-

11-03-2019 01:12 PM #46

"Antiquing" Where you go up there Ann Arbor? You look for anything special? We do that all the time even have a booth in a mall in Elkhart.

Great work on the car too.Charlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

11-04-2019 08:27 AM #47

Hi Charlie, There are quite a few shops and malls around us in any direction you want to drive. The Howell area is about a 1/2 hour drive south for us. The Mason/Jackson area is a hot spot as well as the Jonesville/ Allen area which is about 30 miles west of M52 right on 12. We hit that area yesterday for the first time and found a lot of neat shops.

Thanks for the kudos on the tin work! It is all pulling together nicely, I hope to have the new stuff welded in by Wednesday.

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-04-2019 11:14 AM #48

Thanks for the locations we will hit them soon. Where did you find the firewall/cowel partCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

11-05-2019 04:26 AM #49

We will be going back as well. 1 day wasn't enough time! We'll make a road trip of it the next time and spend a couple days down there.

The replacement outer cowl is available from everybody. Danchuk, Ecklers, etc., etc. The inner pieces are the ones that need to be reproduced. I talked with Joe at Real Deal Steel about the parts they make for their steel bodies and he said their manufacturer doesn't want to break the extra parts out of a sub-assembly they are already producing...If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-15-2019 06:19 PM #50

Didn't get much done last week other then house and family stuff...

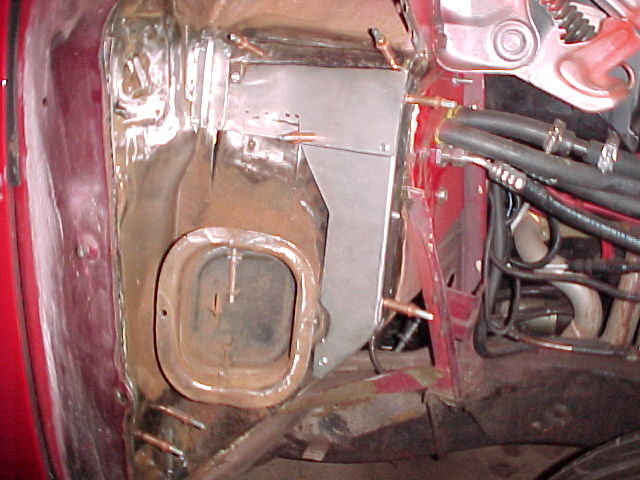

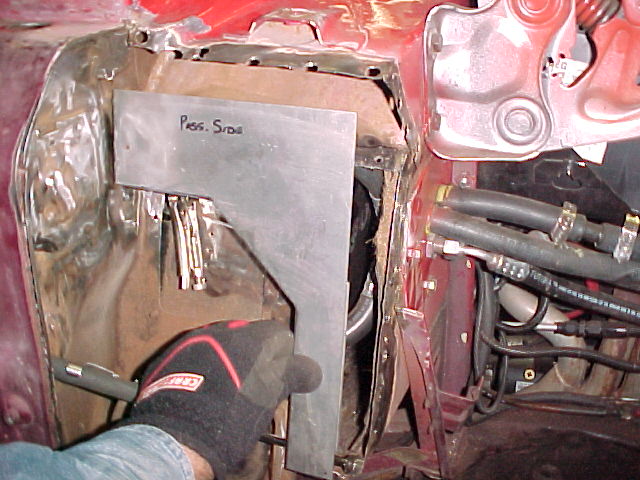

I got a couple of pieces made for the inner repairs. Still have some fit up and shaping to do but the bulk of the work is done and the panels fit fairly well.

Still using the dead blow hammer and the edge of a steel top work table to form this stuff.

Formed the top piece and got it fit up, under the cowl.

Clecoed in.

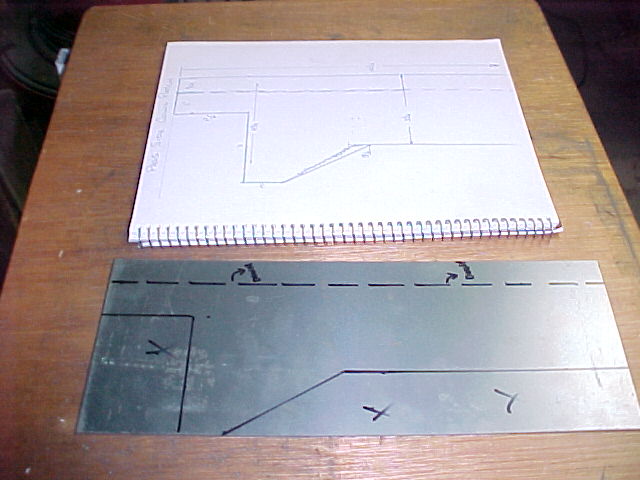

Measuring and drawing up and laying out the lower panel.

Trimmed out and the firewall flange is bent up.

Both pieces Clecoed in. I still have to shape the break at the bottom of the firewall where it kicks back for the toe board. The hard parts are done though and I was getting pretty cold by this time...

It's gotten very cold here in Mi. Tuesday was the first snow of the season and we are looking at over 6 inches for a total.If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-15-2019 06:20 PM #51

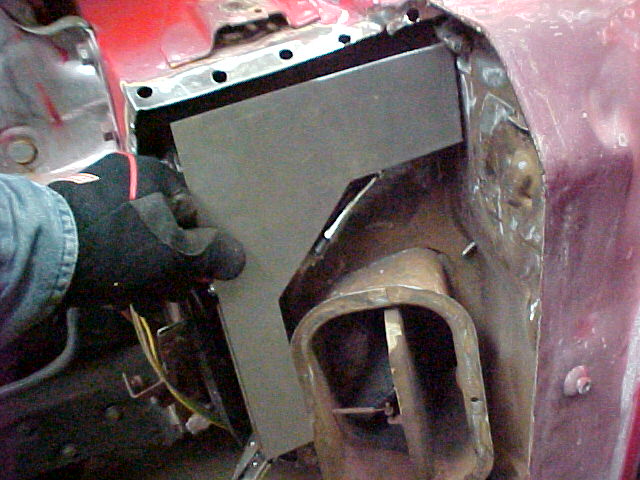

Got a bit more done on the passenger side. Fitting the new panels in and getting the lower flange bent up.

What should I do with that old access panel? Leave it be and reattach with screws? Or just take it out and weld it up?

Been so dang cold I can only work for an hour or so. I need to prep and paint the cowl before I weld these patches in. Don't know when that will happen.If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-15-2019 06:22 PM #52

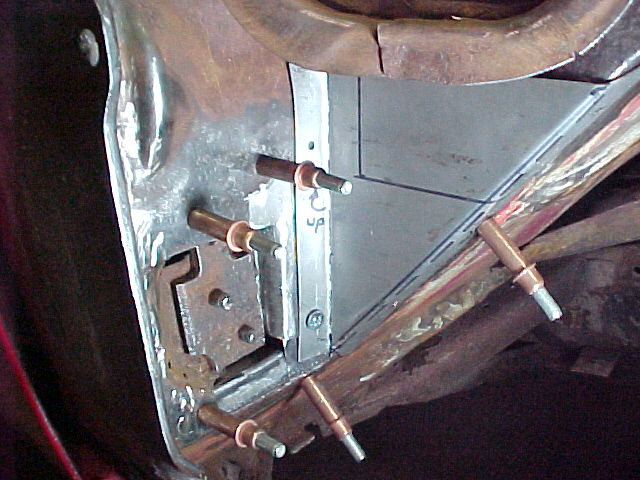

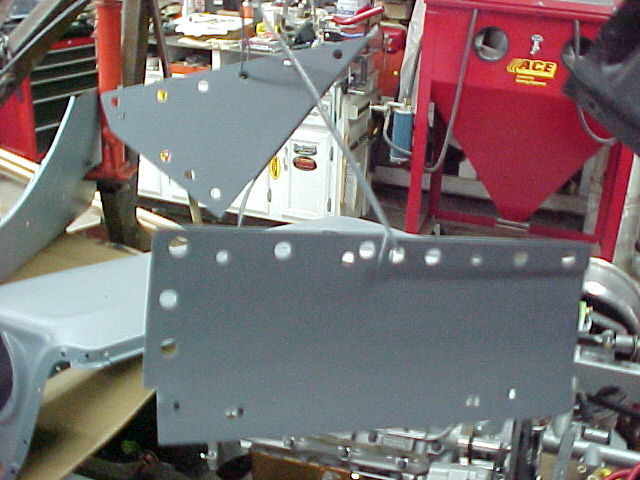

All of the major patch panels are done. I need to drill and punch plug weld holes in the passenger cowl and pieces yet but I was not getting on the floor tonight.

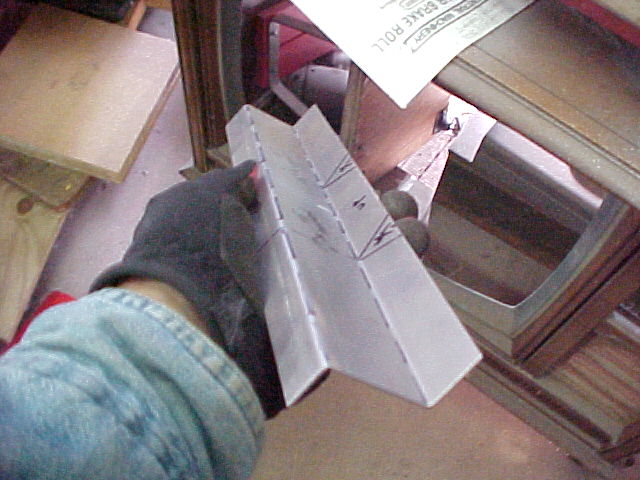

Here is the last piece I made last night.

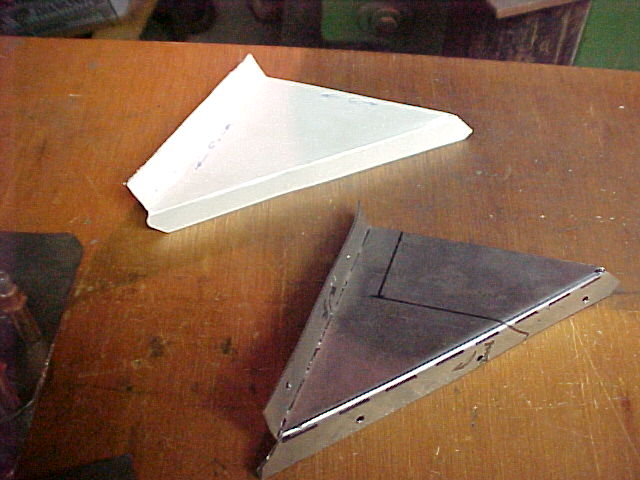

I developed the bends using a piece of cardstock cut to size.

Now if it would warm up so I can paint...

If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-15-2019 06:25 PM #53

Okay, last installment for tonight!

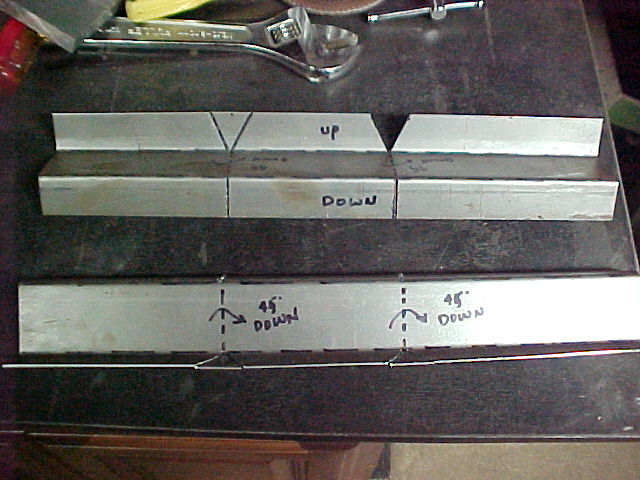

I went out this afternoon and cut out the replacement drain channel parts. I am doing this in two pieces rather then one just to ease getting everything welded in.

These are the tall covers that keep water coming off the upper cowl from splashing down on the fresh air vents. LH and RH.

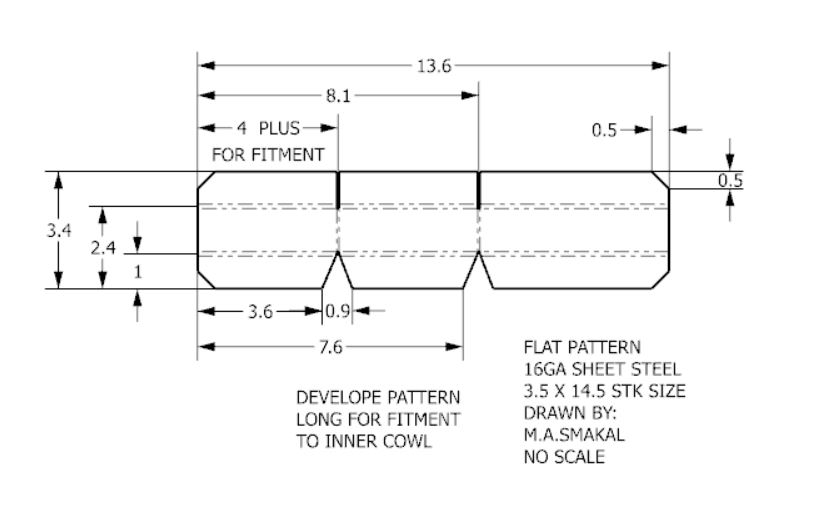

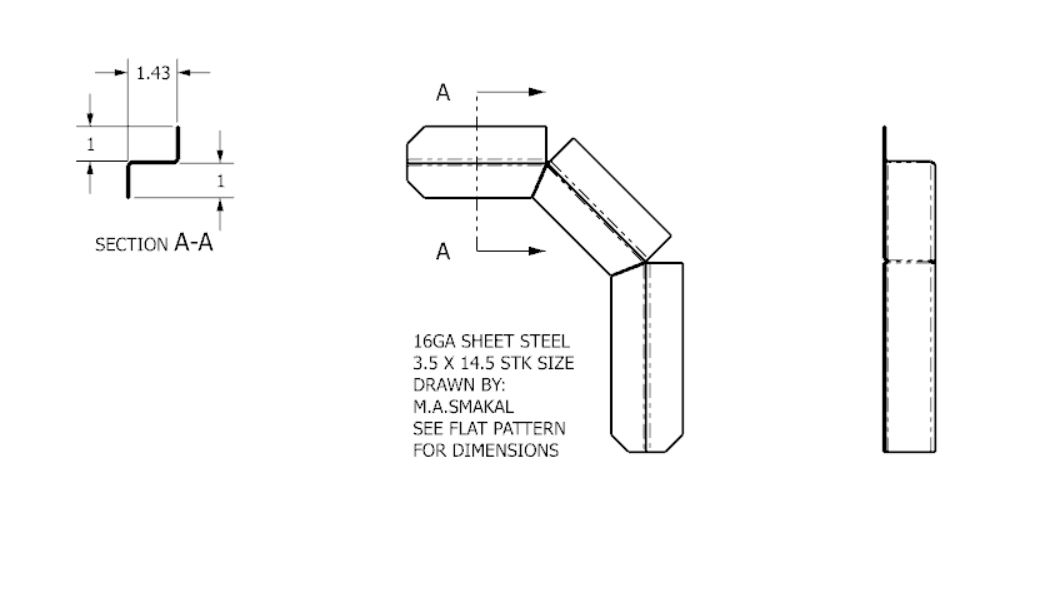

These are the flat patterns for the actual channel that goes under the cover. One is left, one is right. I'll get these bent up tomorrow.

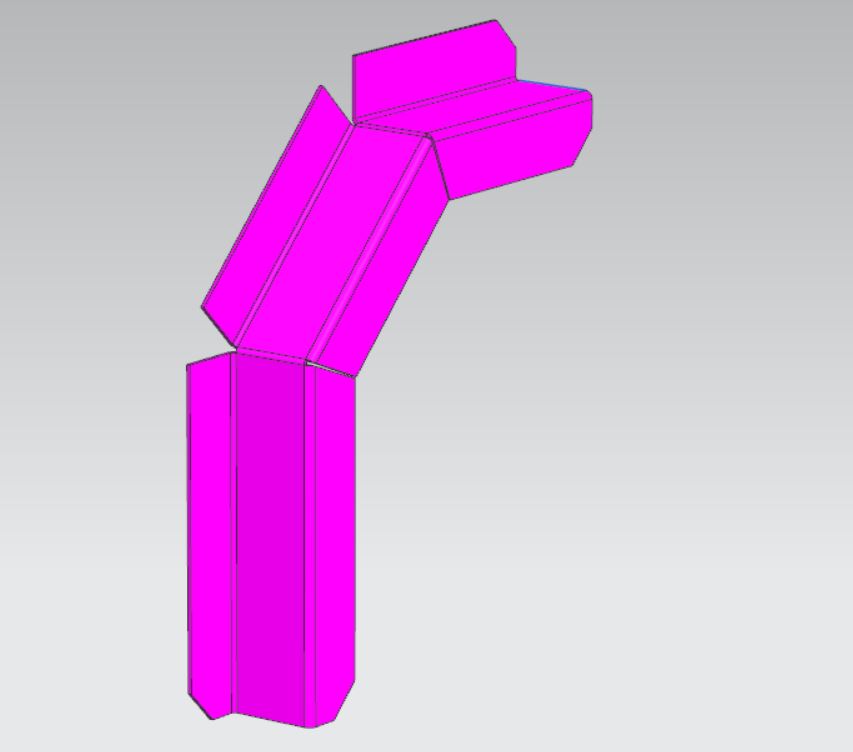

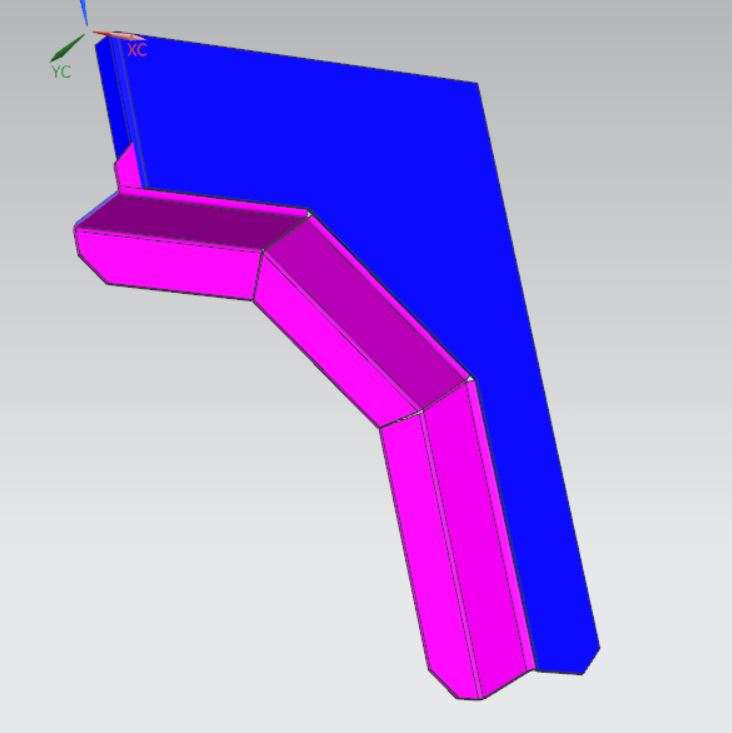

I modeled these up last Monday... It was 9 degrees here, I was NOT going out to the shop...

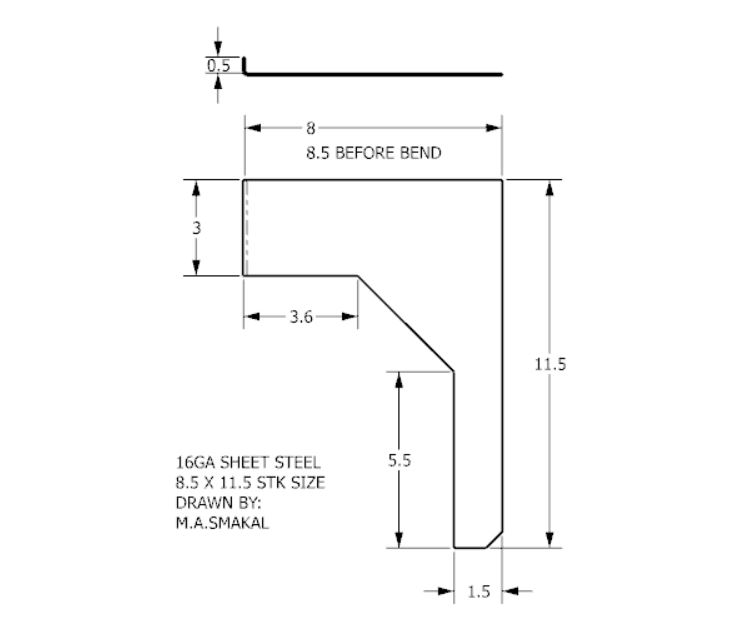

Here are dimensioned drawings if you want to copy them. Anyone with a tri-Five with rusty cowls will need these.

The covers, 1 right, 1 left, mind the bend, this is the right hand side.

This is the flat pattern for the channels. Again there are two needed, 1 left and 1 right. This is the right side.

This is the right side bent up.

These are some screen shots of my computer models.

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-16-2019 12:08 PM #54

Are you using weld thru primer before assembly? Just wonderingCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

11-18-2019 05:06 AM #55

No, just regular epoxy. I have used weld thru before and hated it. Caught on fire, couldn't get decent welds and it still requires finishing after welding anyway.

I use the epoxy, clean the weld spots before welding and touch stuff up afterwards.

No real benefit to "weld thru" primer that I have seen and I will not use it again.

With that said I did get a lot of work done this weekend.

I dug out the 3 in 1 Saturday morning and got the two channels bent up.

For a cheap HF bender this thing does a good job. I've been using it for 8 years and have not been disappointed with it...

Getting them bent the long way was the hard part. After some offhand cutting on the bandsaw I could get the them bent into the shape needed for the cowl.

There isn't much I can do to get these fit to the cowl until I get the patch panels welded in.

Passenger side.

[imghttps://media.fotki.com/2v2HofE2Fx9EDKg.jpg][/img]

Drivers side.

With the channel covers held in place. These should work!

Thanks for watching.

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-18-2019 05:32 AM #56

I did fire the car up and move it outside while I did the bending. I really appreciate the TBI F.I. The car hadn't been started since August and she fired right up! I let her idle for about half an hour while I worked on the channels.

After Going in to warm up and have some lunch I hit it again. This time I was working on the warm side.

I pulled off all of the patch panels earlier and had them on the warm side. I punched the plug weld holes in the pass. side stuff, hit them all with a wire wheel and got some self-etching primer on them.

Drivers side parts.

Passenger side parts.

Primed and ready to go!

That's what I did Saturday. Now, to get the Astro chassis moved so I can get this car on the warm side...

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-21-2019 06:03 AM #57

You've seen the Pro-Touring Astro van chassis I am building on the heated side of the shop. I had an issue with the hidden valve stems on the front wheels hitting the Vette calipers. To get the chassis movable I had to fix the problem.

I had a buddy weld up the old holes, and I drilled new ones outboard of the spokes so they would have no interference with the calipers.

Now to get the shop cleaned up and the wagon rolled over here.Last edited by astroracer; 11-21-2019 at 07:17 AM.

If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-23-2019 01:49 PM #58

Did a lot of cleaning and vehicle shuffling today. The wagon and Astro chassis have swapped places so I can get to work finishing the cowl tomorrow.

These pics are off my phone, sorry for their largosity...

If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-24-2019 05:31 AM #59

I totally understand the shuffling cars ordeal! If I ever had a shop big enough for all my toys I probably couldn't afford to heat it anyway!!!!Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

11-26-2019 04:15 PM #60

Yea, bigger isn't always better but it would be nice to have one space to set up ALL of my metal working tools and leave them there...

Got a bit done tonight. My wife helped pull the hood, she's had this duty a few times before so it went smoothly. I pulled the hinges and did some more clean up on the cowl. Found a bit more rust in the top of the cowl, buried under filler and bubbling like an unwatched pot... and about 10 more colors under the red...

More rust in the cowl...

Far OUT Man! Should I offer signed posters in a limited run?

Wire brushed and sprayed with converter.

With this done I hope to start welding in panels tomorrow!

Mark

If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

Welcome to Club Hot Rod! The premier site for

everything to do with Hot Rod, Customs, Low Riders, Rat Rods, and more.

- » Members from all over the US and the world!

- » Help from all over the world for your questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and hundreds of thousands of posts!

YES! I want to register an account for free right now! p.s.: For registered members this ad will NOT show

282Likes

282Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

You're welcome Mike, glad it worked out for you. Roger, it's taken a few years but my inventory of excess parts has shrunk a fair bit from 1 1/2 garage stalls to about an eight by eight space. ...

1968 Plymouth Valiant 1st Gen HEMI