Thread: Hidden Costs

Hybrid View

-

11-28-2012 02:53 PM #1

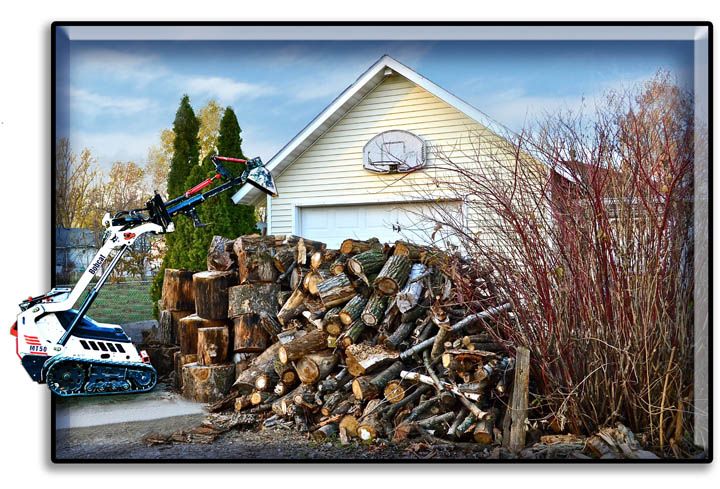

Did somebody say they needed a stump???

"PLAN" your life like you will live to 120.

"LIVE" your life like you could die tomorrow.

John 3:16

>>>>>>

-

11-28-2012 03:59 PM #2

The camera I use now is a Canon EOS 50D with a 28-135 lens

Parked are 4 or 5 Minoltas and a Haselblad----

-

11-28-2012 04:14 PM #3

Yea', I've been infected too. It's sad really........

It's sad really........

"PLAN" your life like you will live to 120.

"LIVE" your life like you could die tomorrow.

John 3:16

>>>>>>

-

11-28-2012 04:14 PM #4

I used to have a Pentax, great camera, I spent way too much on it. but it gave up after about fifteen years.

Anyway, I want some of the cool tools too. Mostly because my time seems more valuable then it used to be. I tore my back up in this last stint in the infantry, so marathon efforts in the shop are less appealing too. I used to think nothing of four hours of turning wrenches after a ten hour work day. Now, not so much. My little Campfield Housend flux core mig does the job, but I'm definitely going to spring on a decent gas mig, if for no reason than to speed up the job and save my back..

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

11-28-2012 05:14 PM #5

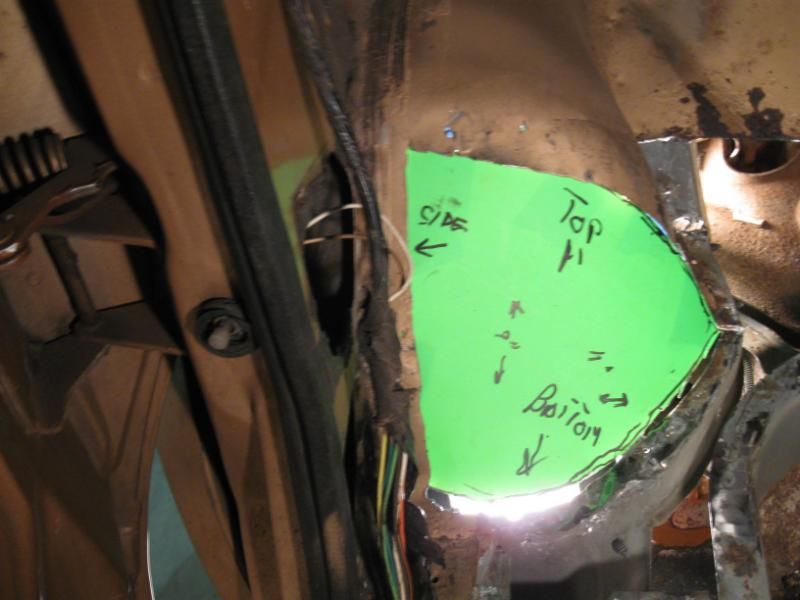

As I was working on the patch for the wheel well I found I didn't have a single pc of round stock in the whole shop.The only thing was a semi flat tire which of course bonce on every hit.I'm close to the final cut size of the floor board it's self.That isn't a problem with only one brake bend in it.

The issue is the wheel well patch that has multi angles in the bent.I has to end up beening a invisible repair.

I do have other medal working projects in the van in other areas,the trailers,and the RV.So I have been working on the van.I just reached apart of it that made me realize what I don't have to work with.That is after I went through a period of buying used a horizontal band saw,Dewalt metal chop saw,B & D jig saw,some minor body hammers.

That is the third construction paper template which is getting closer to the size and shape I want for the wheel well patch.

-

11-28-2012 05:38 PM #6

bent alot of stuff over my knee alot of time on floors i would get it to a close shape tack weld it in the corner of old floor then work it tack weld .work it more with a hammer weld up .Irish Diplomacy ..the ability to tell someone to go to Hell ,,So that they will look forward to to the trip

-

11-28-2012 07:56 PM #7

I have some cut off panels that I am not planning to use on this van.So I did cut out one test pc to see what I could do with it.I think I found out it is 19 gauge.It does bent,but not that easy.The floor is I think 19 gauge.I have in stock a 4' x 4' sheet of new 18 gauge.

Well the "test pc" didn't come anywhere near what I wanted.I mean I made me realize I didn't have even the basics to work with. So it made me think of only $299 cost of a HF E-Wheel and I started to investigate what it would take to make one of those useable.Super smooth curves.And yes,I obsess over perfection.

To answer the question about me wine'ing.I look at body/medal working like this.If a manufacture can build it,I can too.Last edited by 1gary; 11-28-2012 at 08:36 PM.

-

11-28-2012 11:56 PM #8

I want to thank everyone who has posted to this thread.Please keep it coming.

-

12-05-2012 05:00 PM #9

Just remembered some of my earliest auto body work. Nothin more than a 4" angle grinder, acetylene torch, and hammer. Beat it close, tack it, heat it cherry red, massage it to shape. I once cut the corner out of a valve cover to patch a running board. Wish I had that energy still.

Ok, my edition to the hidden costs thread:

Just what does it take to build a box out of 3/4" ply?

Actually, it's a kitchen cabinet, so I'm trying to keep dimensions +/- 1/64".

My efforts produced a parallelogram. It's out of square 1/8". Oh well. On to the hidden cost!

3/4 horse skillsaw $75

Cheap tablesaw $150

Two carbide blades $50

Router, $75 (used)

Small carbide bit set $30

DeWalt 18V drill $250

Tri square $12

Carpenter square $15

Lots more odds and ends which easily add up to another hundred.

Over $700 to build a bloody box..

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

12-05-2012 08:11 PM #10

You missed the cost of building the trailer to go fetch that sheet of ply...and the running expenses of car and trailer...and the cost of power to run the router/drill/skilsaw...

It's a hopeless task trying to quantify the cost of the equipment in a workshop...for insurance purposes the contents of my shed is in the vicinity of NZ $100,000...that's about what it would cost me to replace it all.

But I'd be 'out-of-pocket' by about the sum of NZ $10,000...if that.

All my tools and equipment have been acquired over the last fifty years at bargain prices, some of it even pulled out of the local dump and rebuilt when spoon-fed and a##e-wiped locals threw it away.

Some of my wood-working hand-tools were my Grand-dad's, handed on to me: no charge; but totally irreplacable.

You just can't buy that quality any more.

I've even got a drop-leaf work-table built by my Great-uncle Johnnie when he was an apprentice...and he was in his seventies when I knew him when I was a teenager.

Gary...if you need an English wheel badly enough you'll justify it.

You can't take your money with you; there's no pockets in a shroud!

Just do it.

.johnboy

Mountain man. (Retired.)

Some mistakes are too much fun to be made only once.

I don't know everything about anything, and I don't know anything about lots of things.

'47 Ford sedan. 350 -- 350, Jaguar irs + ifs.

'49 Morris Minor. Datsun 1500cc, 5sp manual, Marina front axle, Nissan rear axle.

'51 Ford school bus. Chev 400 ci Vortec 5 sp manual + Gearvendors 2sp, 2000 Chev lwb dually chassis and axles.

'64 A.C. Cobra replica. Ford 429, C6 auto, Torana ifs, Jaguar irs.

-

12-05-2012 09:15 PM #11

Yeah,I do think it would be a good addition to my shop having a E-Wheel.I'm thinking after the first of the yr,I'm going to visit Dutch Comstock a master medal worker to try out his E-Wheel and get some tips from him.He is about 2 1/2 hrs away,but he has extended a open invite.One of the corner stone members of Allmetalshaping web site.

-

12-06-2012 07:18 AM #12

Hidden costs???? well, over the years I got lots of stuff to do engine work because couldn't get it done right, on time------

But, one of the biggest tools I got, was a Hunter Aliignment rack set up which I used form frame fab work where I could check out all the suspension travel and specs as I built things------------

-

12-06-2012 09:45 AM #13

Posted this once before.Been tire kicking on a used two poster lift shopping on Craigslist.Pricing ranging from $500 to $2500.Got the landlord to agree to allow me to install it.Well really I would get a company that does installs to put it in.No way I would do that.I want to be sure it has the proper base for safety reasons.Been told it has to have a minimum of a 6" concrete base and I'm not sure how thick the floor is in the shop.They might have to cut the floor,jack hammer it out and pour a re-bar'ed(sp?) base by where the base of the two posts would be.

I think with a lift,it would be a positive game changer in that shop of the kind of jobs I would be willing to take on.

-

12-06-2012 12:23 PM #14

''cut the floor,jack hammer it out and pour a re-bar'ed'' ............. count on it.I have two brains, one is lost and the other is out looking for it

-

12-06-2012 01:45 PM #15

4 post lift dosen't require all that expence and is just as versital as a 2 post...I have owned and used both. It realy depends on how you work.Charlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

46Likes

46Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Several years ago we did quite a good trip of USA, and on our trip we got to meet Mike and Christine Frade. We didn't stay long with them, but in that relatively short time we both gained a great...

We Lost a Good One