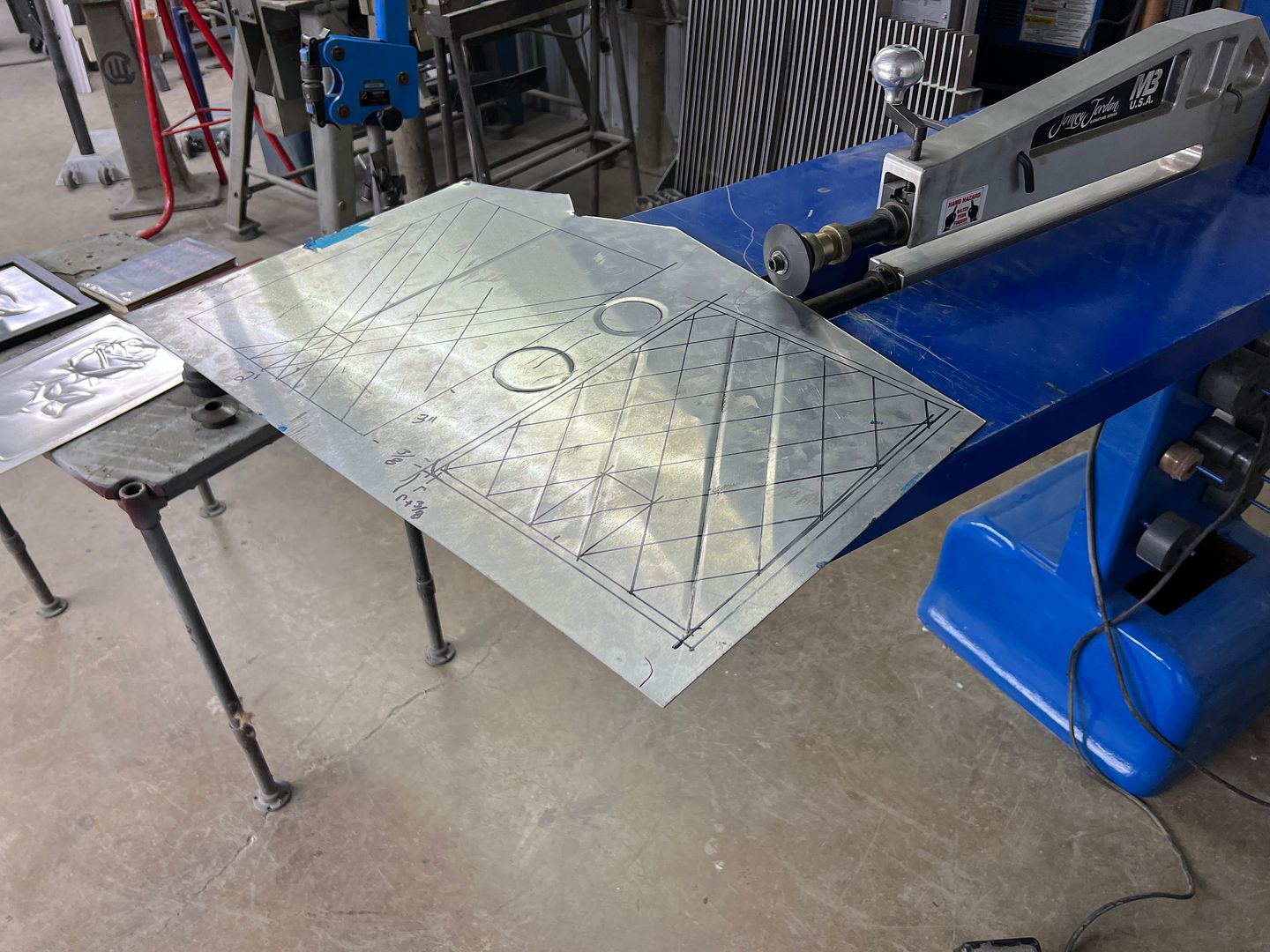

I spent a week in Tennessee just south of Nashville, attending a metalshaping workshop and delivering the Pullmax there for Mike Abbott of Steel Rose Metal Co in Memphis TN. We had a good time learning tips and tricks, meeting old friends and making new ones.

Jesse Harris, who lives about 15 minutes from me, travelled out as well, and gave an awesome demo on using the bead roller with a focus on artwork.

A leading demo on an aluminum Rolls Royce door...

One of the attendees lives just north of Nashville, and a few of us travelled one evening to check out his shop, Ace Chassis. He has been building pulling tractors for about 20 years now and has quite the setup for machining, welding, and sheet metal fabrication.

Upon return from TN, Jared brought over his 39 Ford so we could install a new wiring harness in place of the convoluted mess that was there.

https://youtu.be/SpXH3K4BGXM

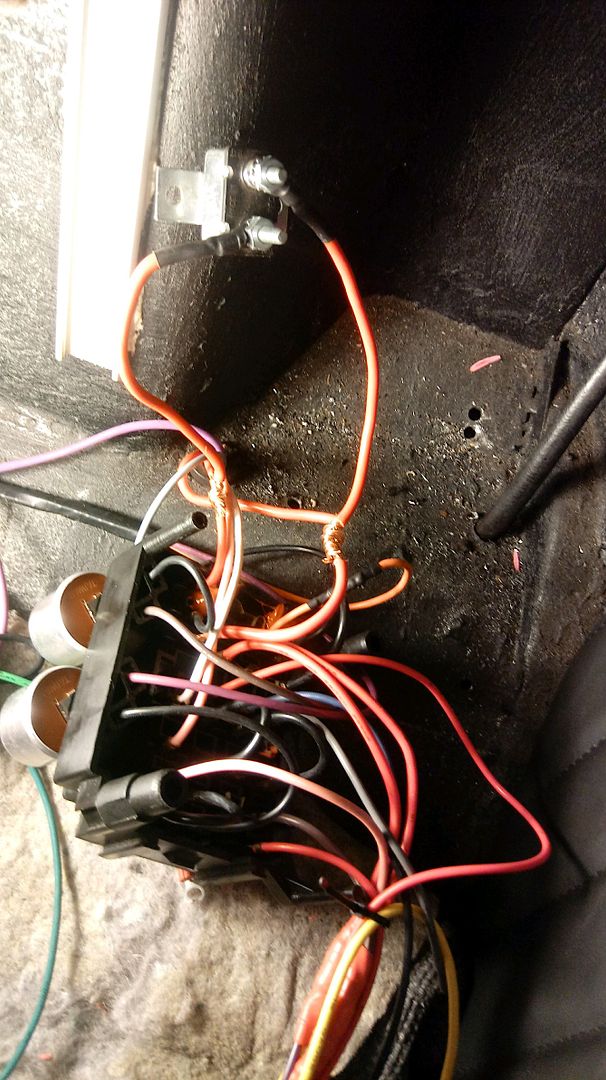

He had some issues and a local fella that wires boats or something had made some repairs. This is his mainstay, I'd never seen the stuff and now having seen his work, I have my doubts about anyone who would use it on a regular basis.

Here's some before pictures to highlight both his repairs and what was done before he got there. For some reason he decided that two separate runs of 12V power from the same source needed a resettable circuit breaker between them.

Personally, I'm confused. But that's not the half of it. This is a "ground" cable that was attached to the frame.

under the dash...

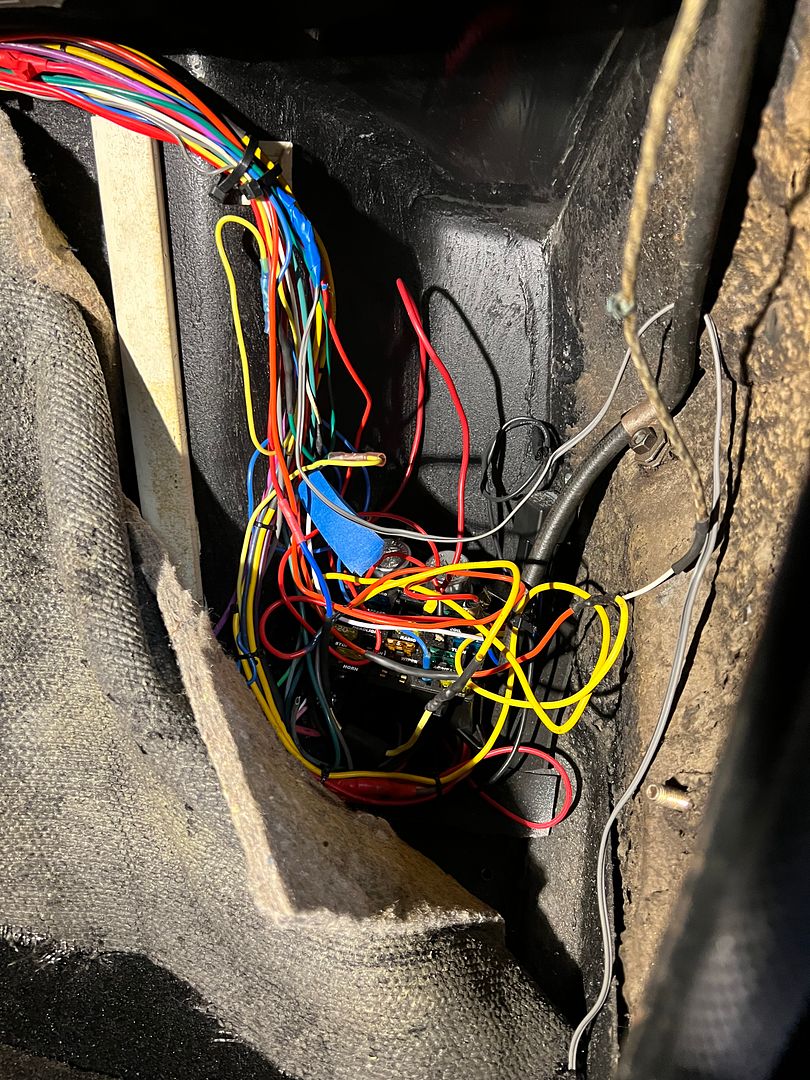

This is in the passenger front floor area, there is a fusebox in there somewhere..

The battery was located behind the passenger seat, and here is the cable routing beneath the car...

Yes, that's the positive battery cable against the muffler.....

With all this we found our best option was to remove the battery and start cutting out ALL the wiring.

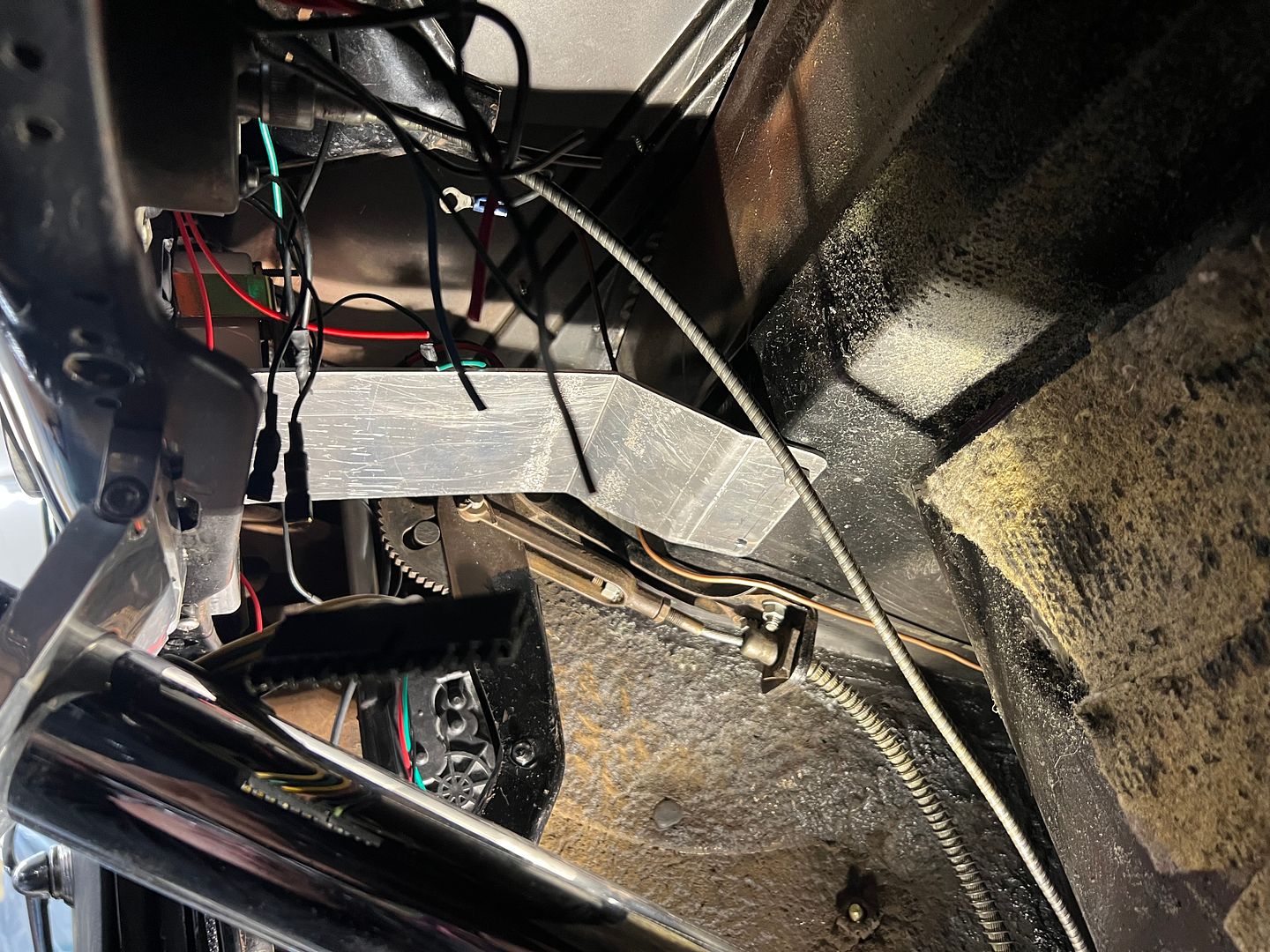

First order of business was to fabricate a mounting plate for the new fuse panel to get it out of the floor...

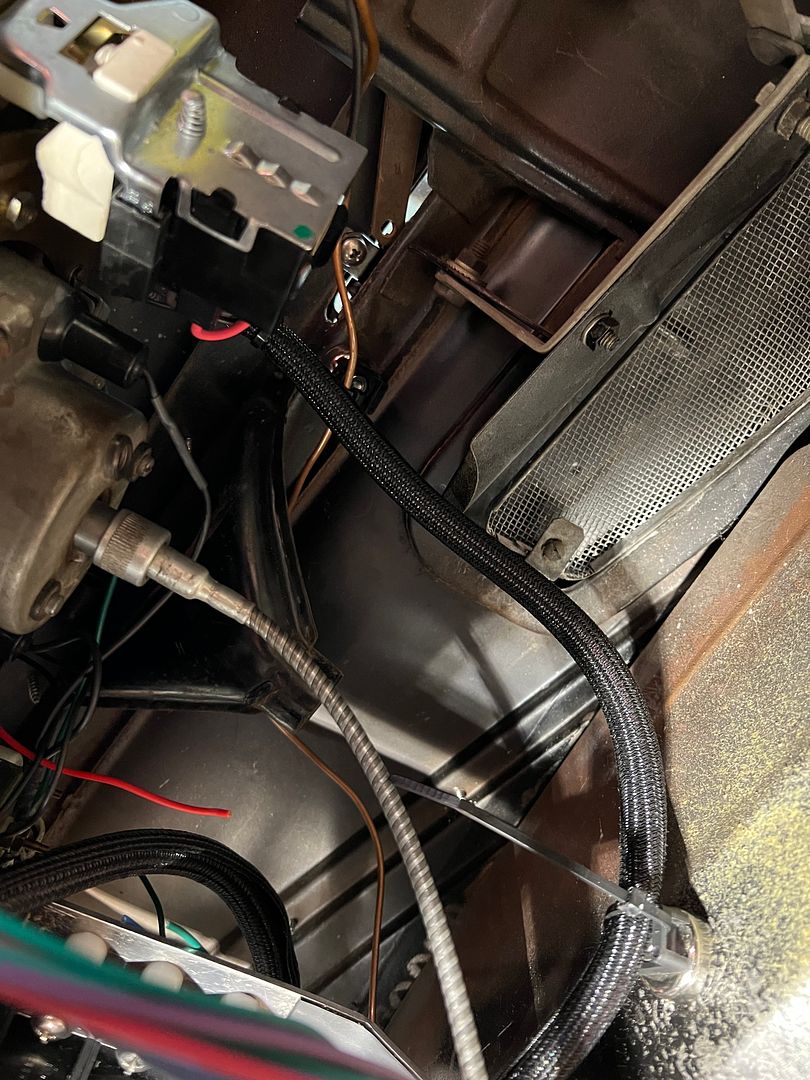

Having removed the most splices I have ever seen under a dash board, our goal was to have as few splices as possible, and make direct runs where we could. W crimps were used throughout, adding glue lined heat shrink in place of the previously favored liquid tape.. Tail light wiring was plenty long so new contact buttons eliminated the typical splicing of pigtails..

Tach and Speedometer connected...

Headlight switch...

For routing purposes, and to keep from drilling the firewall, we made some cable management using rare earth magnets and cable saddles..

more to come......Robert

-

09-07-2022 09:33 PM #14

That was one of the most convoluted messes I've seen, hope that clown isn't wiring airplanes.Ken Thomas

NoT FaDe AwaY and the music didn't die

The simplest road is usually the last one sought

Wild Willie & AA/FA's The greatest show in drag racing

-

09-08-2022 08:09 AM #15

Downright scary.

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

_IMG_4062.JPG)

_IMG_4064.JPG)

_IMG_4068(1).JPG)

RIP Mike....prayers to those you left behind. .

We Lost a Good One