-

06-27-2005 05:33 PM #46

Man looks like that thing will be looking great! How much money have you put into that thing to get it to where it is now?www.streamlineautocare.com

If you wan't something done right, then you have to do it yourself!

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

06-27-2005 11:41 PM #47

Thanks guys, I appreciate the good words.

As for how much?,... Oh man, I've done all the labor & fabrication myself, thats saved about 80% of the cost alone. The aviation grade wiring harness would run upwards of $1K alone!

All together if I had to put a value on it, about $10K so far.

The rear end will add quite a bit once thats done, the external metal is only a part of it. The firewall will be moved, and I need to build up the roll cage & tie it into the body panels to keep the rear end rigid. Once all that is done I'll have the bulk parts done. The engine is a whole other can of worms, I need to start getting the part together for the turbo system. :PI dig ALL cars, old & new, whether they were hammered out of american iron, German steel, or Japanese tin cans. Being unable to appreciate them all is missing out on a world of great things.

But thats just my opinion.

-

06-28-2005 12:53 AM #48

If your worried about the rear end holding together, you could always do like GM did with the larger cars. Connect the mounting points with extra braces. That way, you can just unbolt the rods to work on the motor. For a good example, open a full size caddy

Right engine, Wrong Wheels

-

06-28-2005 12:31 PM #49

I'm gonna weld in a couple braces here & there, & had thought about a large cross brace in the back that I can either unbolt or have pinned in place to bolth protect the engine in the unlikely event I get hit, & firm up the rear. Once the firewall/package tray is out & I have the rear cage tubes in place I can get all of that lined up.I dig ALL cars, old & new, whether they were hammered out of american iron, German steel, or Japanese tin cans. Being unable to appreciate them all is missing out on a world of great things.

But thats just my opinion.

-

07-14-2005 05:04 AM #50

Got a lil burned out on working incessently on the panels & working on someone elses motorcycle for the last couple weeks. So over last weekend I didn't do anything to either of them. Trying to avoid burnout here.

Have been grinding the welds down & am now in the process of slowly beating the panel smooth. As I progress I'm learning things, foremost of wich is like many things I make, I usualy do one for practice & trail & error, then I do another for the final work. Looks like I'll need another donor hood coz this one is a mess. lol All things taken into account tho, it's actualy coming together pretty well.

Have concluded that I'm not gonna make the show this weekend, not with the car anyway. Didn't expect to have too much done, but I cant drive it as is & I'm having difficulties locating a trailer. I cant use the flippin transporters from U-haul or the like, car's too low.

Cant believe how much a simple trailer is around this part of the country. For the price of one I could get 4 in the South East. Something I'm thinking of when I go see the family, could make a tidy profit off that trip.

ANYway, what I DID do last weekend was get a matching spare for the car (same tire/wheel as the fronts) and make a cover for it.

Came out quite well I think, and really wasn't all that difficult. then again, having acess to an industrial grade machine at work does help alot. :PI dig ALL cars, old & new, whether they were hammered out of american iron, German steel, or Japanese tin cans. Being unable to appreciate them all is missing out on a world of great things.

But thats just my opinion.

-

07-14-2005 11:50 PM #51

Looks like your comming along well though VW. That stitch work looks really good too! I wish I had a machine like that to do a few things I need done on my truck... Keep it up and hope to see the final pics soon. I am pretty interested in your build. I would love to build something like that because I have never been into VW stuff or seen nothing like that or even know much.www.streamlineautocare.com

If you wan't something done right, then you have to do it yourself!

-

07-15-2005 12:09 AM #52

Hmm... Doesn't look too bad. I am not sure what material I will be using for my truck. Only material I know of is Tweed (which makes me itch too much), suade (sp), leather, ultra leather... I can't think of the other two but I like the look of tweed just can't sit on it, I will start itching real bad and get a rash. I like ultra leather but I think it's really expensive last time I looked. Oh there's plush too.www.streamlineautocare.com

If you wan't something done right, then you have to do it yourself!

-

07-15-2005 02:32 AM #53

Oddly enough, I have a similar model machine I got for $25 at the local pawn shop. Mines a bit different tho, your's looks like an early aluminum bodied ultralite model. Mine is a 1939 model made of cast iron. HEAVY, but it does well.

I dont have the needles to handle thicker stuff, broke 3 putting the edge together. :P I just needed the industrial machine to clean it up & tighten the piping up on the seam. Workin with 4 layers of naugahyde with a parachute cord center for the piping is a bit much for the little one. I managed it OK to tack it together, but the part where the piping is overlapped & tucked makes it a total of 6 layers & then the cord.

Given the proper needles & heavier thread I could do these at home, but the power & depth of the one at work is much nicer.

I've been toying with the idea of making custom design covers if there was an actual interest in them,...I dig ALL cars, old & new, whether they were hammered out of american iron, German steel, or Japanese tin cans. Being unable to appreciate them all is missing out on a world of great things.

But thats just my opinion.

-

07-15-2005 11:48 AM #54

Hard to beat the old Singers. I sure wish I could have gotten the one my grandmother had when she passed on.

BTW Denny, what kind of search did you do on ebay to find the material?Last edited by NTFDAY; 07-15-2005 at 11:51 AM.

Ken Thomas

NoT FaDe AwaY and the music didn't die

The simplest road is usually the last one sought

Wild Willie & AA/FA's The greatest show in drag racing

-

07-15-2005 07:13 PM #55

I was in my fathers 2000 Crew Cab dually chevy truck the other day looking around for idea's and I think I got it. I wanna try to find either some front or back seats out of the same year in that grey color that is real popular in the 1998-2000 trucks and then get the same material that is on his door panels and ceiling. Also I wanna rip the center consol out as well and take that to put into my truck. Then I can say I have Chevy stuff in Ford tough. hehe I'd rather the whole thing say chevy including the motor but nothing I can do about that.

Thanks for the info though guy's. I am going to check out that ebay link and see what I can find.www.streamlineautocare.com

If you wan't something done right, then you have to do it yourself!

-

07-15-2005 11:47 PM #56

Denny, quit teasing me, you know that you have my dream vehicle. I may not care for my 66 Ford as much as I would like to have a 30's Chevy truck but once I get my tranny in it, about 80 more HP, my interior done, lowered with wheels and tires then I will like it tons.www.streamlineautocare.com

If you wan't something done right, then you have to do it yourself!

-

07-15-2005 11:57 PM #57

Thanks Denny for the link. I've been wanting to redo the seats in my Duster and that looks like the ticket.Originally posted by DennyW

Not a problem.

I found this, and it's the same people I got mine from. I was a little leary about it, but, this is the heavy material. I also got the nine foot one. 39.99, plus 15.00 shipping. You will be surprised when it gets there, just how heavy it is. They have different colors also. The nine foot is a good coverage size. Just plan your layout.

http://cgi.ebay.com/9-Black-NAUGAHYD...QQcmdZViewItem

Ken Thomas

NoT FaDe AwaY and the music didn't die

The simplest road is usually the last one sought

Wild Willie & AA/FA's The greatest show in drag racing

-

08-05-2005 01:56 AM #58

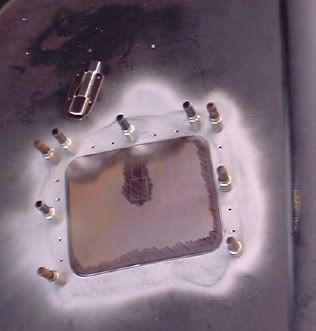

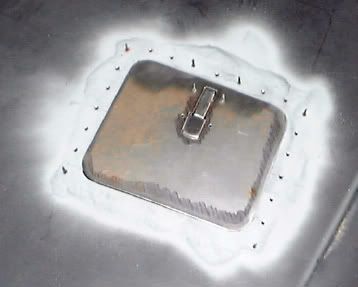

Evolution of a fuel filler door

Start with the location, cut the shape out of the panel, cut the door to fit, add backing plates to make it sit flush. I elected to use this aviation panel latch I've had around for years.

Latch cleco clamped in place for fitting

Door with hinge plate & half hinge riveted on, painted with primer & blitz black to keep the bare steel rust free. Ready to instal once the other half of the hinge is placed & riveted

Looking forward from the side with door open. Need to rotate the tank back a couple degrees, but otherwise it's just fine.

Looking at a lower angle from the front. Need to tweak the hinge plate a bit to get the alignment down & get the curve of the panel correct. Then it will come off again to grind the welds on the backing plates, sand & primer until time for paint.

Start back on the rear decklid frame tomorrow. have templates made to match the left side placement, time st start cutting!I dig ALL cars, old & new, whether they were hammered out of american iron, German steel, or Japanese tin cans. Being unable to appreciate them all is missing out on a world of great things.

But thats just my opinion.

-

08-05-2005 08:30 PM #59

Looks good still. Keep it up, your that much closer.www.streamlineautocare.com

If you wan't something done right, then you have to do it yourself!

-

08-09-2005 10:41 PM #60

OK, here's a view of the semi-finished product from the left rear.

I ran a piece of 1/2" square tubing across the bottom & then made filler panels. Rolled a bead into them to stiffen them a bit, altho I botched the bead a bit (hard to do alone with a hand roller!). All in all, looks pretty decent & makes a very stiff section.

Side view, starting to mock up the windshield bow sections.

Today I started late but got most of the right side bow bent to shape, mounted, & welded in place. The sheet metal clamps from Eastwood are great!

Altho I did try to keep the piece level with the body lines it twisted some while I was welding & I have a slight offset on the filler panel. I am hoping I can hammer it level(ish) once the welds are ground down & the rest can be masked with a light coat of body filler.

So far I haven't done more than grind the welds smooth, so once the welding is done on the back I have a metric ass ton of sanding/filling/sanding/filling/repeat ad nauseum to do. yay!

Hopefully tomorrow I can get the other side done & start on the center gap filler. Will be fun as I need to replicate the sheet metal contours entirely by hand. The section is about 12" long too. Think I'll be making a couple of the sharper bends on the brake at work, then form the curves at home.

Oh,... Joy!I dig ALL cars, old & new, whether they were hammered out of american iron, German steel, or Japanese tin cans. Being unable to appreciate them all is missing out on a world of great things.

But thats just my opinion.

Welcome to Club Hot Rod! The premier site for

everything to do with Hot Rod, Customs, Low Riders, Rat Rods, and more.

- » Members from all over the US and the world!

- » Help from all over the world for your questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and hundreds of thousands of posts!

YES! I want to register an account for free right now! p.s.: For registered members this ad will NOT show

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

How much did Santa have to pay for his sleigh? Nothing! It's on the house! .

the Official CHR joke page duel