-

10-27-2019 02:33 AM #31

Wow.. Pandoras fender / slippery slope all the same thing right!?!?!

But your doing some great work with it. Oh, and the picture size is perfect.

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

10-27-2019 06:14 AM #32

Wow, that pretty red paint covered up a lot of sins! Looks like it's in good hands though, nice Fab work!Seth

God cannot give us a happiness and peace apart from Himself, because it is not there. There is no such thing. C.S.Lewis

-

10-27-2019 04:02 PM #33

Thanks guys! I appreciate the votes of confidence!

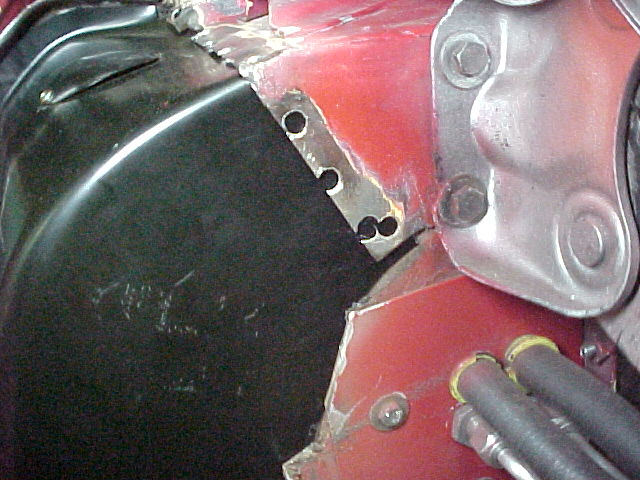

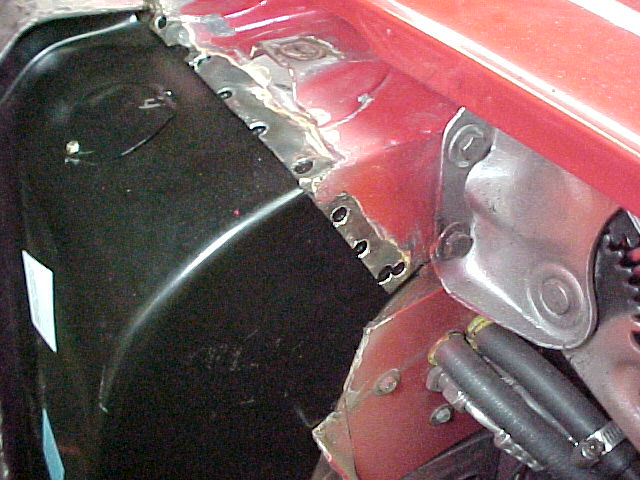

Today I worked on getting both sides cleaned up some more. Cut more chunks out of the driver side at the lower door hinge reinforcement.

I will probably clean this up some more as I develope the patch.

Before doing a bit of trimming.

I was laying on the floor looking at this for 15 or 20 minutes... Using the angle grinder to trim out junk that will serve no purpose when the patch is welded in.

I came up with a plan to fill this hole. Tomorrow I'll start building the steel pieces. The passenger side will be similar.

I also got the rest of the old cowl cut out of the passenger side. A little bit of finagling and I got the new cowl panel set in place. This fits very well. From what I can tell the driver side will fit well also.

Still need to build the inner patch panels but those are very easy and not going to take much time at all. I should have this patched up this week.

Thanks for watching!

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

10-28-2019 02:36 PM #34

As always, thanks for sharing Mark.

-

10-29-2019 03:11 AM #35

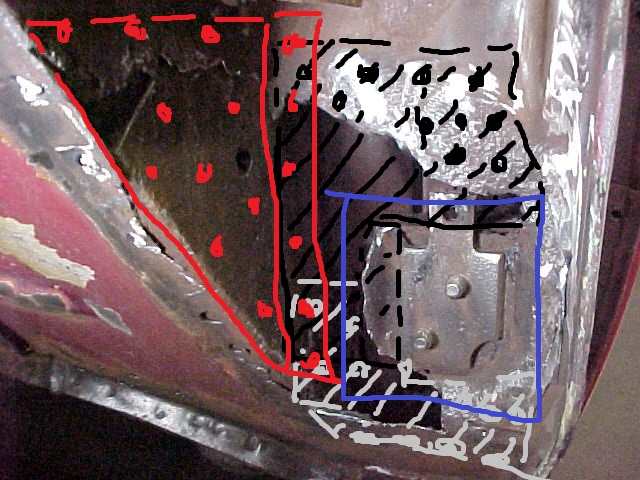

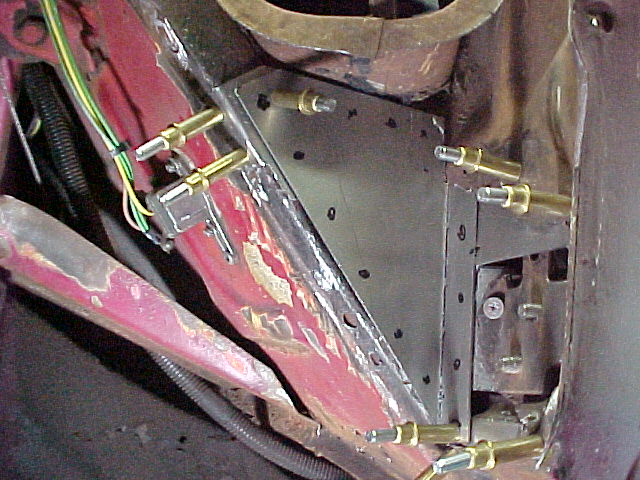

I marked up a pic with my plan. This repair will be done in four pieces. Let me know what you think.

The black and silver pieces I would like to do "one piece" but getting them in, behind the old steel is the trick.

1). Spot weld in the black piece.

2). Spot weld in the silver piece.

3). Spot weld in the red piece.

4). Spot weld in the blue piece.

Prior to welding, all of this stuff will get buried in epoxy primer. After welding it will get rust converter and then more primer.

I am thinking about popping a 2" hole in the lower A pillar, under the fender just for ease of access after it is rewelded. I will probably do the same on the new outer cowl before it gets welded in just for access after it is welded on.

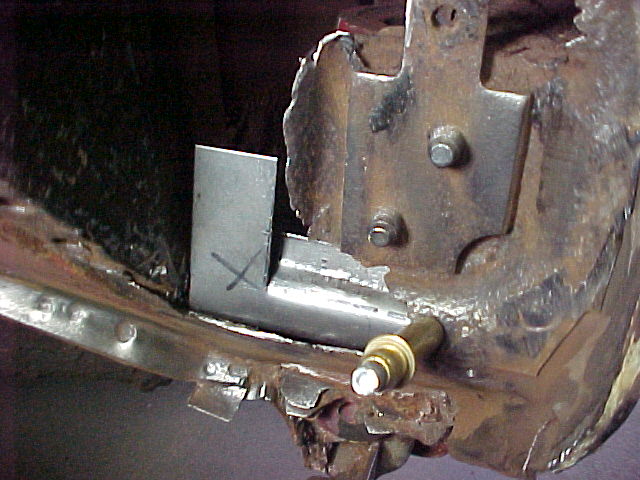

Got a couple of the patch panels made for the lower A Piller hinge reinforcement. I made the top one twice... Why you ask? Because I LOST the first one in the shop somewhere..I looked for the dang thing for three HOURS! I made the 2nd one in ten minutes....

I'll do some adjusting of the fit before these get welded in. There are two more plates to make. The "red" one that will weld to the left hand wall and the "blue" one that covers the nut plate.

The upper (black) piece.

The lower (silver) piece.

I wasted a shit load of time tonight looking for that missing piece otherwise I would have had the red and blue pieces done as well...

Fitting the top piece.

Fitting the bottom piece.

Pulling everything together with screws and clecos.

I'll get the rest of the parts done tonight and get a good start on the passenger side.

Thanks for watching.

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

10-29-2019 10:29 AM #36

You know winter is coming. Take your time looks goodCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

10-29-2019 05:49 PM #37

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

Nice work. That poor car sure had some rust hidden. The deer hit may have saved you a lot of issues down the road!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

10-30-2019 06:23 PM #38

Made some progress tonight. I got the "red" piece made along with a smaller "gap filler" to strengthen the gap between the new piece and the original steel on the side of the cowl.

This one will get some plug welding holes punched into it and be ready to go.

I also got a good start on the inner cowl patch. I cut a piece of 16ga to fit the upper opening and put a roll on it to match the curve of the cowl. It's amzing what a block of wood and a dead blow hammer can do in 10 minutes...

The curve developed pretty quickly using the dead blow hammer.

It was getting close at this point.

A little more tweaking and it will be good.

Fits like a glove! I'm pretty happy with this piece. It will plug weld in nicely.

I will get the bottom halve of this patch made tomorrow and This will be ready to prep and weld!

If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

10-31-2019 06:32 AM #39

Good progress, the repairs look great!Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

10-31-2019 04:03 PM #40

Thanks Dave! I know they are not perfect but they will do the job and put a lot of strength back into the firewall and A pillar. All of this work will be hidden under the new outer cowl panel anyway so all I have to do is make it functional and water-tight.

I fabbed the lower part of the inner tonight and spent more time taking out useless metal. I stripped out the leftover flange from the inner cowl, the piece I am replacing. Now all that is left is the firewall flange so, with the patches I am putting in and the new outer cowl panel, the thickness will be back to three layers which is what it should be.

The cleaned off firewall flange.

Surprisingly this is pretty solid. The new pieces will weld to this just fine.

Making the inner patch. I bent this flange to fit over the firewall flange. Dead blow hammer comes to the rescue again!

I'll get out the shrinker/stretcher to roll this flange to match the cowl.

Punching some 1/4" holes for plug welding and getting all of the joints cleaned up is next on the list. Getting this welded up will be a big step.

Next on the list is the drain channels....

Mark

If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-01-2019 06:40 AM #41

Looks great and it should certainly be strong! I need me a new shrinker-stretcher, who's do you have and how do you like it?Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

11-01-2019 08:36 AM #42

Thanks Dave! I know it will be better then the open holes, that's for certain!

My Shrinker/Stretcher is a Woodward Fab piece. I've had it for a long time and it works as well as the high-dollar set my buddy has...

If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-01-2019 05:42 PM #43

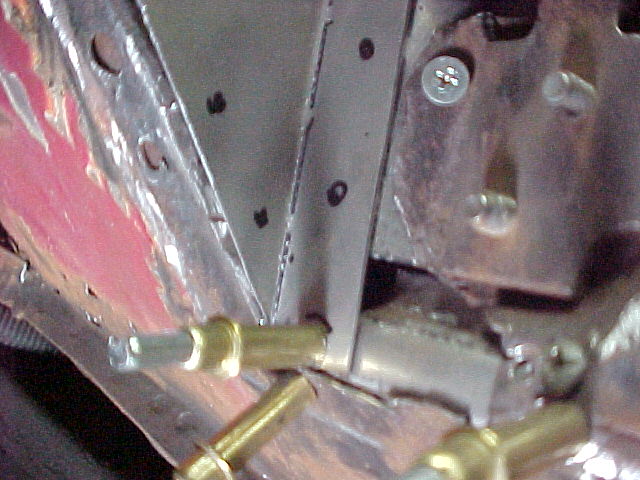

I have the left hand side panels ready to weld in. Finished up the pieces and worked on fitment. Got everything fitting pretty sweet so I pulled it all out and punched and drilled the plug welding holes. Ran the flap disc over a lot of the mating surfaces to clean things up a bit more but I think it's as ready as it will ever be.

Now, on to the passenger side tomorrow!

This is the fit of the side piece under the cowl top piece. Took three hits with the shrinker dies to pull this around.

Worked on fitment.

After drilling and punching the plug weld holes.

Nice tight fit all around. This should weld up beautifully. I made a small patch for that gap in the back. it will get welded in when I do the rest of the parts.

I'll get to work on the other side in the morning!

Thanks for watching!

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-02-2019 06:40 AM #44

Was there life before cleco's were invented?Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

11-02-2019 04:17 PM #45

LOL! Not in this guys world! I did use a few screws though. They just draw the pieces tighter together.

Thank You for the compliments, this has been "kind of" fun actually. It's a big mess and a pain the arse but it's been a while since I've done fab work like this. The last was on the van and this is just getting me pumped to get the body finished on that...

Got a good start on the passenger side today. Went through the same routine, removing dead metal from the firewall flange, as I did on the drivers side.

After a couple of hours of cutting and grinding... Same as the other side, the flange cleaned up very well so I will get good welds when I stick all of this together.

Cleaned out the lower A pillar pocket and got two patches fabbed up for that area. Went pretty smooth and the fit is really good.

I ran out of steam about 6:00pm, came in, took a shower and had some dinner. Got a lot done though and the rest of this wont take to long.

Won't get anything done tomorrow, going antiquing with some friends.

Thanks for following along!

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

Welcome to Club Hot Rod! The premier site for

everything to do with Hot Rod, Customs, Low Riders, Rat Rods, and more.

- » Members from all over the US and the world!

- » Help from all over the world for your questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and hundreds of thousands of posts!

YES! I want to register an account for free right now! p.s.: For registered members this ad will NOT show

282Likes

282Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

You're welcome Mike, glad it worked out for you. Roger, it's taken a few years but my inventory of excess parts has shrunk a fair bit from 1 1/2 garage stalls to about an eight by eight space. ...

1968 Plymouth Valiant 1st Gen HEMI