Thread: 55 Wagon Progress

-

02-19-2019 09:33 PM #1321

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

02-21-2019 10:01 AM #1322

Well the owner sent me a "concept photo" complete with cardboard cutout... The piece of cardboard against the hood side will be chrome plated, the next will be a contrasting color to the car, and topped off with the Impala fender trim..

Last edited by MP&C; 02-23-2019 at 11:31 PM.

Robert

-

02-23-2019 10:41 PM #1323

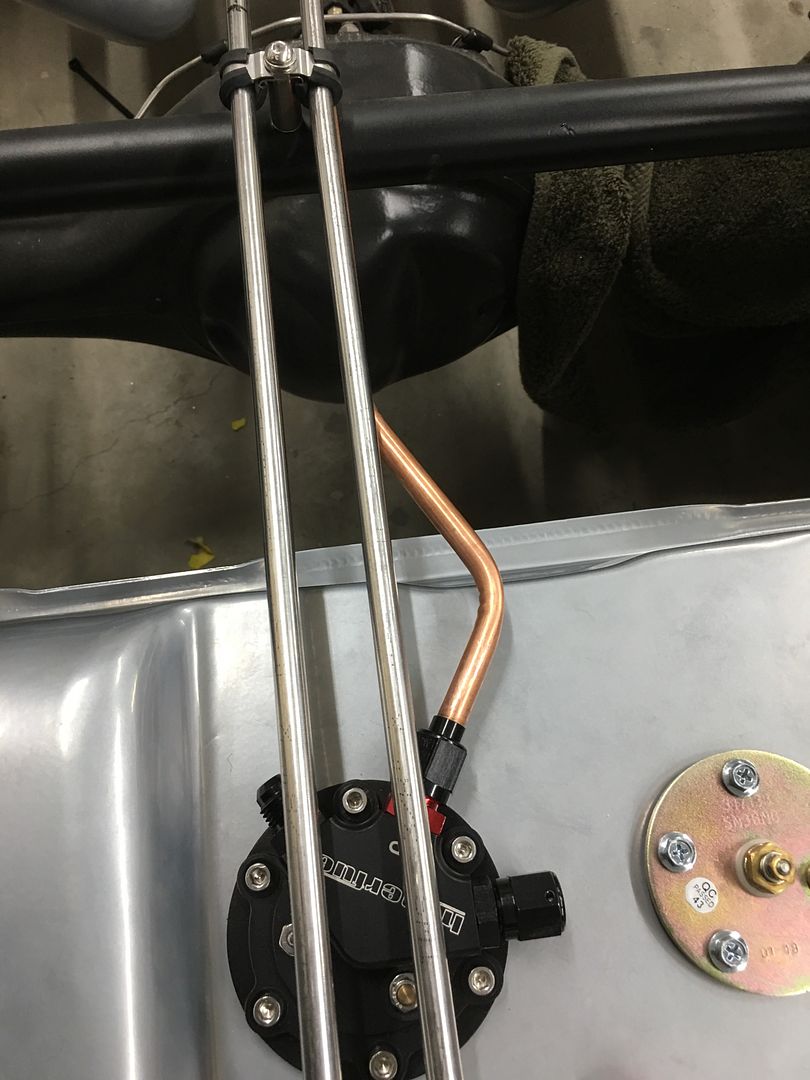

More progress on the fuel lines, with both lines now routed, we opted for glue lined heat shrink as an abrasion resistant covering where it passes closely to the body, and regular heat shrink to keep the two together.

Mike installs an anchor point for adel clamps in the shock crossmember

Test bends at the fuel pump..

Next to add some AN fittings..Robert

-

02-25-2019 06:42 AM #1324

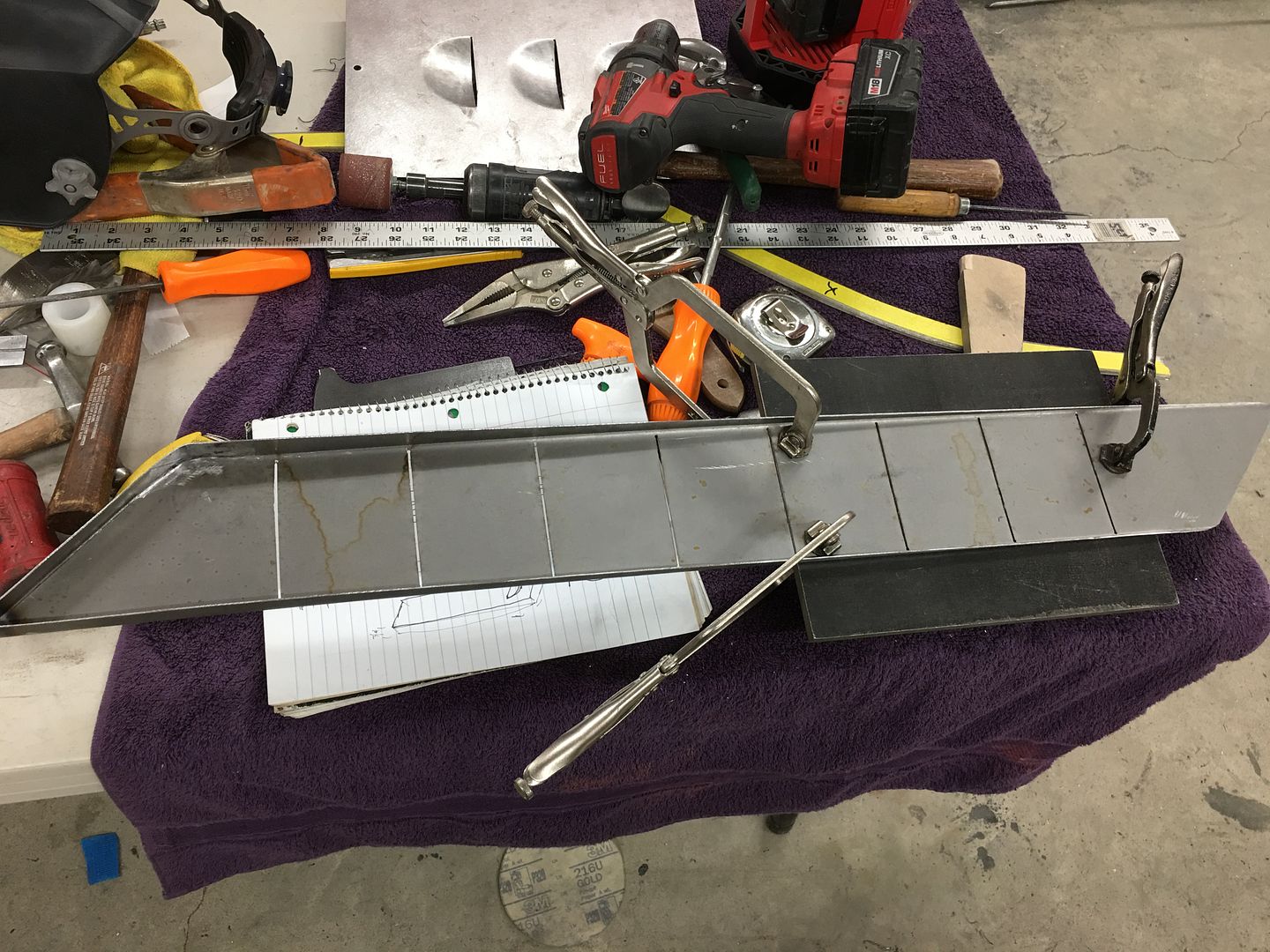

Hood side number two completed yesterday. The flanges of the tapered pan get some stretch treatment in the kick Erco to match the profile of the hood side..

For the questions about the cutting device, it is a long nose pneumatic cut off tool from Blue Point. For keeping the cut nice and perpendicular, and disc width, the long nose works better (for me anyhow) by having the long nose as a visual guide to keep it parallel to our centerline. I don't think I would have seen as good of results using the standard cut off tool.

Each slot has stop drill holes at the end, to help remove any cracking issue and also to better determine end of cut.

E helped out with the punching efforts...…

Panel gets tacked in and welded with the TIG...

Robert

-

02-25-2019 06:04 PM #1325

My hat's off to ya. Cardboard is notoriously difficult to chrome!

Kidding of course.keep up the good work, it just may inspire me to eventually cut up my tools with the blow torch.

If you ever change your mind about taking in a broken down old veteran as apprentice, let me know..

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

02-27-2019 04:51 AM #1326

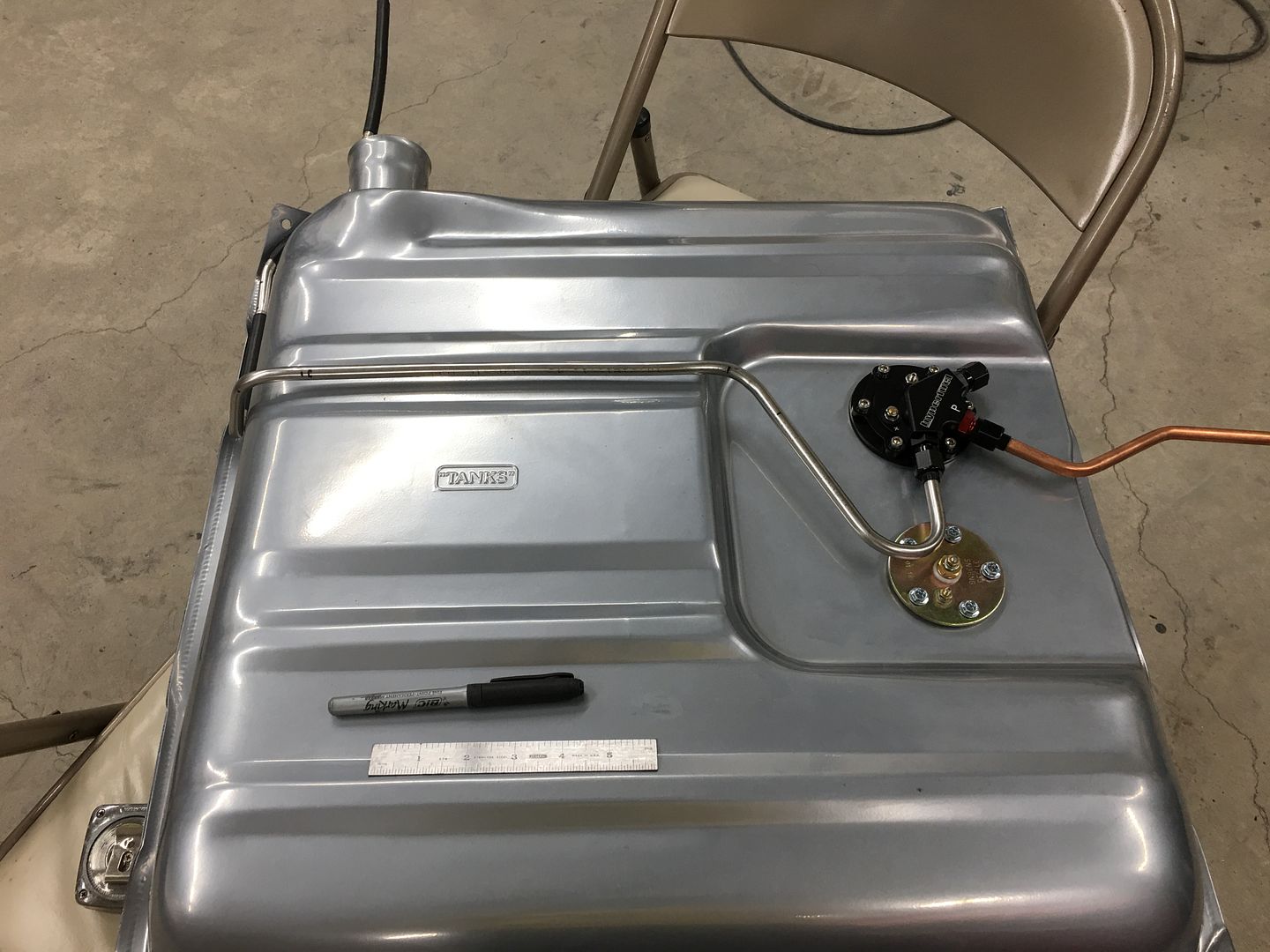

That may be a bit of a commute though.....

Our vent/check valve for the fuel tank will get mounted up behind the driver's tail light by the filler neck. We bent up a piece of stainless tubing last night for the vent line. The glue-lined heat shrink works well to provide a cushion/vibration dampener up against the tank.. For our stainless bends, we had also bought a roll of copper tubing to use for test bends. Inch increments were marked, bends made, and then these marked "starting points" could be transferred to the stainless for more accurate bends.....and less of a scrap pile.

Video version..

https://www.youtube.com/watch?v=NE_3...ature=youtu.be

.Robert

-

02-27-2019 08:41 AM #1327

Nice work-But, I have to suggest to NOT run a metal gas vent line near a light fixture--------you don't want gas fumes anywhere near a electrical warm spot or a metal line to carry electricity down to a fuel tank---------a bump in the corner could damage the light causing a short, a simple bulb switch, etc ??By popular opinions-just a grumpy old man key board bully--But really, if you are going to ask for help on an internet site, at least answer questions about what you are asking about-----

-

02-27-2019 08:59 PM #1328

johnboy

Mountain man. (Retired.)

Some mistakes are too much fun to be made only once.

I don't know everything about anything, and I don't know anything about lots of things.

'47 Ford sedan. 350 -- 350, Jaguar irs + ifs.

'49 Morris Minor. Datsun 1500cc, 5sp manual, Marina front axle, Nissan rear axle.

'51 Ford school bus. Chev 400 ci Vortec 5 sp manual + Gearvendors 2sp, 2000 Chev lwb dually chassis and axles.

'64 A.C. Cobra replica. Ford 429, C6 auto, Torana ifs, Jaguar irs.

-

03-02-2019 09:51 PM #1329

Jerry, thanks for the tips. The vent has a barb fitting so we will have a hose between the two. Hopefully that will eliminate an electrical path.

Got the rear brake line installed on the frame..

Last edited by MP&C; 03-02-2019 at 10:23 PM.

Robert

-

03-07-2019 12:30 PM #1330

Well after about 12 years, the Lennox TE150 is leaving the building. When we did the 35 Chevy louvers for Cody Walls, it hinted then of it's limitations. Simply put, not enough throat capacity with some of the automotive panels.

I bought this from Northwest Airlines and picked it up from their then recently closed DC-9 maintenance facility at the Hartsfield Atlanta airport. They had shut down the operation and moved maintenance overseas. This and a 100 ton drop press was the last that remained in an otherwise vacant building.

I've found another metalshaper that has a larger machine, but doesn't really use it for the capacity. So after negotiating the terms, he will be using this for the (mainly) motorcycle fabrications, where I will have more capacity for larger automotive panels.

Robert

-

03-07-2019 01:54 PM #1331

On one trip to the US of A we had the good fortune to be taken on a guided tour of 'Larry's Machine Shop' just outside Perry OK.

They had a horizontal drill there with a capacity of drilling 25 ft.

I asked him "What's your margin of error at the far end?"

" + 25 thou."

Crikey!

"But this is the small one. Over there," (pointing.) "is the large one. Fifty feet."

Crikey again!

Fifty ft is a looonng way!

It seems they came from a naval shipyard, and were used to drill gun barrels for warships.

The owner of Ditch Witch had come through Larry's not long before us, and had told him "Larry: if you get a larger drill you're going to have to take into account the curvature of the earth before you set it up."

Are you heading down the same path Robert?johnboy

Mountain man. (Retired.)

Some mistakes are too much fun to be made only once.

I don't know everything about anything, and I don't know anything about lots of things.

'47 Ford sedan. 350 -- 350, Jaguar irs + ifs.

'49 Morris Minor. Datsun 1500cc, 5sp manual, Marina front axle, Nissan rear axle.

'51 Ford school bus. Chev 400 ci Vortec 5 sp manual + Gearvendors 2sp, 2000 Chev lwb dually chassis and axles.

'64 A.C. Cobra replica. Ford 429, C6 auto, Torana ifs, Jaguar irs.

-

03-07-2019 09:13 PM #1332

Curvature of the Earth! Crikey!!

The only thing sadder than the Lennox leaving you is that it (and its many custom dies) are not coming to me.Last edited by firebird77clone; 03-07-2019 at 09:15 PM.

.

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

03-08-2019 04:48 AM #1333

Hello, my name is Robert and I have a tool hoarding problem..Robert

-

03-08-2019 11:24 AM #1334

HA HA HA your not the only one.Charlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

03-08-2019 02:25 PM #1335

Hello. My name is Michael.. I'm a toolaholic!

(everyone in room, in unison) Hello Michael.

3377Likes

3377Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Yep. And I seem to move 1 thing and it displaces something else with 1/2 of that landing on the workbench and then I forgot where I was going with this other thing and I'll see something else that...

1968 Plymouth Valiant 1st Gen HEMI