-

01-19-2020 07:57 PM #136

Thanks Guys! I really do appreciate the support!

The floor is fit in and screwed down as of today.

The inner rocker is in place and the fit at the bottom of the outer, at the back, is questionable to say the least...

Looking rearward from under the car... I may be replacing the back half of the rocker as well.

The floor fit to the middle brace is perfect, as is the middle brace to inner rocker.

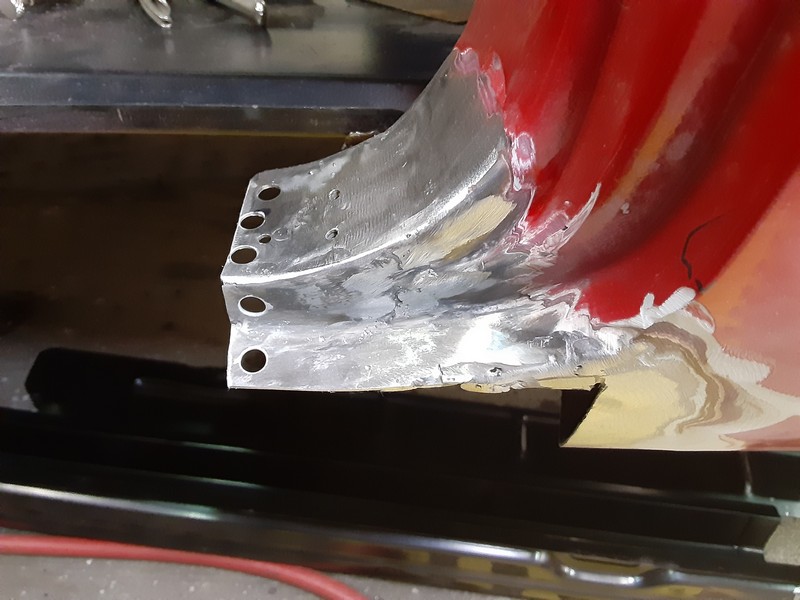

This is the rear cross car brace I trimmed off. I will clean this up and fit the splice to the inner like I did the other side.

I am also building a locator for the front lower fender bolt. Just some angle that will bolt and weld in so I verify the position of the front of the new rocker is where it needs to be.

Pic is from the tire side looking down.

Looking at the body mount bracket from underneath. I will tack this short piece of angle to the bracket. This will lock the location of the bolt down to the car.

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

01-26-2020 06:19 PM #137

Okay... Need some insight, advice, knowledge...

Getting the new rocker fit to the car I have found the A pillar on the drivers side has dropped 3/4's of an inch. This is due to years of no support from the front floor brace, nothing I have done... The door still shuts with a click

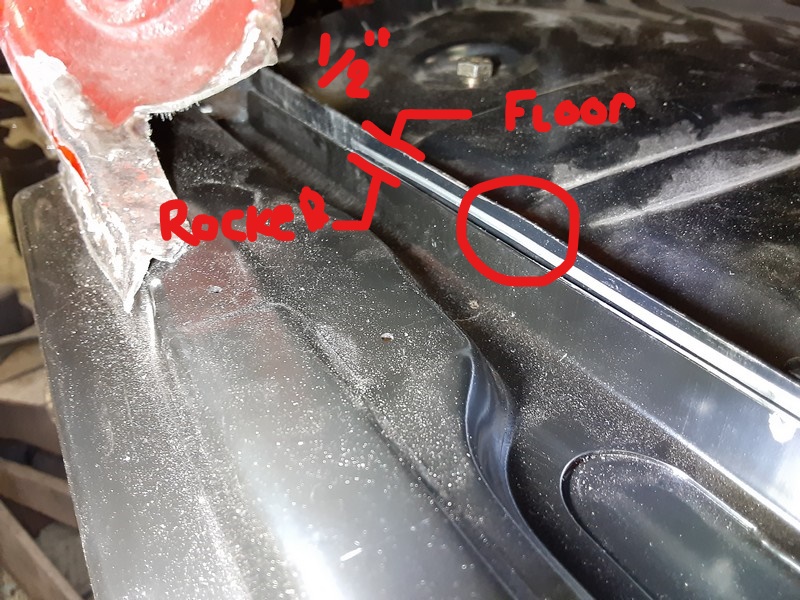

With the front floor brace installed the floor flange is 3/4's of an inch higher then the rocker flange.

Here is a pic I marked up. This is AFTER I put a jack under the pillar and raised it about 3/8's of an inch. At this point the door will not close....

I can come up with a few things to chase this down but I want to hear what you guys think...

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

01-27-2020 04:11 AM #138

Okay, thought about this yesterday afternoon, using the jack to determine how far the A pillar will lift before the whole car starts to raise up.

That's about a 1/4", raising it that far "just" starts to get into the door operation. Easily adjustable at this point.

If I section the front floor brace, taking a half inch out of the height, I can bring the floor down to the new rocker height.

Big picture:

1). Raise the cowl 1/4".

2). Section front floor brace a 1/2".

3). Readjust door after the work is done.

I know for a fact the A pillar will never raise back up to it's original height. Meeting in the middle seems like a viable solution to the problem.

Any thoughts? I am going to alter the brace tonight and get it fit back in.

Thanks for watching.

MarkLast edited by astroracer; 01-27-2020 at 04:14 AM.

If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

01-27-2020 05:30 PM #139

Just catching up myself. I'd say you're on the right track, compromise where you can and mendo blendo the package.

1/2" - 3/8" no one will ever know!

-

01-28-2020 07:07 AM #140

Mendo-Blendo! I like it! That is exactly what I will be doing...

This is what I came up with last nite.

I can raise the cowl 1/4" inch and it doesn't affect the door gaps or operation at all, BUT... As I was looking at the brace and marking it up to section it my WIFE said, "Why don't you just make one?"... I thought about that for a second and said, yea, why not?

So that's the plan.

I will raise the A pillar a "bit", maybe that 1/4", then bring the floor down to the rocker, letting it sit where it needs to sit. Then build a new brace to fit the hole. I have a sheet of 10ga. calling my name.

Any other suggestions? Ideas? Am I going about this right?

of course I have a few small patch panels to build for the lower A and B pillars as well. These need to be built and welded in before I can weld in the rocker anyway...

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

01-28-2020 09:27 AM #141

When working with this stuff you have to do what you have to do. By raising the A piller the door stays the same top and sides, What is it doing to the bottom? Are you raising the rocker also? How will that match up at the bottom of the rocker? I'm probably not picturing this at all. did the whole side of the car drop?Charlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

01-28-2020 10:13 AM #142

Hey Charlie, thanks for chiming in, talking this stuff through helps clarify it in my mind as well.

Raising the A pillar 1/4 inch does not effect the door gaps or operation. It still shuts with a click. I ran through this a number of times over the last few days and took pictures before and after. The door gap at the roof does not change one iota...

The reason I am wanting to raise the A pillar is to give it some "support" AFTER the new floor brace is installed. I could leave it where it is and weld all of this together but then it is, essentially, just hanging off the floor brace which "may" provide some support after the pillar has sagged a bit more to compress the new stack...

My plan is to get the rocker rebuilt, get the floor installed and then build the new floor brace to fill the revised gap at the body mount.

Mark

The rocker will go up with the pillar.If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

01-28-2020 11:50 AM #143

And now I am envisioning that you need to raise both the "A" & "B" pillars the same amount ( or close to it) to keep the body alignment in check.

But I am unsure how you could verify it from side to side..... Perhaps a measure to the floor? I am curious if the body sagged an equal amount side to side and fore and aft. But - you ARE doing a great job with it! 8-)

-

01-30-2020 10:03 AM #144

Hard to say with accuracy of todays aftermarket parts, but if assembled as shown it MAY allow that corner of the car body to droop, or require more shimming given the mount in front of the firewall. How does the flange height compare between the two parts? If both flanges are identical height, I would think they were supposed to be flush. If they were noticeably different heights, then I'd lean toward MFR of part was lazy and saved money by not trimming to size.Robert

-

01-30-2020 11:19 AM #145

I live in a very urban area not far from the Santa Monica Mountains open area. About 15 years ago a friend got hit in the RF door of a 7 series beemer by a deer that came out of the brush on the right side of the road. Did over 5K damage and the deer ran back the way it came. Remember these guys but heads for prolonged periods of time as foreplay.

-

01-30-2020 02:24 PM #146

https://www.trifive.com/garage/56%20Chevy%20index.htm

maybe this will helpCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

02-13-2020 07:11 PM #147

Thanks Charlie! I printed out a few of those, they will come in handy!

How about a small update?

Spent last week with my son and daughter-in-law, they came home from Vancouver for a week, so I didn't get a lot of shop time. A little, but not a lot.

I have been picking away at the A pillar patch and got it fairly well banged out. I started welding that together last Friday afternoon and I think it looks pretty damn good.

Starting to tack the pieces together.

This is the inside patch. I still have some fitting to do but the shape will work.

The outer cap welded on. This is welded inside and out so there is enough thickness to be able to shape it to match the original bend on the pillar.

This will get welded and finished, inside and out, before the rocker gets welded in.

I was worried about fabbing this piece and making it look right. I had to do it in multiple pieces but I think it will look pretty good once it's in and finished.

This is what the A pillar looked like when I started...

I will be doing the same thing at the B Pillar to rocker interface but that is a simple curve and shouldn't be as daunting as the A Pillar piece was. This is so thin back here I would never get a weld into it without it blowing out...

I should have all of the pillars rebuilt and the rocker tacked in by the end of the day.

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

02-13-2020 07:13 PM #148

I am really pleased with the way the patches turned out. Very little arguing and a lot of cooperation.

I welded them in last night. Everything welded in fine with just two small blowouts that were easily chased out.

The front patch.

The rear patch.

Getting everything cleaned up and smoothed out.

Got the welds finished and coated the inside with rust converter. Soaked everything real well and let it sit for the night.

This afternoon I cleaned up the rocker, sanding the paint off where the plug welds will go and got that welded in!

Cleaned up the welds and these look good!

Now I can start working the floor and inner rocker!

Thanks for watching!

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

02-14-2020 09:53 AM #149

Very nicely planned and executed Mark! That old Chebbie going to be solid again, excellent work!Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

02-14-2020 02:10 PM #150

Thank God for vise - gripsCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

Welcome to Club Hot Rod! The premier site for

everything to do with Hot Rod, Customs, Low Riders, Rat Rods, and more.

- » Members from all over the US and the world!

- » Help from all over the world for your questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and hundreds of thousands of posts!

YES! I want to register an account for free right now! p.s.: For registered members this ad will NOT show

282Likes

282Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Down all day yesterday, up today, shit or get off the pot.

Where is everybody?