Thread: 55 Wagon Progress

-

01-30-2017 07:36 PM #961

Amazing car and congratulations to both Cody and the owner.I maybe a little crazy but it stops me going insane.

Isaiah 48: 17,18.

Mark.

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

01-30-2017 09:08 PM #962

Thanks guys for all the kind words..

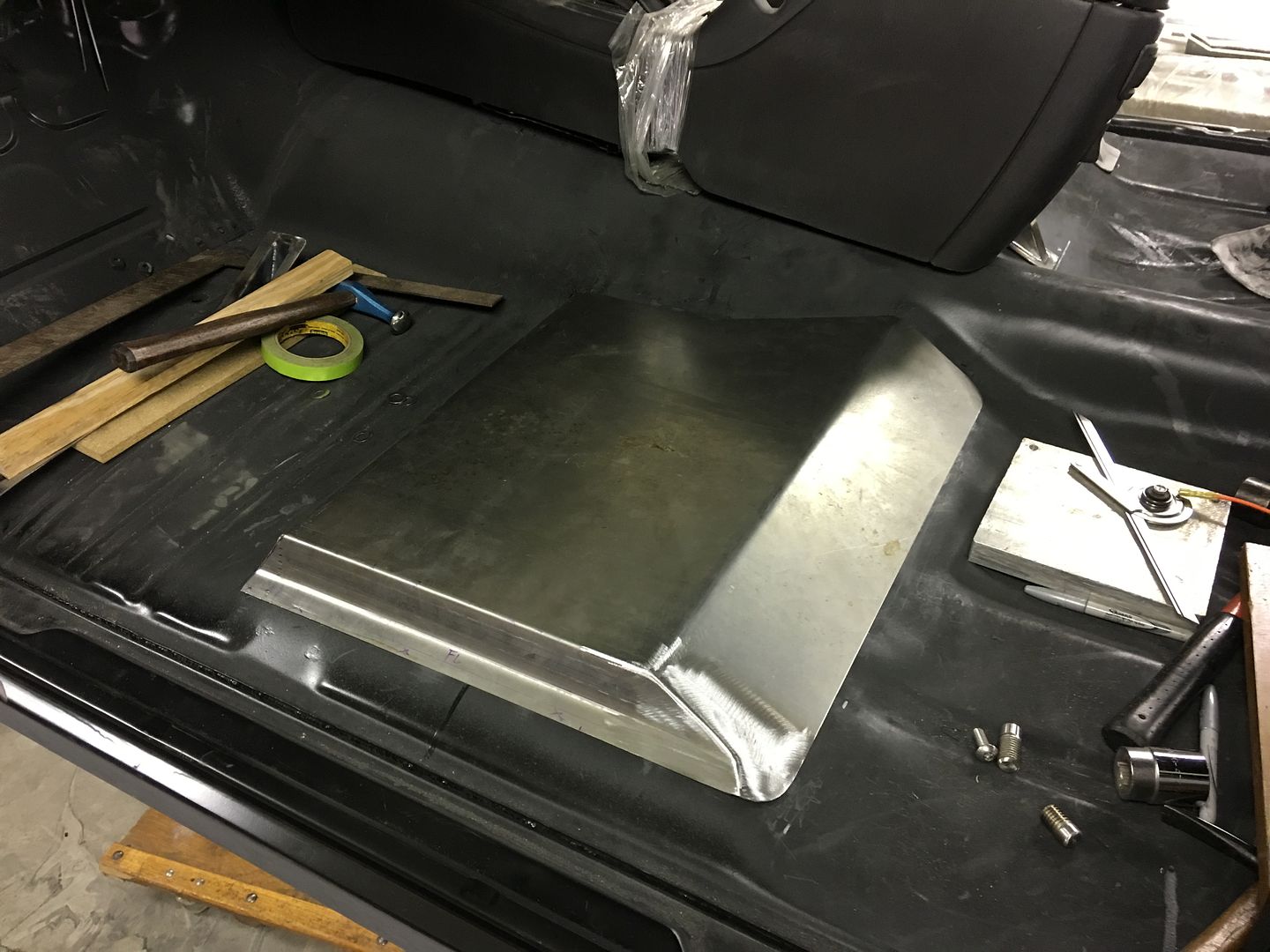

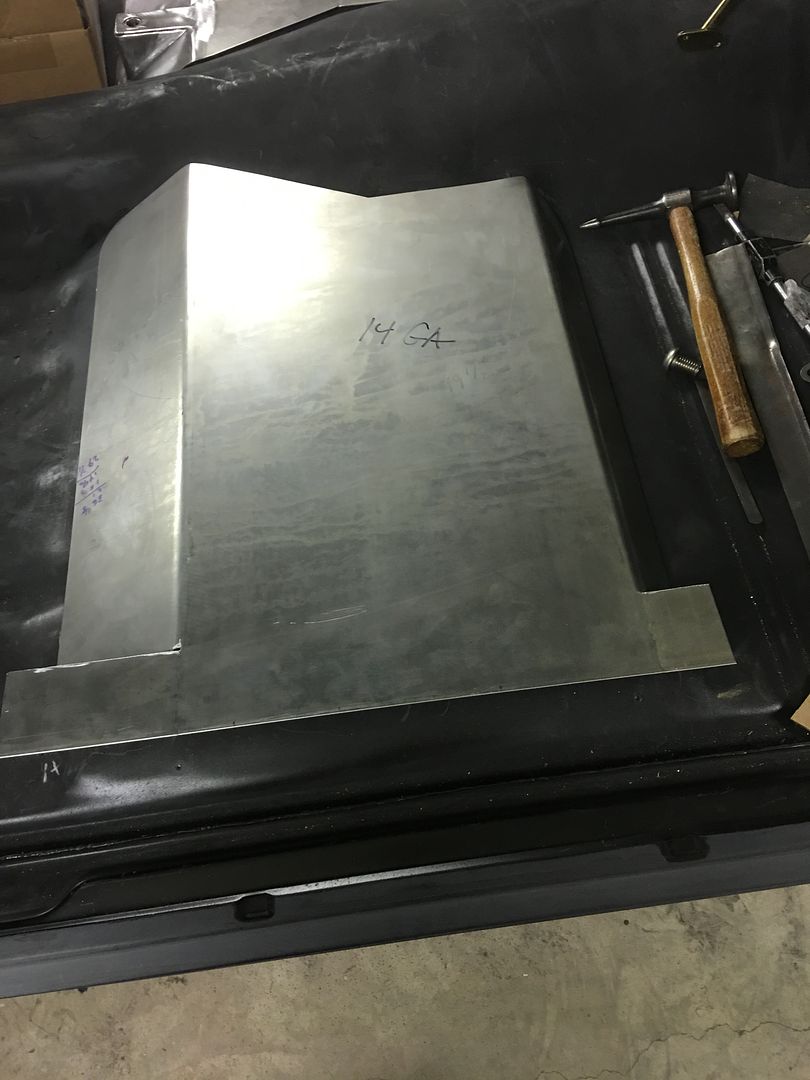

Well, let's back up and punt one more time. The owner of the 55 stopped by about a week ago and sat in the mocked up bucket seat. She said it sat too high, so our version 2 seat brackets were out. Cutting the floor pan was over-ruled (for recessing the brackets) so we opted for a 14 gauge flat seat pan directly on top of the floor, which also gave us a shape we could eliminate the "step" in the floor.

https://www.youtube.com/watch?v=JYklSvTtTTQ

https://www.youtube.com/watch?v=CfWqQyOeXJo

Next is to add the wedges to the rear ramp for attaching the rear of the track slides...Robert

-

01-31-2017 06:51 AM #963

It's times like those when you repeat over and over.. "rule 1, the customer is always right. rule 2, when the customer is wrong, refer to rule # 1"....

sigh. I guess you can always look at it as job security? LOL..

-

02-01-2017 03:49 AM #964

Yeah, we also moved it rearward almost two inches.. She sat in the car as it was up on the rotisserie, so I thought that may be giving a false sense of being too high. So we went to my B-I-L's to sit in his still original 56 and compare.

Where the seat heights were the same, the original 56 seat has more "compression" to its springs . The buckets are both power heated seats so we opted to slam them down as far as we could without cutting the floor pan, they can always be adjusted up.

. The buckets are both power heated seats so we opted to slam them down as far as we could without cutting the floor pan, they can always be adjusted up.

Robert

-

02-01-2017 06:26 AM #965

That stinks, more parts in the money pile

-

02-04-2017 08:27 PM #966

Final design on the bucket seat brackets... and owner approved today as well. One down, one to go.. This is made from 14 gauge cold rolled steel and puts the seat about as low as we can go without cutting the floor pan..

Video of the seat bracket:

https://youtu.be/YF7LOe7eLTQ

Seat test fitted:

Robert

-

02-04-2017 09:01 PM #967

Beefy comfy seat there with a side airbag?"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

02-04-2017 09:08 PM #968

The side airbags are coming out when they get upholstered..Robert

-

02-14-2017 07:27 PM #969

Always a new challenge every day....

The strong winds this weekend knocked over a dead oak tree across the chain link fence at the local high school, and this was the bus that found the overhang..Robert

-

02-14-2017 07:46 PM #970

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,299

- Blog Entries

- 1

Nice work on that seat base. That sure looks to be a nice C10 setting there. Yeah, the bus lost on that tree deal for sure.

Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

02-15-2017 08:01 PM #971

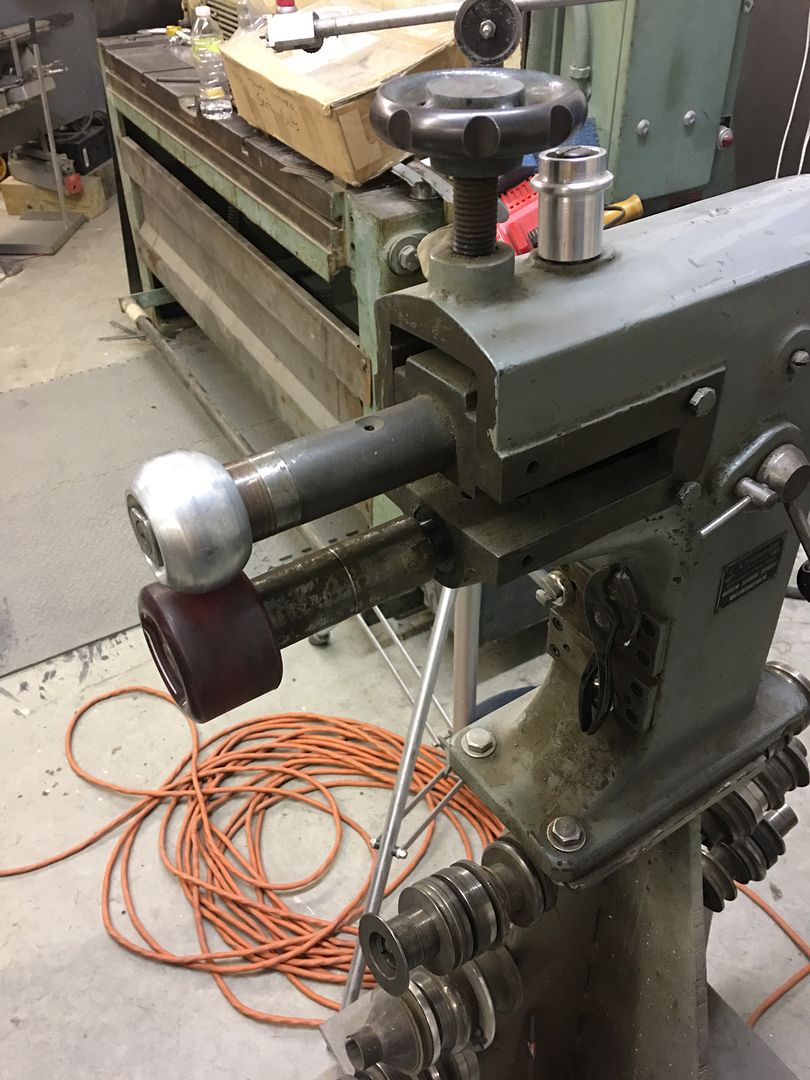

Don't think I showed this on the other side, but here's how we find the center of the bend for dimensioning the seat bracket..

Bent up and a test fit...

Relief cuts made for the next fold.....

Robert

-

02-16-2017 03:23 AM #972

More great tips!

-

02-16-2017 12:20 PM #973

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,299

- Blog Entries

- 1

Thanks for that! So simple but I never thought of it.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

02-21-2017 03:41 AM #974

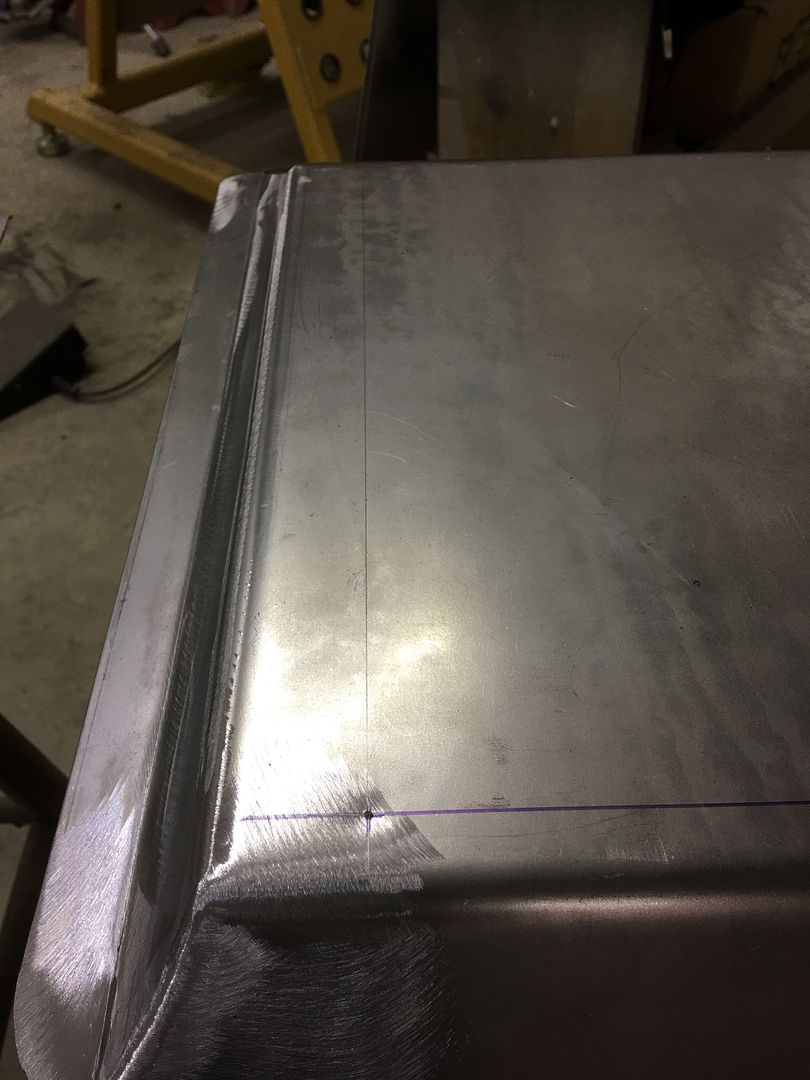

.......then the outer flange area is rolled through the bead roller

and then the brake is used to fold the outer flange. Here, all welded in place...

The front hole pattern is laid out to match the drivers bracket, and then some perpendicular lines laid out for locating the rear risers...

Robert

-

02-21-2017 06:40 PM #975

You can't pull the wool over our eyes, we all know you just randomly drilled some holes in the metal and then marked it out to make it look good

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Several years ago we did quite a good trip of USA, and on our trip we got to meet Mike and Christine Frade. We didn't stay long with them, but in that relatively short time we both gained a great...

We Lost a Good One