Thread: 55 Wagon Progress

-

10-04-2016 07:12 AM #886

Most of the copper tubing we see on the general market is either Type K or Type L, and sometimes Type M, and all come in either drawn tubing (hard copper) or annealed tubing (soft copper). The difference is only wall thickness for these common products with Type M being thinnest, Type K thickest for higher pressure service. The other difference that we see is that tubing designated "air conditioning/refrigeration (ACR)" is by actual OD dimension vs nominal OD (1/8" larger than the tube size). All tubing carrying the ASTM designation is 99.9% pure copper (according to the Copper Development Association), and is deoxidized by adding a small amount of phosphorus during processing.

I can't explain why the weld backed by tube vs buss bar material is different, other than perhaps the buss bar being dead flat, and the tube being pounded flat and having a bit of air gap that expands when heated? There's likely a better answer than that, but I don't have time to look any more right now.

Thanks again for the tip!Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

10-09-2016 10:45 AM #887

Thanks for posting the additional info on the copper. The bar being flat against the panel is a likely scenario, next time we employ the tube we'll have to bend in a flat area to see if that helps our issue.

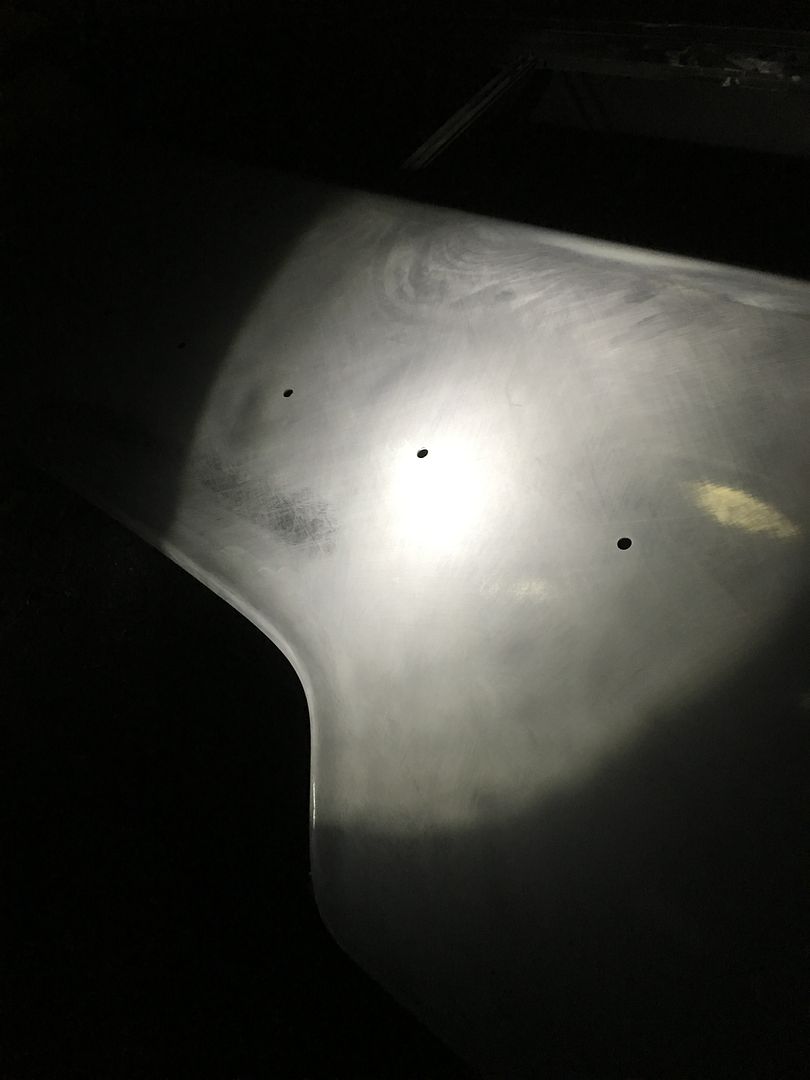

Progress from this past week.. Kyle got started on media blasting the drivers side wheel well and I "assembled" the two components for the passenger side..

We plan on epoxy primer on these prior to installation, so the media blasted surface will give a good bite for the primer.

Here's the test fit of the assembled passenger side wheel well...

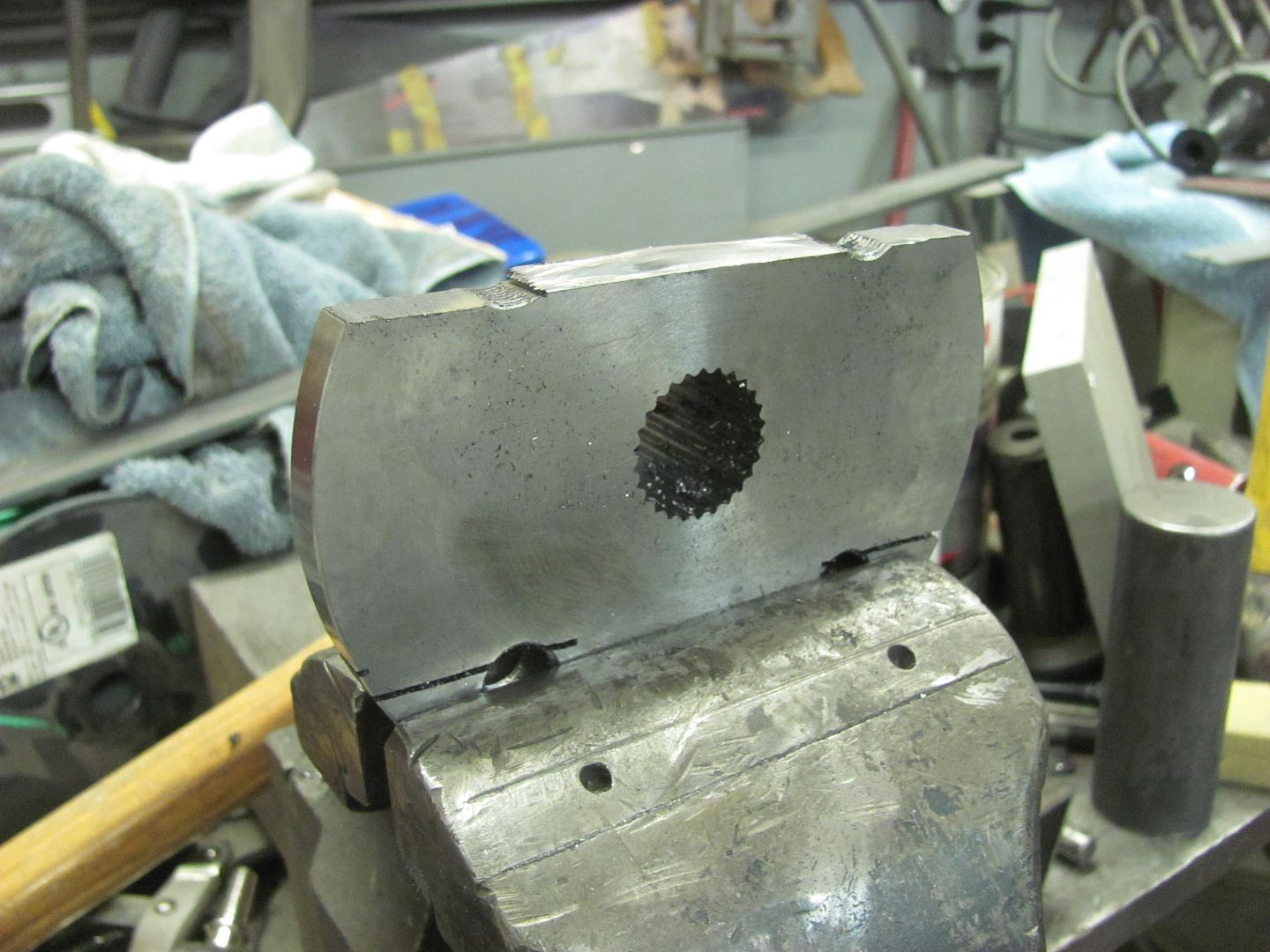

Next, the road trip on Friday.. To preface, a couple weeks ago someone had posted a link showing a Baileigh English wheel on eBay (the big one). In the background was one of the Baileigh power hammers. So I called the contact number in the ad, asked if the hammer was available, which he said yes. He gave me a price, asked for a deposit, and this past Friday was the pick up day. I left the house at 1:45 am, picked up my nephew Chris, and drove to CT. Got it loaded up, made it back to the house by 10 pm, quite a long day. Wait....it's supposed to rain tomorrow, let's unload! So we got it off the trailer and inside by 11. Saturday, after sleeping in, was spent locating a spot for the machine, hooking up power, and trying it out on some scrap metal..

Excited to have this additional capability in the shop.Robert

-

10-09-2016 12:45 PM #888

Nice machine. Liked the custom pinstriping"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

10-09-2016 01:25 PM #889

Those came out wicked for sure. Amazing work

-

10-09-2016 01:48 PM #890

Love the work on the wheel wells!

New tool, it's like Xmas!

Richhttp://www.clubhotrod.com/hot-rod-bu...del-coupe.html

-

10-10-2016 01:22 PM #891

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,299

- Blog Entries

- 1

The wheel well looks great. That new piece of equipment is awesome! Since we're on the topic of power hammers, what are your thoughts on one of these for a beginner?

Pneumatic Planishing HammerRyan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

10-10-2016 05:45 PM #892

Thanks for the comments!

I've never used one of them to be able to provide a critique, but what are you trying to use it for? A planishing hammer is primarily used to smooth out dings/dents caused in forming process or perhaps body damage. If you're looking at it for shaping, it will likely be underpowered or take quite a bit of time to complete the process.. Where I've never been in my local HF store, I've read enough to know that you either need a coupon or pick up one of the many on CL from people who already have them. Perhaps answer a CL ad and ask to try it out first, see if it performs to your expectation. Not sure that the store has air available to kick the tires...Last edited by MP&C; 10-10-2016 at 05:48 PM.

Robert

-

10-10-2016 06:41 PM #893

Ryan: I show that same machine on page 9 post #132 in my build log.

Cheap, but works fine for planishing the blisters on my hood.

Any hammer form project makes it useful for me. Used it on

the tyrannie cover also.

Wait for a 20 percent off sale. No air at stores.

Richhttp://www.clubhotrod.com/hot-rod-bu...del-coupe.html

-

10-11-2016 12:35 PM #894

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,299

- Blog Entries

- 1

Thanks guys. I was thinking of using it for tranny covers and some odds and ends stuff. Something to try to learn on too I guess.

Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

10-12-2016 02:50 PM #895

I was referred to the post from my build log and wow this is some really in depth incredible work you have going here. The way you explain each picture n give a brief description of what's going on is really helpful, I will have to remember that for the next time I post. Looking forward to the progress, going to be a wicked mean ride.

-

10-23-2016 07:37 PM #896

Thanks!

Was working on finishing blocking roof and quarters Saturday when the high winds took out the power for a couple hours.. Not to be deterred, the Milwaukee flashlight comes to the rescue...

Power came back on just after lunch and we got the next dose of Epoxy applied. These sure are some long quarters, I think I'll try a Yugo for the next project, shouldn't need anywhere near the paint prep...

or the video version:

https://www.youtube.com/watch?v=06HesZWWT5I

.Robert

-

10-24-2016 09:45 AM #897

Those quarters were probably perfect 3 blocking ago! LOL..

-

10-24-2016 10:05 AM #898

Next time your out of power your welcome to use my garage and any tools, and ply your trade to my 48 F1! Nice work!

"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

10-24-2016 11:05 AM #899

[QUOTE=34_40;561447]Those quarters were probably perfect 3 blocking ago! LOL..[/QUOTE

Given the amount of painstaking, amazing work, attention to detail and resulting perfection of this project, that first door ding at Walmart is probably going to make the owner consider a choice between murder & suicide.....

"It is not much good thinking of a thing unless you think it out." - H.G. Wells

-

10-24-2016 02:55 PM #900

If the "owner" is foolish enough to take this to Wal-Mart, one of us needs to go take it away from him/her!

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Sorry for your loss of friend Mike McGee, Shine. Great trans men are few and far between, it seems. Sadly, Mike Frade was only 66 and had been talking about retirement for ten years that I know...

We Lost a Good One