Thread: 55 Wagon Progress

-

03-07-2017 04:24 AM #991

You get a slight odor, but with the amount of air the booth pulls through, is rarely lingers.

A window is opened just to the left of the air handler to make up the air exiting. The booth is on the opposite end of the building, the air handler is set to constant fan and the heater is aimed at it to put heat at that end of the building (vents in ceiling, as are booth filters) first before the cold air from outside gets there.. It seems to keep the entire building warm except for directly in front of the open window. You can actually step in the booth and it feels warmer..Robert

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

03-07-2017 08:48 PM #992

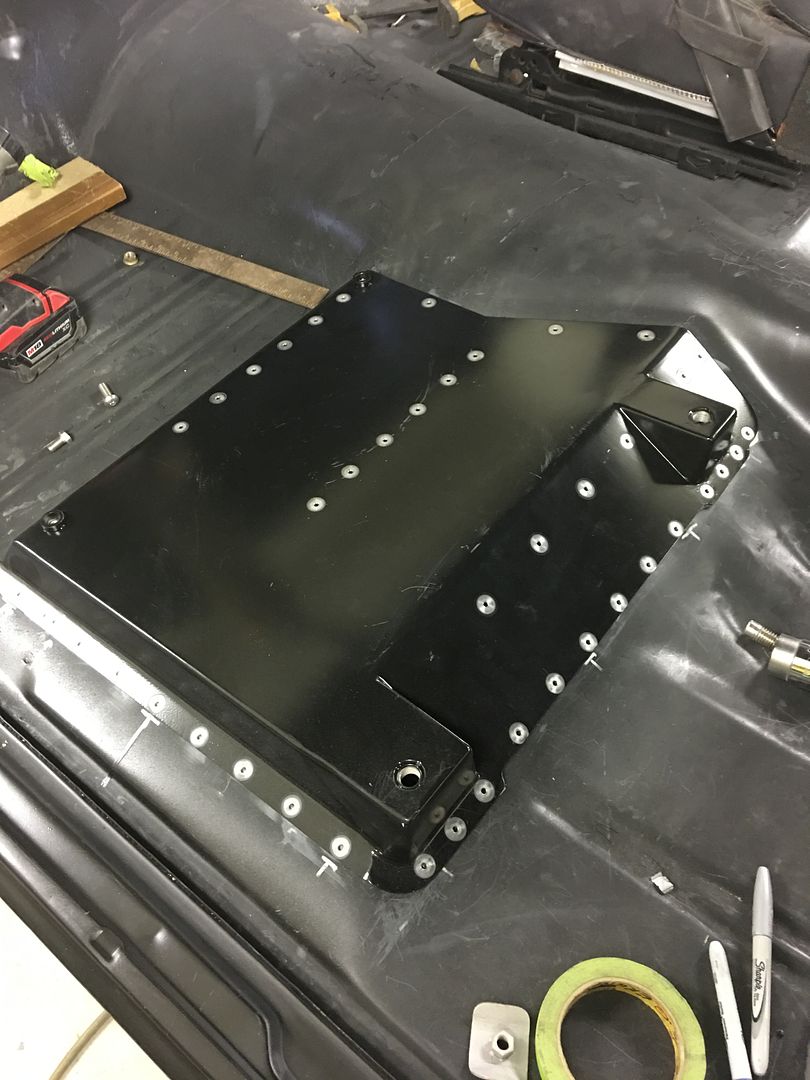

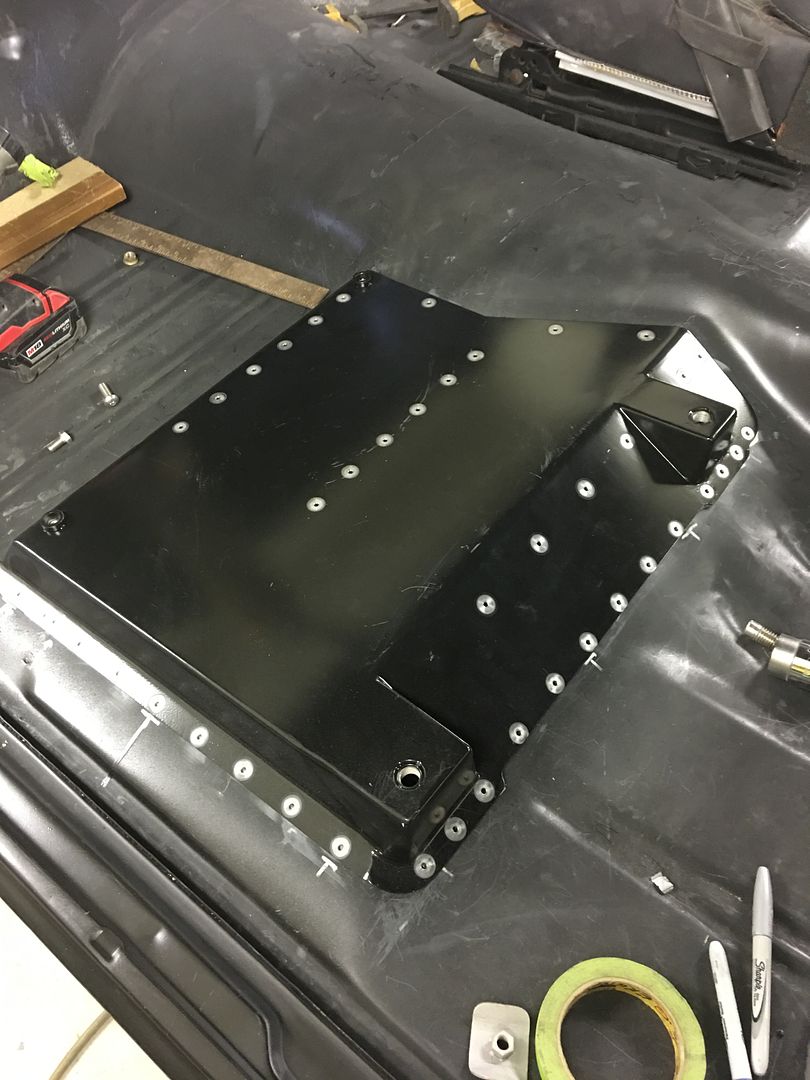

Got started on drilling plug weld holes this evening, here laying out the hole patterns to align with the floor crossmember where possible...

Once drilled to match our piloted burnishing brush, the paint surrounding the plug weld gets cleaned to prevent weld contamination..

https://www.youtube.com/watch?v=ELG55mmG2I0

Robert

-

03-07-2017 09:13 PM #993

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

I really dig that. I need to take the time to get my Dad's tig welder out and do these things to the next build.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

03-08-2017 08:48 PM #994

I love that pilot brush you have, I will be getting one of those for my next project. That thing works great.

-

03-08-2017 09:22 PM #995

Tonight found us working on the bus to remove some of the damage from an oak tree. Here's our damage...

The headliner above the step area was cut out to give us better access to the roof skin..

We got much of the damage roughed out, but there's quite a bit of stretch in that roof skin still to remove.

Robert

-

03-08-2017 09:35 PM #996

You got that pounded out pretty straight. Are you going to make it like new again or is it one of those just get it the best you can projects ?Seth

God cannot give us a happiness and peace apart from Himself, because it is not there. There is no such thing. C.S.Lewis

-

03-09-2017 05:52 PM #997

Amazing that you can get the twisted metal to look so close to the way it started. What tools were used if I can ask?

-

03-09-2017 06:58 PM #998

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

I agree with what they said. Definitely some expertise that went into the process of getting it to that point you have it now! Did you apply any back ward force while beating the panels around?Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

03-09-2017 09:08 PM #999

My limited experience would be grabbing the torch and burning 20 or 30 holes in the paint (shrinking) to tackle the stretched steel. Let's grab some popcorn and watch the show..

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

03-11-2017 08:01 PM #1000

Spent a few more hours getting the light opening to match the new, unbroken light, welded up some of the screw holes that had torn, and given some of the structural members in the way of the roof, we had to settle for no oil canning and a slight low that needed filler.. Here's some of our implements of correction, yes, some force is required in areas...

A few more sanding sessions and we'll get some epoxy primer on....

Getting some seat brackets welded in so we can finish off the bottom of the floor...

Plug welding...

https://www.youtube.com/watch?v=VofyZCliZRg

But before we get all the front seats in and make it harder to access the back, lets get the seat riser plug welded in for the back seat...

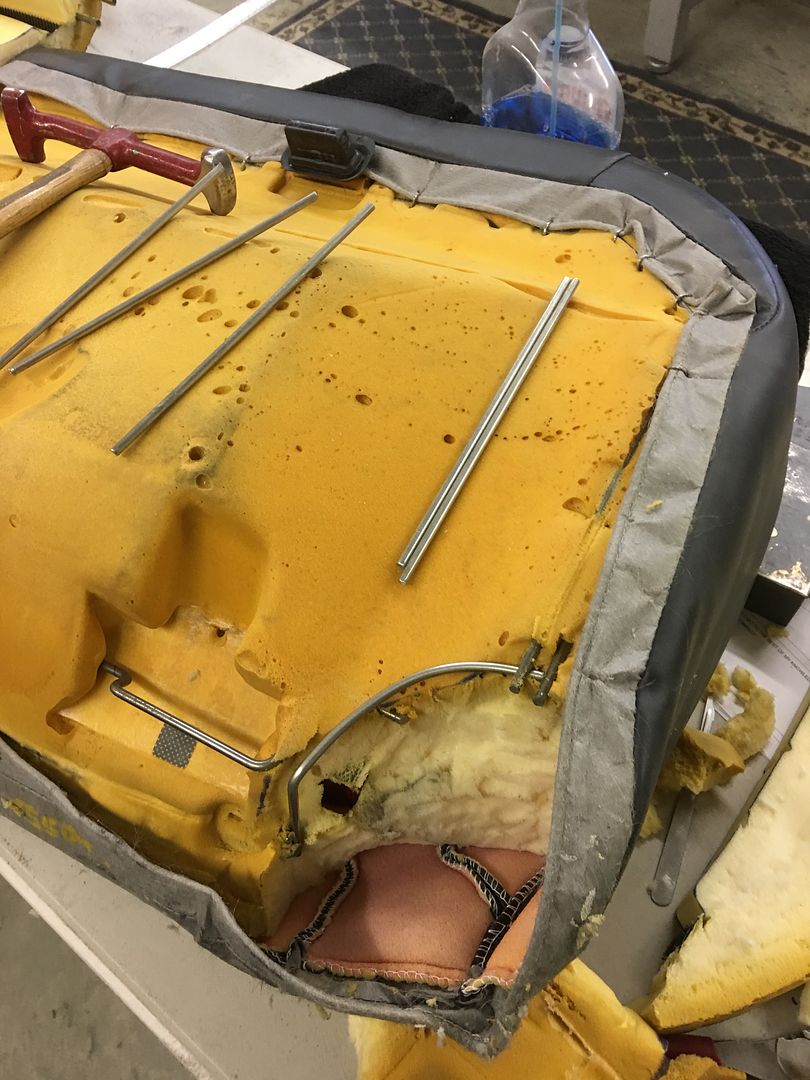

Next, our rear seat that came with the buckets was slightly oversize for our widened wheel wells. Some quick measurements showed we need to lose about 2" in width..

Then the rear corners needed relieving for the wheel tubs.....

Some 3/16 diameter stainless rod was used to reconnect the pieces in the new rear corners

Some fire prevention for the foam..

With both sides fitting individually, time to join our sides back together...

Video of the surgery results....

https://www.youtube.com/watch?v=0ingFICYYws

With the overlap of material trimmed, this part is looking pretty good!

Robert

-

03-13-2017 12:38 PM #1001

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

Very nice work on that!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

03-15-2017 04:59 AM #1002

Thanks Ryan!

Last night we finished up sanding the roof repair on the bus, and started to get things covered up for primer.. Being the lighter of us two, guess who got roof duties for rolling out the shark grip?

This is starting to look like a hazmat incident...

Tonight we'll get some SPI epoxy on the bare spots and filler

The sheet metal on the front cap seems a bit thin for it's purpose, so rather than trust the new light to clip nuts again, a surround ring is made from 14 gauge cold rolled steel to make an anchor plate. The Vise-jigsaw is used to cut out the center...

note throttle control...

Using transfer punches, mounting holes from light are marked onto the ring and drilled to 17/64 to accommodate 8-32 rivet nuts...

It was also media blasted to prep it for the epoxy primer session for this evening.Robert

-

03-15-2017 08:34 PM #1003

Nice work, It looks like the lighter one of you two did not appreciate her photo being taken

Seth

God cannot give us a happiness and peace apart from Himself, because it is not there. There is no such thing. C.S.Lewis

-

03-20-2017 04:49 AM #1004

Haha! Winding down on the bus work so we can get back to some 55 seats..

All ready to spray...

Here's the SPI epoxy sprayed on the repair area...

as well as on our bolting plate we fabricated. This will be riveted behind the panel using stainless pop rivets..

First coat of BASF Urethane, and a shot of the scaffolding setup used...

Final coat...

https://www.youtube.com/watch?v=AiYA19ELpj8

Unmasked, we'll let this set a bit and get it re-assembled on Tuesday night.

Robert

-

03-20-2017 12:54 PM #1005

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

More great work. I like the scaffolding too.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

3382Likes

3382Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Many of the long tube cast headers I've run across had a relief ground on the back side for starter bolt clearance. I just trimmed the bolt on mine. On these new shorty's, they eliminated the...

55 Wagon Progress