Thread: 55 Wagon Progress

Results 1 to 15 of 1865

Threaded View

-

03-06-2017 04:30 AM #11

Keeping options open...

This weekend we got the three hex nuts welded underneath seat bracket number two, fourth hole is a bolt through......

1/4" tall spacers fabricated to make the seat tracks level, then tacked in place on the front holes..

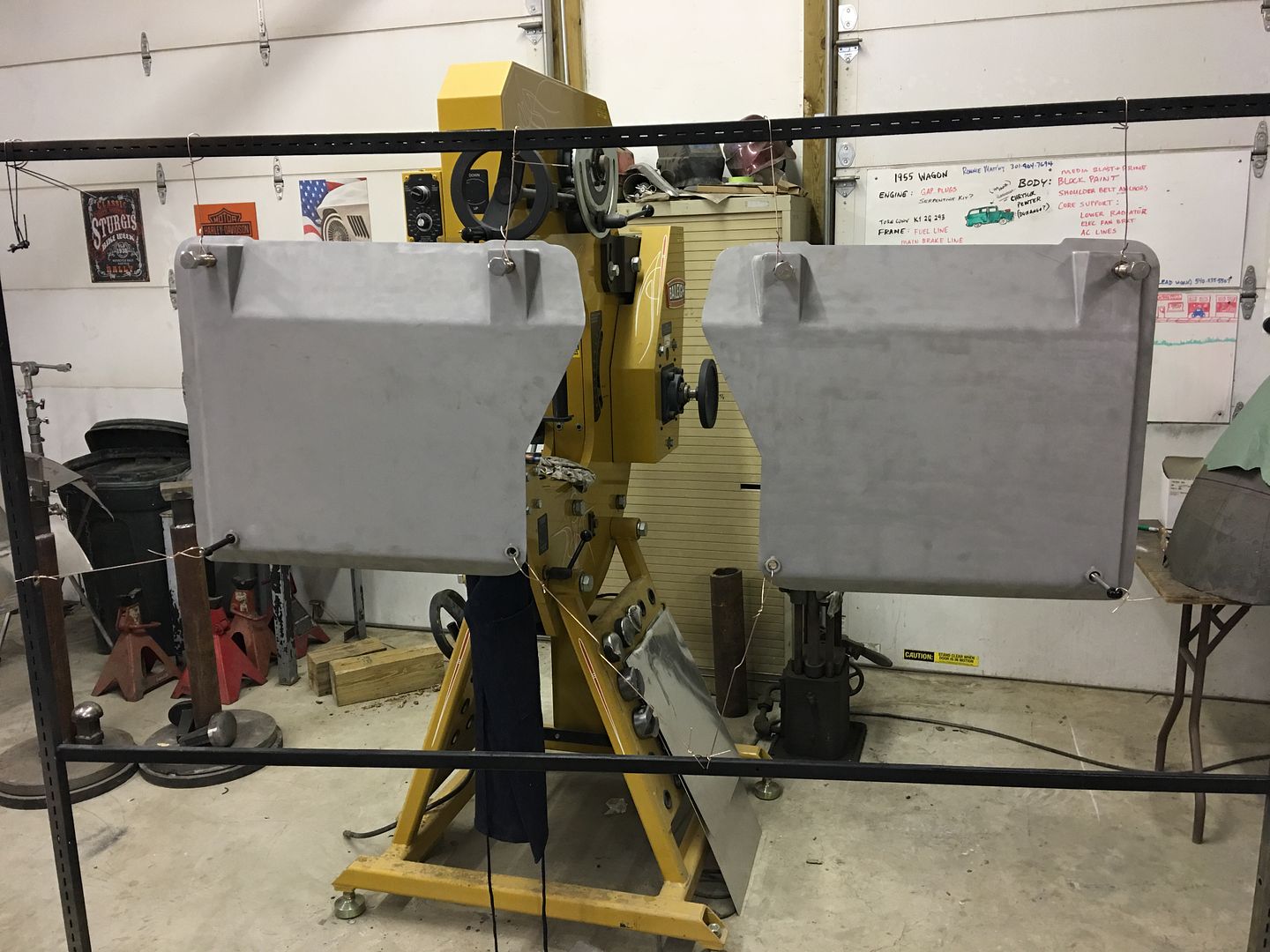

Prepped and hung up for epoxy primer...

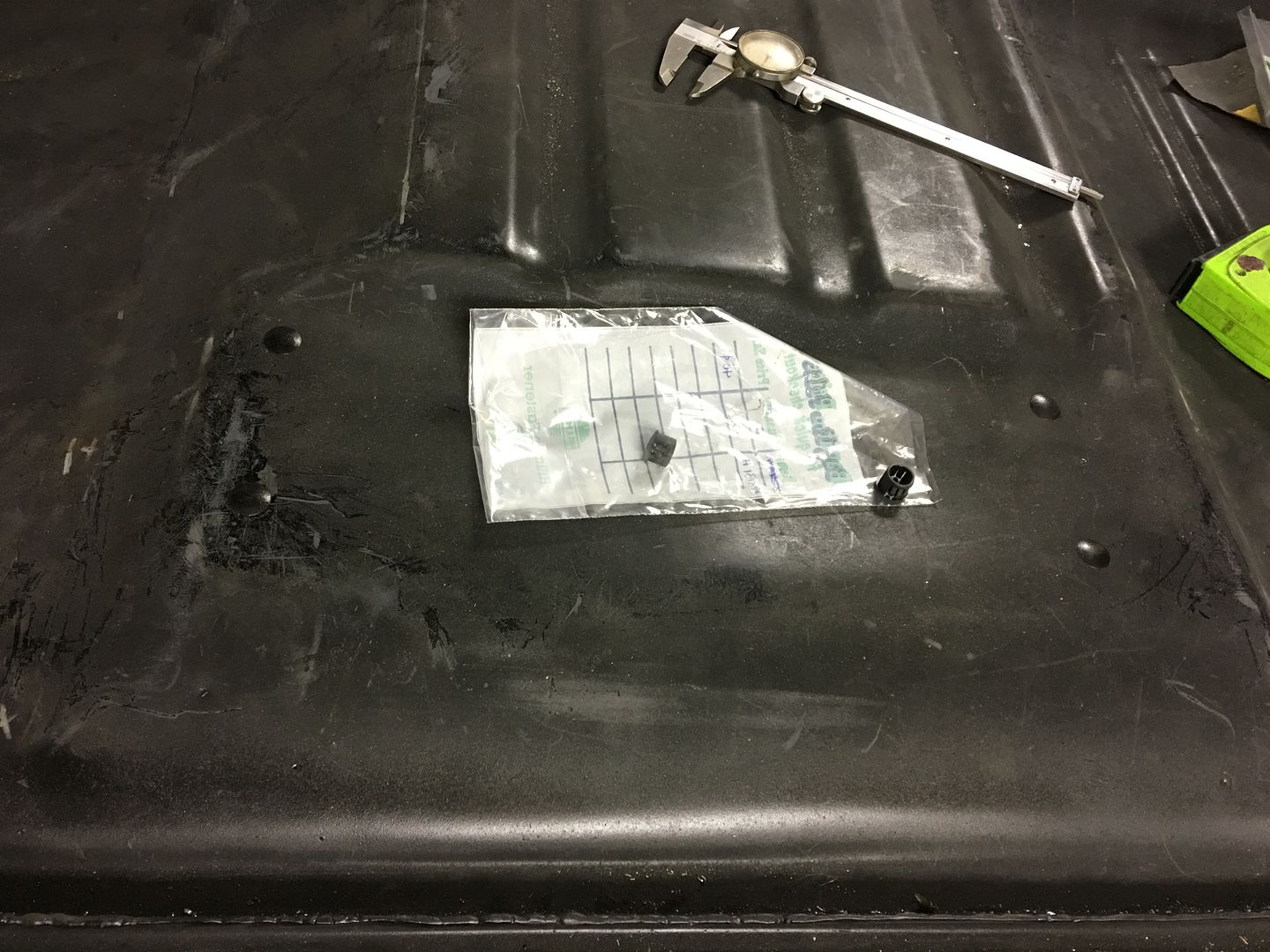

OEM seat bracket holes in the floor pans open to the inside of floor crossmembers. Rather than weld them closed and warp the floor pan, we opted for these fancy hole plugs.

SPI epoxy primer applied...

When it's 39* outside and the paint booth is sucking the heat out of the building, this is how you keep the temps up to a balmy 75* in the paint booth..

We'll let the seat brackets cure for a few days and then get started on plug welding them in place..

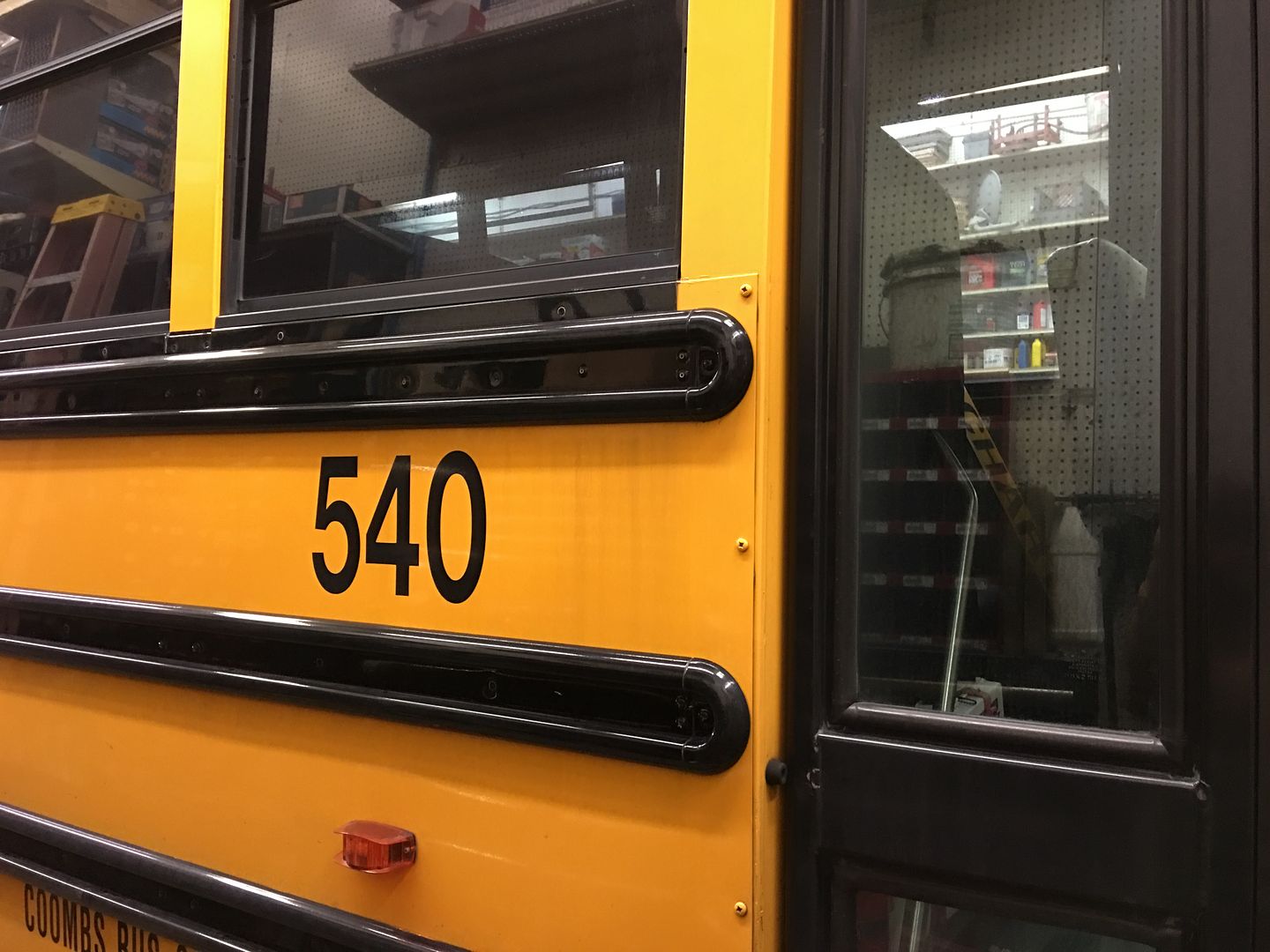

Stopped by to visit the next big yellow project...

Got the larger bits of the oak tree removed, still some vacuuming to do for the remaining splinters..

Looks like we have an electrical repair as well.. While we're fixing the Atlantic Ocean syndrome on the roof top, may as well clean up this rusty cover.....

After a bit of media blasting, I think we'll change course and get a new vent cover. Too much ventilation in this one..

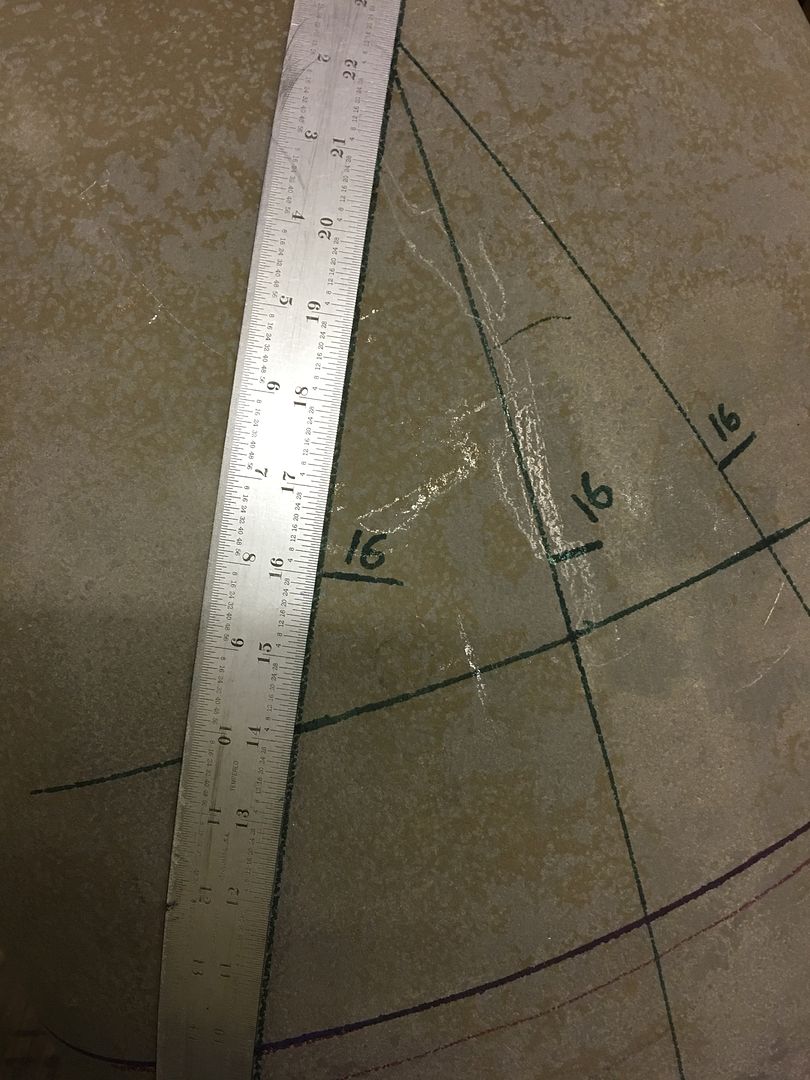

And let's not forget the Biederman.. Time to start the layout of fender repair number 2... Proposed horizontal cut line was added using our trusty Carpenter laser...

And some reference lines marked to locate the bottom edge after welding on the new patch..

....and a paper pattern used to get the size we need for our patch.

Robert

3390Likes

3390Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Looks Factory!!

1968 Plymouth Valiant 1st Gen HEMI