Thread: 55 Wagon Progress

-

10-05-2015 07:15 AM #601

Final update of the class, pictures from yesterday.

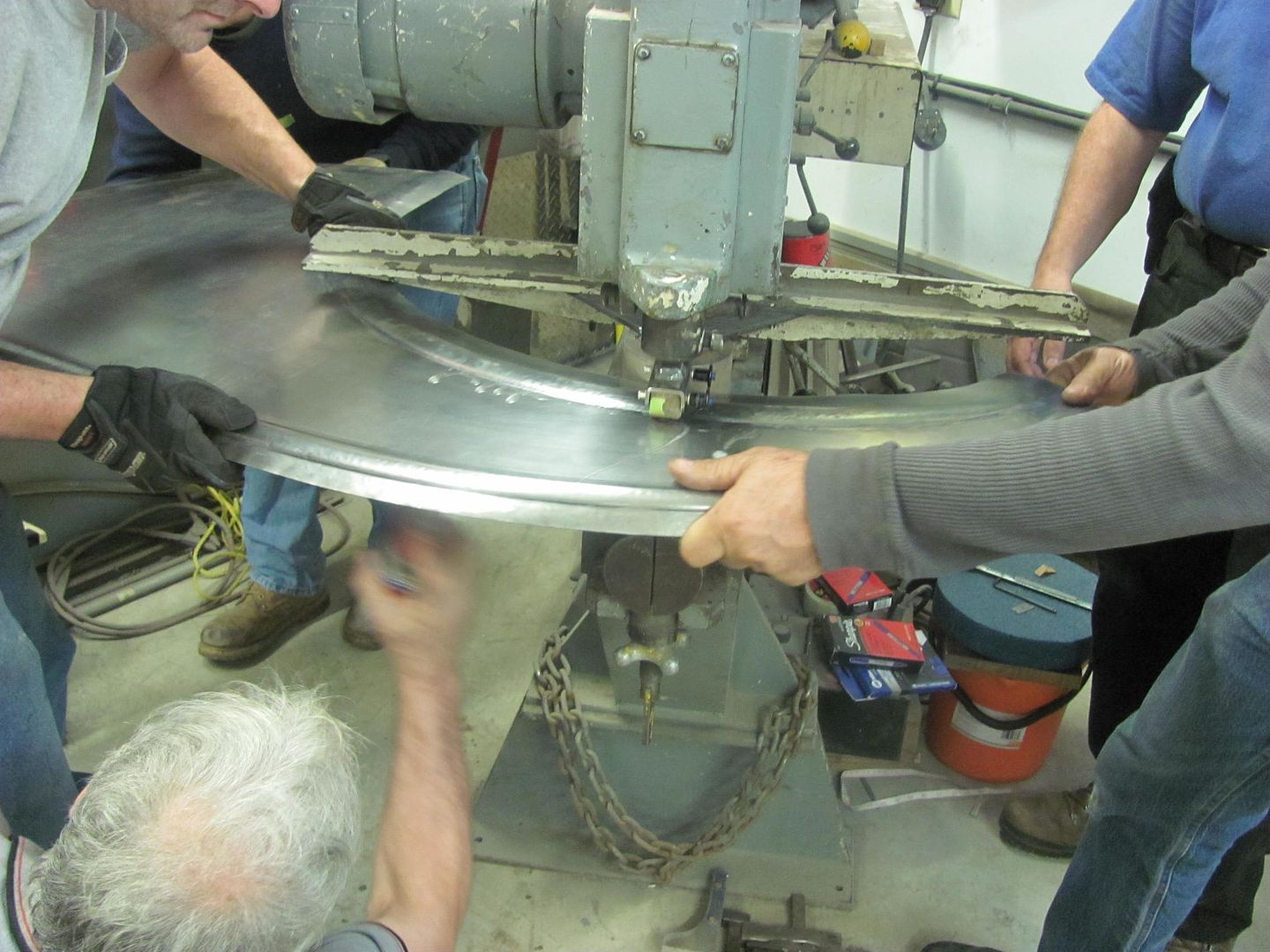

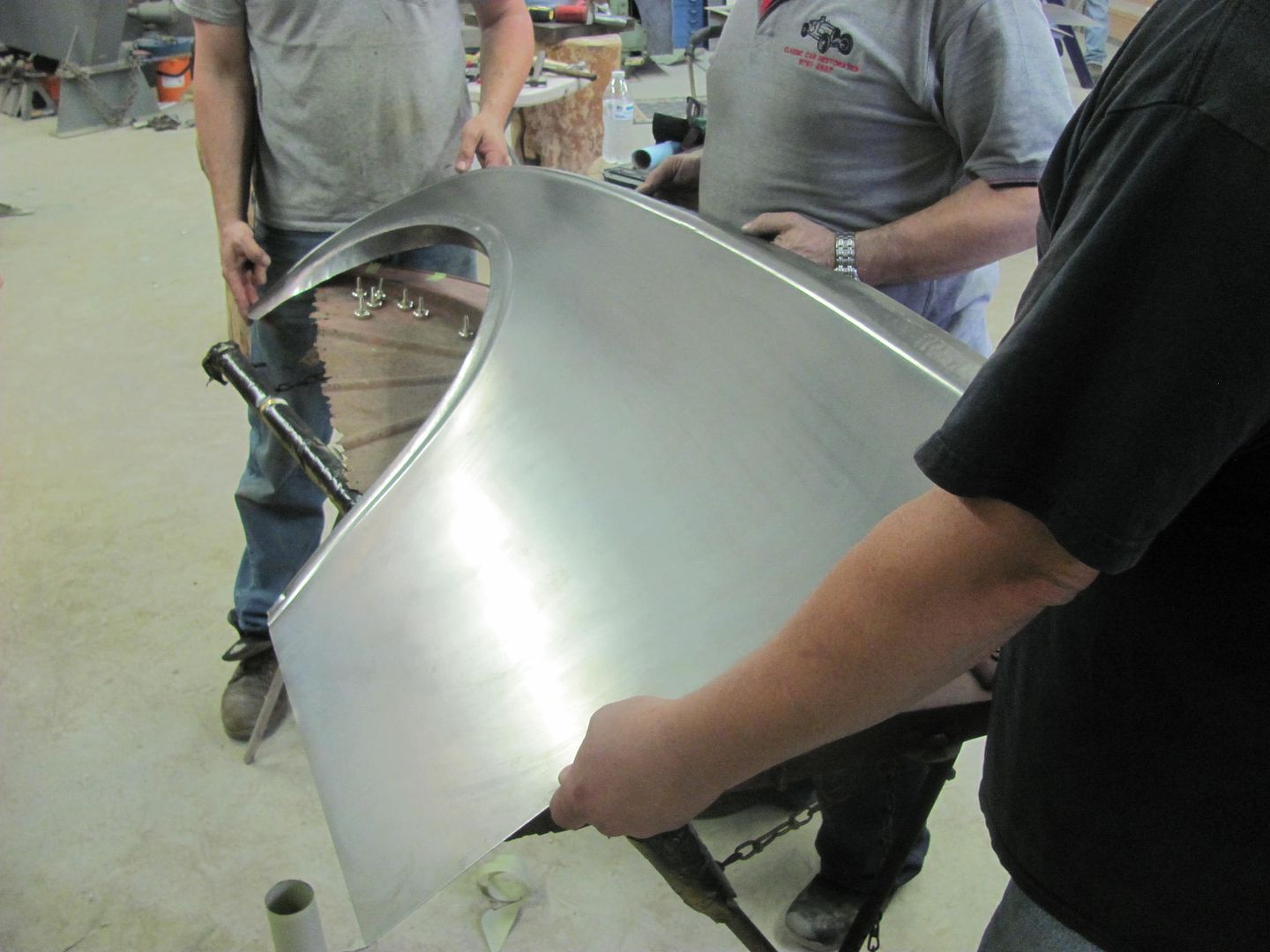

Wheeling door skin for a sport coupe:

Annealing copper wire to use as rivets:

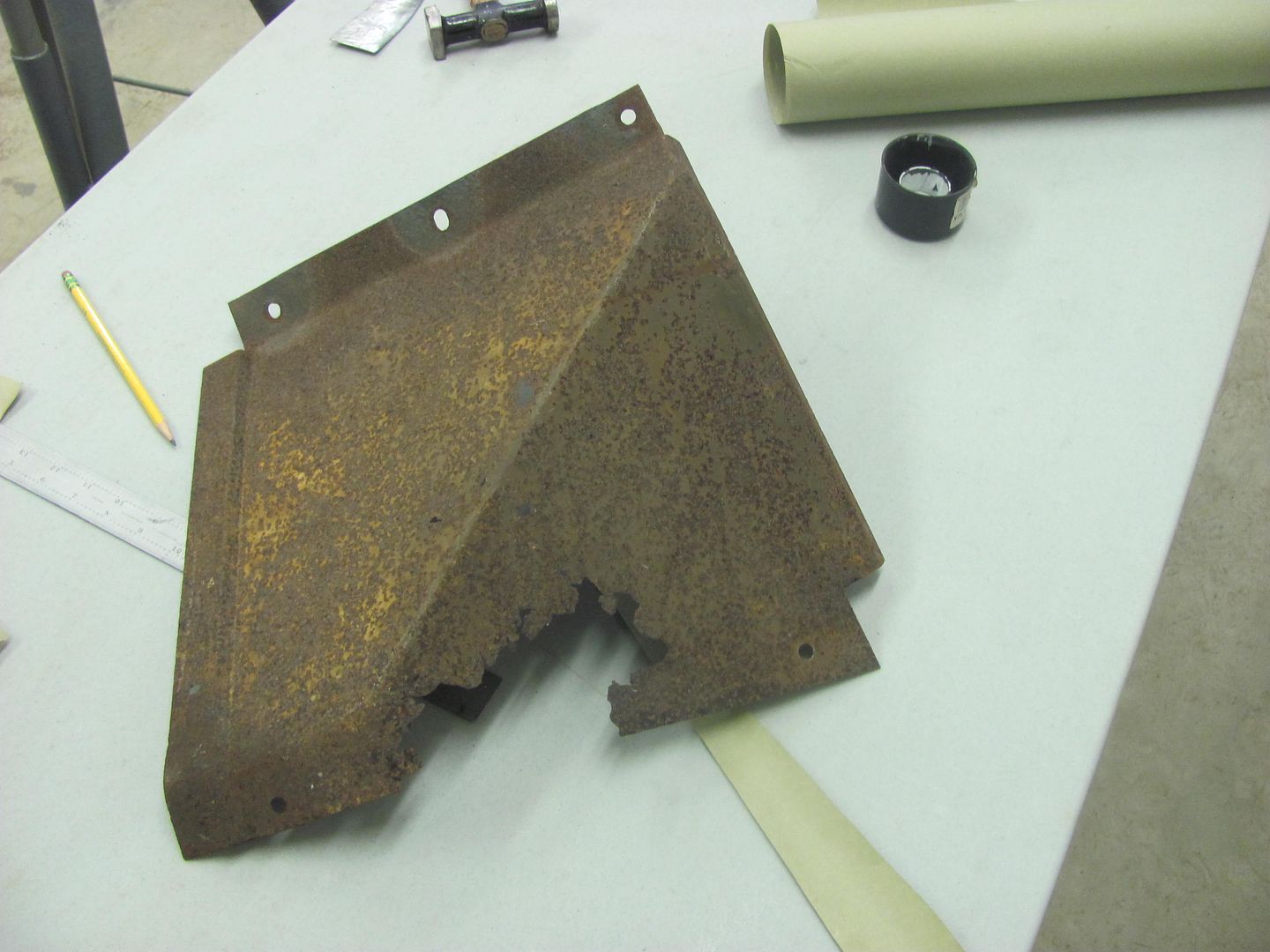

Cover plate for military vehicle:

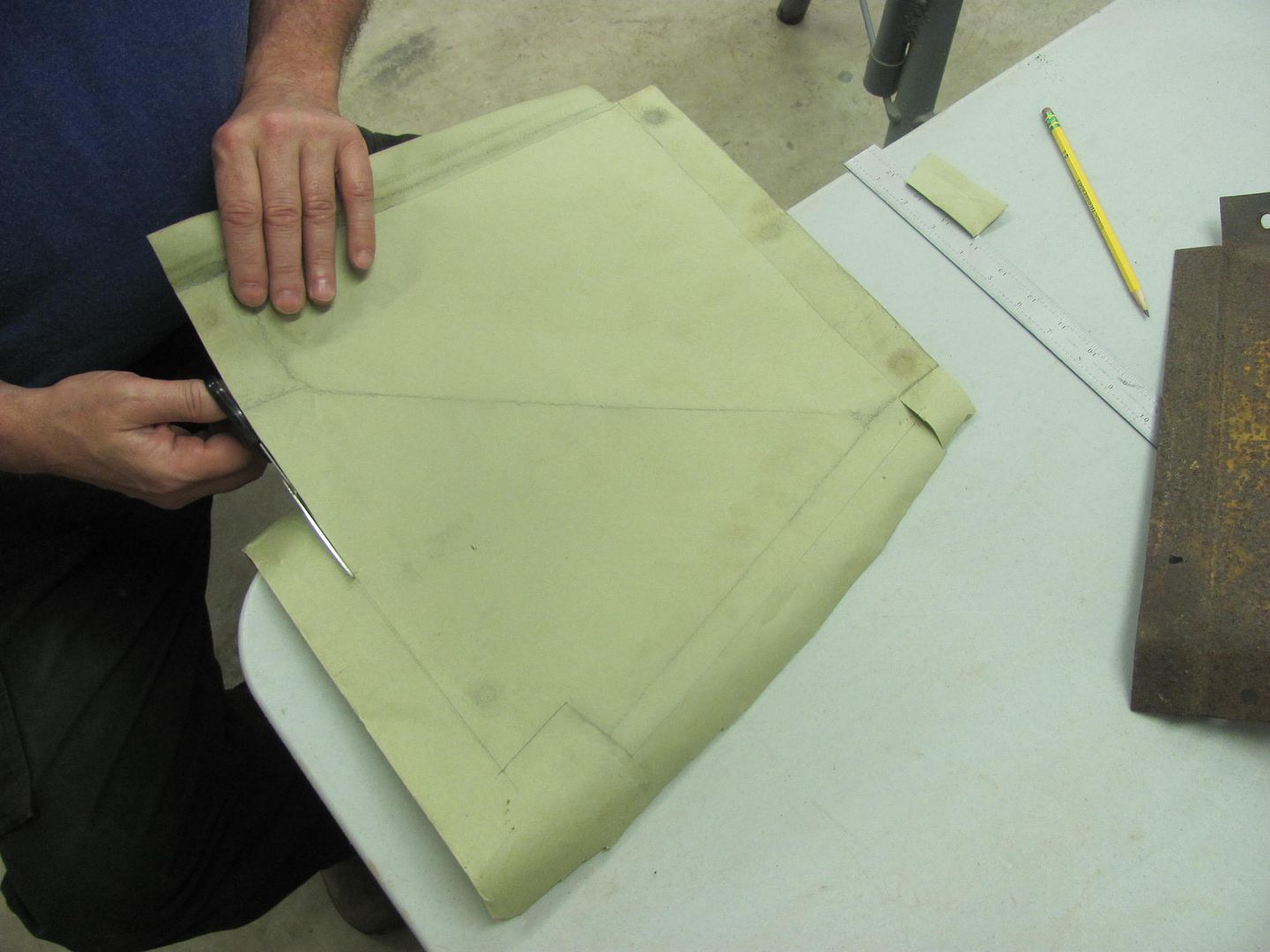

Paper pattern

Tuck shrinking on post dolly

Forming upper quarter reverse

Wheel opening bead detail added

Tipping flange with vise grips with jaws that have been smoothed...

Stretching

Loading stumps for the journey to their new home..

This class has been a blast, Peter is a wealth of knowledge and experience, and we are honored to have him share and pass this on to others. Anxiously looking forward to next year!Robert

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

10-05-2015 08:31 AM #602

Why would you want to lead load aluminum sheet metal? Interesting process but not sure what the benefit is? Metal illiterate I am!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

10-05-2015 08:34 AM #603

For an aluminum vehicle it makes a good filler for any panel seams, etc, as the heat opens the pores and the lead becomes impregnated into the aluminum. The panel used had been "door dinged" by a ball peen hammer and the lead was to simulate a repair..Robert

-

10-05-2015 08:40 AM #604

Ah now that makes sense, thanks!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

10-05-2015 08:42 AM #605

So if the back side were fully accessible you'd probably shrink it back into original form as much as possible, but if it's blind backed the lead is a good fix? Just wondering.

Also, thanks for the pictures of the stumps being used. I happen to have a big ol' Hickory down, and just might cut one or two chunks out for beater platforms.Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

10-05-2015 02:40 PM #606

Thanks for sharing. Very informative..

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

10-06-2015 04:13 AM #607

An aluminum car has the same panel "connection" challenges as the steel cars. For the most part, aluminum is less than "receptive" to such fillers in it's static state, but given heat, the pores in the metal will open up to impregnate the lead into the aluminum. So in this application, lead makes a good transition across panel joints, or for dent/ding repairs.Last edited by MP&C; 10-06-2015 at 08:58 AM.

Robert

-

10-06-2015 04:36 AM #608

And the old becomes the new, again....

-

10-08-2015 09:02 PM #609

Finishing up the scooter fender..,

Marked for trimming...

Tipping wheel to set the side flange....

Profile comparison, front to rear...

.....and side to side...

about ready for shipping to AZ.....

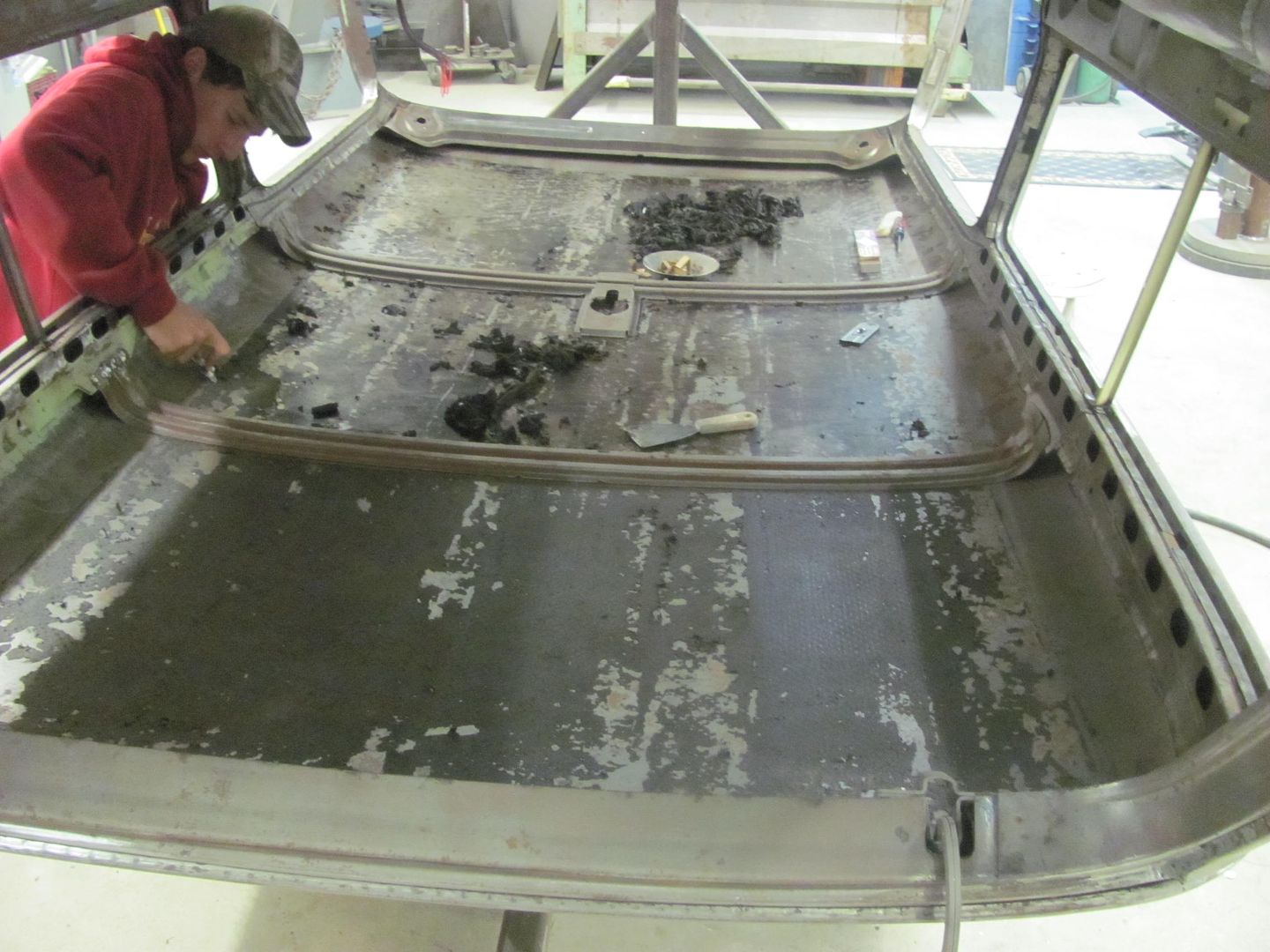

.... and Kyle is dressing some welds and weld touch up to get the body ready for media blasting...

Hey. you can still walk in this place...

Robert

-

10-09-2015 06:16 PM #610

You guys do some amazing work with metal! Thanks for sharing!

-

10-10-2015 09:20 AM #611

And you make it look easy. I could probably learn to pound a rough shape, given time, instruction and the right tools, but I don't think I could convert it to a perfect replacement panel that looks better than the original!

"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

10-10-2015 08:01 PM #612

What an amazing class, and projects! I would pay to just sit, and watch!

Richhttp://www.clubhotrod.com/hot-rod-bu...del-coupe.html

-

10-13-2015 08:29 PM #613

Thanks for the comments guys, the class was a blast!

Not much to show, still working on grinding welds and filling pin holes... A good testament to using Tig or O/A welding

Also welded up/shaved the upper firewall seam....

Lesson for this evening is to watch welding around stuff mounted JUST BEHIND the firewall!

Robert

-

10-15-2015 08:06 PM #614

Well, more welding, grinding, and then we decided to give the roof insulation removal a try. Picked a spot and dumped on some lacquer thinner, which softened it up nicely and then made a sticky mess. So we put the putty knives aside and tried the paint scrapers..... without solvents. Dry removal was definitely better...

Also got another shipment of shirts in from Bonehead Graphics...

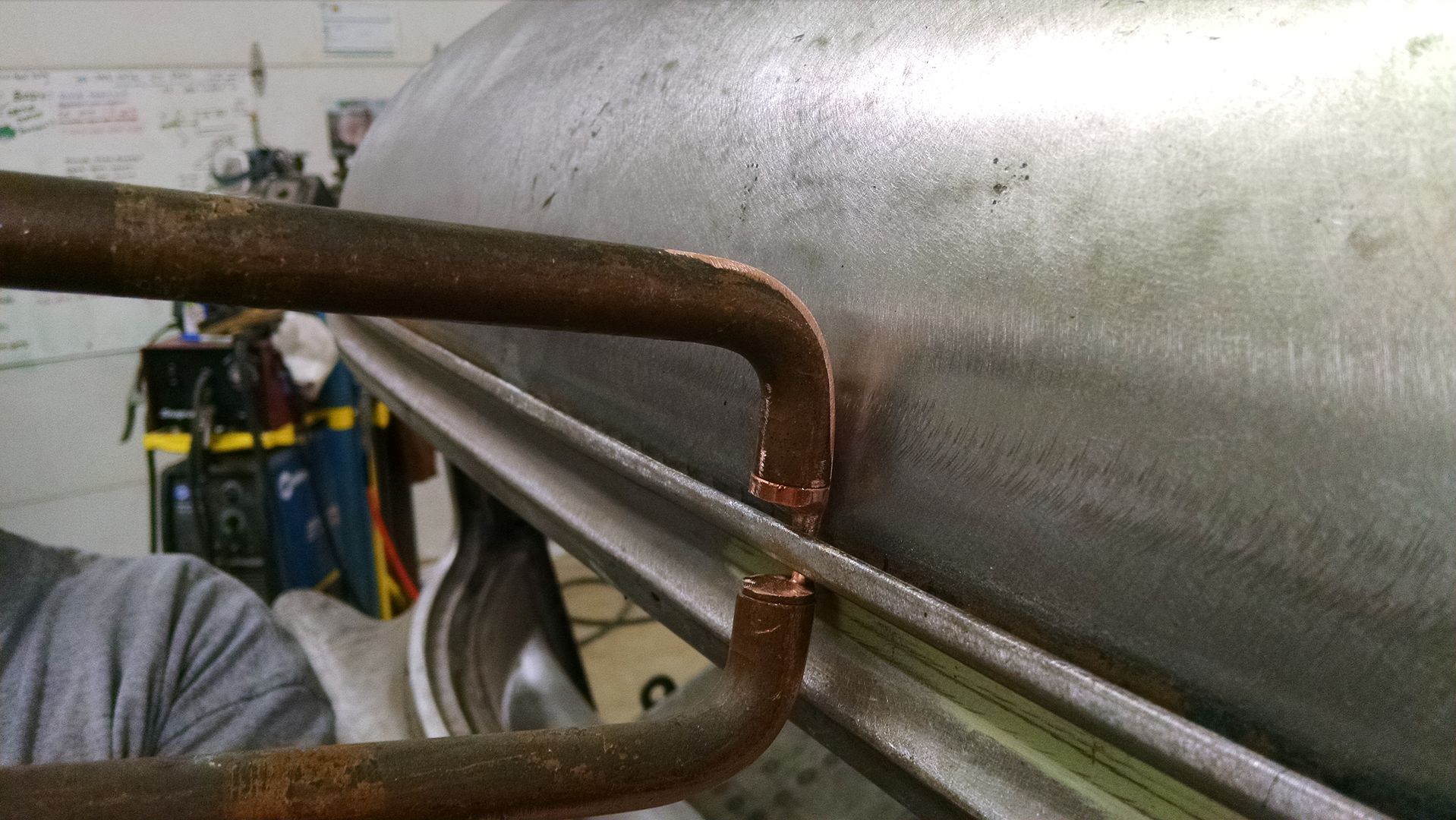

and promised the owner a modified set of spot welder tips to tackle his own wagon roof repairs...

Robert

-

10-16-2015 11:22 AM #615

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,299

- Blog Entries

- 1

Are you selling the shirts to the general public, or are they your uniforms?Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

I did not know Mike very well, we exchanged some messages from time to time but from what I understand he was a very good man. I was sad to learn about this

We Lost a Good One