Thread: 55 Wagon Progress

Hybrid View

-

09-16-2015 08:30 AM #1

Wow your attention to detail just never stops, excellent work"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

09-19-2015 06:19 PM #2

Thanks!

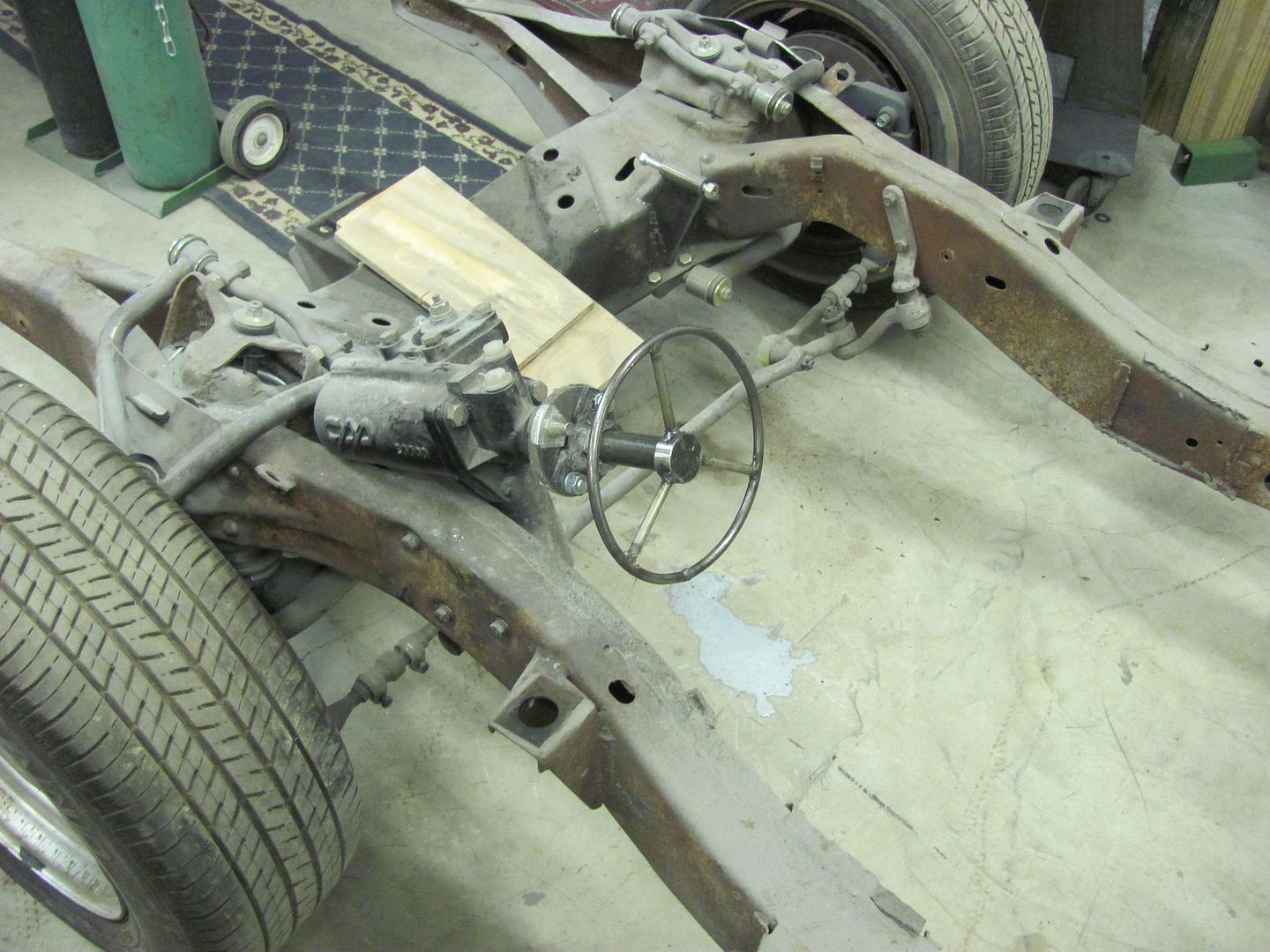

Todays progress, we've had to move the frame a couple times and it becomes a chore to steer, so a 1" bolt was modified with a home made steering wheel. Works well, good thing there's no weight on the front end!

....and Kyle's been busy getting the bare metal prepped for epoxy..

Picked up some stump blanks last night to have some extra stations for the upcoming metalshaping class...

This afternoon, Debarking with a draw knife...

Kyle took over as I used the chain saw to cut some to length...

This one is about all the JD bucket could stand..

....and some Talstar to take care of any remaining ant domiciles.

Robert

-

09-19-2015 06:30 PM #3

"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

09-26-2015 10:15 PM #4

Nice Anvil!

We're checking this week with a local machine shop to see if we can get the body media blasted... should be a much quicker prep for the epoxy..

In the meantime, the downside to plug welds and mig welds.... cleaning up all those welds..

Kyle working on more welds..

...and to get ready for the class next week, we put all the 55 parts away in the paint booth...

Robert

-

09-29-2015 07:58 PM #5

Getting ready for the metal shaping class at the shop this week, picked up Peter today from the airport.

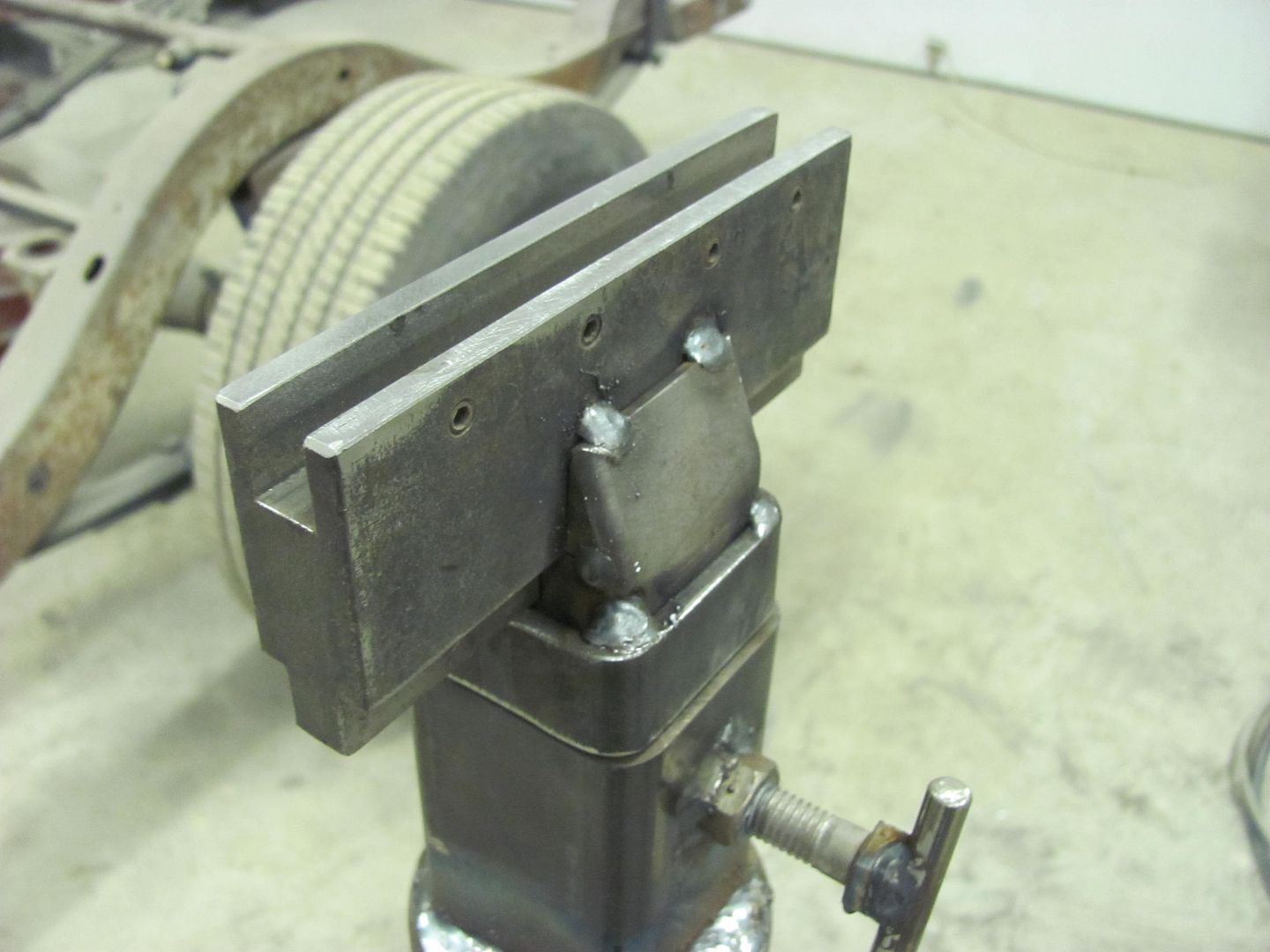

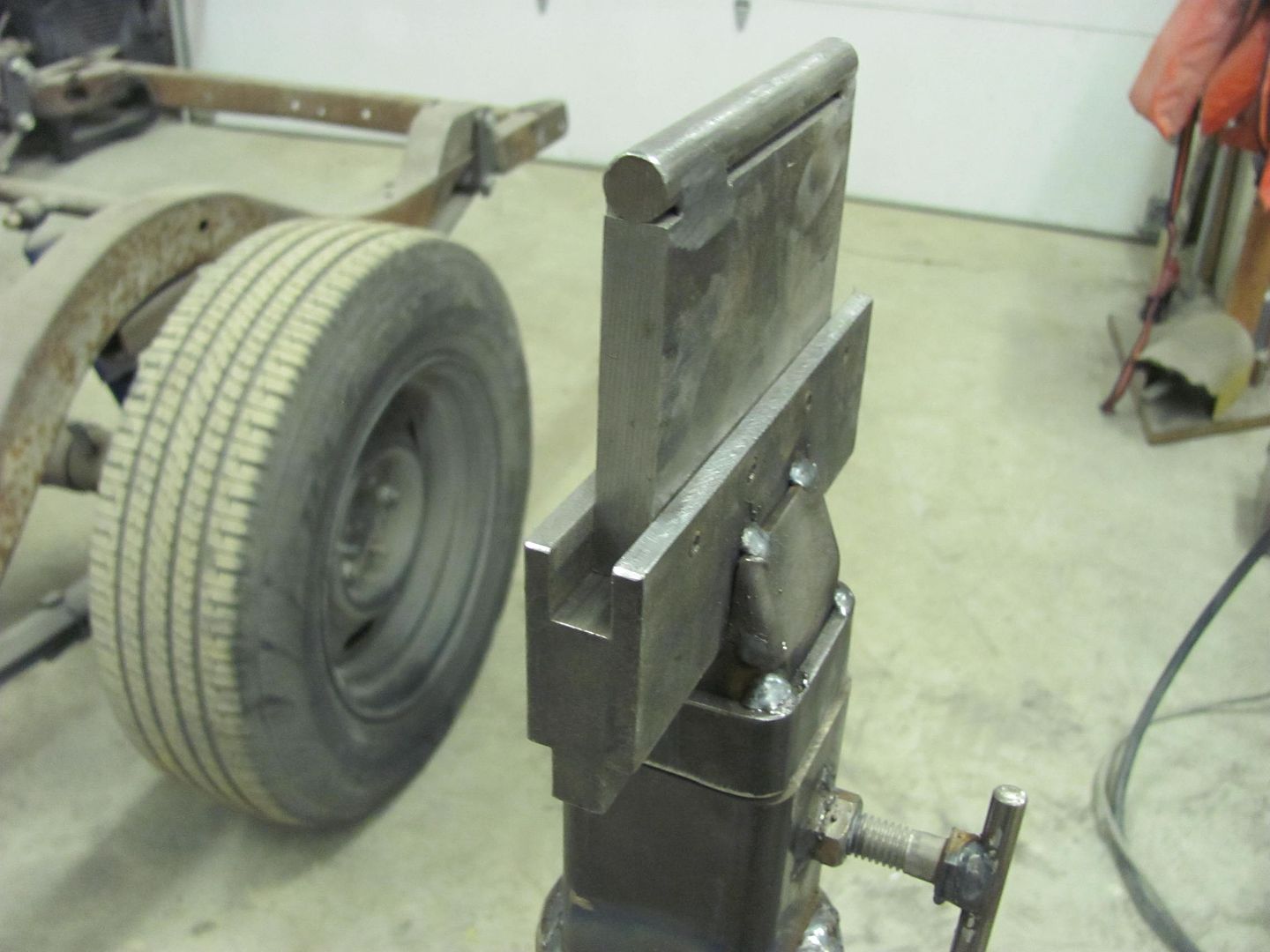

Last night Kyle and I made a pedestal for some home-made stake anvils using a couple 45 lb dumbbells and some pipe/tubing, tonight made the round-head anvil and another with a holder for press brake dies....

.....and stopped by the upholstery shop this morning to get another shot bag stitched up...

Counting the hours!Robert

-

09-30-2015 08:35 PM #6

A few of the projects showed up this evening for the class, more to come tomorrow....

One of the attendees brought a CP hammer for us to use...

I'm going to have to get Peter here more often, forces me to clean up the place!

Robert

-

09-30-2015 09:40 PM #7

Ooohh, I like the possibilities presented by the sheet copper, plus all those sheet metal forming gizmos!.

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

10-01-2015 07:26 PM #8

Here are some of the highlights of today's class....

Peter shows how to prepare a stump for shrinking....

Discussing weld location in panel forming....

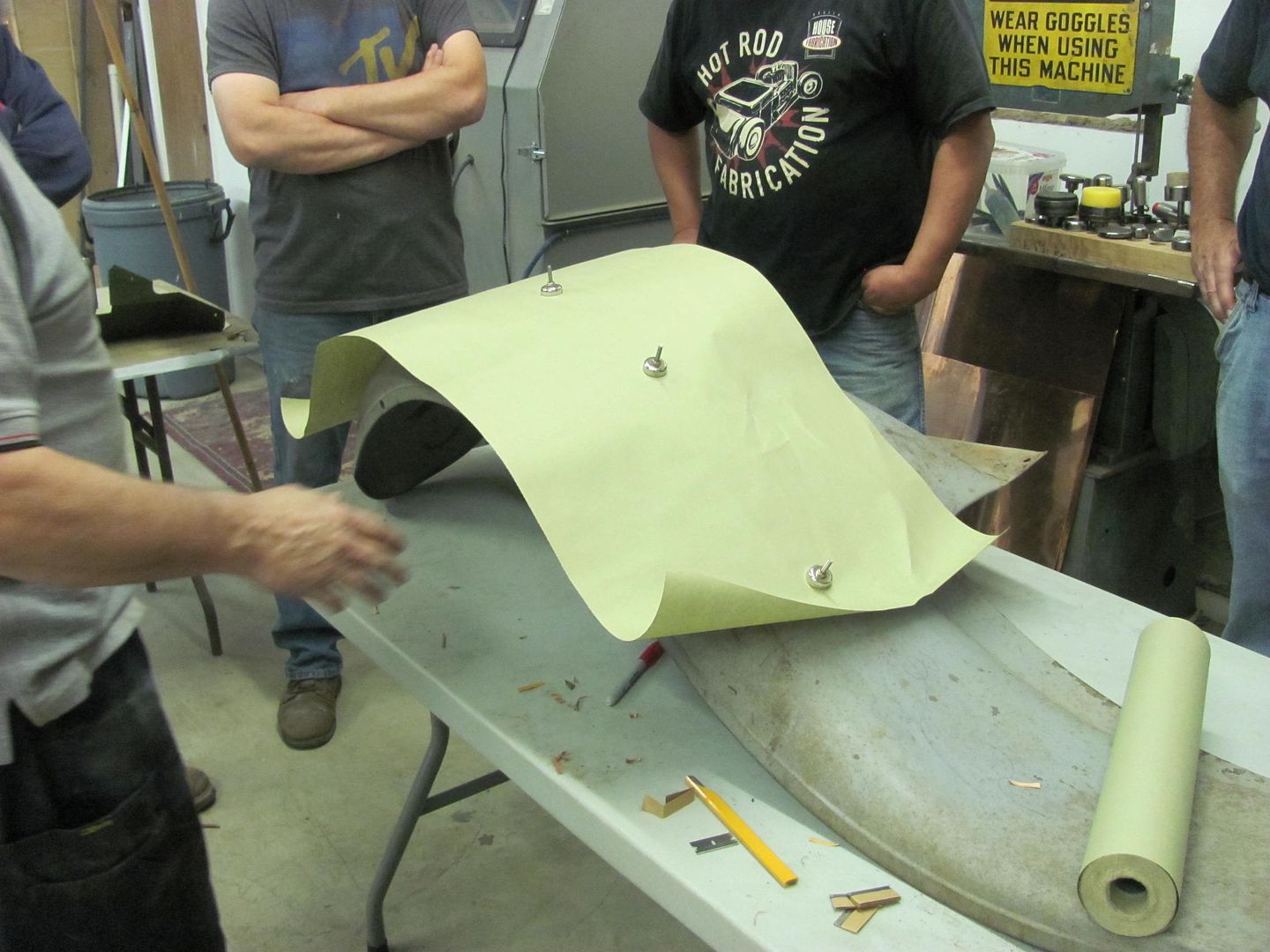

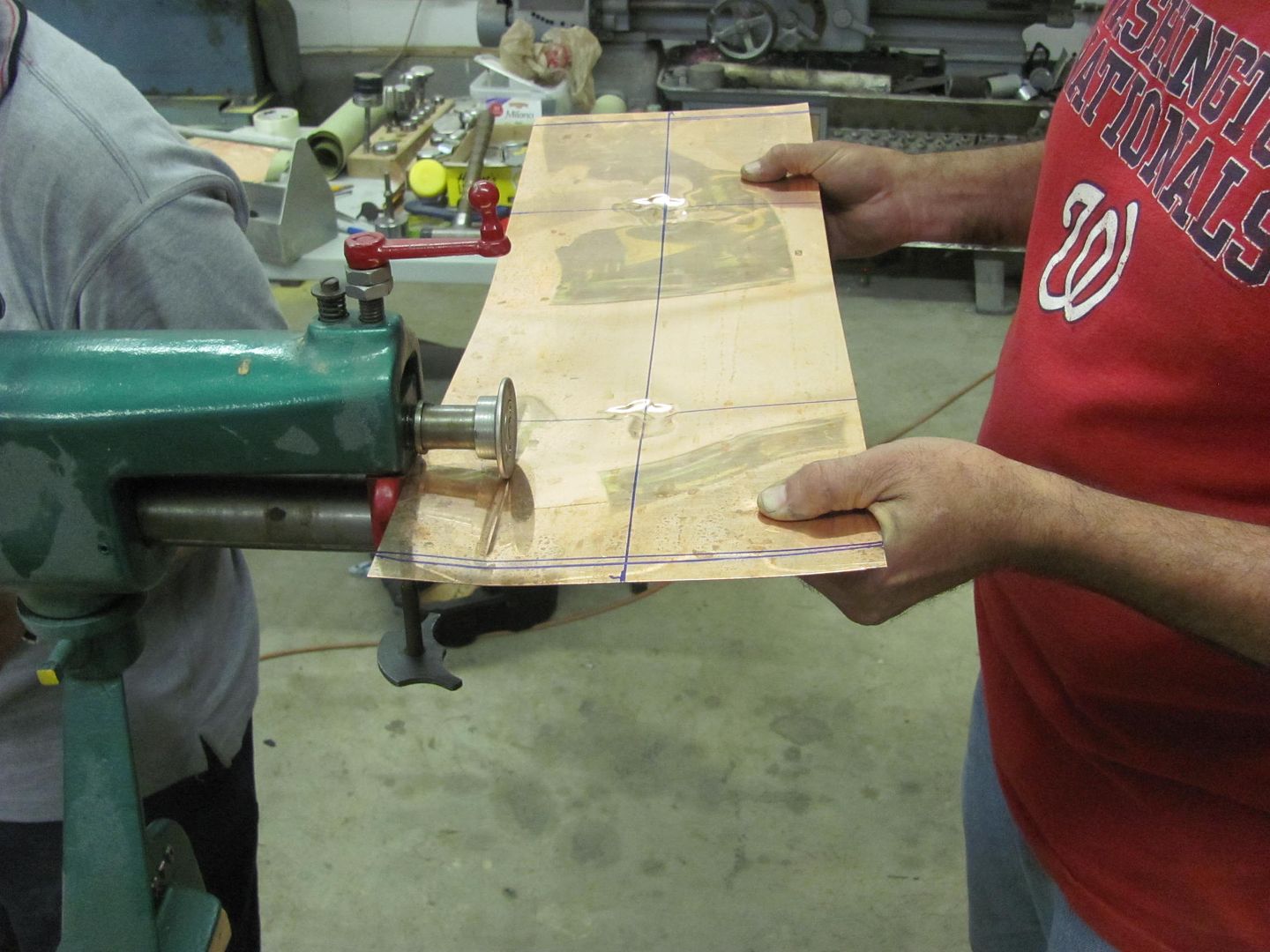

Using magnets to hold a paper pattern for layout....

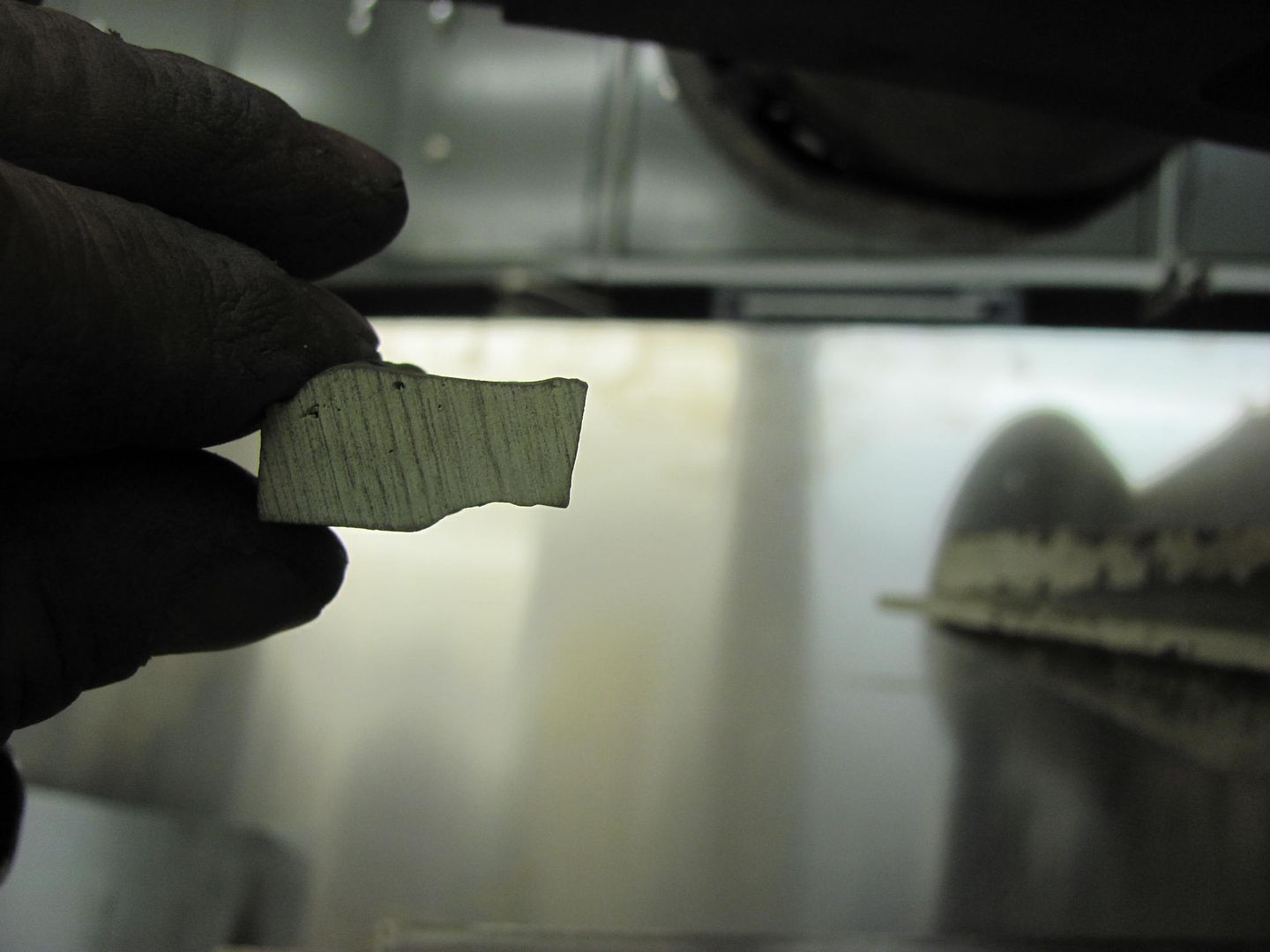

Wheeling, tuck shrinking and annealing aluminum sheet...

Capturing the tuck and shrinking on aluminum sheet

Blocking and wheeling our 19 gauge steel fender panel...

Forming the rear corner for a Model A..

Blocking on the sand bags and shrinking on the stump....

Wheeling....

Robert

-

10-01-2015 08:56 PM #9

Sorry I missed it!.

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

10-02-2015 07:45 AM #10

Cool metal working /shaping class. Thanks for sharing, and Man does your shop look clean!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

10-02-2015 11:24 AM #11

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

The shop looks great! I'm sure the class was great! Those pieces turned out awesome!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

10-02-2015 04:59 PM #12

It's great your helping pass on these skills!

Richhttp://www.clubhotrod.com/hot-rod-bu...del-coupe.html

-

10-02-2015 07:18 PM #13

Thanks for checking in guys. Here's some of today's class projects.

The start of a scooter fender...

Test fit of a fender panel...

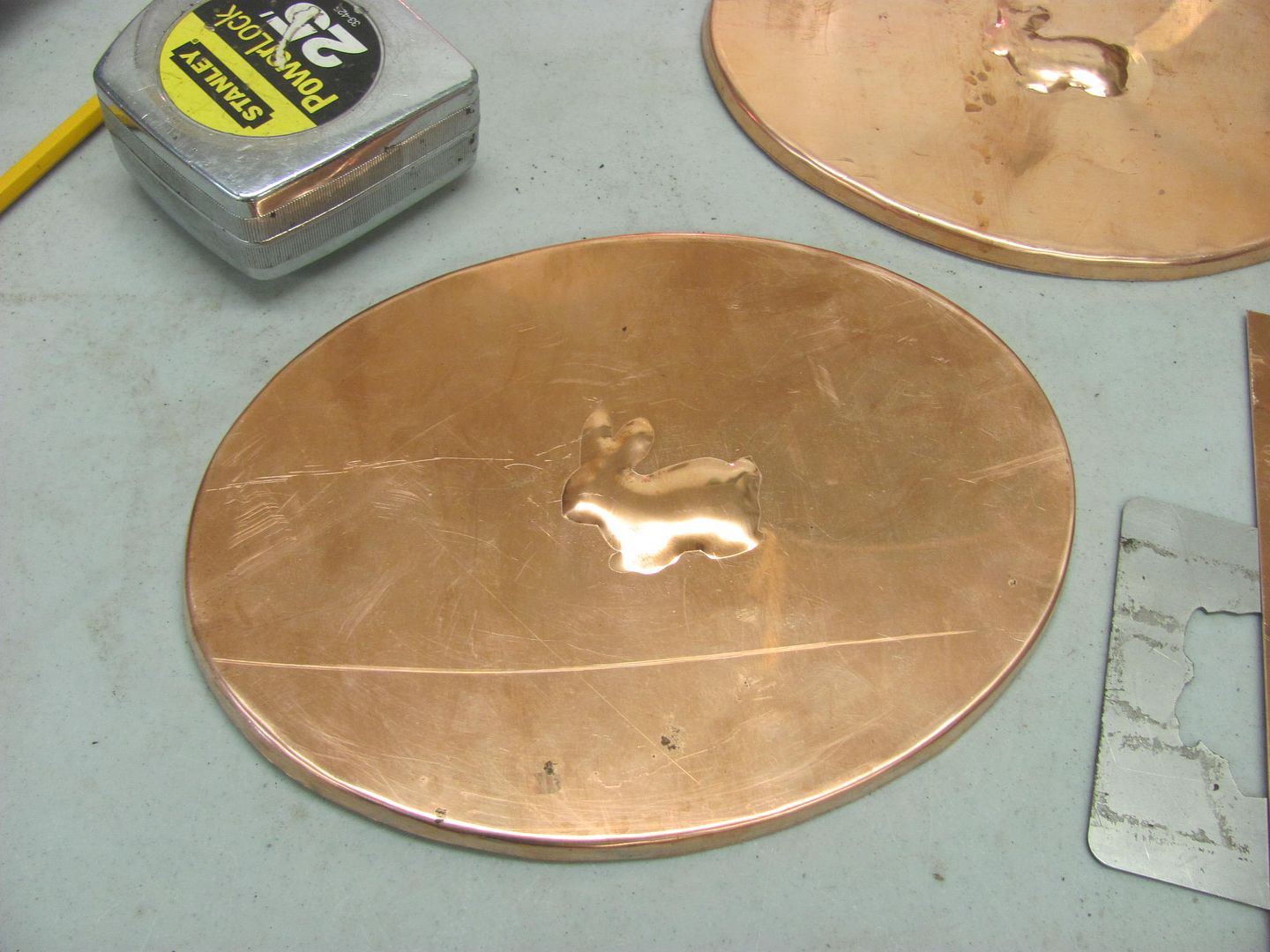

Copper work, trash can taking shape...

Paper pattern on a roadster quarter panel....

Using the blocking hammer to pre-stretch

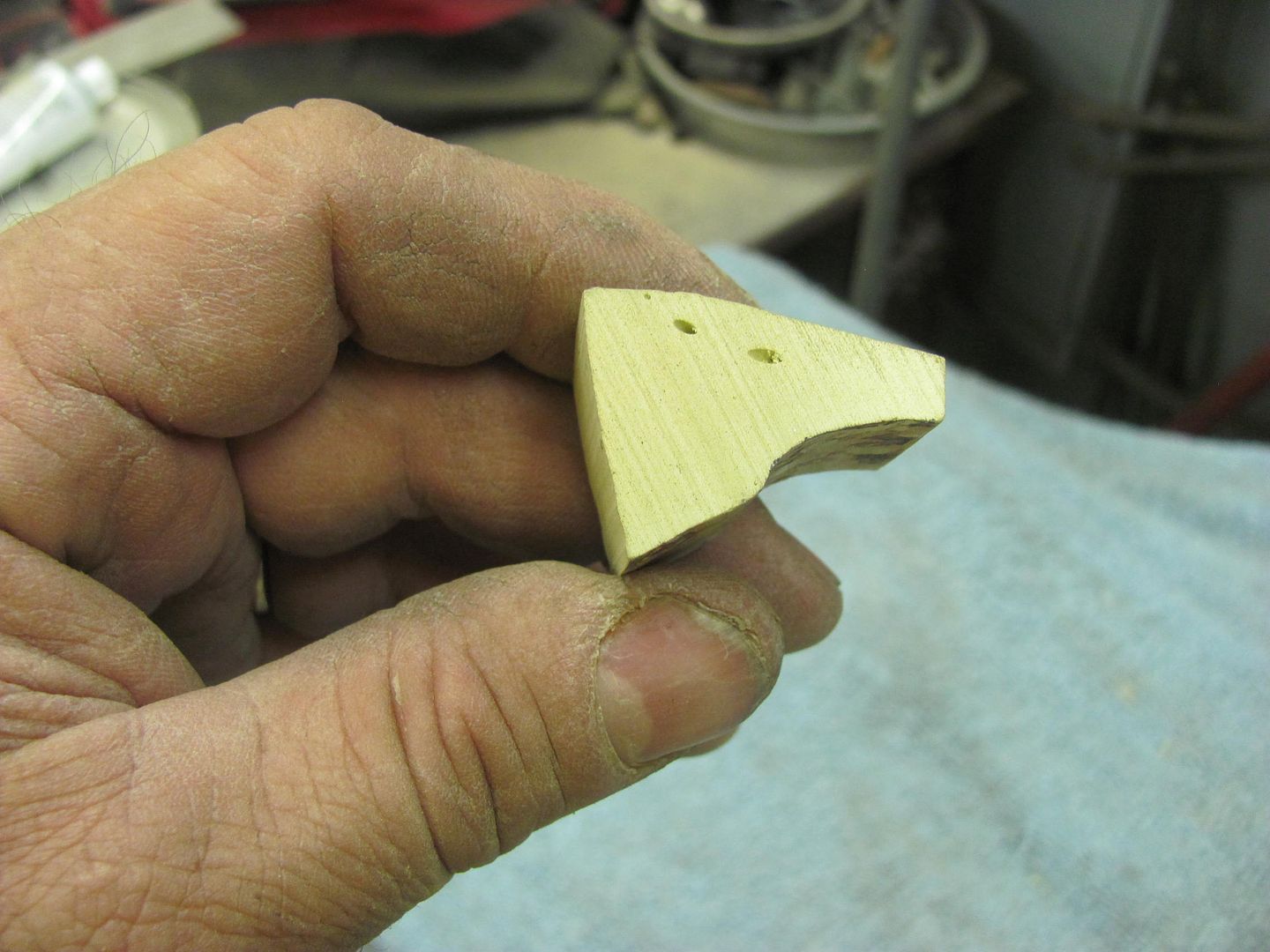

Making a pattern for the dies

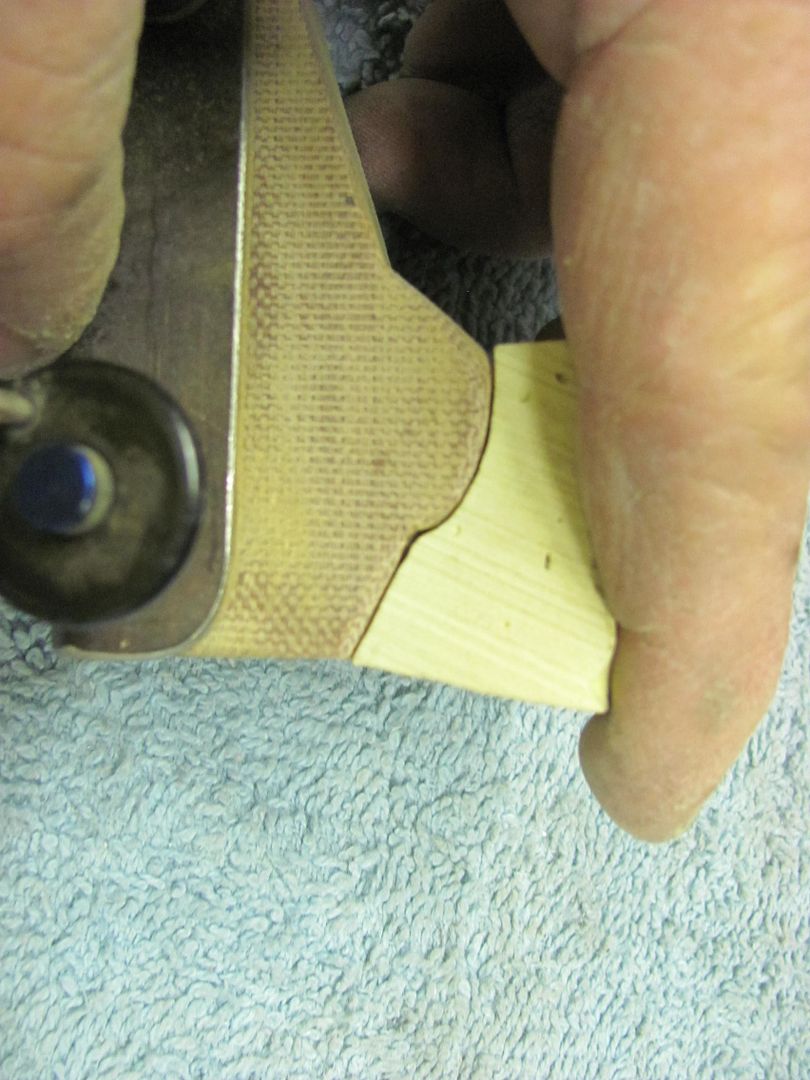

Making a pattern of luan board for a divider offset in trimming the top edge..

What happens when a metal shaper gets around wood products...

Trimming and filing up the top edge....

On to the Lennox....

Robert

-

10-03-2015 08:34 PM #14

Project updates for todays class:

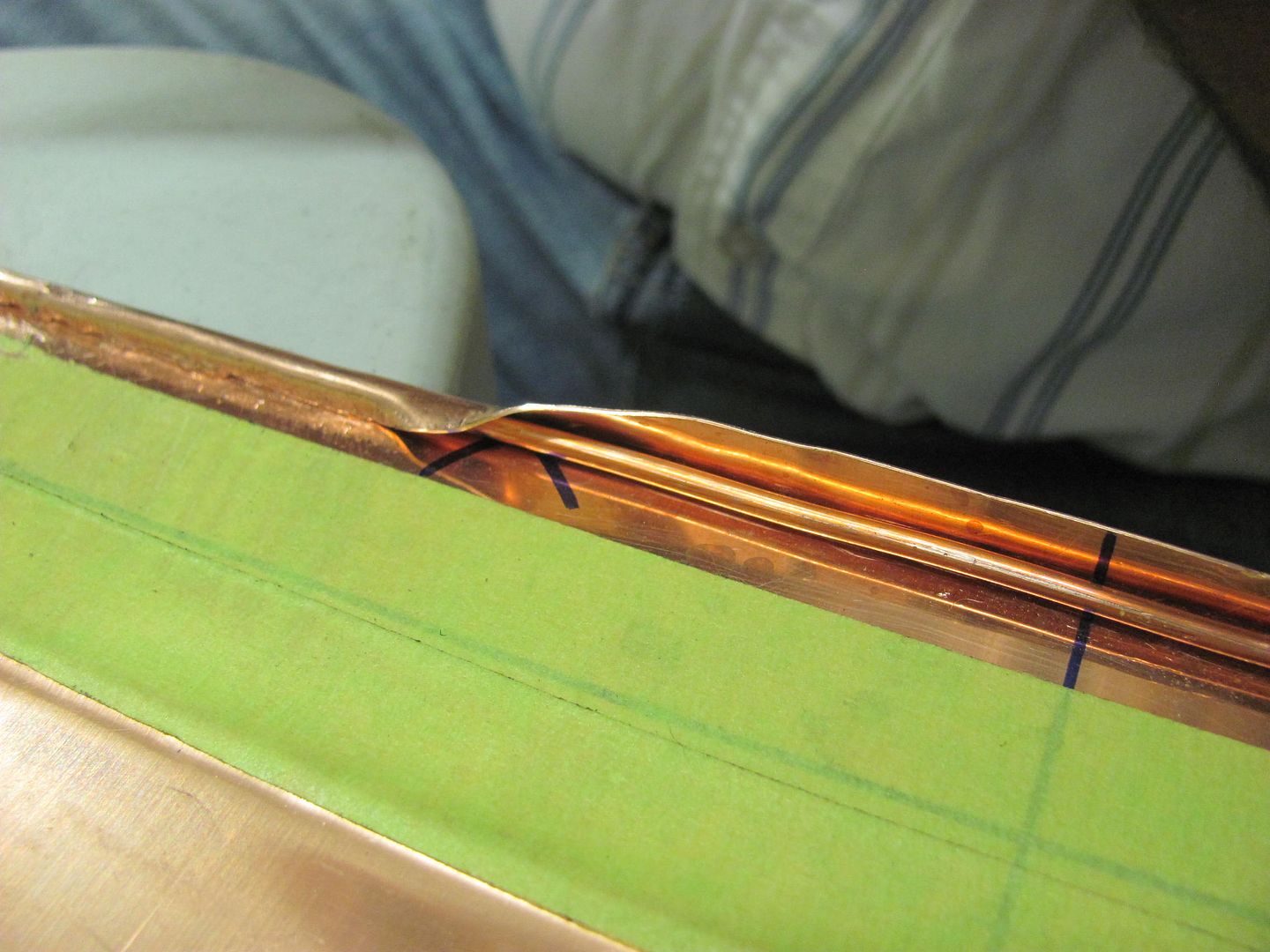

Wiring top edge of the copper trash can..

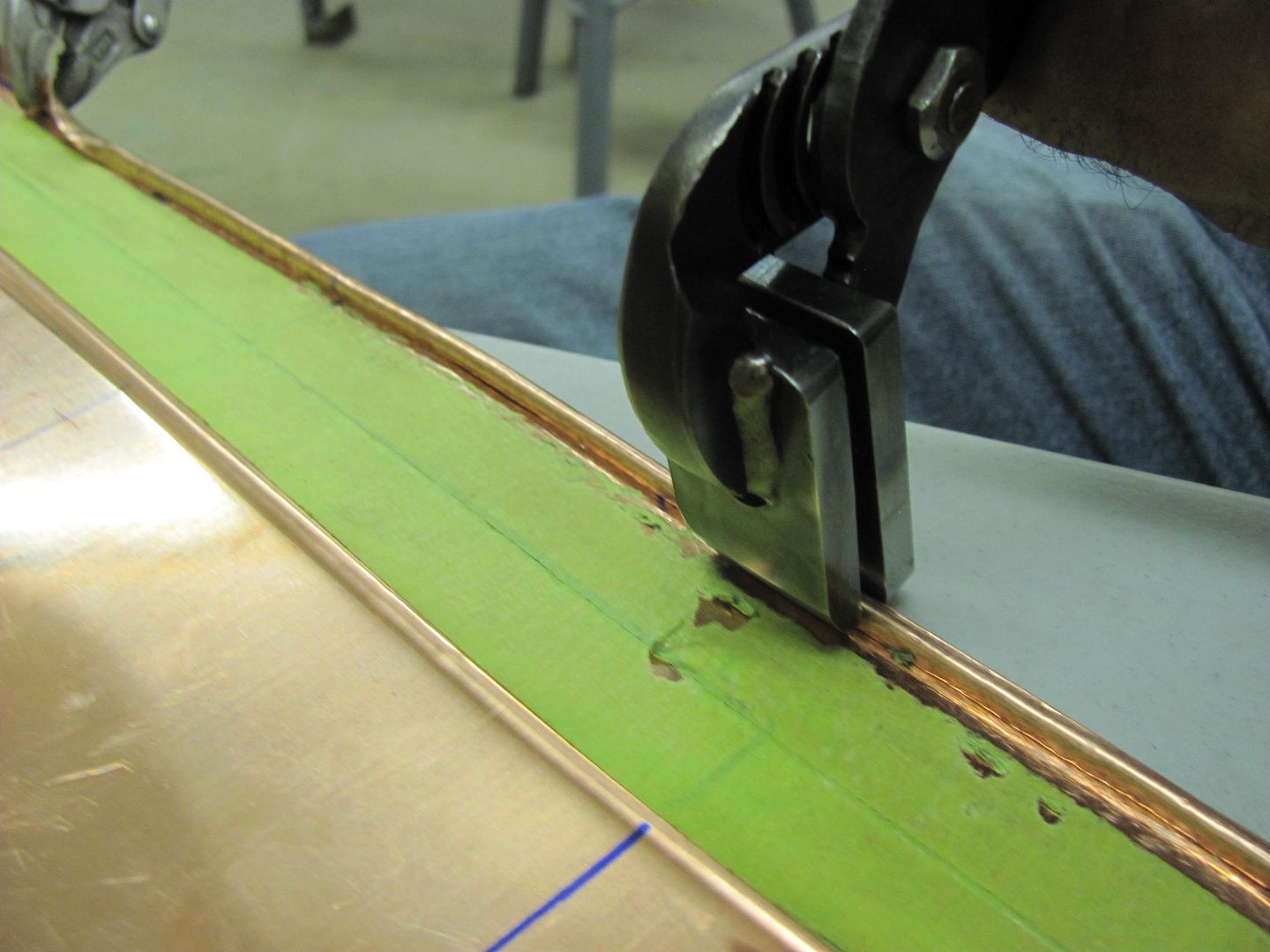

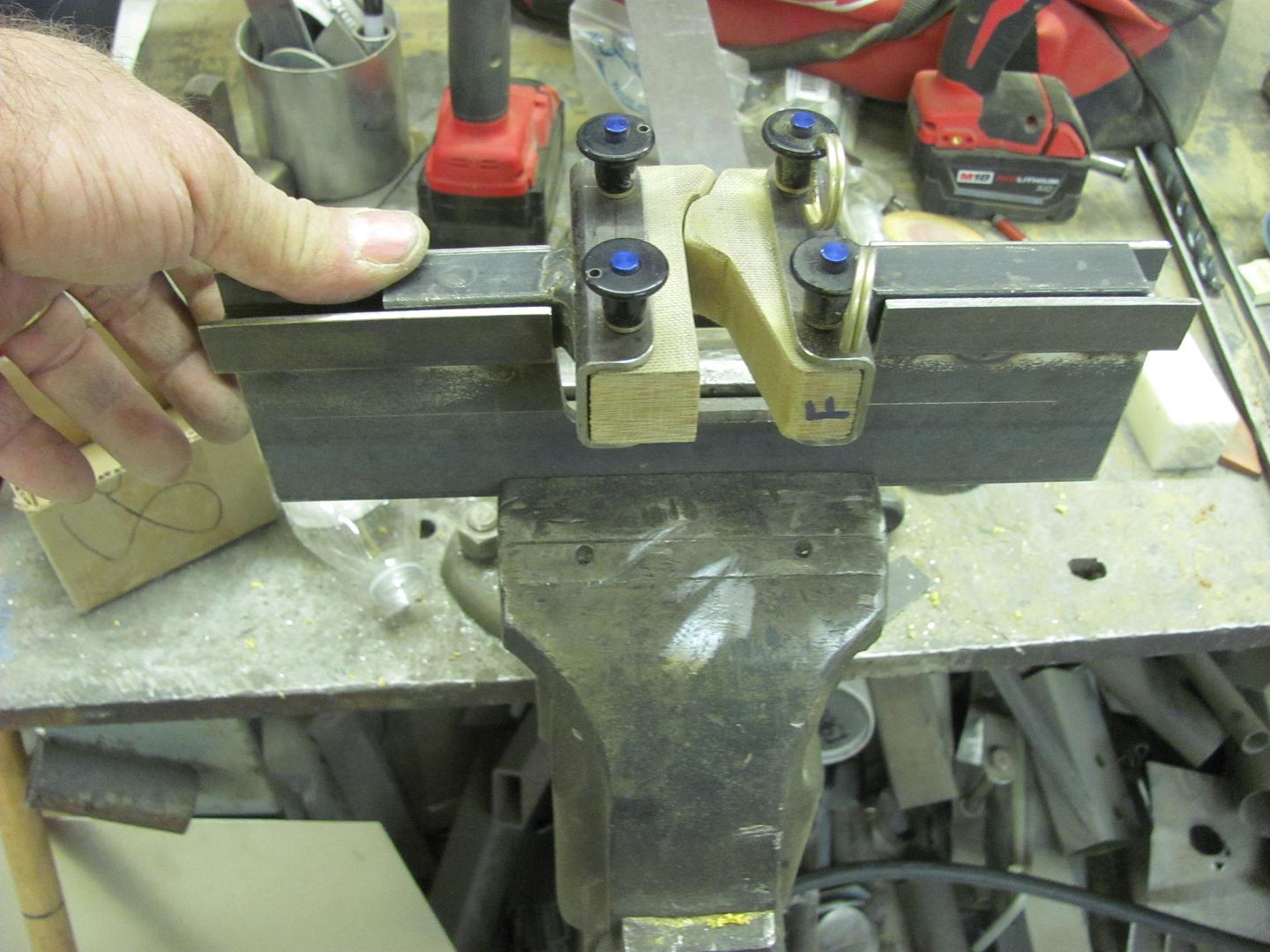

Roadster quarter, making dies for the upper bead detail....

Sharpening the crease

A bit of shrinking....

Test fit...

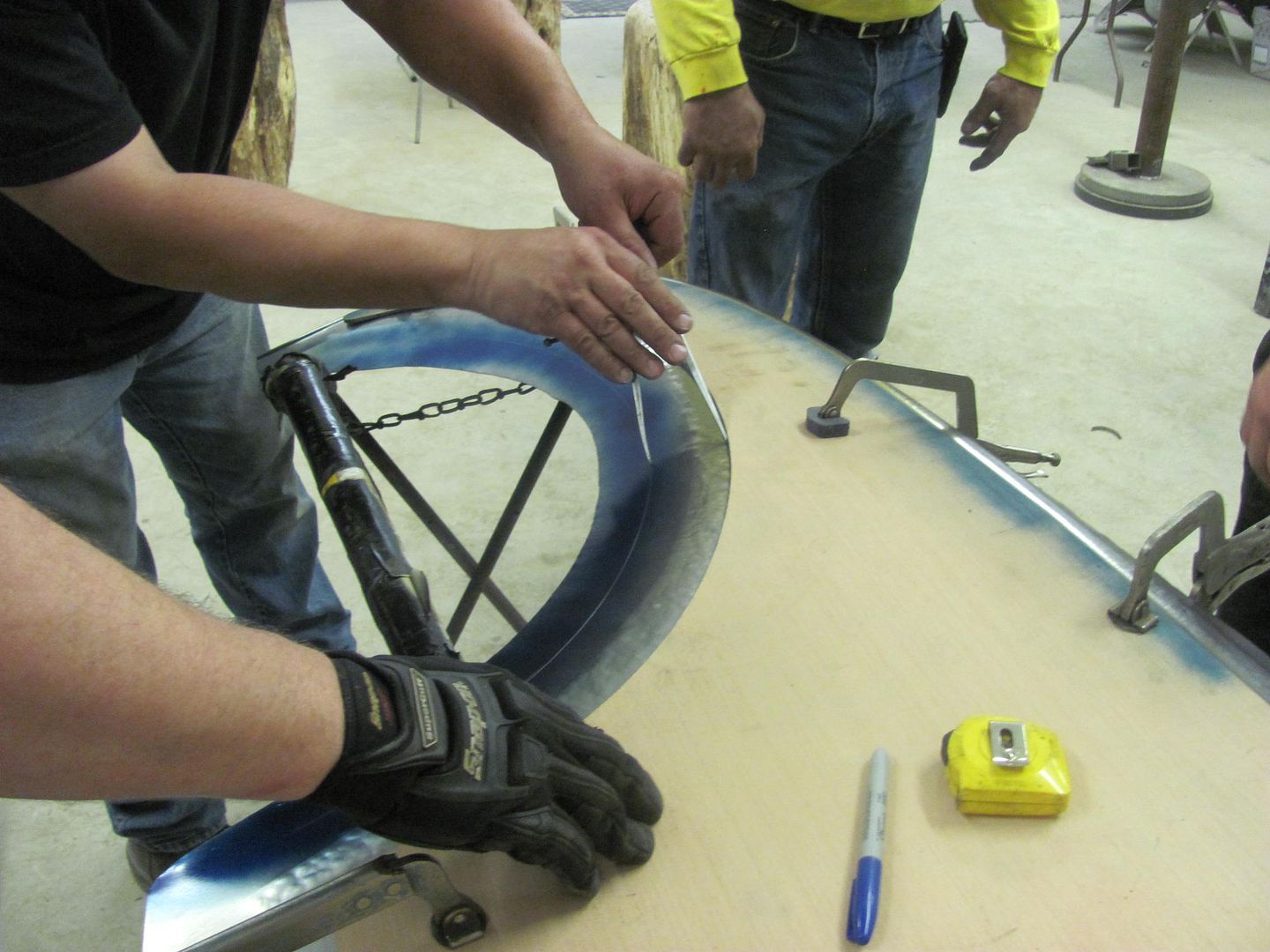

Marking for trimming the wheel opening...

Inside radius backstop

Scooter fender...

Trimming...

Prepping for Sport Coupe door skin removal

We took a short break for a Maryland treat...

of course, using only the correct utensils....

Blocking the top section of the roadster quarter.....

Robert

-

10-04-2015 09:18 AM #15

Like the crab "claw hammer" shot! Man you guys know how to have fun, metal working and a crab feed lunch with beer!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

It was SWMBO's little dog. .

the Official CHR joke page duel