Thread: Tools of the Month Club

-

02-29-2012 10:44 AM #61

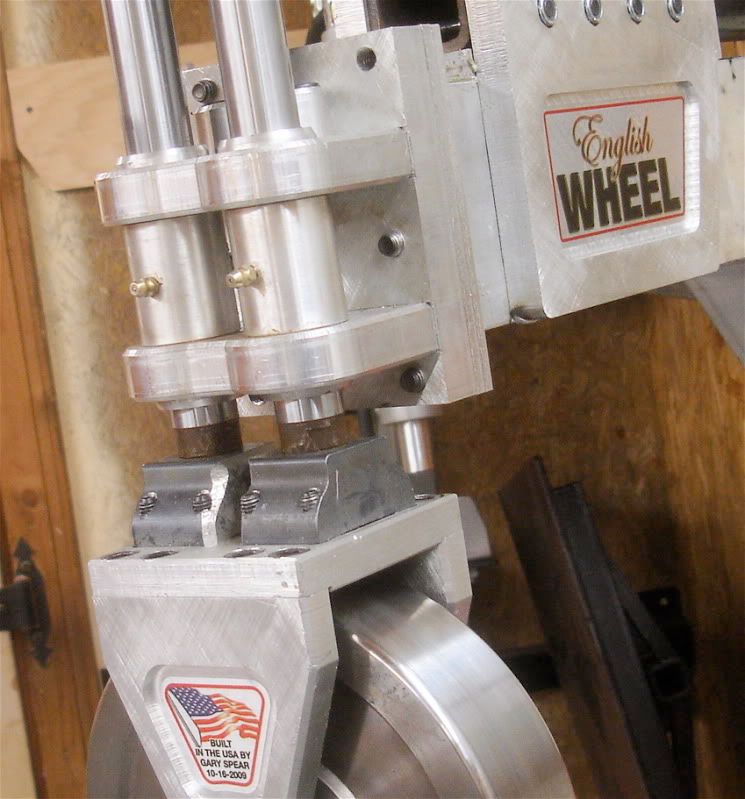

American made English wheel. They aren't produced any more.

"PLAN" your life like you will live to 120.

"LIVE" your life like you could die tomorrow.

John 3:16

>>>>>>

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

02-29-2012 11:26 AM #62

-

02-29-2012 02:30 PM #63

English Wheel----I've seen some amazing stuff come off one of them Never tried one but would not hesatate if the oppertunity came alongCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

02-29-2012 04:18 PM #64

Thats gotta be the most amazing creation I've seen..Its beautiful...Micah 6:8

If we aren't supposed to have midnight snacks,,,WHY is there a light in the refrigerator???

Robin.

-

03-01-2012 12:05 PM #65

Stevie inspired me with his comment about rusty bolt removal, so this may be more than just "a" tool, rather a group of tools for similar situations.

In the attached picture on the right is the age old favorite that almost all of us have: the cold chisel and a bfh. I've seen newer chisels that have a handle on them I guess intended to protect the hand from a misaimed hammer blow, but I still have the old fashioned kind.

At the bottom of the picture is a nut splitter. Basically a chisel point and a screw to tighten it through the nut. These come in handy when there isn't room to swing the hammer or line up the chisel. You need enough room to fit it over the nut and to be able to get a wrench over the screw portion so it too has limitations.

Upper center is a 'bolt out", useful for bolt heads that have been rounded off. These have a spiral tooth configuration inside that is intended to bite into the rounded head so that you can turn the bolt out.

The other day I had to take a Model A trans off it's bell housing. One of the bolts had a rounded head and none of the above bolt outs was large enough to fit over the head. So I dug out the Blair Rotabroach kit on the left side of the picture. These are more intended for making nice, round holes in sheet metal, but the cutting heads are very tough and sharp, and with the use of a good cutting oil will cut a bolt head fairly easily. Just drill down slow and straight. I chose the cutter size to match the bolt shank, center punched the head, and basically machined away the head around the shank, then got the stud wrench and backed out the remaining portion of the bolt.

If you haven't used these rotabroaches they're a real delight for clean holes in sheet stock. And the smaller ones work for drilling out spot welds as well.Your Uncle Bob, Senior Geezer Curmudgeon

It's much easier to promise someone a "free" ride on the wagon than to urge them to pull it.

Luck occurs when preparation and opportunity converge.

-

03-01-2012 02:17 PM #66

Uncle Bob you left out the most important tool of all when working on this rusted STUFFCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

03-01-2012 02:26 PM #67

Yeah Charlie, I thought about adding the plasma cutter to the mix as well....................but that might have seemed ostentatious.

Your Uncle Bob, Senior Geezer Curmudgeon

It's much easier to promise someone a "free" ride on the wagon than to urge them to pull it.

Luck occurs when preparation and opportunity converge.

-

03-01-2012 02:28 PM #68

You know you can scarf with a plasma cutter if you take your timeCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

03-09-2012 06:09 AM #69

Here’s one for you guys. Ever try to get one of those quart squeeze bottles up in the transmission tunnel to top off the old 4 speed or rear end. Ever try to fill up a differential with the little pump that comes on the gallon jugs of gear lube.

This makes life a whole bunch easier. It’s called a suction or siphon

gun and is used for transferring fluids. There are a couple of ways to fill it, either stick the tube in the gear oil bottle and pull the handle back, or as I prefer, just pull the handle back, unscrew the end cap and pour the gear oil in and screw the cap back on. It holds about a pint, and really makes life easier (and cleaner), especially if you’re working on a car on jack stands.

Oil Suction Gun - Save on this Suction Gun at Harbor Freight

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

03-09-2012 06:23 AM #70

I keep a few of those conical bottle tops hanging around, slide on a piece of 3/8" tubing. Squeeze it in..

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

03-09-2012 06:33 AM #71

Many years ago Fram used to give the the suction guns out to garages as a bonus for using their products - my last one finally died at about age 50 a couple years ago when the flexible snout broke off. These were used for the old bypass oil filters that were on many American cars though the '60s, at least on the 6 cyl engines. Next time I'm in Harbor Fright, gotta look at a replacementDave W

I am now gone from this forum for now - finally have pulled the plug

-

03-09-2012 10:05 AM #72

-

03-09-2012 12:13 PM #73

Well since we'er diging up old tools ....How many of you remember these. Found this at an antique store and just couldn't leave without it. Used one like it MANY years agoCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

03-09-2012 02:16 PM #74

-

03-09-2012 02:33 PM #75

20Likes

20Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Yep. And I seem to move 1 thing and it displaces something else with 1/2 of that landing on the workbench and then I forgot where I was going with this other thing and I'll see something else that...

1968 Plymouth Valiant 1st Gen HEMI