-

02-15-2020 12:39 AM #151

While the site was down I kept wondering... "Jeez, how is Mark making out?!?! "

Thanks for the updates. 8-)

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

02-15-2020 08:29 AM #152

Mark, between you and Robert (MP&C) I'm so intimidated I think that I should sell my welder and all of my hammers! Thanks for the great posts!Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

02-15-2020 09:43 AM #153

-

02-15-2020 08:06 PM #154

johnboy

Mountain man. (Retired.)

Some mistakes are too much fun to be made only once.

I don't know everything about anything, and I don't know anything about lots of things.

'47 Ford sedan. 350 -- 350, Jaguar irs + ifs.

'49 Morris Minor. Datsun 1500cc, 5sp manual, Marina front axle, Nissan rear axle.

'51 Ford school bus. Chev 400 ci Vortec 5 sp manual + Gearvendors 2sp, 2000 Chev lwb dually chassis and axles.

'64 A.C. Cobra replica. Ford 429, C6 auto, Torana ifs, Jaguar irs.

-

02-16-2020 07:48 AM #155

Ditto what they said ^^^!

Awesome work...

-

02-16-2020 05:49 PM #156

Thank you guys! And don't be intimidated! Be inspired! There is nothing I am doing here that takes specialized equipment. It is 95% hand work and sticking stuff together with the welder. Anyone can do it...

Got some work done on the floor today. Getting the rocker in was a big deal. Now I can move forward with the floor installation!

I used a cup wire brush on the inside of the main crossmember and got it buried in rust converter.

Drilled and punched all of the plug weld holes around the perimeter.

Fit the back corner to the original floor and welded in a doubler for that seam.

Drilled all of the holes for welding the floor braces.

Fit the seat brace and got it welded to the center crossmember

Started fitting the seat brace to the floor and inner rocker.

And welded in the foot board patch.

A little more fit up and some work on the inner rocker and this will be ready to weld in!

I have some thinking to do on what is left of the old outer rocker. Even though it was replaced a long time ago it is pretty rusty on the inside so I am debating cutting it off and replacing it like I did on the other side...

Thanks for watching and for all of the comments!

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

02-17-2020 10:36 AM #157

Looks like you're coming down the home stretch now. Well, for the metal work part of this project anyway.

-

02-17-2020 05:53 PM #158

Yes, it's coming along, still a long way to go though.

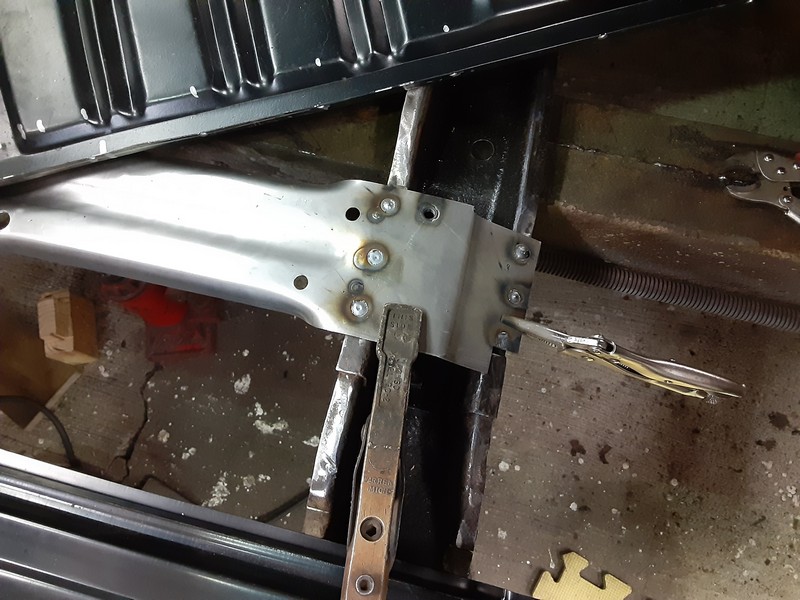

I worked on it a little bit tonight. Finished up the A pillar reinforcement panel and got it welded in. Did some bending to match the new rocker profile and punched and drilled a bunch of holes for welding.

This pillar is getting some strength back into it now!

Doing the fit up. Two bends to match the rocker profile and some of the plug weld holes.

All welded in and touched up with a grinder.

I started trying to weld the A pillar panel to the foot board patch but the gap was just to wide so I will make a little doubler and plug weld that in after I clean out the "bubble gum"... it will look a whole lot better...

it will look a whole lot better...

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

02-18-2020 06:00 PM #159

Well, picked away at a few things this afternoon... I fabbed up that doubler plate for the floor to A pillar junction. This probably isn't needed but it will tie the floor and A pillars back together which is a good thing.

I won't weld this in until the floor is ready to go in.

I also dropped the floor back into place. Starting to fit the inner rocker to that and new outer. Running into an issue with the inner being a bit to short. The lower flange is not matching the new outer when it is fit up against the floor flange. You can see the mismatch in this pic.

You will ALSO notice the original front floor brace is in place. I guess my working with the jack and raising the front of the rocker has allowed the rocker and A pillar to come back up. The door still operates with a click so this is an unexpected happy moment!

Obviously I am going to have to do some tweaking to the brace to get it to snuggle up to the rocker but that is pretty standard fare with all of these braces...

I also came up with a Band-Aid to make the two rocker halves match up along the bottom. I will weld a strip to the bottom of the inner to extend it down to the outer flange. I made up those strips tonight and punched a bunch of holes for welding. This will work fine and it will make for a strong repair.

I made three pieces and will use most of them.

getting that brace in is a big deal! I was taking measurements to start fabbing the replacement brace but, when I realized the measurement was the same as the brace I slid it into place... Lots of saved time right here.

Thanks for following along!

Mark

On a side note:

I have been using that hand punch for a long time, 26 years or so. It was a gift from one of the best metal shapers in the business. Ron Fournier gave that to me back in '94 when I was doing some work for him. I was developing some photo etched pieces for him, grilles and suspension parts, for some large scale Indy Roadster models he was building. I hadn't talked to him since his wife, Sue, died in '03. I was looking to reach out to him tonight and I discovered he had passed in 2017.

It makes me sad to find this out but I am sure he is pounding and shaping away in a better place.

MASLast edited by astroracer; 02-18-2020 at 07:21 PM.

If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

02-19-2020 05:13 AM #160

quote"You will ALSO notice the original front floor brace is in place. I guess my working with the jack and raising the front of the rocker has allowed the rocker and A pillar to come back up. The door still operates with a click so this is an unexpected happy moment!

Obviously I am going to have to do some tweaking to the brace to get it to snuggle up to the rocker but that is pretty standard fare with all of these braces..."

Glad to hear that the repairs are solving some other issues. it's all coming together.

Sorry to hear about your friend.

-

02-22-2020 05:22 PM #161

Thank You Sir, I was sorry to hear he was gone as well, he was a great guy to work with.

Thanks guys! It seems like it is taking forever but I keep picking away at it and surprise myself with how much I can get done in a day.

Took a bit of a step back yesterday though. I decided to cut off the rest of the rocker. It was full of holes and didn't line up the new front half so I removed it.

This is what I cut off.

Holding it up to the light...

I will also have to rebuild the bottom of the wheel well as it is about a 1/2" to high. The rockers are straight, front to back, and this is part of the reason for cutting the old one off. The new piece shows you where the bottom of the wheel well "should" be...

I flanged that raw edge and punced weld holes for welding from the back side. I also got inside and ground off all of the rust and crud to help with the welding.

Today I got a lot done. I welded up the extensions to the inner rocker.

Smoothed off the welds and this is ready to install.

I welded up the front seat brace, which had been split in two places and fit to the floor a few nights ago. (just like the other side...)

and built the patch for that triangle hole at the bottom of the B pillar.

Didn't do any welding today but tomorrow will be different. I'll get the wheel well rebuilt out of new steel and then I can start sticking stuff together.

After getting everything mocked up, it is all lining up great except for the bottom of the inner rocker which that extension I added will fix. The floor is in for the last time, the front floor brace fits perfectly so, as soon as the rocker and little patches are done I can weld this in...

Thanks for watching!

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

02-23-2020 03:55 AM #162

As I started to read that you had cut more away, I was like "WHAT?!?!"

But once I saw the pics I knew it was the only choice. And especially notable at the rear wheel well. Keep at it, it is definitely coming along great.

And thanks again for sharing the ride with us!!!

-

02-23-2020 04:22 PM #163

You're continuing to make great progress! I'm sorry to see that you learned of Ron's passing, but as you say he's in a better place, free from the burdens of this crazy world. Like Mike said, keep at it and we'll all be riding along with you in spirit when you take this bad boy for it's maiden voyage!Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

02-27-2020 04:24 PM #164

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

I'm sorry for your loss. Good choice on cutting the rest of that rocker off. That thing was no bueno. That poor car had a lot of not good choices made on it before. Poor thing! Keep up the great work!!!

.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

02-29-2020 07:55 PM #165

Thanks for the condolences guys, very much appreciated!

And yes, this poor car was a mess. The stuff I am doing is far from perfect but it is whole lot better then what was there.

I haven't posted much on the wagon repairs but stuff has been getting done!

Last weekend was spent rebuilding & replacing the back half of the outer rocker. As you can see in my previous post I had to rebuild the front of the rear wheel well also. It was 1/2" to high once I got the new outer in place and lined up with the new front half.

I built the new piece from scratch as the old one was pretty rusty inside and the shape just wasn't right to blend into the new rocker.

The shrinker dies did a good job pulling that 16ga around. I thought it would wrinkle up worse then it did.

The corner of the wheel well was a 2" radius and I got the new piece pretty close.

Got an outer piece fit in and this is ready to weld up.

The new piece got welded to the rocker and, with a little grinding, looks like it is one piece. I finished the inside as well. This will all get painted on the inside after I get it welded in.

The new wheel well edge looks great! I still have a bit of trimming to do though.

Thanks for following!

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

Welcome to Club Hot Rod! The premier site for

everything to do with Hot Rod, Customs, Low Riders, Rat Rods, and more.

- » Members from all over the US and the world!

- » Help from all over the world for your questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and hundreds of thousands of posts!

YES! I want to register an account for free right now! p.s.: For registered members this ad will NOT show

282Likes

282Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

You're welcome Mike, glad it worked out for you. Roger, it's taken a few years but my inventory of excess parts has shrunk a fair bit from 1 1/2 garage stalls to about an eight by eight space. ...

1968 Plymouth Valiant 1st Gen HEMI