Results 1 to 9 of 9

Threaded View

-

09-27-2008 04:08 PM #1

Reverse Engineering-New Tech for Old School Rides

We're building a model of a tranny tunnel to pull a fiberglass mold from.

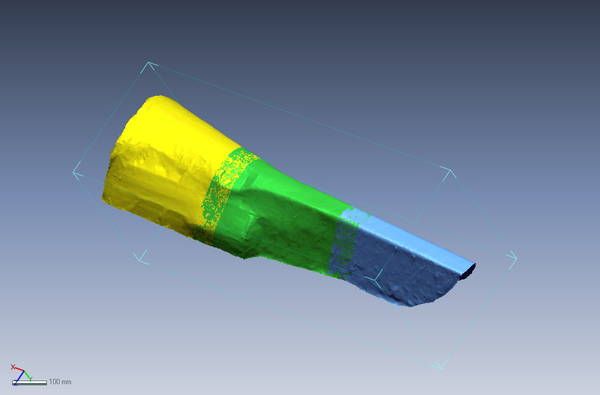

Here is a mock up of the tunnel that has been prepped for 3-D scanning.

The blue covering is painters tape, we used it to reduce reflections and make it easier to remove the reflective reference dots after scanning.

A 3 head 3-D portable laser scanner was used for scanning.

The dots are placed (semi randomly) on the surface to be scanned. The 3-D laser scanning camera uses these dots to create a "World" by recording the position of the dots. A "Point Cloud " can then be achieved by triangulating the recorded positons using proprietary scanning software..

From there the point cloud can be reformulated for solid modeling via RapidForm software.

Also design changes can be incorporated at this point.

You can see where two steel rods were afixed to the top of the tunnel.

The designer wanted to raise the top surface of the tunnel to the level of the steel rods.

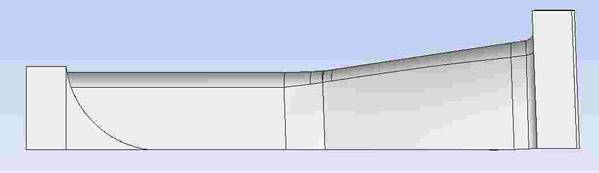

Here are the completed changes.

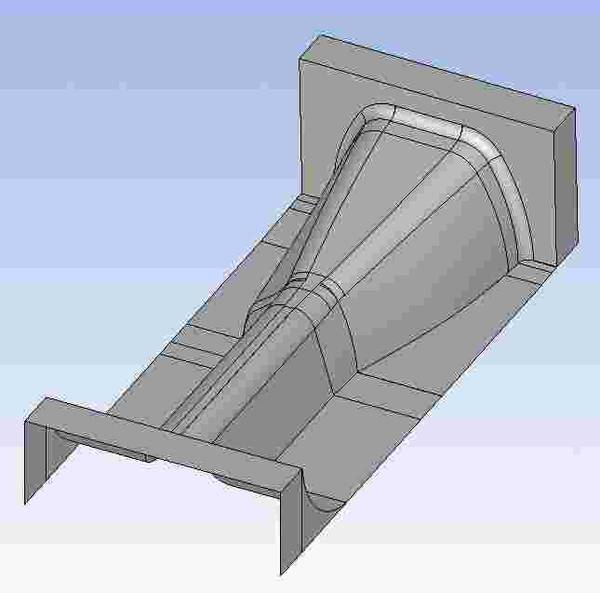

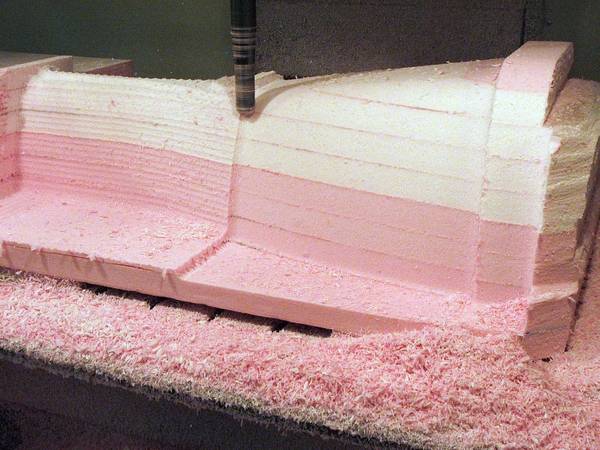

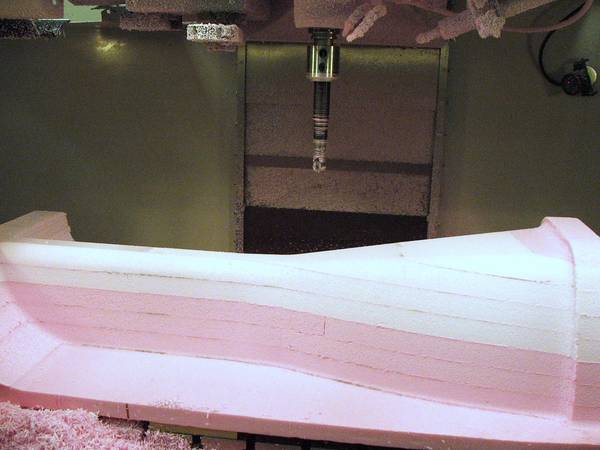

Once the model meets the design criteria, the RapidForm file is exported to a CAM package, In our case either MasterCam or Cimatron where toolpaths will be formulated and written into G-Code then downloaded to a CNC Mill.

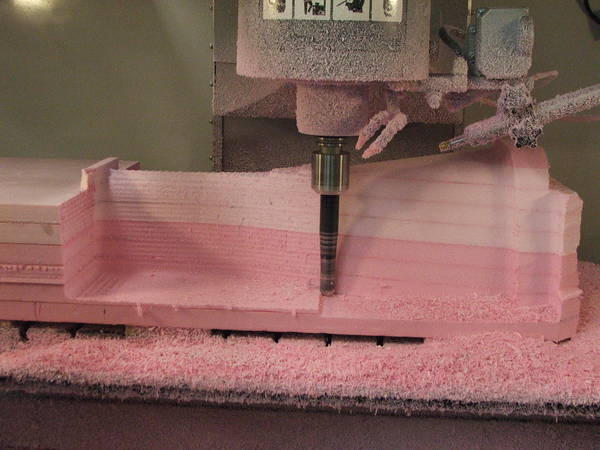

The part is then cut.

We used 1.5" thick home insulating foam cut into 24"X 56" rectangles laminated together to give us the proper size blank.

A 1.25" Ball Nosed carbide indexable cutter was used for "whittlin".

Here is the final outcome of the machining process.

Last edited by Supa Roosta; 09-27-2008 at 04:28 PM.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

I did not know Mike very well, we exchanged some messages from time to time but from what I understand he was a very good man. I was sad to learn about this

We Lost a Good One