Thread: 55 Wagon Progress

-

07-24-2017 02:53 PM #1066

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

More ingenious ideas and solutions. Great work. Thanks for taking the time to help out and make other's lives easier. I know I've looked at things different since following your threads.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

07-24-2017 09:25 PM #1067

I agree with Ryan, he hit the nail on the head. One thing I appreciate about you and all your post besides the obvious awesome work you do, is how you take time out to fix the school buses, help kids learn how to do what your doing ,and quick making patches for people when they stop by.

Seth

God cannot give us a happiness and peace apart from Himself, because it is not there. There is no such thing. C.S.Lewis

-

07-26-2017 05:16 AM #1068

Thanks for the comments guys!

Well time to relocate the wagon out of the paint booth so we can get some bus parts painted and on the way out the door..

started with two coats of SPI epoxy on the bumper and end caps, the rivets were media blasted and will get black urethane only..

In between coats the hood was removed and started stripping all the bolt on items. The fiberglass repair was sanded once more and prepped for a layer of Evercoat Kitty Hair.. starting to get crowded in here..

A couple coats of the black urethane and we'll let it set a couple days...

This shows the prep on the new hardware, media blasted using 80 grit garnet abrasive, then it gets Urethane only. Primer has shown to have too much build and results in chips from the Phillips bit, media blast and urethane only has shown to hold up the best.

Robert

-

07-26-2017 11:56 AM #1069

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

I always wondered how none of the bolt heads on some restored tractors didn't have chipped paint after assembling them. Urethane only with no primer is the key?

Also, does Thomas just put their name on Freightliner chassis now, or is Thomas actually building their own chassis now?Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

07-26-2017 04:11 PM #1070

The first sentence began with the 55 moving out of the paint booth.. so I start thinking it's heading back onto the frame right??? Sigh... nope - not yet! LOL.

-

07-27-2017 06:05 AM #1071

Urethane only has been the key for what we're using it for.. The skirt panels are primarily installed using Phillips head screws and pop rivets. I've probably repaired a good 20 buses thus far, and we found that primer gives us too much build, resulted in chipping. Without abrading (media blasting) the paint didn't want to stick regardless, resulting in chipping. When we install the hardware the paint has usually set for about three days, so the paint is a bit "green" still, making it still somewhat flexible and less likely to chip. We've removed old hardware to find them rusting pretty good in the wheel well areas, so we strictly use stainless screws. As we aren't using hex head, I can't speak to how well this process would hold up, but it does work well with the Phillips..

Not sure on the Thomas chassis.

Next stop for the body (once we get done with floor welding) is the local Line-x dealer..... on the rotisserie still. But yeah, I feel your sigh. Believe me!!!Robert

-

07-27-2017 02:00 PM #1072

Sorry if I'm becoming anxious Robert.. I can't wait to see it come together. As I'm sure employee "E" is also! LOL..

-

07-27-2017 08:57 PM #1073

No problem... I'm ready for it to be done too.. Dang day job getting in the way...

Back on some yellow, Time to do some sanding on this hood....

Applying some 3M platinum....

Missed getting a picture of the sanding part there, and then sprayed a coat of SPI epoxy, will add another coat tomorrow morning..

Robert

-

07-29-2017 06:02 PM #1074

More back seat work on the 55. Mike is trimming up our brackets to give us a bit more clearance around the wheel wells so the upholstery can wrap around our panel...

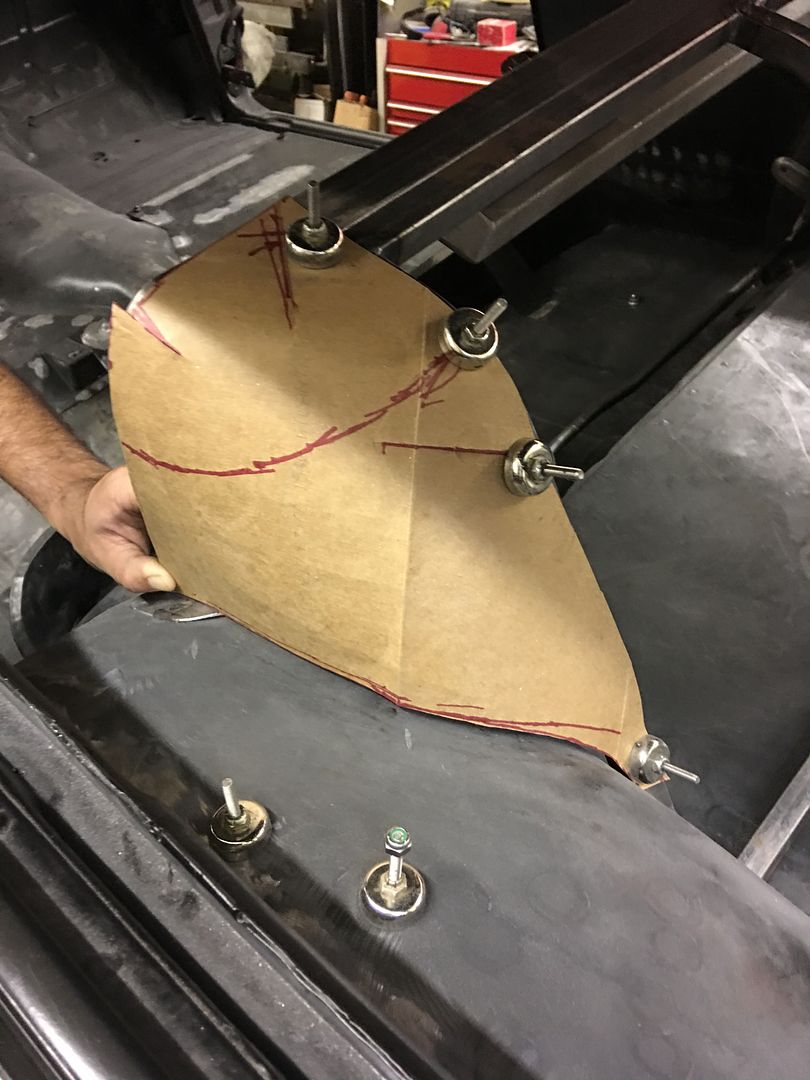

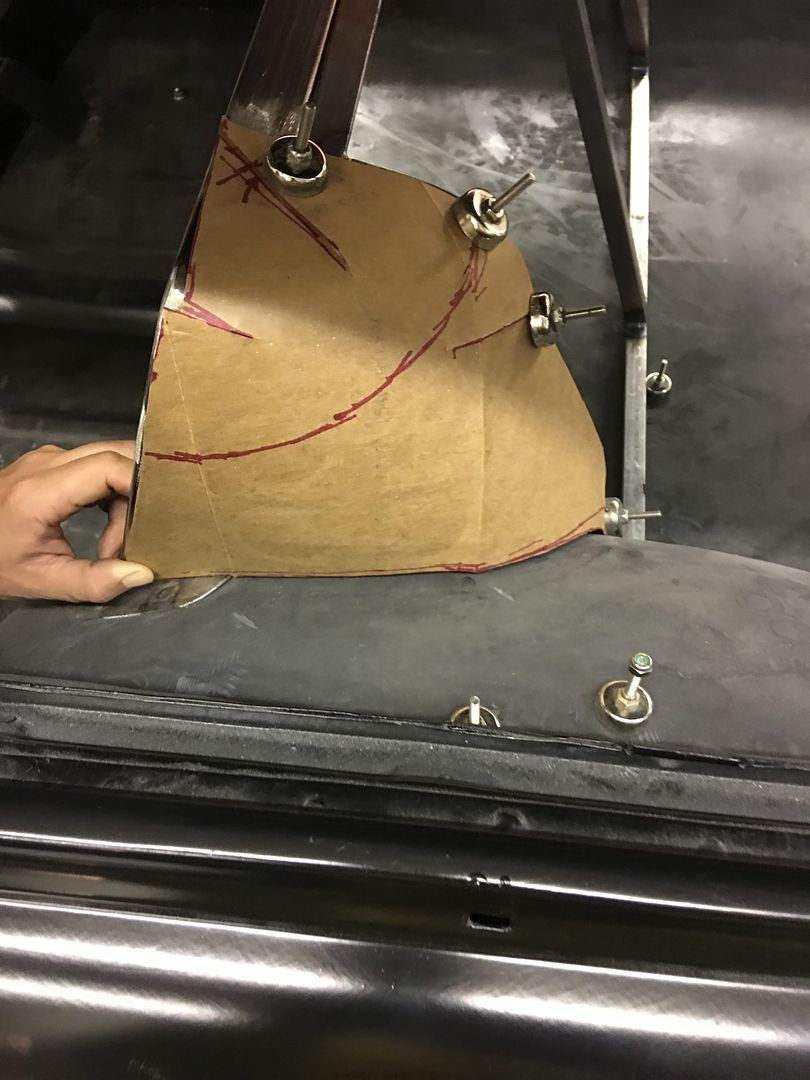

....and I worked on taking some patterns of the rear corners...

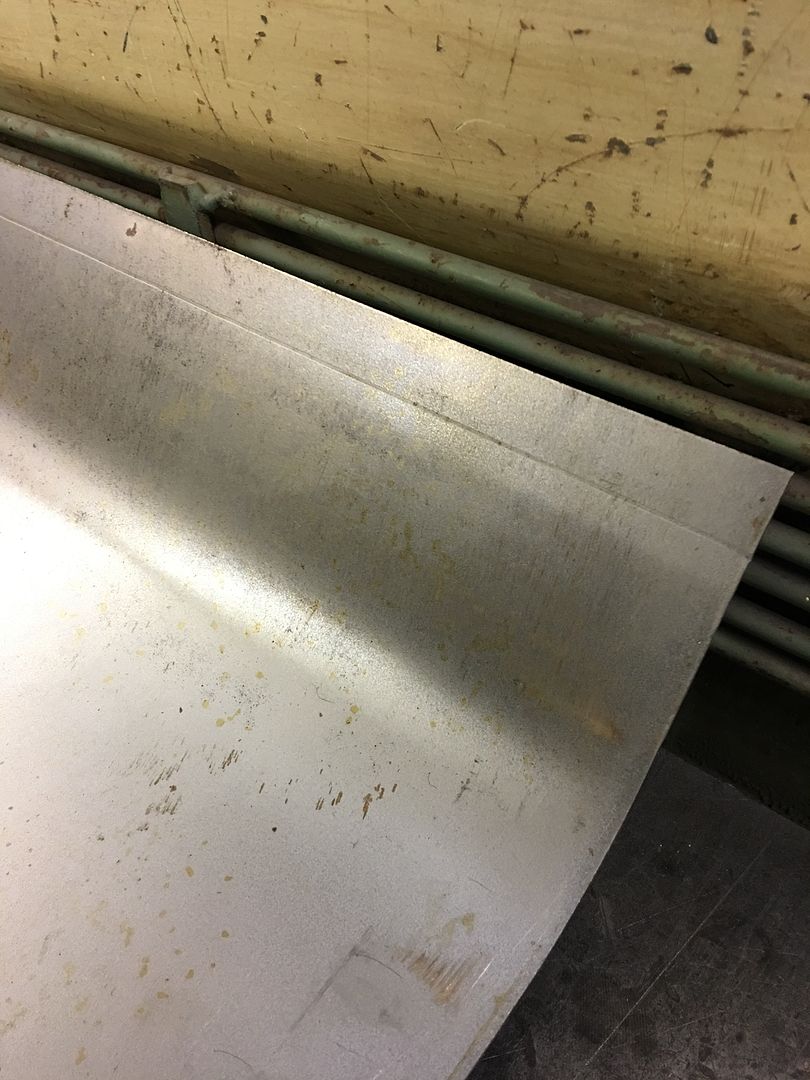

Transferred the pattern to some 18 gauge cold rolled steel and started some shrinking on the Baileigh power hammer..

https://www.youtube.com/watch?v=DII2zSpYT5A

Test fit....

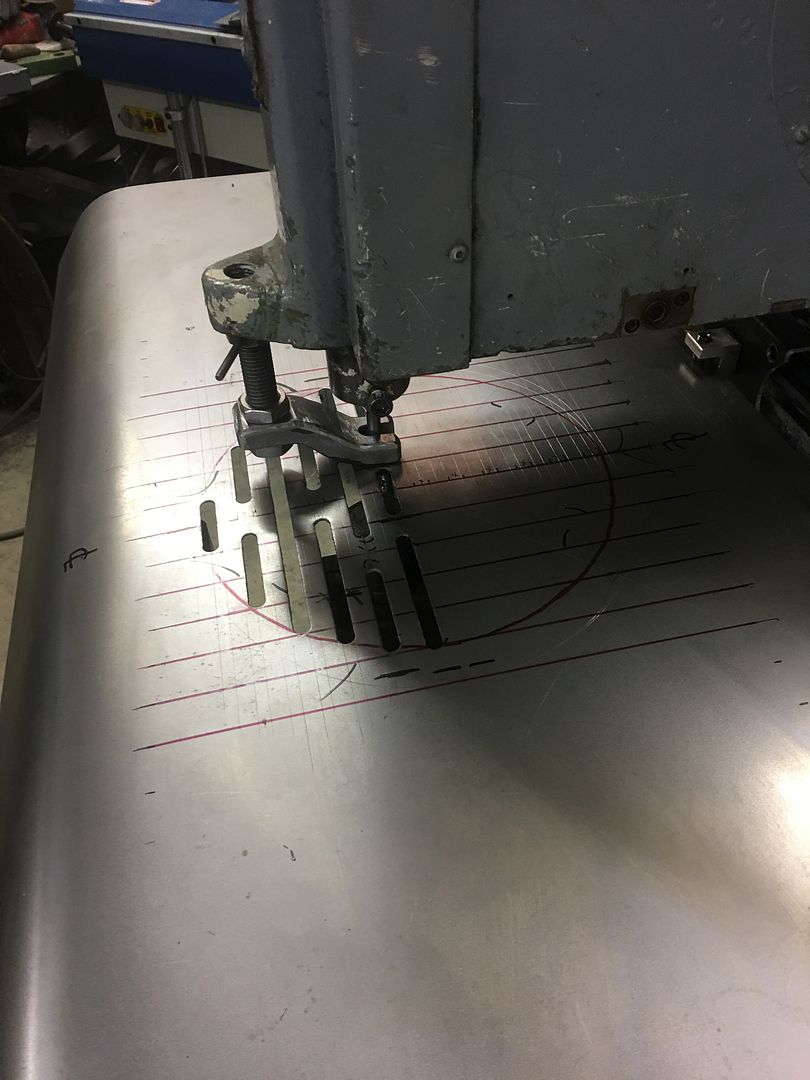

Bottom edge gets hemmed so the upholstery cloth has less chance of cuts...

A bit more cleanup work, but I'm real pleased with how this is turning out..

https://www.youtube.com/watch?v=1-S5g5g5J6k

.Robert

-

08-05-2017 08:59 PM #1075

More work on the seat back, a test bend to see how well it matches our corner....

Then to bend the radius on a piece of 19 gauge for the full width...

Then to bend down a flange to "hook" the frame....

The metal is thinned at the bend line using a tipping die to give us a more crisp bend...

Bent at 90* in the magnetic brake..

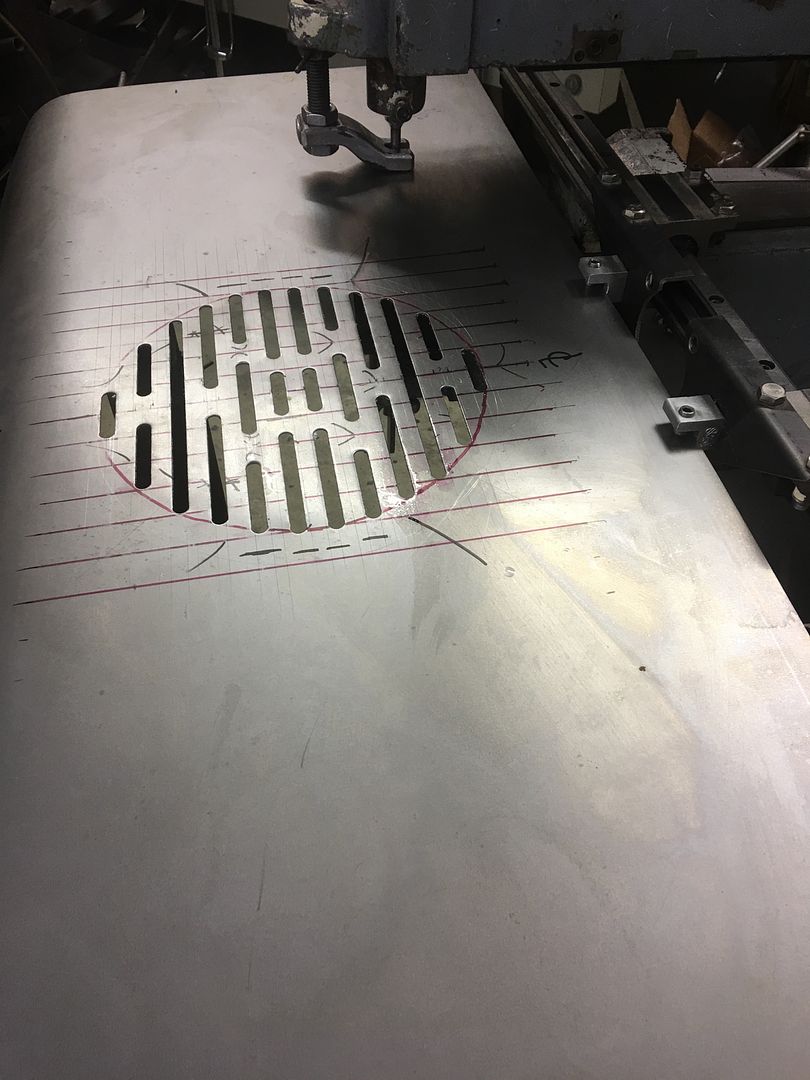

Next we slotted the panel for our 10" bass speaker. This should let out the sound but still support our upholstery material for a more subtle look..

Then the bottom flange is also thinned at the bend and bent on the magnetic brake..

https://youtu.be/krzfbvw9DV8

.....and our test fit into the car...

Robert

-

08-05-2017 11:32 PM #1076

Wow you guys continue to amaze with your excellent fab skills! After all this work gonna be hard to let this one go!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

08-06-2017 04:26 PM #1077

Looks like it's all coming together very nice.Seth

God cannot give us a happiness and peace apart from Himself, because it is not there. There is no such thing. C.S.Lewis

-

08-07-2017 03:19 PM #1078

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

Very nice! I'm really jealous.

Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

08-10-2017 08:41 PM #1079

Thanks for the comments!

Today was paint day for the remaining bus parts. One hood, three rear skirts, and attaching hardware.. After a sealer coat of SPI Epoxy..

And our yellow...

We'll let these cure a bit and get 580 put back together this weekend..Robert

-

08-10-2017 10:30 PM #1080

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

That looks very nice. Do you always use the black sealer? I'm guessing this is the preferred one you like to use?Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

3382Likes

3382Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Many of the long tube cast headers I've run across had a relief ground on the back side for starter bolt clearance. I just trimmed the bolt on mine. On these new shorty's, they eliminated the...

55 Wagon Progress