Thread: 55 Wagon Progress

-

11-24-2019 12:36 PM #1456

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

11-24-2019 12:55 PM #1457

I say beat on it. You can't hurt it..

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

11-24-2019 06:38 PM #1458

Had some visitors at the shop a few weeks ago, John Glenn and his father (from Anderson Auto Glass, Anderson SC) came up so we could use the truck floor dies to modify the ribs on a 2009 Ford replacement floor for use in a 1966 Ford they are restoring. The new floor has flat area provisions for a fifth wheel bracket and the original floor in a 1966 has full length ribs front to rear. We needed to modify the flat areas to provide these full length ribs. James McKenzie also stopped by to help in the activites.

QUOTE (John Glenn) I didn't go into much detail about this earlier, but the F250 bed floor had four flat areas for a fifth wheel hitch that looked really out of place for use in a '66 F100. I contacted Robert (MP&C) about having him make dies for his Lennox to reshape those spots into continuous ribs to look more like the original bed floor. I sent a sample so he could make dies a while back, and yesterday our schedules finally aligned so we could work on the bed floor.

We started by gas welding plugs in the four holes that won't be used on the F100. I didn't want to weld those with a MIG at our shop since the weld would be more brittle and would probably crack during the reshaping process. Gas welds are much softer and more workable.

The welds were smoothed down and the flat areas were pre-stretched in the english wheel with a bit of guesswork as to how much we should pre-stretch.

Then into the Lennox to add the ribs. This was done gradually in multiple passes, adjusting the depth of the dies after each pass.

Slightly reworking the dies to gain more rib height.

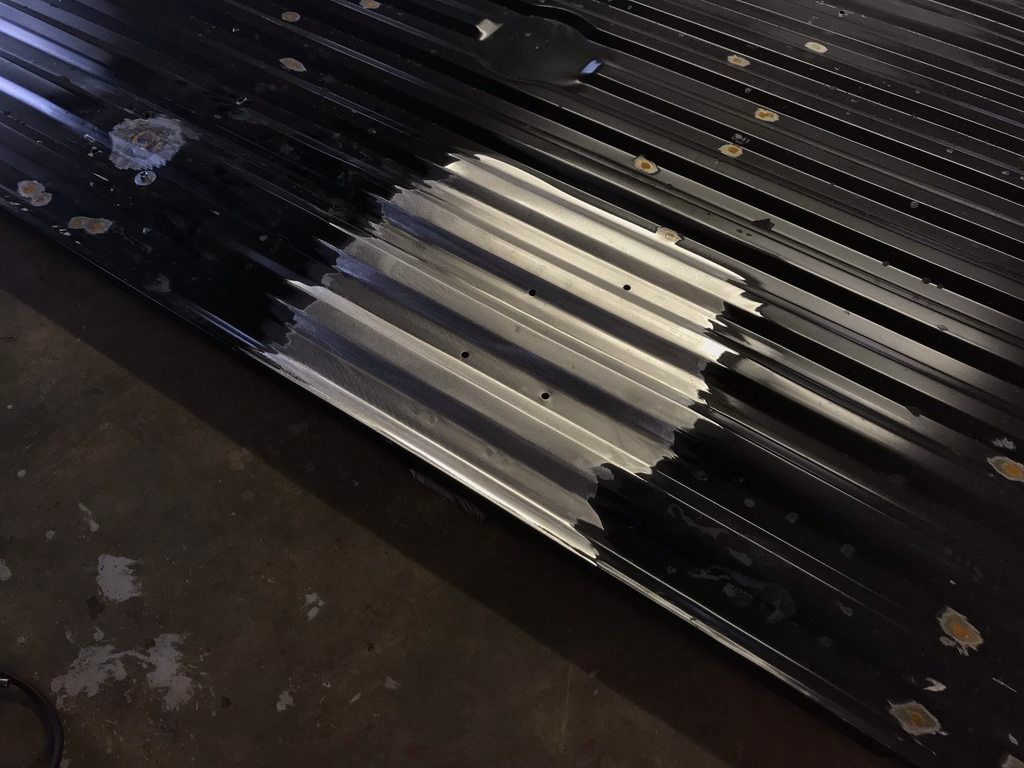

Finished ribs. These are hard to photograph so I stripped an area with the two new ribs in the center of the outer original ribs to show the matching profile.

James (duallyjams) dropped in to hang out for the day, it's always good seeing him! He was a big help and also shot vids of us working.

Time lapse:

Shaping Full Length Bed Floor Ribs- ?66 F100 - YouTubeRobert

-

11-24-2019 07:49 PM #1459

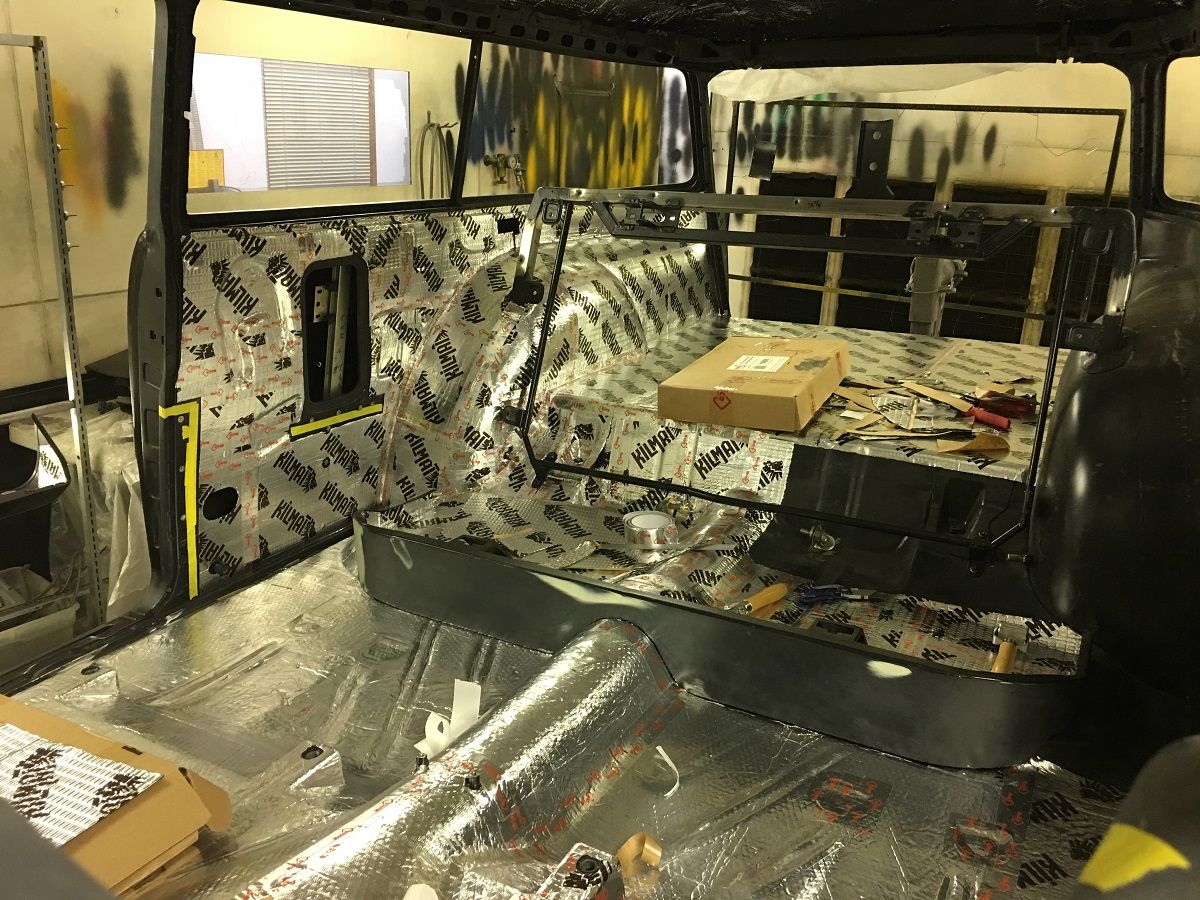

Today Mike sent time blocking out the epoxy on the sign parts and addressing any low areas. I continued working on sound deadening, have one inner quarter panel left to go..

https://www.youtube.com/watch?v=f-ByQZLYwRURobert

-

12-07-2019 09:51 PM #1460

Sign progress, Fine tuning of some of the parts....

…..and for mounting it on the steel pole, this "shoe" is made of 14 gauge cold rolled and formed using the Go Kart slick.. The "sleeve" will slide over the pole and a set screw will hold it in place..

All ready for a splash of paint...

The sound mat is installed inside the wagon...

https://www.youtube.com/watch?v=H0X0t0nT4t4

.Robert

-

12-07-2019 10:07 PM #1461

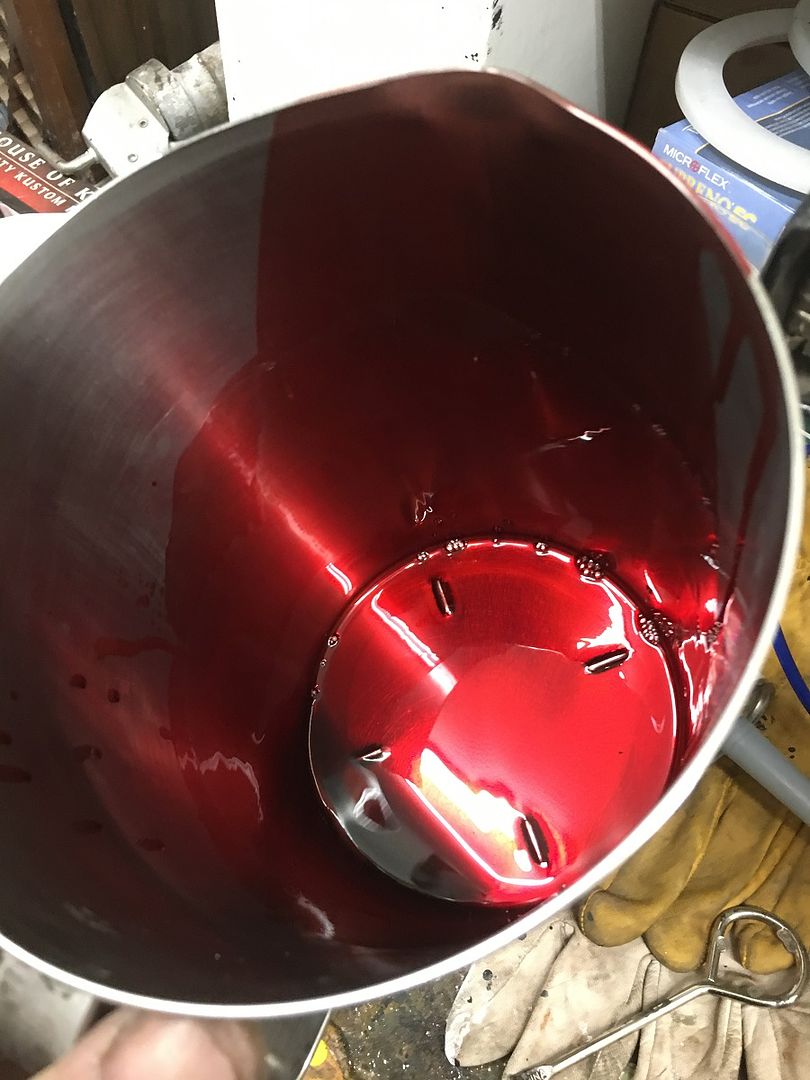

A couple coats of Epoxy last night to seal things up....

….and then a white face added to the lighted surfaces...

Then they were masked off for painting the silver....

and a bit of color for the "drum"

video:

https://www.youtube.com/watch?v=lPbuYB1HTTo

Now to see if Mike can get this assembled this week...Robert

-

12-08-2019 07:32 PM #1462

The sign was partially assembled today, and a test of the lights...

Lighting:

https://www.youtube.com/watch?v=XSX80znqiAo

.Robert

-

12-09-2019 04:24 PM #1463

Not that it matters in the least but... Cosmo and I approve completely!

-

12-12-2019 09:29 AM #1464

Well the Logo has just been added, and the sign has left the building. Mike did the majority of the work on this project, I'm real pleased with how it turned out. More importantly, so is the customer!!

video:

https://www.youtube.com/watch?v=qewqepgfapc

Robert

-

03-01-2020 06:08 PM #1465

Time for a long overdue update. I've had too much travel for the day job since the first of the year. Case in point, we've had more than one Taco Tuesday at the Sand Bar in Cocoa Beach...

Since completing the Drum Sign, Mike has been removing dings from the wagon's stainless trim. Here Vince and I test fit the side spears..

We've done some stainless repair before using small hammers and handmade punches to match the rear side of the profile, but during the last metalshaping workshop I attended at Will Cronkrite's shop in SC, I picked up a stainless dent/ding removal fixture that he had made up.. The blue sleeve at the top works on the premise of a slide hammer, with the force applied controlled by the operator. The die at the bottom (punch) is removable to allow a wide variety of specialized punches to fit the application.

This tool allows more controlled manipulation, especially to those of us that don't do this type of repair every day...

Here's one of the purpose built punches made for the trim...

Here's some of our efforts in polishing out the trim after ding removal, filing, and about 6 steps of progressively finer grits of w/d and trizact….

Reflection....

We also were test fitting the dash trim that the owner had picked up. I know, billet is a bit played out, but let's see what works here...

In fitting the corner pieces, the rear point of the trim does not match the unequal radius of the recess in the dash. Then when the middle (concave) radius is pushed into the recess, the rear "point" drops down out of the recess. So the underlying message here it the fit of these parts is piss poor at best.

So we are not going to use these, but opting for something in a stainless trim.. final design TBD...

Lastly, all the travel I've had for the day job really interferes with long term efforts, paintwork in particular. So in the interest of keeping progress moving forward, we have farmed out the paintwork to Brandon and Richard Glymph at Absolute Rod and Custom Paint. So last weekend the body and various parts were delivered to their shop in Annapolis..

So we should be doing assembly here in the near future!!Robert

-

03-01-2020 08:11 PM #1466

That's exciting, Robert! What a ride it has been...your attention to detail is amazing and inspiring! What color is it going to be? Cant wait to see it in paint!"It is not much good thinking of a thing unless you think it out." - H.G. Wells

-

03-01-2020 08:49 PM #1467

Thanks, Organic green Kandy basecoat and grey roof... Here's the sprayout sample we did:

https://www.youtube.com/watch?v=WmaE49JBgbs

.Robert

-

03-02-2020 05:53 AM #1468

Beautiful color! It'll look fantastic!

-

03-02-2020 10:13 AM #1469

this project must be adding up over the years!

Your attention to detail is close to perfection!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

03-02-2020 01:24 PM #1470

He could paint it with mud and the quality will show through..

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Thanks for the happy birthday wishes, so far 50 feels a lot like 49 LOL

Happy Birthday 53Chevy5