-

05-07-2008 03:45 PM #3316

I rolled my ankle three or four times getting in and out of the roadster while trying not to step on the running board. The last time was close to a sprained ankle so I just had to git 'er done and was inspired by the previous picture. Besides I was able to get some aluminum diamond plate for about the same price as a step plate and I needed to reinforce the "bouncy" 'glass running boards. I bolted the diamond plate on top of the 'glass running board and added a 2" wide strip of 1/4" aluminum along the under edge of the 'glass for added strength. It is a bit gaudy and against the general "dechromed" school of rodding taste but the previous picture looks pretty good with bright running boards so here is what I have now. Now I can step up into the cockpit without worrying if the 'glass running boards will crack. I used stainless carriage bolts with nice rounded heads and they are essentially invisible in the picture. This will be a "ten foot car" that looks good from ten feet away! The reflection "speckles" are an unexpected and perhaps undesireable effect.

Don Shillady

Retired Scientist/teen rodderLast edited by Don Shillady; 05-07-2008 at 04:47 PM.

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

05-07-2008 04:01 PM #3317

Don,

You scared me - I thought you were up and running already with that first photo.

You could do this as well. tho I do have steel RB's.Dave W

I am now gone from this forum for now - finally have pulled the plug

-

05-07-2008 04:42 PM #3318

DennyW, that's an interesting idea. The reason I did not just add a step plate alone was because I really needed reinforcement strength but maybe now I have something to bolt a step plate to with more substance than the bouncy 'glass. I was afraid putting four holes in the 'glass alone would lead to a board which would break at the holes; now there is more strength but with only a bit more weight.

IC2, putting stock boards on would have involved cutting the one-piece-floor-fenders of the Bebops body. I considered just putting rubber on the glass but that lacked strength, so now I have the diamond plate complete with "speckles". I could fake quick progress by putting on the radiator, shell and hood but that would ignore the big challenge of the wiring problem!

For those interested in details of a Bebops body I note that Bebops recommends "chopping" the running board brackets but I avoided the cutting and rewelding (of an unknown amount) by putting the 1/4" aluminum strip under the edge of the 'glass board. In the front, the added 1/4" matched up pretty well but I had to use spacer washers under the aluminum strip in order to meet the lower stock rear running board brackets. Although most of the "downhill" look of my car is due to the big/little tires and the 5" dropped axle, it is not clear to me why the body sits higher on the frame in the rear, but I don't plan to change it now and for sure I don't plan to put a mirror under the chassis for a show car. My goal is to drive it and have it look good in a parking lot and that is it.

Don Shillady

Retired Scientist/teen rodder

-

05-08-2008 09:16 PM #3319

Falcon sounds like your having to much fun driving the truck .

Pro really admire the craftsmanship it takes to build this type of car .

Well before this summer cold set in monday i was in garage and installed all the hard lines for brakes . Then It came to me i didnt have the rubber lines for it . So Sunday was a call to NPD and they where delivered Tuesday but still not ready to get back in there yet. Colds S^^k this time of year .

-

05-08-2008 09:30 PM #3320

Well I went for a ride in my 27 T today. I rode shotrun because I haven't moved the drivers seat back so I can get my long legs under the steering wheel. My friend Wayne checked out the coils and I started it with the crank and then Wayne said lets go for a ride. We went around the section (4 miles), about 3/4 of a mile from my son's place it boiled over right when Wayne was signaling with his had out the window and it got all covered with antifreeze (second picture show hood and windshield wet with antifreeze).

He said it rode and drove very nice for a stock T. He suggested that I get the radiator cleaned and take a look at the cam gear, pull the starter and fix it and to have the coils up dated. I pulled the radiator out right after he left and will rip into the rest tomorrow.

Really wanted to get a 26 T coupe done before diving in on the 27 but it's more important for Dave to get well than for him to over work himself on my project.

Also tomorrow I have to bleed the brakes on my 20 year old motorcycle so I can start getting some great gas milage

-

05-08-2008 11:02 PM #3321

Hey that looks really good, now I wont have to wash it

-

05-09-2008 07:56 AM #3322

Pretty cool, Tom. Wish my dad were still around, he had many stories about his first car when he was 16. A 27 Model T that his grandfather traded a mule for to give him on his birthday. He said he had each fender painted a different color and two squirrel tails hanging from the headlight bar. Always sounded kind of bizzare to me but I guess that was the style in 1938. Can someone photoshop that?

Can someone photoshop that?

-

05-10-2008 10:32 AM #3323

Don,

I was looking at that same Grant aluminum wheel in the Speedway catalog just before I logged on. Does it use the same installation kit as their street wheels?

As for milling aluminum, there was an article in one of the magazines a few years ago about using carbide bits in a regular router table. They made a dash insert and it looked fairly easy. One thing I remember is that they said aluminum has a grain and you get a real smooth cut going with the grain but not so smooth going against it. They said you could feel the difference when feeding the aluminum into the bit so you could tell which way you should go with the cut.

Tom

-

05-10-2008 01:01 PM #3324

Tom, Thanks for your interest in my car. I can't tell from your list if you really have a '39 Ford but for me that is a wonderful time machine since many of my high school friends had cars in the '39-'48 Ford era and I once tried to piece together a '40 convert body and a '40 Standard Tudor which would have been a phantom model with a grill like the '39 Deluxe but I did not have funds to finish it. Anyway, yes, I used the Grant adapter No. 3196 which is pretty common. The wheel has six small holes near the center. You need three holes for the horn mechanism and I wanted to make the wheel come out with the "Y" at the top to see the speedometer so I used the three smaller holes. It was necessary to use a rat tail file to oval the holes inward about 1/32" but hardly anything on my car has not felt the touch of the rat tail file anyway. The horn wire then comes up through one of the larger holes at ten o'clock. Since I had the wheel powder coated, Grant sent me an adhesive disk with aluminum foil on one side to provide an electrical contact. The aluminum wheel could be painted, powder coated or anodized. I liked the aluminum color so if it gets scratched it will not show as much as if I had it coated maroon. Note that the wheel is only 13" in diameter which will lead to "quick steering" but with the tight '29 cockpit and my slight body paunch, the smaller wheel makes it easier to enter/exit. I have since installed the ignition, light and wiper switches around a 2 3/8" TPI speedometer that I squeezed into the '32 style dash in front of the "Y" in the wheel so I only have to glance down to see the speed instead of over to the center of the dash. I put a tach in the speedometer hole and I will post a picture of the dash soon. By the way I have a '76 Corvette block which came with the cheap no-design rocker covers and I have plain chrome covers on there now but I would like to put the aluminum "Corvette" covers on there but I do not see oil input holes on the old aluminum covers. Does your Vette have the aluminum covers and do they have an oil hole on either side? I have purchased an end mill bit for my little drill press but have not tried it yet. The spiral bit is rated for cast iron and alloy steel so aluminum should be like cheese for that bit and the only question is whether the side force on the drill chuck is too much.

Don Shillady

Retired Scientist/teen rodderLast edited by Don Shillady; 05-10-2008 at 01:12 PM.

-

05-10-2008 01:49 PM #3325

One thing I found with the spiral bits is they break a little easier given side pressure than a straight bit of the same size. They both work, you just have to be more careful with the spiral bit."PLAN" your life like you will live to 120.

"LIVE" your life like you could die tomorrow.

John 3:16

>>>>>>

-

05-10-2008 04:16 PM #3326

Thanks ProZ, I will watch that. The bit is only 3/16" diameter but I may order another at 1/4" diameter. I am replying today to Tom-39Deluxe again. I forgot to mention that the V8 horn cap is not included in the Grant kit, it was $11 separately but if you look at the Grant site you will find a number of different designs for the horn button. I am attaching a new picture of my dash mockup now with the speedometer in the "Y" of the steering wheel. You can see the light switch to the left of the wheel which is easy to reach. The wiper switch is hidden behind the wheel to the right of the light switch. The unusual red thing on the dash is a plastic key holder that I added to the ignition key to prevent other keys on the ring from scratching the dash and to widen the grip on the small key since the spring-loaded starter switch has a pretty strong spring and I wanted the added leverage of a wider key. No doubt this is much simpler and much less beautiful than the custom instrument panel ProZ28 has produced but it is functional and now I will have to start the wiring. The camera is at an angle but when sitting in the driver position you can see the speedometer through the wheel and the all important gas gauge just to the right of the wheel in the quad cluster. The tach is to the right but will probably only be used for fun to see what the engine is doing. The black thing on the right is an AM/FM/PM3 unit with a removeable faceplate placed where my wife could mess with the station selection if I can ever coax her into a short trip in the roadster!

Don Shillady

Retired Scientist/teen rodderLast edited by Don Shillady; 05-10-2008 at 04:21 PM.

-

05-10-2008 04:18 PM #3327

I dug the ol' 48 out yesterday and cleaned the winters muck off, fixed all the bugs I had from driving it in the winter, also fit the new wiper motor and it's going to take some fabricating to get it in. Today was our clubs show so I got to cruise her down there and back. Our 4th show was our largest with 113 cars which for our little town is ALot! Tomorrow we'll figure out that wiper motor, it looks like its going to rain all year so I better. I drove it home in the rain today with no wipers.

I am liking how clean all of your wiring is, mine looks like a spider web. Some of the trouble was using a harness that the wiring was already attached to the fusblock. Any suggestions lue of tearing it out and redoing it how I can straighten it out?Last edited by brickman; 05-10-2008 at 04:22 PM.

"Sunshine, a street rod and a winding beautiful Ozarks road is truely Bliss!"

-

05-10-2008 08:08 PM #3328

I think the dash looks great Don. Nice & clean looking. Just right for the roadster. Originally Posted by Don Shillady

Originally Posted by Don Shillady

I got the steering mocked up & started welding in mounting tabs & brackets, making due with the stuff I have until the back ordered parts get here.

"PLAN" your life like you will live to 120.

"LIVE" your life like you could die tomorrow.

John 3:16

>>>>>>

-

05-11-2008 07:35 PM #3329

Looks great Don. I like where you put the speedo and the reason you put it there. The '39 Deluxe in my avatar picture was my first car back in 1964. It was lowered with a warmed over '55 Chevy 265 and an Offenhouser adapter to the '39 box. I wish I still had it.

Corvette script valve covers were never made with any holes in them. When that became necessary they changed to the LT1 style with fins only. Here is a fairly new item you will like though. These are Corvette script with a boss on the intake side that you can bore out for a pcv or vent. A 90 degree fitting for oil fill could be made to fit also. They have baffles internally where the holes would go in also.

Click on the valve cover to go to the site.

Tom

-

05-11-2008 08:46 PM #3330

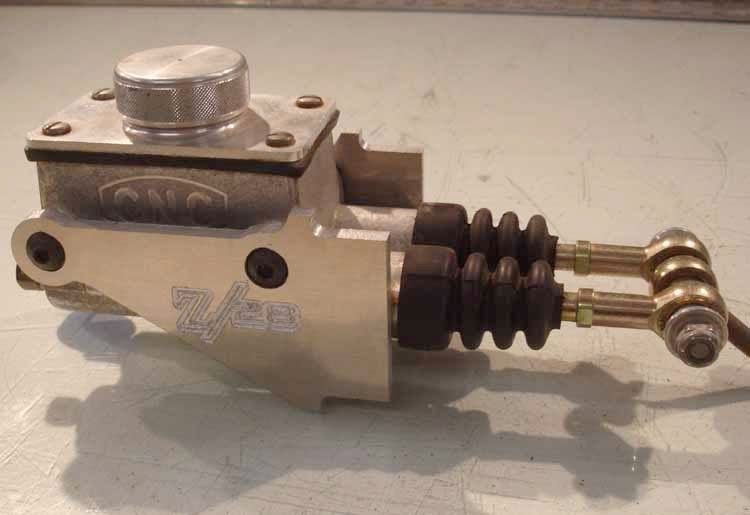

Started making a bracket for the MC. Still have to make the base that mounts on the firewall. I decided that would be better than under the floor & having to mess around with B-R-A-K-E bleeding issues.

"PLAN" your life like you will live to 120.

"LIVE" your life like you could die tomorrow.

John 3:16

>>>>>>

Welcome to Club Hot Rod! The premier site for

everything to do with Hot Rod, Customs, Low Riders, Rat Rods, and more.

- » Members from all over the US and the world!

- » Help from all over the world for your questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and hundreds of thousands of posts!

YES! I want to register an account for free right now! p.s.: For registered members this ad will NOT show

188Likes

188Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Thanks guys! One more trip around the sun completed. Lots of blessings and things to be thankful for (like still being able to type this message!!) Here's to us "over 70 guys.." Glenn

HBD Glenn!!