Thread: 55 Wagon Progress

Hybrid View

-

05-22-2017 12:11 PM #1

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,300

- Blog Entries

- 1

More awesome work. I really like the tool and idea on building that retainer!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

05-22-2017 12:17 PM #2

The hoop on the back adds strength (in my mind ) and keeps someone from putting a longer bolt through the side of the car down the road...

) and keeps someone from putting a longer bolt through the side of the car down the road...

Robert

-

05-23-2017 07:26 PM #3

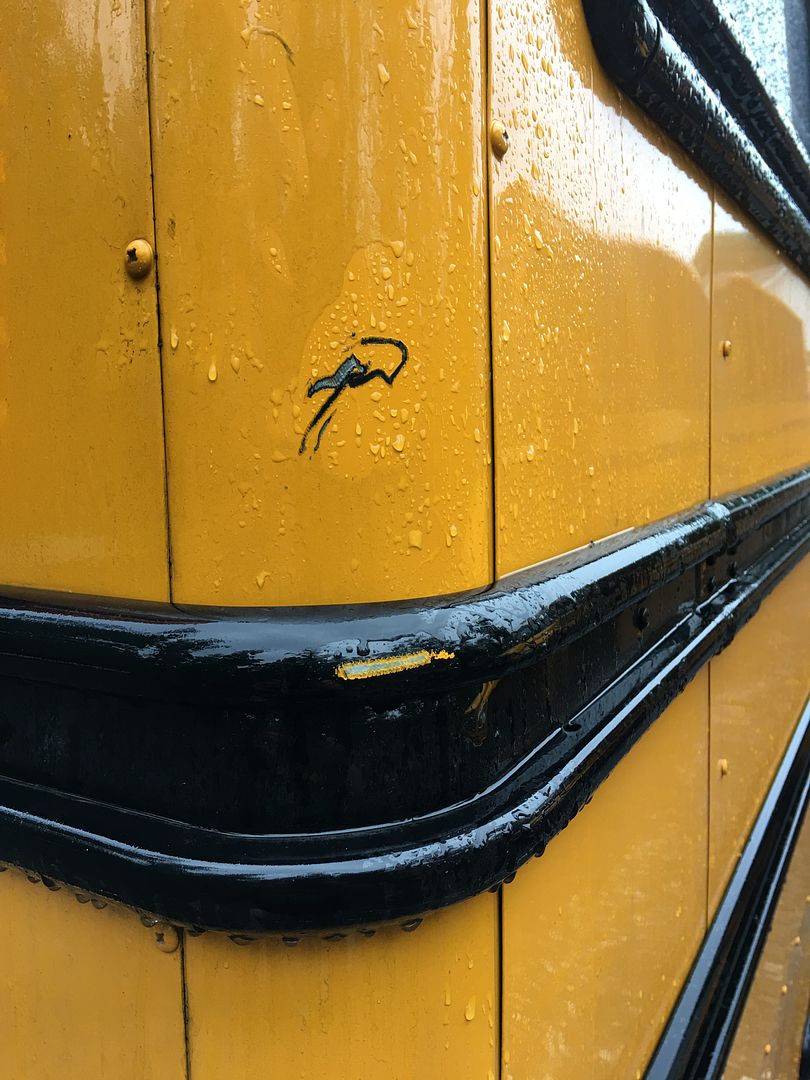

Had a late start in the shop tonight as I had to go look at a school bus. Yeah, week and a half to go until the end of school.

Looks like something gave the spot mirror a nice push..

The mirror mount looks like it's no longer straight....

OK, so we found it hard to fathom something hitting the mirror that high in the air as the bus was driving into it, so the other possibility was something backed into this one.. A quick search of the buses parked close by revealed this one with some nice shiny metal showing...

A quick test drive showed that the mirror didn't vibrate/move around that much so we're going to address this after school is out so this one can still be used for the next couple weeks..

Back at the shop, time to weld in the seat retainer brackets...

https://www.youtube.com/watch?v=o9Gj...ature=youtu.be

....and then started the next shoulder harness anchor bracket....

Robert

-

05-24-2017 09:49 AM #4

Fun how stuff happens and the driver doesn't report it or may truely be oblivious, hmmm!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

05-24-2017 11:59 AM #5

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,300

- Blog Entries

- 1

Yeah, driver amnesia happens a lot where I work too. We had over $150k worth of unreported accidents last year alone among 100 trucks at 2 different locations. Crazy how these people keep their jobs.....Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

05-24-2017 08:45 PM #6

I hate you as usual for making it look so easy, nice work as always.

nice work as always.

Seth

God cannot give us a happiness and peace apart from Himself, because it is not there. There is no such thing. C.S.Lewis

-

05-25-2017 06:54 PM #7

Let me guess. You guys probably fix fiberglas as good as you do metal work!

Well.. I guess another lesson is at hand, I'll sharpen my pencil!

-

05-26-2017 10:25 AM #8

-

05-27-2017 08:33 PM #9

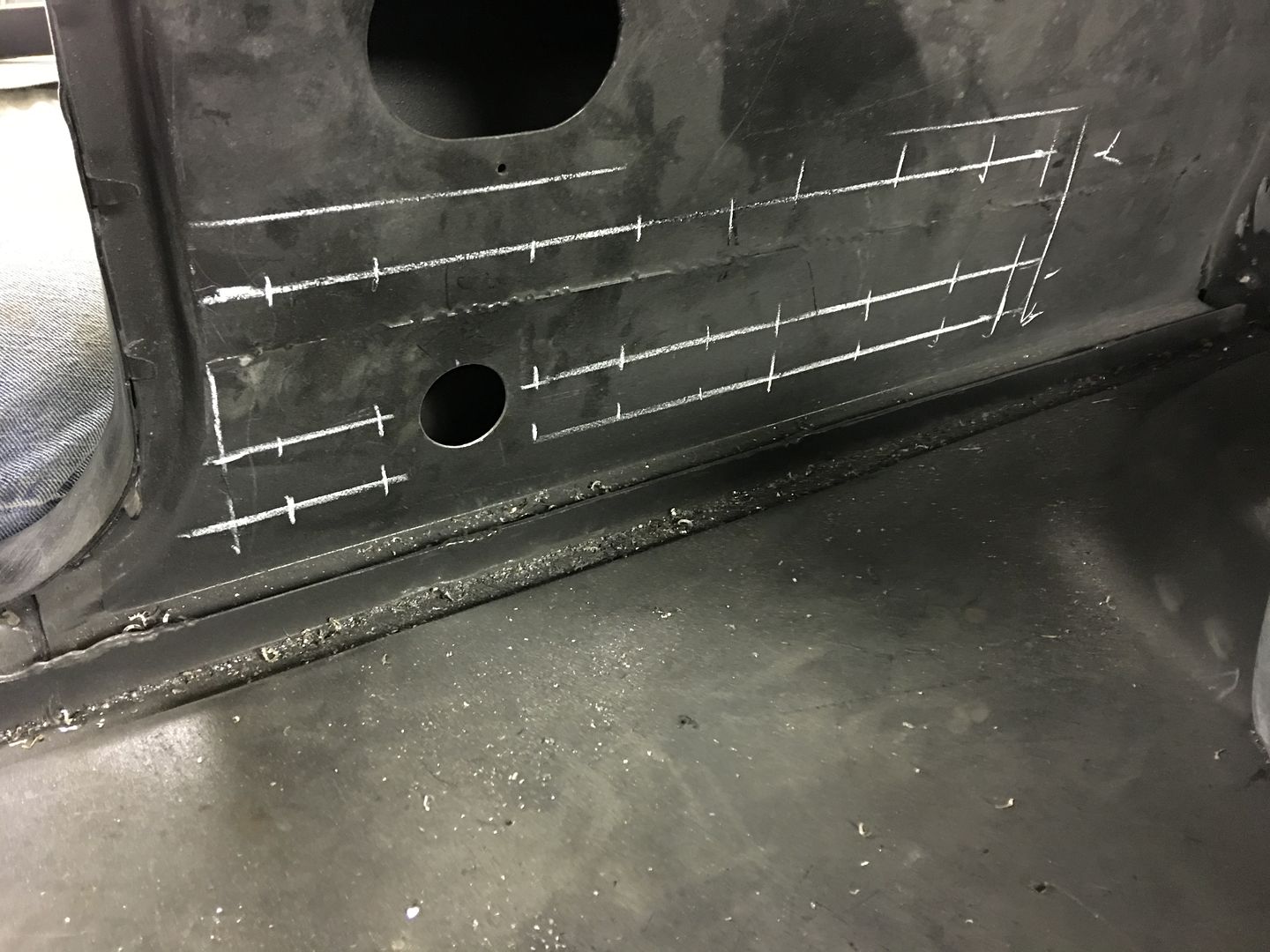

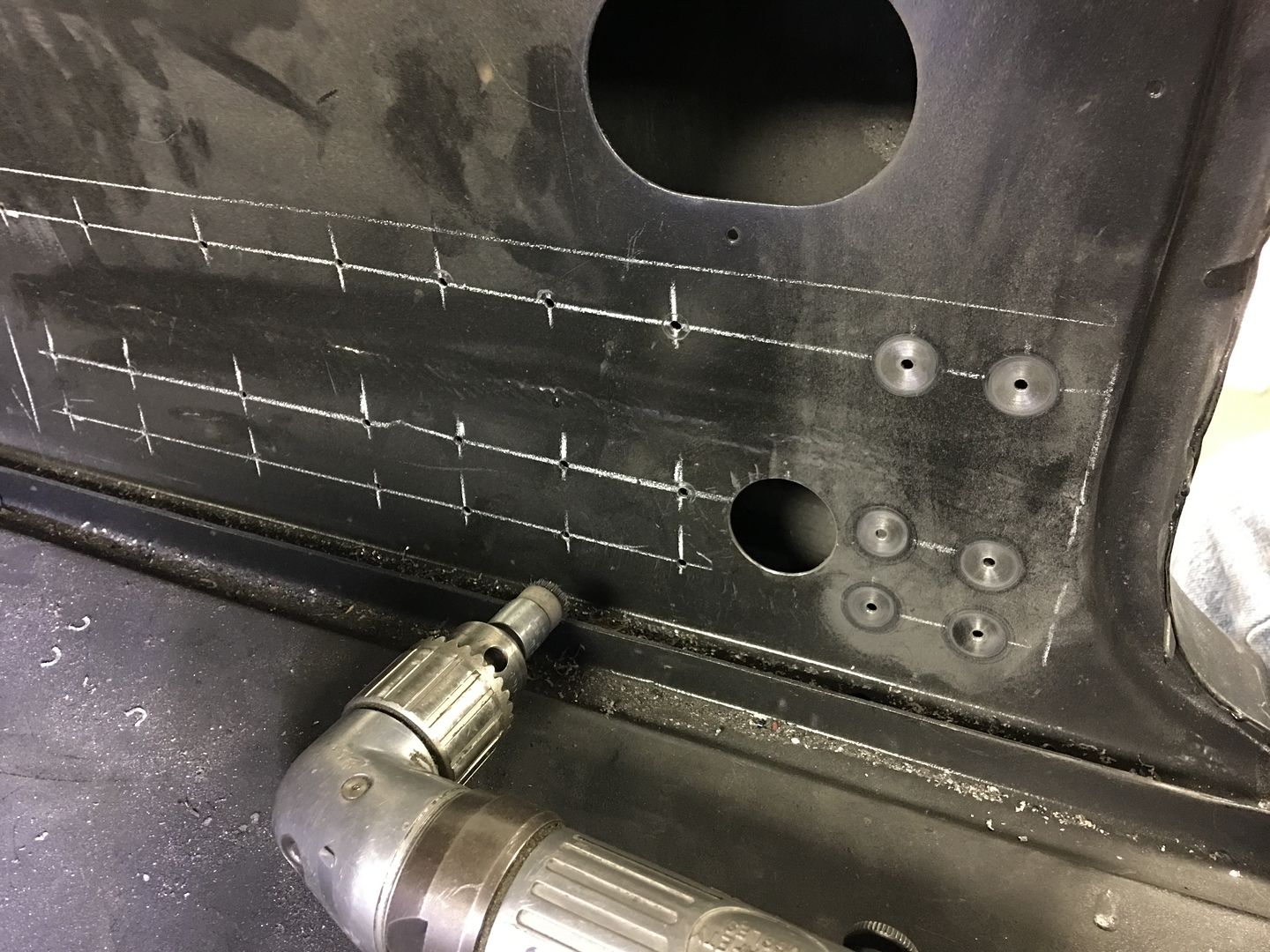

Pilot hole drilled for the passenger B-Pillar.....

The center point is spring loaded, but they seem to locate better using a pilot hole vs. just a punch...

The plug weld holes drilled for the anchor and paint cleaned off in prep for welding..

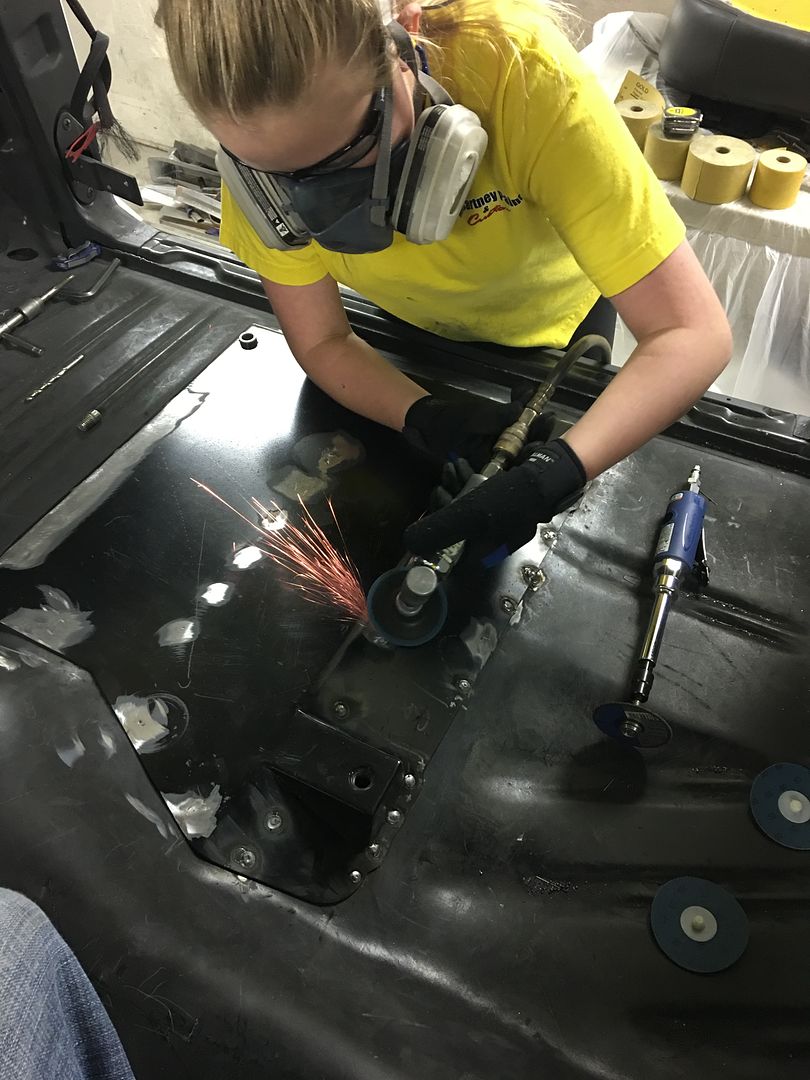

Apprentice E worked on smoothing off the plug welds from last week..

Welding in the anchor .....

For the lower anchor point, which will hold both the retractor and the lap belt, we used some 14 ga that will be plug welded to the back side of the inner quarter panel just behind the B Pillar.. A 1/2" lock nut is welded to the back side, and a spacer added to the front side to keep the lap belt off the side wall.

Or the motion picture version....

https://www.youtube.com/watch?v=4na-...ature=youtu.beRobert

-

05-30-2017 07:40 PM #10

Tonight we have both seat belt retractor anchor plates welded and waiting for apprentice E to media blast and epoxy prime..

Next, we have the side filler panels to either side of the fold down rear seat that don't fit with those pesky wheel tubs in the way...

So we plan to make new ones, with a relief to fit snugly to the wheel tubs at the bottom end.. We used the Baileigh MH19 hammer and the shrinking dies to shape a piece of 14 gauge cold rolled to fit the wheel tub. Glad I didn't have to do all that shrinking by hand.

A flat piece from the top section will be welded to this piece, and then foam will be glued to the assembly and upholstered to match the seat..Robert

-

06-05-2017 08:39 AM #11

To catch up on the wagon, the seat belt retractor anchor bracket will be located inside the quarter panel, here we are laying out for the plug weld holes that hold it in place...

Holes piloted, then use the burnishing brush to remove the paint from the weld area...

Then the holes are enlarged for plug weld size, I use a letter A and plenty of heat.

Back to our rear seat back modification, some 14 gauge steel is shrunk in the Baileigh MH19 to fit the driver's wheel well..

After some cleanup on the Tommasini cast wheeling machine...

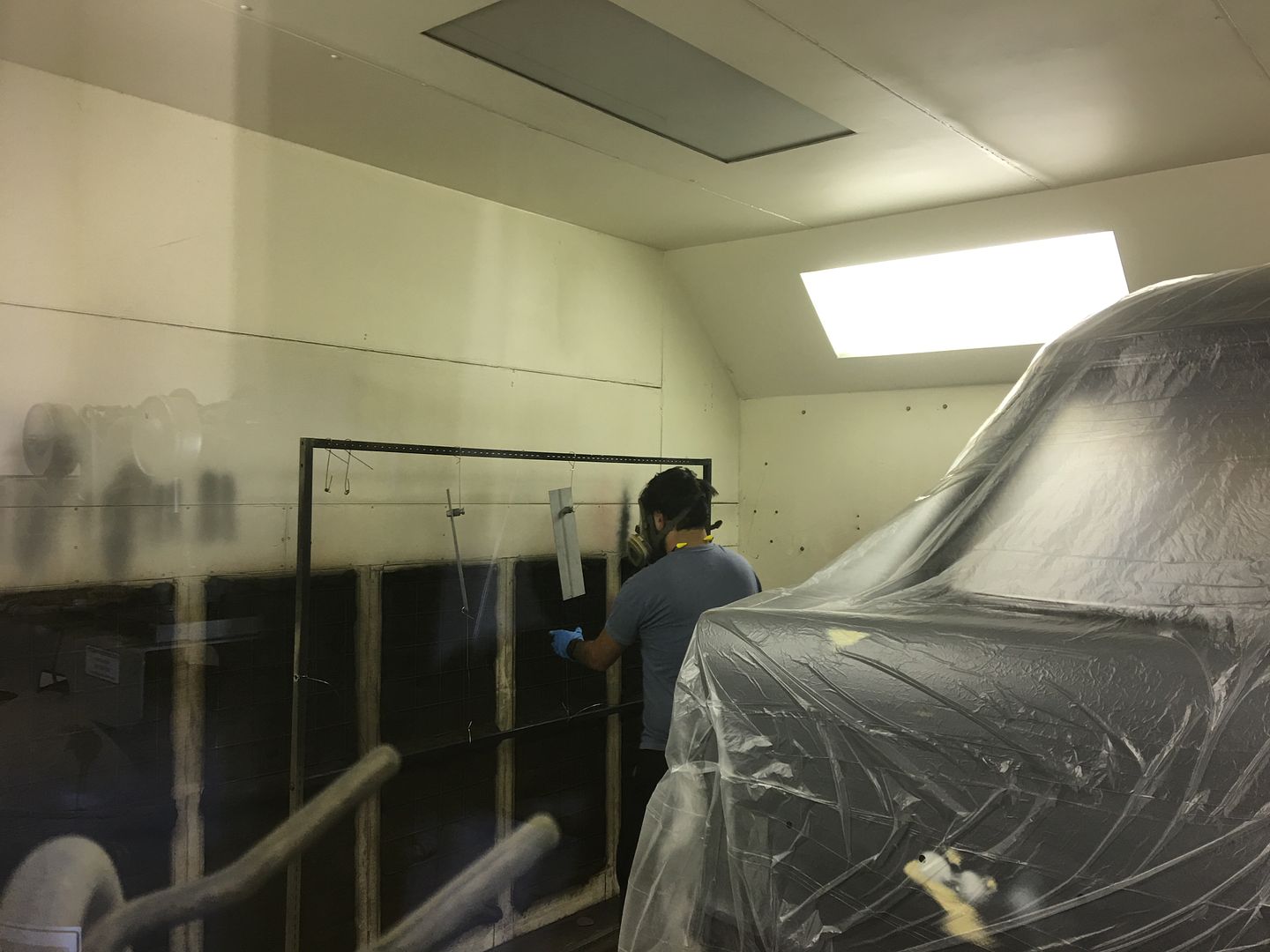

Meanwhile, Mike has media blasted the anchor brackets and is here spraying them with SPI epoxy primer...

The 14 gauge is then held to the wheel wells and marked a line parallel to the seat frame. We'll use this line to start the transition to flat, using a linear stretch die in the MH19.

Linear stretch die also used to add this detail to blend into the bottom part...

Tacked together and fitted....

Tig welded....

This should JUST hide the wheel well, but doesn't look like the foam will be all that thick at the bottom...

Weld dressed and another fit, I was going to trim the sides but we'll be adding some stiffener beads to the flat area, so we'll wait until after that process to trim the sides.

Robert

-

06-05-2017 09:08 AM #12

Fantastic as usual!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

06-05-2017 11:50 AM #13

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,300

- Blog Entries

- 1

Very nice work! Those side panels look great. That 35 Chevy is a master piece!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

06-05-2017 01:49 PM #14

Amazing car, a real testament to all who contributed to the build!!

Richhttp://www.clubhotrod.com/hot-rod-bu...del-coupe.html

-

06-11-2017 09:15 PM #15

Saturday Mike worked on the 55, with the seat belt retractor anchor plates now epoxied and cured for a week, they're ready to weld inside the quarters. He clamped them in place, scribed all the holes, removed them and cleaned paint off the hole locations....

clamped in, ready to plug weld.....

then he dressed the plug welds on the anchor plates as well as a few remaining ones on the drivers bucket seat pan. next on the list is to fabricate some arm rests for the rear seat area that will also serve to enclose the seat belt retractors.Robert

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Thanks for the happy birthday wishes, so far 50 feels a lot like 49 LOL

Happy Birthday 53Chevy5