Thread: 55 Wagon Progress

-

12-20-2016 11:07 AM #931

Jack, block. Jack with spacer, block. Jack with taller spacer, block. Etc. Fun times! These buses all belong to a buddy of mine, he has somewhere around 20 buses. So yeah, he can keep me busy at times...Robert

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

12-20-2016 02:19 PM #932

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,301

- Blog Entries

- 1

Very nice bus repair again. Does your friend lease routes for the buses or just lease the bus's services to the school district? I'm just curious. Around here it seems most school organizations own their buses.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

12-21-2016 11:48 AM #933

Our local BOE has a transportation dept that manages the buses, and they issue local government plates to the actual owners for use on their buses. They have a mandated annual safety inspection, and since they "own" the tags, can and will remove them if safety issues warrant removal. Because of the local government tags, the only use these buses are available for is actual BOE sanctioned activities, be that school, field trips, school sports activities.. The BOE does own a few of their own buses, some used as Driver training platforms, but for the most part, local bus owners are contracted for the various bus routes. Most of the buses I have repaired involve luggage doors. My buddy has them on most of his fleet as those type buses are some of the first to be contracted for the extracurricular activites, sports events and field trips.

Fitting up the one piece wheel well into the passenger side quarter. Once fitted, the edge is marked with tape, wheel well removed, and the width available beneath for plug welds is noted. Then holes are punched in the wheel well to match, and it gets refitted. We started at the front so we could use vise grips to clamp, and worked progressively toward the back.

We did have a few plug welds that were contaminated from the epoxy primer, so we'll grind everything smooth, fix those areas, redress the welds and finish any bare areas with epoxy primer. One step closer to the Line-x coating on the underside...

Here we are all tacked in place:

https://www.youtube.com/watch?v=GuCIhFYUMXY

.Robert

-

12-23-2016 06:20 AM #934

All plug welds completed and dressed. Now for the other side and we'll epoxy prime again..

Robert

-

12-27-2016 09:19 PM #935

Tonight we worked on getting the driver's side wheel well installed. To help eliminate the contamination issue from the close proximity of the primer, we used these piloted burnishing brushes to remove the paint around the plug weld holes on both front and back sides...

That did the trick, no volcanoes this time...

Next we'll need to dress these welds and epoxy prime the bare spots. In the meantime, a test fit of the bucket seats. We're going to need to make some adapter brackets to weld to the floor, I don't think the wood one is going to fly...

Robert

-

12-28-2016 06:07 AM #936

That piloted drill/brush is a real slick idea! Where'd you find that?

-

12-28-2016 06:16 AM #937

McMaster Carr, look here toward the bottom of the page for the Pilot guided....

https://www.mcmaster.com/#end-brushes/=15nxj2wRobert

-

12-28-2016 06:52 AM #938

-

01-03-2017 05:17 AM #939

We started using them when modifying composite shelters for Hummers. Same deal, work well for grounding to the shelter skin.

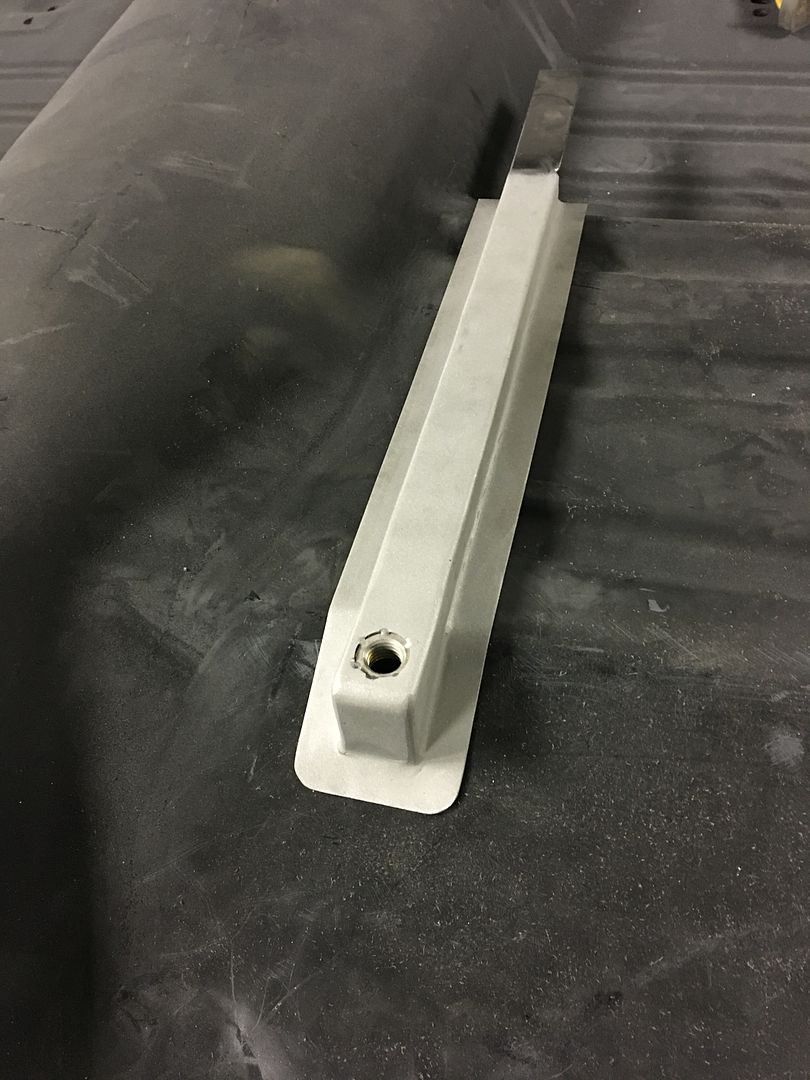

Here's the path we took on the seat risers....it's been a while now that GM has used wood in the vehicle, no sense in us bucking that trend! Started by fabbing up some 14 gauge steel into a hat section and left some longer ears on the ends to fold down and close the ends off..

Stainless hex nut welded inside for the seat frame hardware..

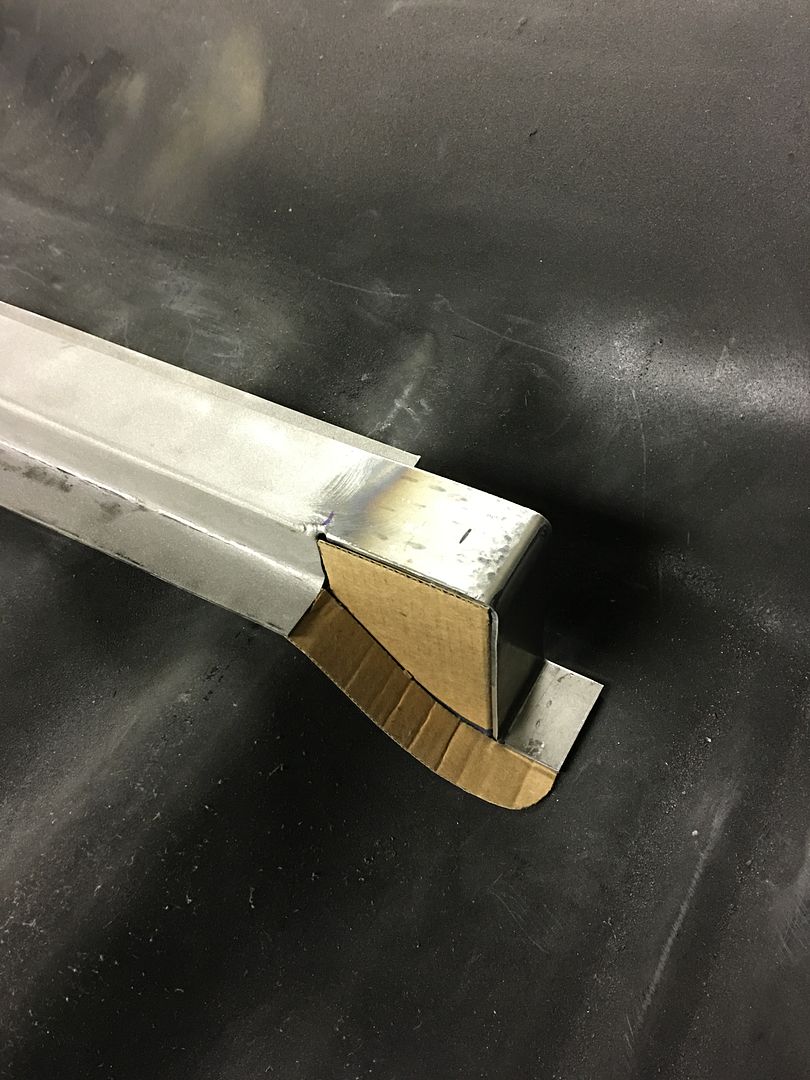

Missed getting these pics on the other end, but cardboard templates were transposed to steel fillers, cut out and welded in place, along with the flanges around the perimeter.

We plan on finishing the inner risers up this evening and leveling the seats across for sizing the height of the outer risers.

Finished up the plug welds on the driver's wheel well. We'll get a few more parts prepped for epoxy and address those bare spots at the same time.

Robert

-

01-03-2017 06:24 AM #940

As I started to scroll through the pics I was thinkin' how did they make that end?? being longer , how would they fold that up?? But, you answered the question with the last couple photos.

As always thanks!

-

01-03-2017 05:08 PM #941

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,301

- Blog Entries

- 1

More very nice work. I really like the seat riser and thanks for taking the time to show how you accomplished such a one piece smooth design.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

01-04-2017 08:15 PM #942

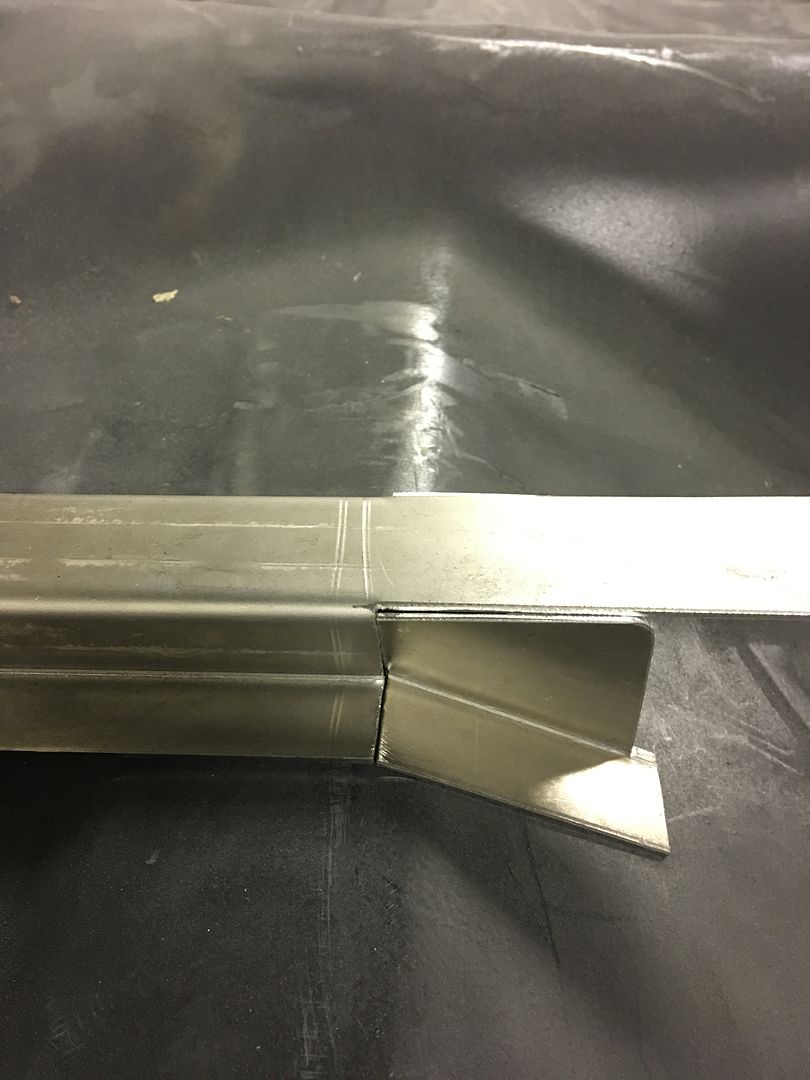

Seat riser bracket number two fabrication, got more detail pictures this time..

Used the Tipping die in the Lennox to thin out the crease line, makes for a more crisp bend, especially given the 14 gauge steel we're using...

After bending in the Diacro manual press brake using the gooseneck die...

Fitting and trimming the end transitions while matched to the floor...

Ready for the TIG

Robert

-

01-05-2017 11:19 AM #943

Like they say having the tools is half the job

Nice workCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

01-05-2017 12:21 PM #944

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,301

- Blog Entries

- 1

Very nice work. I'll be getting a bead roller and metal brake soon. I'm anxious to try some of your new tips and make some cool parts.

Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

01-05-2017 03:17 PM #945

I've got a bead roller , Troutles shear, brake, and his best tip (for me anyway) using the stainless wheels for grinding spot welds down.

Keep all that good stuff comingCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

To the top

Where is everybody?