Thread: 1940 Ford Pickup

-

02-04-2014 05:31 AM #301

THANKS Randyr and Roger for the post. Its that kind of post that keeps me going in the right direction, THANKS again !

gordy

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

02-04-2014 07:07 AM #302

I've read this post a half dozen times and felt compelled to say "something".. but what???

First is your concern about some of your choices coming back to haunt you. Things like the tailpipes going under the axle vs. over is im-material in my opinion, as far as collecting condensate at the bottom of the "U" is no different than condensate collecting in front of the "U" when going over the axle... And using what's on hand is the key to hot rodding! "We" are the original recyclers! Being creative and finding uses for things that were never intended go hand in hand with rodders.

Take a step back, breathe deep and realize we all can't be Chip Foose and have a budget like they do. I for one think your doing great work and if I see something terribly un-safe, I know I and everyone here, will not hesitate to say so.

Sometimes our rods, like life, is a series of compromises... will the car ever be done? If you're like me? probably not.. I no sooner get a part of it completed and then am un-happy with something or see something I can "improve"... and there I go again.. my wife says I'm a consumate "tinker-er"..

But, if you're like me, don't let it get you down, use what's on-hand.. use your knowledge.. your doing great work and most of all... consider the replies that are given and decide what works best for you!

Stepping off the soapbox now... sorry for the rant.

-

02-04-2014 07:46 AM #303

Sooooooooooo-----------I take it that you don't know that the shocks are typicaly mounted on the front side of the axle leaning in and forward???????? this was to not dampen some of the side to side rolling action but to dampen the forward/upward rotating motion of the rear end housing under acceration with leaf springs------------

and when you say that you can raise the truck by the frame without the axle housing touching the pipes---is it hanging by the shocks????????

Post 287 pic of battery---have you considered putting a plate from the lower inside of frame rail over to the tube of the tubing in the center structure??? and then a thinner sheet around the front of that bend to shield the battery area?????????might be a lot simpler that trying to change gravity, earths rotation and global warming---------Last edited by jerry clayton; 02-04-2014 at 07:52 AM.

-

02-04-2014 09:19 AM #304

No I didn't know about the rotation , NOW I see !

No it's not hanging by the shocks, I was just saying that the pipes won't hit no matter how far the rear travels downward or upward for that matter.

Yes that was my 1st thought. In my 1st post on this subject I was wondering if that might be too much stiffening in the frame if I boxed the area for the battery, or perhaps welds would crack after a while from frame twist ? Thanks for the input.Last edited by Navy7797; 02-04-2014 at 09:22 AM.

-

02-04-2014 09:36 AM #305

Thanks for your kind words. I'm not to worried about the pipes rusting out at this point, the money has been spent and they can be fixed when they do. Now that I understand the reason for the shocks being mounted in the front of the axle is different an I'll have to take a good look at that. Yes it seems like I'm never going to get this ride done so every set back seems like a mountain and most likely is just a hill. Thanks for your input.

-

02-04-2014 10:24 AM #306

We all go through the same things on most any build unless it's something really common and you have a big checkbook, those folks just order up the stuff and it all bolts on!!!! Lots of things get done twice, or done once and then modified a bit---main thing to remember, if it was easy everyone would be doing it!!!!!!Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

02-04-2014 10:36 AM #307

Dave's right.. even on the biggest build by any pro, things will change during the build and that's why on the blueprints there's little spaces on the lower right for revision numbers. You can decide for yourself what needs the revision of course.. will the shocks work as installed? sure.. Is Jerry pointing out a better way? Sure, but at what cost and does it outweigh any change? Actually.. if you are going to "play" with shock mounts.. consider staggering. That is one side in front and the other in the rear. Helps to slow down axle wrap. But if your asking opinions, leave it for now is what I'd say. They'll still work, but not as efficient as either of the other choices.

And remember, we can help spend your money of course but it's still in your hands and you get the final say.

-

02-04-2014 10:44 AM #308

That type shock aren't dual action---they pretty much have so much compression/rebound-----when they went to staggered shocks( one forward/one back side of housing) it was pretty much after they went to coil springs, which didn't have the wrap up tendency---

On the exhaust dip collecting water/condensation---drill an 1/8 hole in the bottom of the bend like on the bottom of lots of oem mufflers---

And----------if you are going to change anything here, its this time to do it---not after all the smoothing and painting

and the cost of this change would pretty much just be a few hours of his time to turn those lower mount plates side to side andweld in another cross bar for the top mounts---and do that before cutting out the one that's there now--use it for rigidty while your working then remove if you want----Last edited by jerry clayton; 02-04-2014 at 10:48 AM.

-

02-04-2014 11:16 AM #309

"........ Is Jerry pointing out a better way? Sure, but at what cost and does it outweigh any change? Actually.. if you are going to "play" with shock mounts.. consider staggering. That is one side in front and the other in the rear. Helps to slow down axle wrap. But if your asking opinions, leave it for now is what I'd say. They'll still work, but not as efficient as either of the other choices......."

I absolutely agree, it's up to you of course but at this point if you are happy with what you have I'd probably leave it until you actually get the truck to the point that it can be driven. As the posts by 34-40 and Jerry point out there have been different approaches and thoughts to shock location over the years. One of the reason for this is is that there is not really a one size fits all ........what may be optimum on one vehicle my be either too much or too little on another based on size, weight, horse power and space limitations.

When I finally get back to my 37 Dodge (something I've been procrastinating on) my next step will be to hang the rear end and redo the springs. My thinking right now is modifying the spring pack I'll be using to a Mopar "super stock" type style, staggered shocks and Cal-Track type bars. Will it all fit the way I envision it, possibly but I won't know till I start building stuff. Will it be enough hook up and go straight.......I think it will but I won't know until the truck goes down the road. If it doesn't I'll try something else. Would I use this if I was building a truck like yours......probably not based on the differences of our drive trains vehicle weight differences.

As I said it all basically boils down to the individual vehicle and how it's used and what you have on hand.......sometimes good enough is more than adequate.

.Last edited by Mike P; 02-04-2014 at 03:41 PM.

I've NEVER seen a car come from the factory that couldn't be improved.....

-

02-04-2014 06:29 PM #310

-

02-04-2014 06:34 PM #311

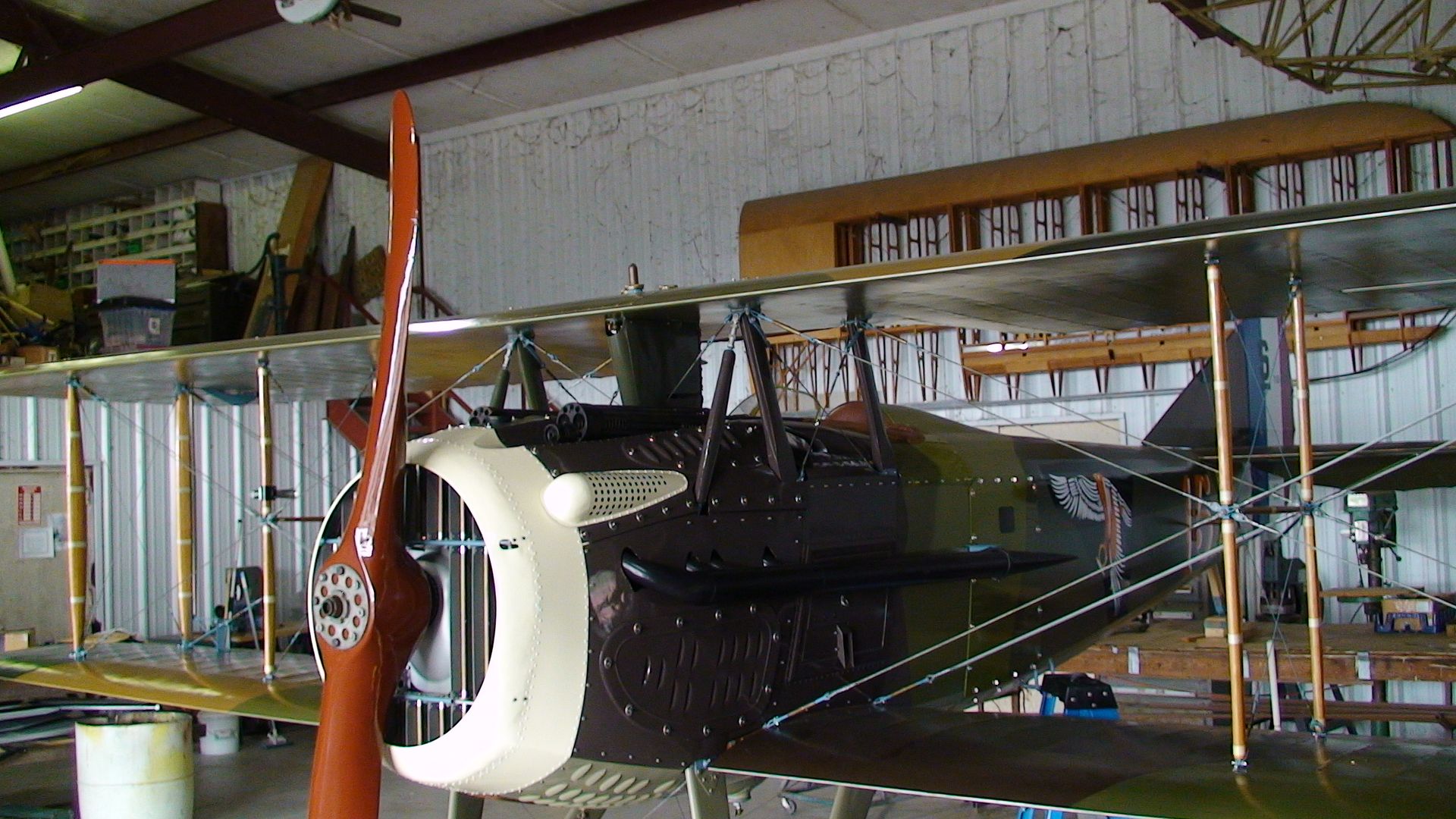

now we 're getting somewhere-------did I ever tell you guys I used to fly airplanes????even tail draggers

-

02-04-2014 06:36 PM #312

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

Very awesome airplane build!!!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

02-04-2014 06:41 PM #313

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

02-04-2014 06:44 PM #314

do you know when they started using them staggered???

-

02-04-2014 06:46 PM #315

New cross member

Ok I'm looking at a new shock cross member. Here's some material that I have on hand. The 2.5 x 2.5 seems like over kill for sure. The 1.5 x 1.5 x .125" might be to weak for the 40" span ? What do you guys think ? Maybe I should just go buy a new 2 x 3" as is the 1st one I made ?

What do you think ? THANKS FOR YOUR INPUTS !

815Likes

815Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Many of the long tube cast headers I've run across had a relief ground on the back side for starter bolt clearance. I just trimmed the bolt on mine. On these new shorty's, they eliminated the...

55 Wagon Progress