Thread: Hidden Costs

-

11-28-2012 04:39 AM #16

Dave S put it very well.

I think we have been way oversold on what we “need” in our hobby shops in large part by what we have seen on TV.

I’d never even knew what an English Wheel was until I saw Jessie James using one on his first TV special what 15-20 years ago, and now everybody feels they need one in their home shop!!!???? Pretty much the same way with TIG welders, bead rollers, tubing benders, shears, planishing hammers and on and on.

I’m not saying that stuff wouldn’t be neat to have and play with, but is it really necessary in a non-production shop? I remember doing the patch panel to fill the spare tire well on my 37 Dodge. My first thought of course was I HAD to find someone with an English wheel. When that didn’t pan out, I ended up doing what I would have done had I never heard of an English wheel, cut a panel out of an old fender and welding it in with my MIG (and frankly I would have gas welded in if I didn’t have a MIG).

Filled primed and painted is anybody going to know that the fender didn’t come that way or care what tools were used to get it there?

And that is minor stuff compared to what guys like Dave, Falcon, Charlie and other are doing without all the stuff the Saturday TV shows (glorified infomercials) say we HAVE to have.

I’m just saying, slow down and look at what you need to do then figure out what you REALLY need to do it.Last edited by Mike P; 11-28-2012 at 05:56 AM.

I've NEVER seen a car come from the factory that couldn't be improved.....

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

11-28-2012 05:20 AM #17

Charlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

11-28-2012 05:38 AM #18

Like Mike says, this new TV approach showing tools we never dreamed existed seems to have everyone scrambling to buy, buy, buy, and the knock off artists have flooded the market with cheap copies of everything made. I'd venture a guess that if you walked into Jesse James shop and challenged him to do the same job without the English wheel he would simply pick up the old hand tools and do it another way, saying something like, "Well, you know it's going to take a little longer this way...." I don't like the guy as a person, but one cannot argue that he's a craftsman who has learned by watching and absorbing from older craftsmen. The point is it's easy to sit back and get into the spiral of depression by thinking, "If only I had those tools, I could do that, too!", when the fact is that the tools are generally only time savers and it's a God given talent that gets the work done, along with a strong dose of what Granny called "gumption".Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

11-28-2012 06:00 AM #19

at my first job i still remember beatinng out a tin roll pan over a telephone pole for a corvair and used a gas welder no one was using a mig at that time i knew of .we many times brazed every thing then cleaned the hell out of it the cap over it with lead still some spots are done on my car this way 30 years ago for wheel lips i would used welding rod to make the form take small chuck of metal and beat in shap then weld around till you ended up with a weel lip patch work quilt .i would get out in the middle of a fender with a gas torch have many damp rags on hand to help keep it from all it warping to hell thats the way i only knew how to do it many did it the same way. i did use steel filler rod did some hammer welding .did not start wire welding till the early mild 80s most shops hand them some still used gas mig was a better out come as you could hit at run it get on the panel and off to tack it and weld it ..with gas /ox welding that was not the case

that was not the case

Last edited by pat mccarthy; 11-28-2012 at 06:25 AM.

Irish Diplomacy ..the ability to tell someone to go to Hell ,,So that they will look forward to to the trip

-

11-28-2012 07:31 AM #20

ive done all sorts of things i didnt know i couldnt do because i didnt have the $1000 tool to do it.a hot rod is whatever i decide it is.

-

11-28-2012 07:36 AM #21

I don't have cable so the only time I have been exposed to Jessie James was times I spent while I was in the hospital.I agree he is a craftsman from what little I have seen and remember.

I am a occasional reader/member of both Allmetalshaping and Meetmetal web sites.Kerry Pinkerton and Dutch Comstock have both told me to start with a buck or sand bag and shaping hammers.In fact Dutch's shop is about 2 to 3 hrs away from me and they have a annual meet for a wkend of teaching and metal shaping.Recently Dutch posted I have a open invite to come to the shop when I want to and to just call ahead.

The two web sites impress me in that is a whole another topic like this one where there are hobbyists who invest in equipment like we do in project cars because their sole interest is metal shaping.On those sites is knowledge levels of various topics in metal shaping like there is here.It is the same as it is here,but my point is it is a topic all onto it's self.And that is huge in the scope of the amount needed to be learned.

I do think I have a feel for making shapes.I do think I can look at a pc of metal and figure out how I what to make it.I've done it before when replacing the floor boards in back haft'ing a Monza town coupe.All the tin work in the race cars I had apart in too,but as I said that shop has thirty yrs of a build-up of equipment in it.In either case at the time I was surrounded by a much better equipment situation.

Pat said am I looking to do jobs to get paid for in metal work??. Well I can't answer that right now. I guess it does depend on how good I really am and what develops over time.I too have some fibro and other physical limitations.

I have been keeping a eye out for a tree stump for the shop for awhile,but haven't found one yet.I do think the basic tools of a decent 220 gas shielded mig,cutting torches and tanks I own,mallets and dolly,sand bag,air DA sander are the minimum.The mig can range from $800 to $1,000 used and the torches and tanks another $500.A Tig isn't in play because I will never have a water source in the shop I rent.I am on Craigslist multi times every day looking for deals.I do know the weld shop here that sells Miller's has a school they run and at the end they discount the welders they used for a price range from $850 to $1250.I do have a limited number of body hammers(very limited). I want to collect various shapes of things like telephone pole pcs,tanks,pipes of various sizes,as I can find them laying around.I did start awhile ago the process of building up some equipment in I bought a Dewalt chop saw used,a horizontal band-saw,110 plasma cutter which is in for repair.I have a 4 1/2" grinder/cut-off, 8" grinder/cut off,new B & D jig saw.But then I let that taper off and haven gotten anything more.

I just got the catalog yesterday from Trick Tools and they are supposed have some really good metal work hammers.I need to look at that closer.

I guess I am trying to lay this out as honestly as I can.The E-wheel idea comes from the cost of the HF model and what can be done to strengthen it and how the wheels could be corrected with some machine work.The out of round as I am told can't exceed .0004.And guys are telling me the true radius wheels are very workable.I does look like alot needs to be learned about how to use a E-wheel.I read a thread about the 4 patterns to follow.

-

11-28-2012 09:05 AM #22

After having cars with body work done by guys like Ken Ellis, Tom Hanna, Nye Frank and Quin Epperly there is no way I could get away with doing that English Wheel stuff myself----I consider myself extremely fortunate to have even been around them , and to be able to get them to do something different than there trademark stuff for me constantly makes me wonder what if????????????????

-

11-28-2012 09:21 AM #23

Although I haven't welded in awhile,I learned mig welding from a cert welder that welded overhead cranes that was a neighbor near my old shop and from friends that worked at Troyer Engineering.Do I wish I had gone to a welding school??. I sure do.Everyone that had been around me told me you got to know your metals to weld well.

-

11-28-2012 10:31 AM #24

Looking for a stump????most are anchored to the groung by roots. Pipes and other things you mentioned are accuired by craftsman with a need. Why would you want all that stuff lying around and no need for it..You mentioned going to school or taking class for welding.Good for you quit talking about it and do it. If you don't know how to use a tool how do you know what it will do for you..If I were you I'd go to a junk yard any junk yard BUY a wrecked fender or hood bring it back to your place and figure out how to fix it. That is exactly How I and I'd bet most guys learned how to fix bent metal...Once you can fix one then you should be able to bend one the way you want it...I'll give you some info I din't learn till I had been doing this for some time..When fixing a busted fender door hood ..look at it then look again..Figure out what happened first then what happened last...After that start fixing the last part first then it will get easier as you go. NOW theres your first body work lesson. You don't need a great aray of fancy tools to work with metal. I didn't do this but I know a guy who has a 68 Cougar xr7 or somthing Very nice car VERY NICE. when he started he had a claw hammer and screw drivers a hand full of busted and rusted wrenches. He used chisels and punches to take two cars and make one when he needed welding done he loaded it up on a trailer took it somewhere and had it done. when it was time for interior same thing paint same thing. The tools he owns wouldn't fill a Walmart shopping bag. The thing is HE did it with out any fancy tools and it got done just the same. I think its called DISIRE. Quit looking for excuses why you can't do a job and go out and do it. SORRY but you just piss me off with all your crying about not having tools when you don't have a clue how to use them.Charlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

11-28-2012 12:17 PM #25

I think that I'm seeing things being looked at in 2 different views---Charlie is talking about straigtening bent up cars, and Gary and I are looking at taking flat stock and building something out of it----------I did body work late 50s to middle 60s, since then its been fabricating things from flat stock, I've seen more one off things done with shot bag and leather hammer, while the nascar (many parts to templets) done with english wheels-----

-

11-28-2012 12:46 PM #26

Jerry, I think what Charlie is suggesting is to get an old bent fender or hood, and take it back and work out the damage to learn how metal moves. The skills of moving the metal back where it was are the same skills needed to mold the metal from flat to smooth bends by stretching & shrinking with small movements over wide areas, or at least that's how I read his message.Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

11-28-2012 12:53 PM #27

No I figured he wanted to make a panel for the floor of his van or what ever it is hes working on. You don't need an english wheel for that. A bag a hammer maybe a brake?? I don't know BUT you don't need $20,000 worth of tools to make a floor pan. The way I see it and I may be wrong...If you can fix a bent fender you should be able to fab a part and I don't mean a Desoto fender.. You did body work first THAT is a great base for fab work as you learn how metal reacts to different ways of forming it. I had an instructor give me a gas tank from a motorcycle that was well banged up...He said fix it. I did I thougfht I did a good job. When I showed it to him he pointed out my (lots) flaws.. THEN took a ball peen hammer hit it a few times and said fix it. When he got it back it was perfect. I haven't ever made a quarter panel but have hung a bunch. I 'v made floor pans firewalls inner fenders tubs . I just think both crafts run together if I'm wrong shame on me.Charlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

11-28-2012 02:37 PM #28

-

11-28-2012 02:50 PM #29

You're not wrong, Charlie. You learn fabrication by doing it, not by sitting around talking about it and moaning about could-of, should-of, would-of about schools, seminars, etc that you didn't attend!!!! Not having a lot of fancy tools and shop equipment is just an excuse, not a reason to not accomplish anything! My guess would be it was another day of playing on the internet and absolutely nothing got done about making a simple patch panel for the floor!Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

11-28-2012 02:53 PM #30

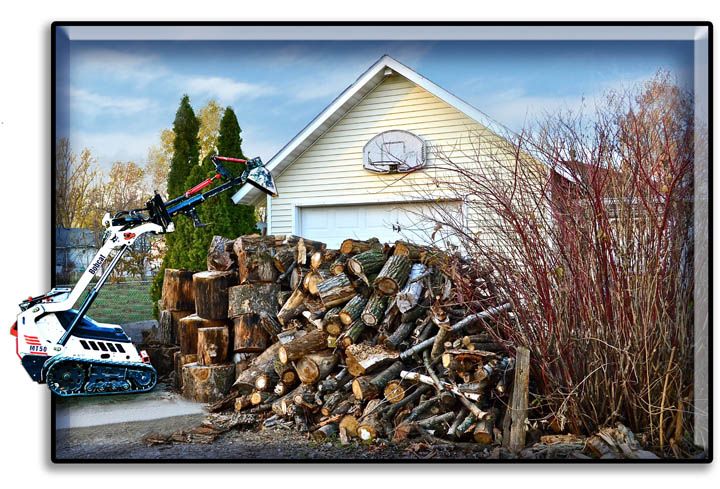

Did somebody say they needed a stump???

"PLAN" your life like you will live to 120.

"LIVE" your life like you could die tomorrow.

John 3:16

>>>>>>

46Likes

46Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Saw this posted on FB, and thought of posting it on the Joke Page as a Model A Donk, but then thought it's not a joke, it's cool!! -

Montana Mail Runner