Thread: 55 Wagon Progress

-

02-13-2019 02:18 PM #1306

McMaster Carr, we are going to make some “pressing” dies. When I get on a laptop later tonight I’ll post the mesh pn’s we used.Robert

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

02-13-2019 04:47 PM #1307

I like the mesh tables in MC cataloques because it shows the reduction in area related to various wire diameters and spacing per inch------By popular opinions-just a grumpy old man key board bully--But really, if you are going to ask for help on an internet site, at least answer questions about what you are asking about-----

-

02-13-2019 04:59 PM #1308

Ryan, we used three different sizes just like the width of the trim rings were three different sizes, so they would be more proportional to the size of the speaker. This was 304 stainless ordered from McMaster Carr. They size by the number of square openings per inch, and the size of the wire. I started by getting their sample pack, good to have if you want to see size differences in person ( or to show customers). PN of sample is 9231T11. For the large bass speaker we used 5x5 mesh size (5 openings per inch) PN is 85385T31. For mid’s we used 8x8 mesh, PN is 85385T42. For tweeters we used 10x10 mesh, PN is 85385T48.Robert

-

02-13-2019 07:54 PM #1309

I'd never have thought to use different sizes mesh. Neat idea. I like them at 45*.

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

02-14-2019 05:30 AM #1310

Been using McMaster Carr for over45 years now great place for things others don't have and they are very reasonableCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

02-14-2019 11:42 AM #1311

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

Thanks Robert. I've been trying to find some SS mesh to put in front of condensers etc to keep them from getting clogged with bug guts. Everything I've found has had too large of holes. I didn't think of them.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

02-14-2019 05:35 PM #1312

-

02-14-2019 07:02 PM #1313

Impressive work, MP&C. Your build thread commentary and pictures are an inspiration to those like me (garage hacks) and to guys that do this stuff professionally. I feel like heading to the garage and working on my t bucket..... even though it's past my bedtime.

-

02-16-2019 06:43 PM #1314

Thanks to all for their input on the speaker grilles, the owner has decided on the 45* rotation. Our other choice to ponder was whether to use chrome, polished, or brushed finish. We clamped some of the rings in the lathe and gave it a brushed finish, others were polished so we can compare..

Here it was decided to go with the polished over brushed, and for ease of maintenance, we opted for chrome plating. So all the holes were drilled, counterbored, and transferred to their respective mounting location. The tweeter trim rings will be held in place with 6-32 hardware, the mids use 8-32, and the sub uses 10-32. Rivet nuts were installed where needed..

With the trim rings ready to send for plating, we turned our attention to the fuel lines, where we wanted a direct run all the way to the tank. Our bending efforts found Mike in a bit of a stretch..

The fuel line passes behind the body mount, we have a heat deflector in place where it passes over the tail pipe, and then it will connect directly to the tank. They will be secured with adel clamps fastened to the floor braces from underneath. Return line in place, supply line to go:

https://www.youtube.com/watch?v=ZbUxujdz2PU

.Robert

-

02-16-2019 07:01 PM #1315

You're showing off.

Don't stop!.

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

02-18-2019 11:39 AM #1316

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

More great work. So you're chroming the rings after the brushed work was done? I really like your body mold trick to make the lines too.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

02-19-2019 04:21 AM #1317

Yes, the samples of each were just done to show the owner the comparison.Robert

-

02-19-2019 07:32 AM #1318

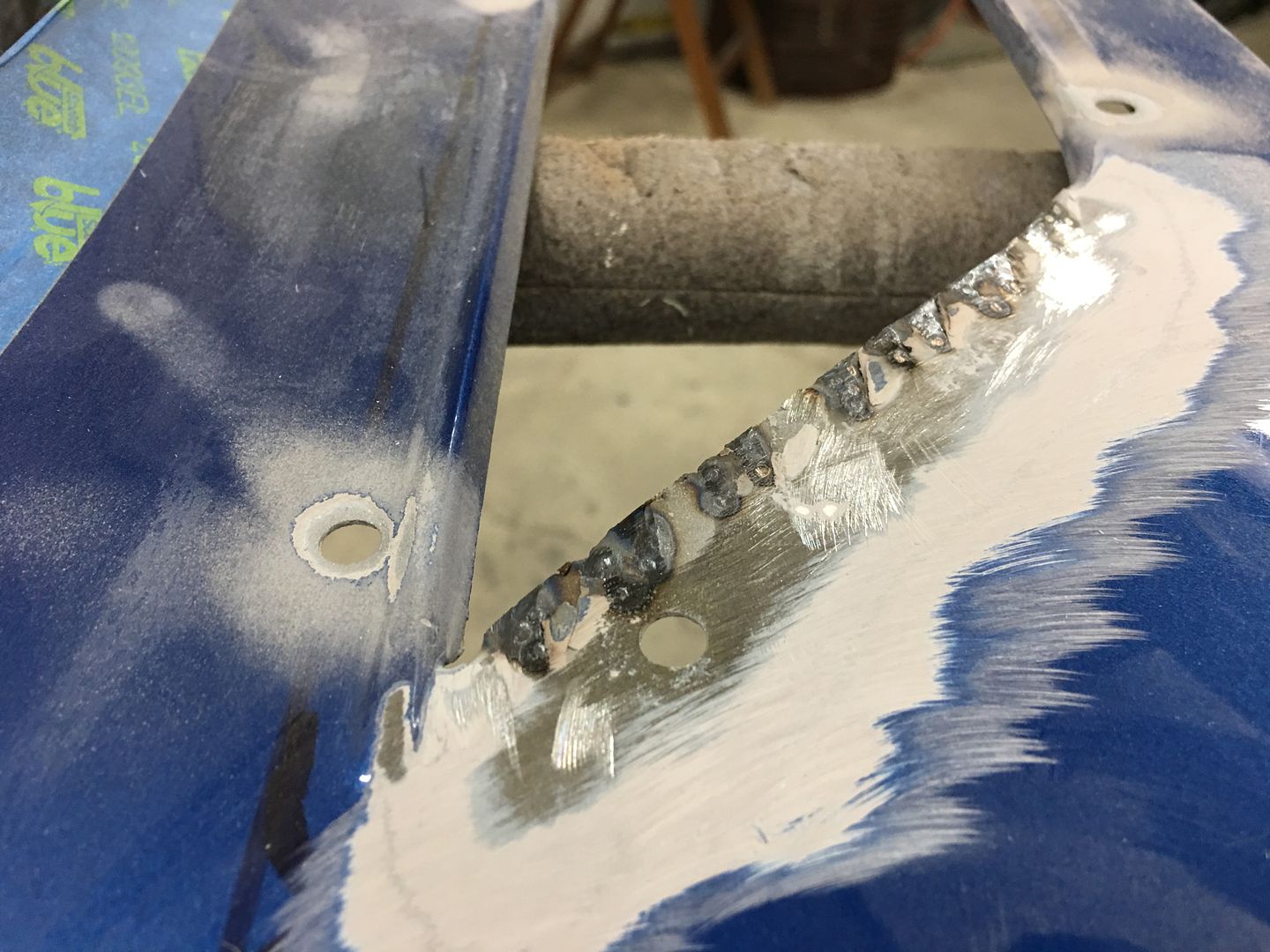

Had a slight distraction yesterday, a couple hood sides for a 37 Ford showed up. The owner wanted to remove the side "grille", and add a tapered recess pan with clamshell louvers. Here's what we started with...

Some cutoff wheel action later....

In an attempt to keep as much metal on the ends as possible, we opted to flatten the sad remains of the horizontal fins. This involved some shrinking via the heating tip in the dent puller..

Looks like someone has spilled bondo all over this panel. Funny the inside didn't look all that mangled to warrant the amount we found.. Must be a TV car..

The shrinking efforts flattened out the ends fairly well...

I filled in the previous trim holes with 18 Ga plugs and TIG fusion while the owner worked away at removing the bondo so we could see what we had to work with...

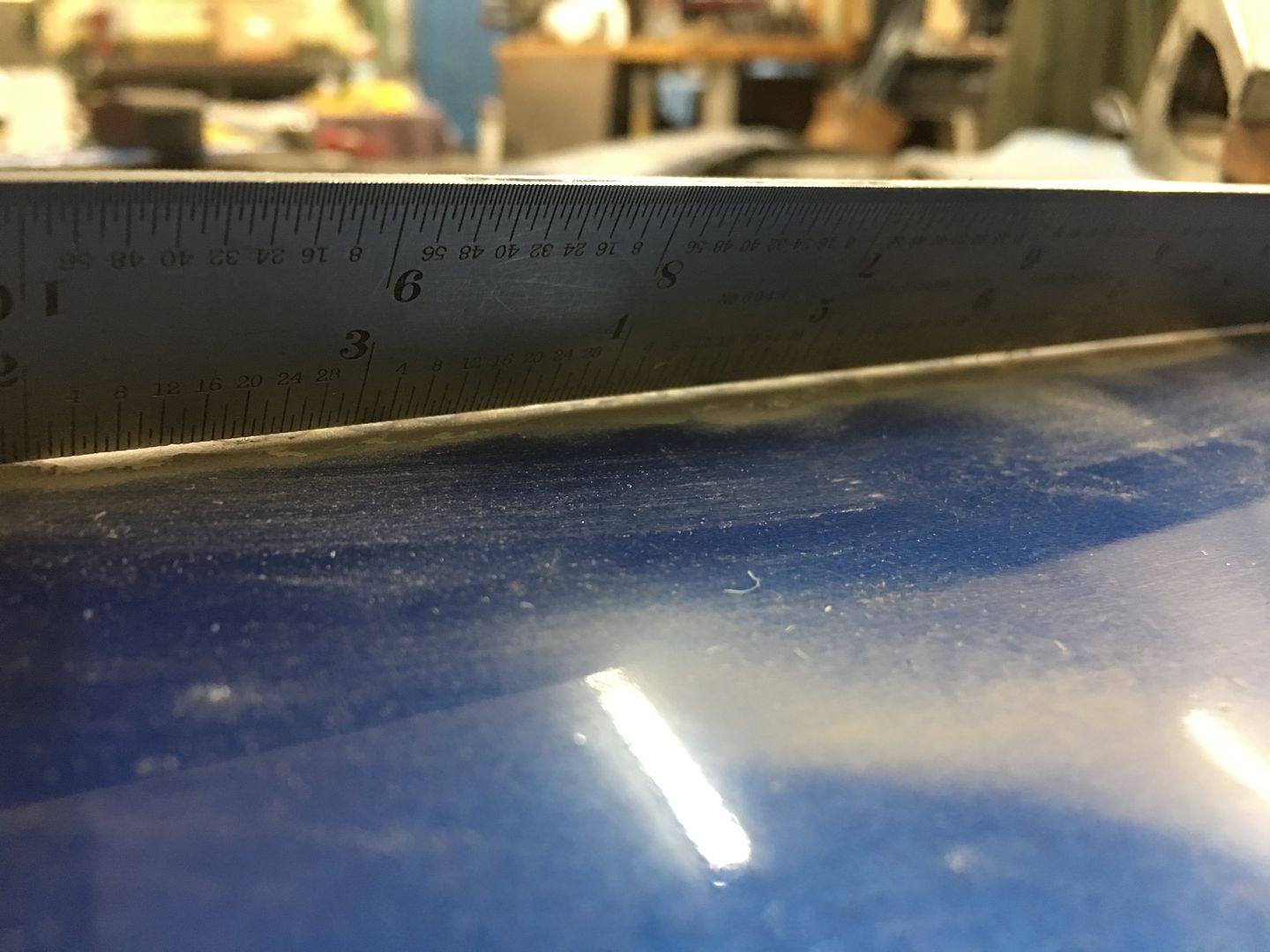

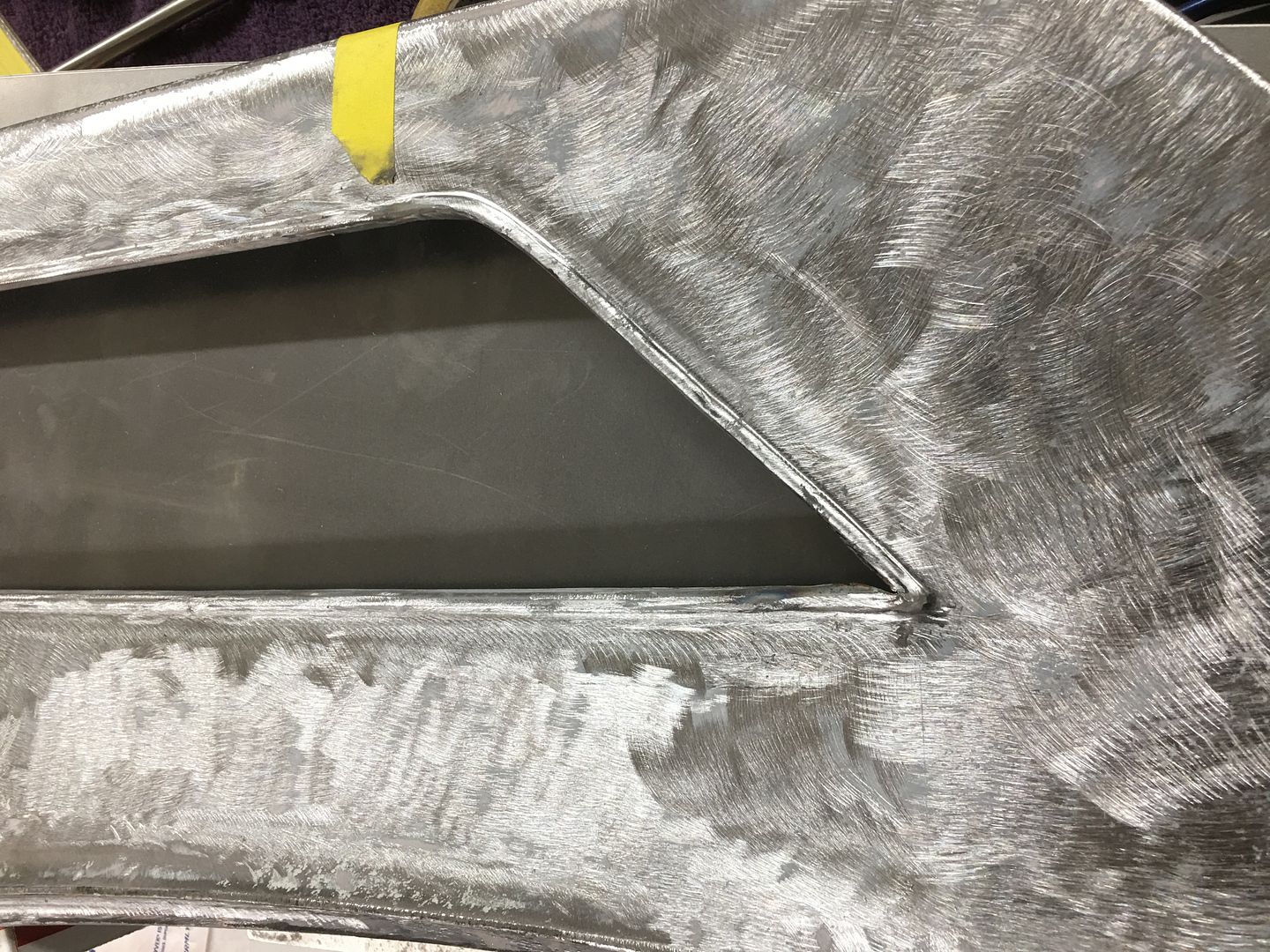

Next, we had to fold a flange in the front and extend the factory bead around the opening down the front where we had flattened the panel. Some of the existing bead profiles had seen better days in the past 80 plus years, so I checked a set of joggle dies I had made for drip rail as it looked close...

New flange folded at the front, bead added using the Lennox, original beads touched up ...

Tapered pan fabricated.....

Louver layout

Welded in place..

He is having some art deco style trim pieces made to accent the louvers down the center, topped by 62 Impala fender trim. We didn't have those, so here it is with alternate SS fuel line for your viewing pleasure...

Robert

-

02-19-2019 02:21 PM #1319

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

Very nice and fast work! Were they bad under the filler?Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

02-19-2019 03:56 PM #1320

Yep, amazing piece of work. I couldn't "see" that outcome in a decade! Way cool.

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

It was SWMBO's little dog. .

the Official CHR joke page duel