-

09-22-2010 09:30 AM #31

-------uhhh, I might have a couple of neighbors that might have a bone to pick with you

As for seeing the car last night - absolutely greatDave W

I am now gone from this forum for now - finally have pulled the plug

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

09-23-2010 09:14 AM #32

nice work but does it have any power? LOL! Sweet car."Sunshine, a street rod and a winding beautiful Ozarks road is truely Bliss!"

-

06-29-2011 09:42 AM #33

Well I finally finished up the Thunderbird I was working on for my friend. It took a bit longer than I thought, but it turned out really good and we were both very happy with it. So now the hot rod is back in the garage and I've started to do some body work. It's already the end of April so there's not much time to get every thing done I wanted to. It would be nice to have it painted by summer though but it's not looking good.

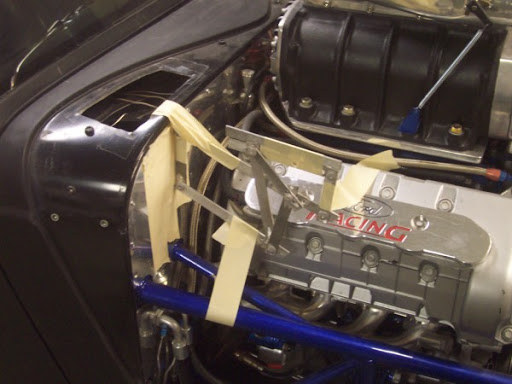

One of the issues I have is the Factory Five hood hinge design wouldn't work with the super charger sticking through the hood. The hood slides forward several inches and then flips forward. Theres not enough room under the cowl area to do a regular type hinge setup, so I have been thinking of a hinge that would attach to the firewall. I came up with an articulating hinge setup that allows it to swing up and away. It works pretty good, but it was a lot of work to get the hood reinforced to handle the stress - especially with the giant hole in it. I origianlly started w/ strips of cardboard and stck pins on the kitchen table just to see how a hinge like this would work. Then I made a mockup out of paint stir sticks with lots of holes in them and used rivets as hinge pins. That allowed me to switch the pivot points around until I got the hinge action I needed.

Then I made prototype out of some scrap aluminum just to verify the pivot points before I made the final product.

I got aluminum bar stock, angle, shoulder bolts and spacers. The curved piece I hogged out of a chunk of 1/2" aluminum I had laying around.

I added mounts to the frame to anchor the struts. It works pretty good but it took a lot work.

-

06-29-2011 09:43 AM #34

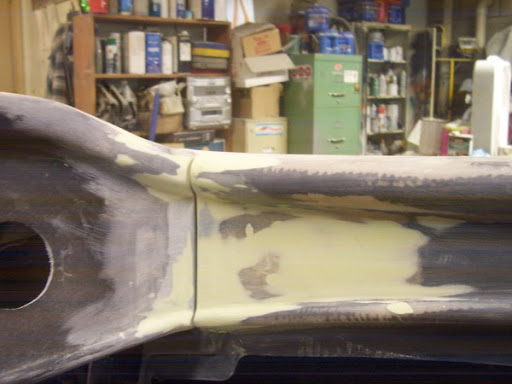

When I had bolted on the roadster windshield and then hardtop, I noticed the cowl was being warped becuase the bottom of the hard top and the roadster windshield frame weren't the same curvature as the cowl. This could lead to cracking of the fiberglass as there would be stress on the fiberglass where the bolts were. Also, you could see the top of the cowl was "dished" between the bolts because of the stress. I had to do some reshaping anyway beciuse of the hood modifications, so I built up the area w/ duraglass. I didn't want it super thick, so I spent a lot of time shaping the hardtop so it fit as tight as possible before adding filler. It was pretty tricky as the shape of the hardtop and the aluminum windshield frame are a little different. If I got the hard top to fit good, the roadster frame was off and vice versa. I finally got it narrowed down to where they both fit very good and here will be no distortion when I bolt either of them on. This how they sit in thier natural state without tightening the nuts on the studs.

-

06-29-2011 09:45 AM #35

Been working a lot on the bodywork, big push to hopefully get the bodywork and paint done before summer is over.

Even though the exterior bodyline lines up perfectly, the area where the door and cowl meet need some work - on both doors.

I had solved my grille/sidepanel/hood alignment problems a little different than most. I pie sliced the leg of the body and brought it up to where the other panels were sitting. A little fiberglass and it saved me a lot of fooling around w/ the side panels and nose cone.

I've spent some time getting the gaps around the grille as consistent as possible.

Last year I was kind of hasty in getting everything put together as I had lost 3 months because of the DMV hassle. So I needed to go back and tighten up some of the panel gaps.

Better now

I thought the panels were pretty good until I really started to feel them and I was noticing a lot of highs and lows. The doors in particular are not curved very smoothly from top to bottom around middle.

I've tried to make the transitions from the door to the body nice and smooth. I had to feather the transitions quite a ways to make them flow. The curvature of the doors and the body don't always match either so that helps. The area around the wheel wells was pretty lumpy also

The trunk also needed a lot of smoothing

-

06-29-2011 09:47 AM #36

I reconfigured the transition from the doors to the cowl so they line up better. It was a lot of work because there are no straight edges and it's hard to block sand. I also filled in the holes I had made for the inside door handles since they didn't work very good and I have a different idea for the interior door handles.

I also finished off the rear of the doors a little different so there is a smoother thansition from the door to the jamb.

Since the top of the doors and the cowl didn't line up very well, I had to reform that area too.

I've spent a lot of time on the hood reinforcing it and making it work with the firewall mounted hinges. The unerside took a bit of smoothing because of that.

-

06-29-2011 09:48 AM #37

Finally got the body off the chassis. My son helped me out and reconfigured the cart so it would hold the body up in the air without anything sticking out on the sides.

This is the first time I've ssen the completed chassis with the blower on the engine. It's pretty dusty but it will clean up fine with the pressure washer.

I finally got to a point where I could shoot some primer. I didn't have all the panels ready, but I needed a break from doing filler work.

I spent a lot of tim getting the filler work blocked pretty smooth so hopefully the primer blocking will go well. I put on three good coats of high build primer so there should be enough on there to get it nice and smooth.

One thing that disturbs me is the rough finish on the inside of the side panels. I know no one will see it, but I just don't like rough finish of the backside of the fiberglass. So I thought I'd try an experiment. I ground down the surface w/ a flap wheel. Not too much, just to knock off the high spots and the fiberglass pattern. Then I sprayed a few heavy coats of slick sand. I let that cure and see how it sands and if it's comes out smooth enough, I'll paint the backsides bodycolor.

-

06-29-2011 09:50 AM #38

I set the body and panels out in th sun to get a good look and found lots of pinholes. Some from the filler, but a lot were in the fiberglass where the gel coat had been sanded through. I spent almost a whole day filling the pin holes and sanding smooth again.

Got the body and the panels block sanded, need to do the hard top, hood sides and nose cone yet.

-

06-29-2011 09:53 AM #39

The bottom edge of the hardtop had a lot of large voids that had to be filled.

One thing I didn't like was how large the flange was around the edge of the door opening. It wasn't cut straight anyway so I took the opportunity to cut the edge down so the gasket would sit up close to the body.

I had already started smoothing over the seams on the hard top. I finally got serious and tried blocking with the long sanding boards. The more I added filler and sanded, the worse it got. It was very decieving as the top panel seemed smooth, but it was almost cupped down the center. It didn't have any curvature, it was mostly flat if not too low. So I had to skim coat the whole top and work the panel to build up the center so it had a nice curvature from side to side.

After finally getting the shape I wanted and filling a lot of little imperfections, it was ready for primer. I was able to prime the hood sides and nose cone too. Even then, there are a lot of pinholes to fix.

-

06-29-2011 09:54 AM #40

Got the roof block sanded. It's pretty smooth, but there are a few low spots still. You can see from the sanding pattern that the roof wasn't as smooth as I thought.

Even the side panels need some more work.

I reassembled the body an panels for a final check for fit. Good thing I did because found a few more areas that neeed attention. I also lowered the rear of the car, that swung the axle back a little so it's closer to center. Looks a lot better this way.

-

06-29-2011 09:56 AM #41

Pulled the body off again for another round of primer and blocking. Everything was in real good shape, but with that many sand throughs, it needed another couple of coats. Oddly enough, with the removable hard top, there are quite a few panels to paint and it's tricky to get everything setup up so there is room to move around,and that's with no fenders.

-

06-29-2011 09:58 AM #42

I block sanded again and I just sprayed two coats of reduced epoxy on as a sealer. Since I'm using a metallic base, I'll wet sand the epoxy w/ 600. Maybe get some color on this weekend????

-

06-29-2011 09:59 AM #43

Wet sanding the epoxy was a drag, took a lot of elbow grease. But I got it all sanded, cleaned the garage, put plastic up and seal up around the doors. Got 4 coats of color on, the silver was slow to cover, need to clear coat tonight.

This is the first coat so it's a little blotchy, but after four coats it's pretty even. You can tell from the picture, but it's really bright mettalic silver.

-

06-29-2011 10:01 AM #44

Got everything clear coated last night. Came out pretty good but had a few runs, no big deal. Very little orange peel so I'm happy.

-

06-29-2011 10:02 AM #45

Welcome to Club Hot Rod! The premier site for

everything to do with Hot Rod, Customs, Low Riders, Rat Rods, and more.

- » Members from all over the US and the world!

- » Help from all over the world for your questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and hundreds of thousands of posts!

YES! I want to register an account for free right now! p.s.: For registered members this ad will NOT show

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Thanks guys! One more trip around the sun completed. Lots of blessings and things to be thankful for (like still being able to type this message!!) Here's to us "over 70 guys.." Glenn

HBD Glenn!!