Thread: 55 Wagon Progress

-

01-07-2017 07:18 PM #946

OK, so sometimes you take another look and think yeah, we can do better than that (more scraps). Today the passenger bucket seat was test fit onto our riser. It could be brought a bit tighter to the floor.

Next, looking at the cross member, the rear flange (red arrows) didn't match up to the rear flange of our riser.

The blue tape shows the rear flange of the cross member below...

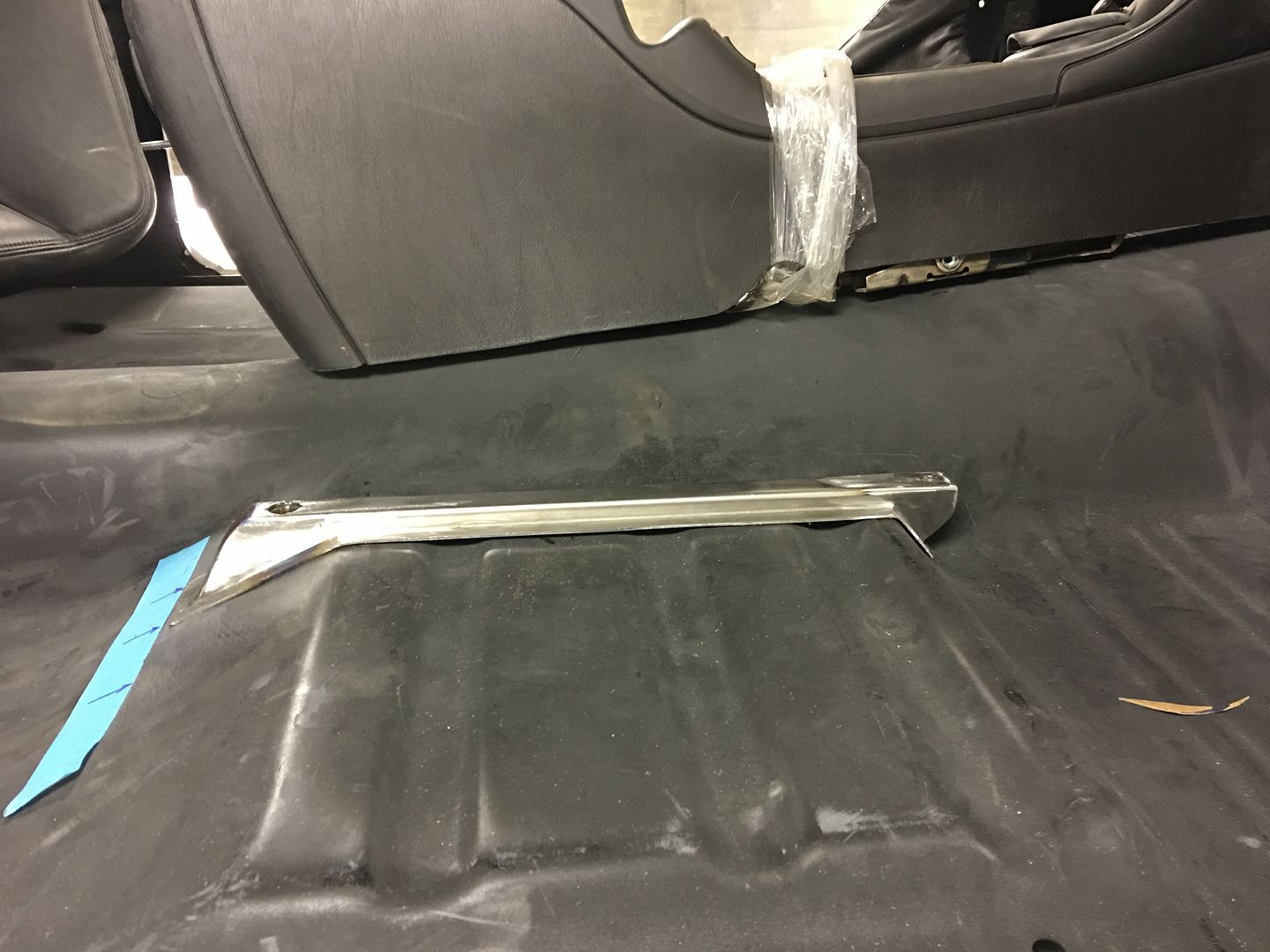

Here's our updated riser, half as tall, and once trimmed the flange will match to above the cross member..

Robert

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

01-08-2017 02:47 AM #947

Good catch Robert.

When you're looking at a picture on a flat screen, you're not always thinking about the structural loading.

The new mount looks so much "sleeker" too. You guys do such nice work.

-

01-08-2017 03:38 AM #948

It's always the littlest things that take the most time, but in the end it really pays off. Those small detailed modifications that are made to any car whether inside or out are never really seen by most, but they still are cool and the builder knows and that makes him smile.

-

01-08-2017 08:55 PM #949

Nice work, I wish I could do metal work like that. My seat risers are flat steel bent at a 90.

-

01-11-2017 06:40 AM #950

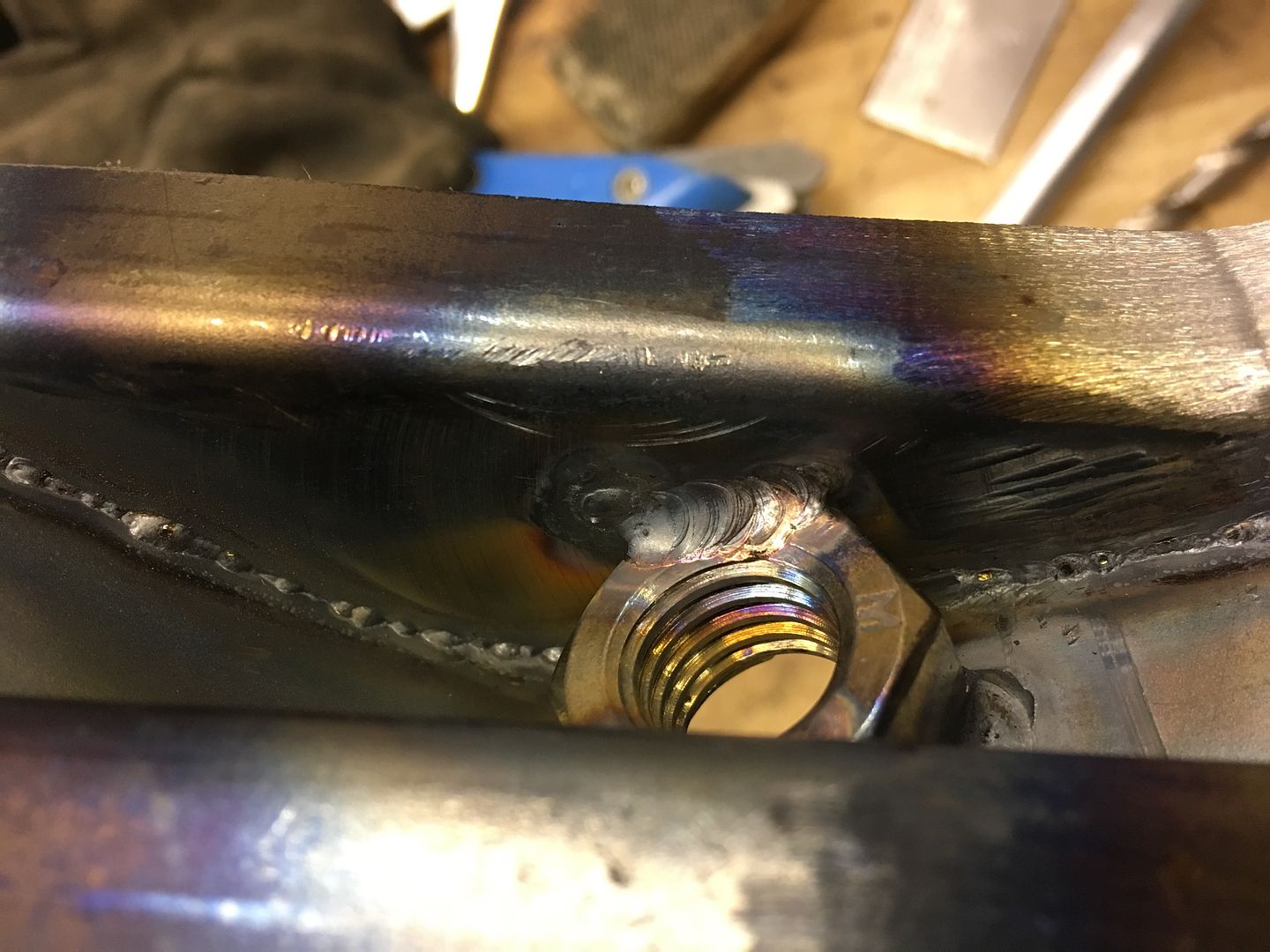

More details on the seat risers, here the 5/8-11 hex nut is welded inside. The tacks at the top are merely to hold it centered within the hole to maintain our correct C-C hole spacing. It gets welded inside as well to keep things anchored in place.

The 5/8 hardware was chosen as the factory seat bracket on these 2002 Monte Carlo seats had a hole that large existing already. The front of the seat bracket actually had another bracket underneath that was held in place with a solid rivet. We drilled out the rivet to remove the obstacle (so the rail was flat across the bottom), and opened the hole up for 3/8 hardware.

Test fit....

Still need to fill in the flange corners on the front and this one will be ready for SPI epoxy primer to coat all the surfaces before it gets welded in place..Robert

-

01-11-2017 06:46 AM #951

Your attention to detail and perfection continue to astound me!!!"It is not much good thinking of a thing unless you think it out." - H.G. Wells

-

01-11-2017 12:56 PM #952

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

Very nice! Were the seat belts anchored to the rear seat track bolt and that's why they were so large? It seems that's how the newer cars are built but i'm not certain.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

01-11-2017 05:44 PM #953

The inside seat belt is attached to the seat frame/track, the outer ones at floor/b-pillar are not. We still need to make some plates to weld into the B-pillar for bolting the shoulder/lap belt. That's a big reason the new version was extended in the back, the riser's rear flange will be plug welded through the floor and directly into the cross member, and the forward flange of the same cross member will be plug welded into where it also intersects the seat riser's side flanges.Robert

-

01-17-2017 05:58 PM #954

I'm not going to show pictures of my seat brackets anymore Seriously, very nice work !

Seriously, very nice work !

-

01-18-2017 06:06 AM #955

Haha! you should see the PRACTICE pile!

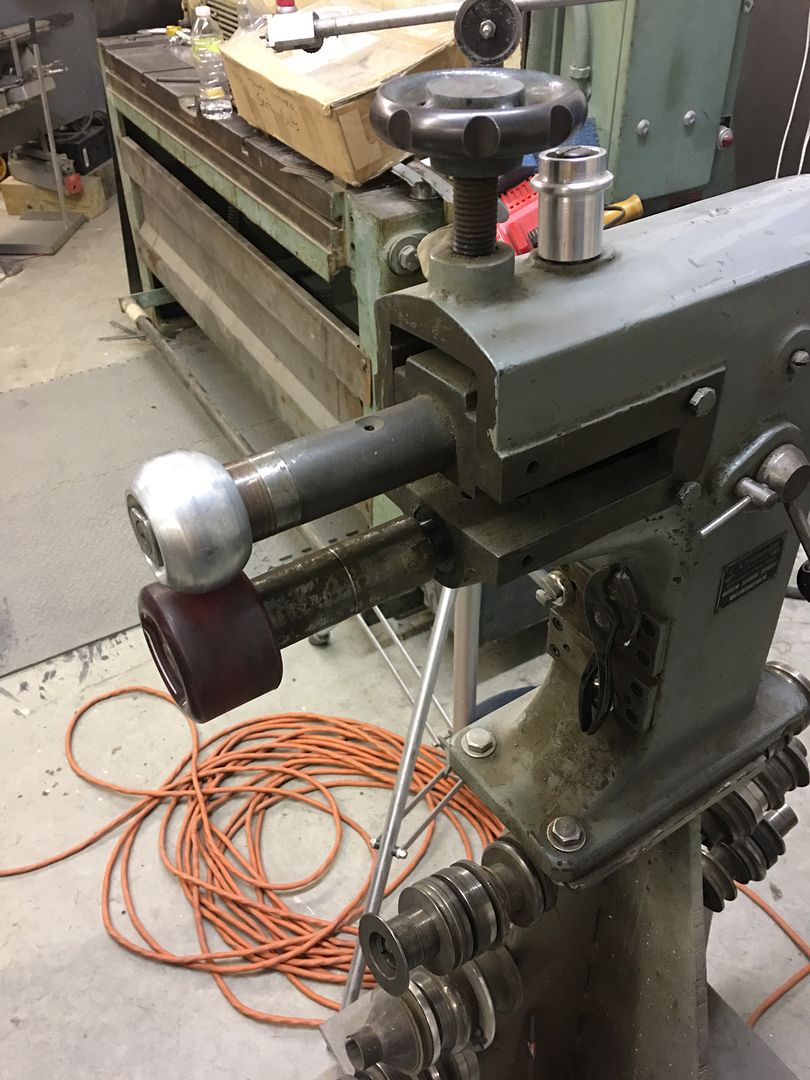

Moving on to the outer risers, these ones will be a bit taller due to the recess where the original seat frames bolted. We started out with using the tipping die in the Lennox to thin the 14 gauge cold rolled steel at the bend line for a more crisp bend.

https://www.youtube.com/watch?v=OKFZqnHb9eY

Next, after making the inside bends, the Fasti-werks bead roller is used with a skate board wheel to add a radius to the outer "leg" of the riser.

Next time in the shop we'll get the ends closed up.....Robert

-

01-21-2017 11:05 PM #956

Moving on to closing up the ends of the outer seat riser... Quite a bit of stretch to get this corner to match up to the seat riser...

https://www.youtube.com/watch?v=wzorB_hwLZM

Then the corner was Tig welded in place and another test fit with the bucket seat..

https://www.youtube.com/watch?v=kf-X5eHc5bE

.Robert

-

01-23-2017 12:51 PM #957

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

Man, you do great work. I think I'd have to section a part of round tube and weld a flange on the bottom since I don't have a roller like that. (That would take a long time compared to what you have done)Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

01-29-2017 07:45 PM #958

Cody Walls took the Dave Thomas 35 Chevy to Pomona this weekend for the GNRS, the car took 2nd place in it's class and also received a paint award for the 57 Cadillac Biarritz colored finish. Well done Cody!

Last edited by MP&C; 01-30-2017 at 09:25 AM.

Robert

-

01-30-2017 02:37 PM #959

Cody learned his craft very well. Congrats Cody!

-

01-30-2017 03:23 PM #960

Proud for you guys!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

It was SWMBO's little dog. .

the Official CHR joke page duel