Thread: The Roofus Special

Hybrid View

-

01-03-2010 04:11 PM #1

Since I pushed the wheelbase out to 109", I'm thinking about moving the motor forward and gaining some gas pedal room. (engine was moved back when I was shooting for 100" wheelbase).

What's cooler...foot room or the idea of engine set-back?There are two things in life where penetration is really important.....and one of them is welding.

-

01-04-2010 04:40 PM #2

I went looking through my early pics....when I did my original mock-up. My feet were completely behind the bell housing. Now they are beside the bell housing.

I lost a lot of foot room with the engine set back.

Looks like I need to try sliding the engine way the hell forward again and see how things look.There are two things in life where penetration is really important.....and one of them is welding.

-

01-05-2010 04:33 AM #3

-

01-30-2010 07:59 AM #4

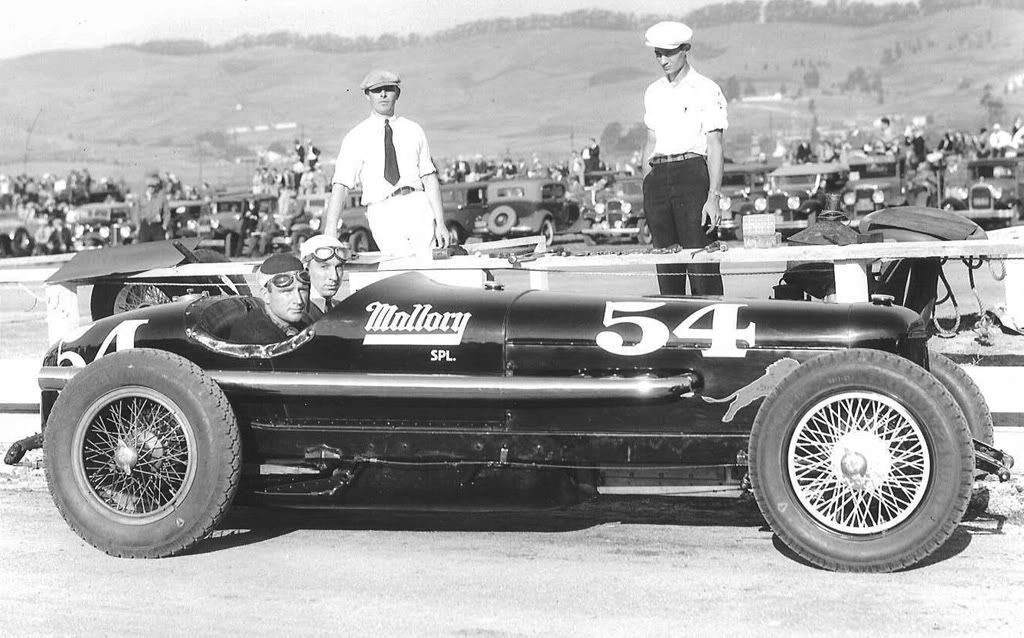

How's this for inspiration. I may change the shape of my doors.

There are two things in life where penetration is really important.....and one of them is welding.

-

03-28-2010 04:50 PM #5

Time to get on with beefing up the front so it can handle A-arms being attached. Started making boxing plates for my "front framerails". ......More cop car roll bar kick panels to the rescue.

There are two things in life where penetration is really important.....and one of them is welding.

-

01-04-2010 05:08 PM #6

I don't know if it's any help, but I have the blueprints for the famous Watson Indy roadsters. They had a 96 inch wheelbase. I realize that they are from a different era, but the cars from the 30s through the 50s were similar in size. In a Watson roadster, the driver's seat back was very close to the rear axle and his feet were beside the bell housing...Jim

Racing! - Because football, basketball, baseball, and golf require only ONE BALL!

-

03-29-2010 06:16 AM #7

The frame doesn't bother me; I don't think it's out of proportion at all. I think when you get the wheels on there to obscure the view, get the hood & sides on, and everything is painted it will look just fine. If you look at old Indy cars, some of them had pretty massive frames and they look OK. Nice work so far; keep it up.

Jim

Racing! - Because football, basketball, baseball, and golf require only ONE BALL!

-

03-29-2010 08:02 AM #8

There are two things in life where penetration is really important.....and one of them is welding.

-

03-29-2010 08:31 AM #9

I currently have two Ford style front leaf spring packs in my stash. One is what I think is a stock model A spring pack. The other was sold to me as a Posies spring pack from a 34 ford (it does have reversed eyes on the main leaf).

Anybody have any guesses as to how close the spring rates might be between the two? ...and what the rates might be?

Anybody have a guess as to how much the spring pack will compress from free state to being on the ground with a 575 lb motor behind the spring?

I am going to use the transverse spring to hold up the IFS set-up and don't really know where to put the spring crossmember.There are two things in life where penetration is really important.....and one of them is welding.

-

04-05-2010 07:56 AM #10

Actually started installing the boxing plates. I really want these things tied to the inner tubes. I am making plug welds to secure the plates near the inner horizontal edges of the tubes.

Drilled holes two inches apart and ground away the paint

Clamped in place to transfer weld spot to the 1.5" tube

Welded

There are two things in life where penetration is really important.....and one of them is welding.

-

04-05-2010 07:57 AM #11

The alxe I "remembered" being a model A....isn't. I think it is a 1940 unit

I think the spring will be better for this application anyways. The wider spring will put the load out farther on the a-arms.

Now I need to figure out what the crossmember needs to look like. Anybody have any guesses as to how much this spring will compress in this car? ...jag engine with a bunch of set-back vs. stock 40 ford ....I don't have a clue.

Spring will be on top of the lower arms ...I couldn't mock that up.

There are two things in life where penetration is really important.....and one of them is welding.

-

04-11-2010 11:57 AM #12

I was planning on setting it up right at the scrub line for that "stupid low" look. Nothing was going to hang below the frame rails. The car was going to be flat bottomed to be driveable down low. ...then last night I saw this car on Northwest Vintage Speedsters.

It has a really nice shape. I especially like the downward slope of the hood.

The car sits higher than I thought I wanted mine to sit. ...But it looks SO RIGHT! It looks like they dropped the motor down to have a lower hood line.

I think I may raise my car about 3-4 inches and lower the motor by the same amount.

There are two things in life where penetration is really important.....and one of them is welding.

-

04-05-2010 01:46 PM #13

Hmmm.... I would have been tempted to split the wishbone and use that entire axle assembly; it would be typical for the time period of the style car ... Anyway, you will probably only need about 6 leaves in that spring, possibly less. Your car will weigh only about half what the '40 weighed and your center of gravity is back further. I would start by removing every-other leaf. If it's too soft or stiff when you're done, you can add or delete more until you get the ride you want.

... Anyway, you will probably only need about 6 leaves in that spring, possibly less. Your car will weigh only about half what the '40 weighed and your center of gravity is back further. I would start by removing every-other leaf. If it's too soft or stiff when you're done, you can add or delete more until you get the ride you want.

Jim

Racing! - Because football, basketball, baseball, and golf require only ONE BALL!

-

04-05-2010 02:48 PM #14

-

04-11-2010 02:21 PM #15

Nicely proportioned car. I like it. Except for the finned aluminum drums, the front end looks like a radically dropped Model-A axle complete with mechanical brakes and un-split wishbone. Rear end looks like Model-A also, but I can't see the spring. I'd like to see the frame on that car to see how it's built. Anyway, if you approximate the shape of this car, you'll be on the right track.Jim

Racing! - Because football, basketball, baseball, and golf require only ONE BALL!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Friday and Saturday (4/11 & 12/25) Chris (my wife) and I made the journey to Homestead-Miami Speedway so I could participate in the Florida Power & Light sponsored Electrathon event.:cool: It was...

Electrathon - A Different Kind of...