Thread: 1931 Model A Coupe

-

01-26-2015 06:54 AM #16

Gotta love it!Your Uncle Bob, Senior Geezer Curmudgeon

It's much easier to promise someone a "free" ride on the wagon than to urge them to pull it.

Luck occurs when preparation and opportunity converge.

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

01-26-2015 07:46 AM #17

Much patience, big skills, many hours!!!

Did you use all - original wood, or did you have to replace any?

As said earlier, thanks for sharing!

-

01-26-2015 07:55 AM #18

Thanks so much for the kind words guys! This is going to be my last full build, and I'm in no hurry to get it done.

[IMG] [/IMG]

[/IMG]

This shows the "good" firewall in for body integrity. I repaired the body edges

where the firewall attaches, and filled all the old spot weld holes. I wanted it

removable so I used 1/4" 20 nuts spaced like the ones across the top to attach

to the car. I have plans for this area in the future.

Rich

-

01-26-2015 08:02 AM #19

Amazing process! Great to see one being saved that was pretty far gone!Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

01-26-2015 08:08 AM #20

t-top havoc, I replace all the wood with new except for the lower door jam

piece. The upper piece by the quarter window I replaced so I could weld

inside when I chopped the top.

[IMG] [/IMG]

[/IMG]

In the previous pic everything looked O.K., but the roof panels did not fit right.

A close look will show the body is now sitting on the frame, and the frame is clamped to the jig. This is many weeks later after repairing the front mounts by the lower cowl, and fitting all the wood blocks for the rest of the body mounts. The visor does not fit well, and is very flimsy.

Rich

-

01-26-2015 08:18 AM #21

[IMG] [/IMG]

[/IMG]

I wanted to add some support to the visor (they start to flutter at 120mph) so I made up a piece of 16 ga to fit against the upper windshield panel. There are 1/4" 20 nuts

welded to the backside, and the wood is relieved so it lays flat.

[IMG] [/IMG]

[/IMG]

Heres the finished support which is not visible when the car is at ride height.

Rich

-

01-26-2015 08:28 AM #22

[IMG] [/IMG]

[/IMG]

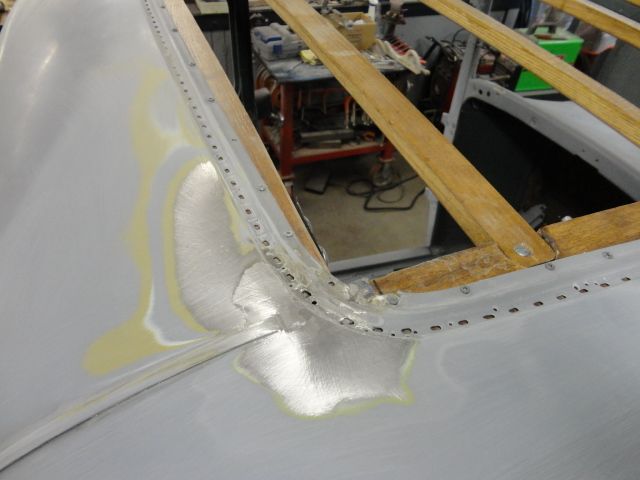

I have had the wood in, and out of the car many, many times sanding shaping

trying to make things fit right! I have finally commited to welding the visor to the top.

There are steps in the panels where they meet the visor which I hammered flat, and slit the top to make them meet correctly.

[IMG] [/IMG]

[/IMG]

Here I have ground everything down, but cannot get to the backside to metal finish.

I have a cure for that.

Rich

-

01-26-2015 08:36 AM #23

-

01-26-2015 08:42 AM #24

-

01-26-2015 08:47 AM #25

-

01-26-2015 08:52 AM #26

-

01-26-2015 08:58 AM #27

-

01-26-2015 10:06 AM #28

Leave the headliner out, that's pretty.

Slinging lead, now that's old school..

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

01-26-2015 06:06 PM #29

-

01-26-2015 06:13 PM #30

[IMG] [/IMG]

[/IMG]

Started replacing the rear panels, none of the reveal would line up with the originals so

I replaced a bigger piece than I had planned on. I wrapped the bottom edge around

the sub frame like the originals.

[IMG] [/IMG]

[/IMG]

Here I'm beating the snot out of the patch panel to make the reveal line match

the one on the car.

516Likes

516Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

This website will not be worth anything until if becones SECURE!

Not Secure