Thread: Hello from an old member

-

03-07-2014 04:47 AM #136

I dont think anyone has tried before. I was playing with an old welded diff cage and my slingshot buddy said I should try a spool as its much neater. He had an old one in his garage that he dropped over before Christmas and its been on the floor until now. It wasnt until I pulled out a spare axle case to take measurements for the new shafts that I put the spool and the MG diff cage side by side on the table and saw that the bearings and flanges lined up pretty well. So we dropped it in loose and then decided to ditch the Minispool and Ford 8.8 side gear idea and go straight for fitting the big spool So I could have got this fitted over the Christmas holidays if I hadnt forgotten about it !! So far so good

So I could have got this fitted over the Christmas holidays if I hadnt forgotten about it !! So far so good

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

03-07-2014 05:48 AM #137

And now your idea is on the world wide web!!! I don't foresee me drag racing any MG's in the future but, who knows!! Maybe I'll "borrow" the idea!

-

03-07-2014 07:03 AM #138

Edison said it a long time ago,I'd say your idea qualifies!Genius is one percent inspiration, and ninety nine percent perspiration.Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

03-07-2014 07:53 AM #139

Ha Ha!!

Thanks Guys

I like to share anything like this that I do because someone else could benefit. Especially someone with a British classic using this type of axle for a budget build. Phase 2 will be altering the brake end to see if that will drop on ok. I guess my easy way out for the wheels would be to find a pair of Ford 5 stud rims to take my slicks. I think the shafts come with holes for 5 x 4 1/2

and 5 x 4 3/4 pcd.

-

03-09-2014 03:15 PM #140

EXCITED NOW !!

I had my Saturday job cancelled so I hauled the rear end out of the MGB. I pulled the diff and removed the crown wheel / ring gear. Then re fitted the diff cage and used a straight edge across the flange to mark the casing. Then fitted the spool and marked the casing again. The result was two scribed lines with a gap of 7.9mm between them. So it will be 3mm off the back of the ring gear and 5mm off the spool flange to get the gears meshing where they were before.

Even after removing 5mm from the spool flange it will still be 5mm thicker than the existing MGB flange on the diff cage. I managed to finf my friend still at his machine shop at 2pm on Saturday so he now has all the parts to machine over the next few days. The fiddly part will be re drilling the spool flange (which is 10 bolts) to accept my 8 bolt ring gear. But thats what my mate Geoff does for a living at his machine shop

Sadly all this got done so quick I didnt think to take pictures DOH !!!

The bolt circle on the spool is larger than the bolt circle on the ring gear by just enough to be able to have the new holes drilled without any of the holes meeting each other. I'm now wondering if its possible to find a 9" spool as an un-drilled blank ? That would be nice...

I did nothing on the car today as I was at the track crewing and tuning for some friends and also helping my Son shakedown his race car after some winter mods. The weather was sunny and quite warm over here at 63F so we all had our jackets off

The cars are now tucked away and under cover so its cold beer while waiting for the Chinese to be delivered while I kick back and watch the "Greatest Drag Racing Movie Ever Made" from back in the day.. American Nitro, featuring the Mongoose and a host of other cars !!

American Nitro - Trailers and Facebook Fanbox

Now thats what I call a good end to a Great day

Peace and love folks

Pel

-

03-09-2014 04:21 PM #141

Thanks for the link.. I hope the video is a lot better than the audio! LOL..

-

03-14-2014 04:40 PM #142

-

03-14-2014 06:28 PM #143

WooHoo!! New Parts!!!

-

03-15-2014 02:20 PM #144

Hell Yeah !!!

The shafts are already at the machine shop being trimmed so my brake drums will fit. I'm going to use the 5x4.5" pcd for some new wheels.

I hope to have all the parts back in a week so I can start trial fitting before final adjustments

-

03-19-2014 03:27 PM #145

-

03-19-2014 03:30 PM #146

-

03-19-2014 05:13 PM #147

Good Stuff there! TWICE!! LOL..

-

04-01-2014 02:45 PM #148

A small update !

Tonight was the first proper trial fit.

I wasnt far off with my guesstimate about where the shaft would end when fitted.

I had both shafts trimmed back to extend the area where the bearings will press on. I used a spare bearing and took the O/D down by 1.1mm on the belt sander so it was a slip fit in the casing. Then took about 4thou out of the bore of the bearing so it was a slide fit onto the shaft with just light pressure required to push it on by hand.

Then I fitted the bearing and brake back plate onto the axle case and slid the shaft in until it hit the stop up against the bearing.

It looks pretty darn good I must say

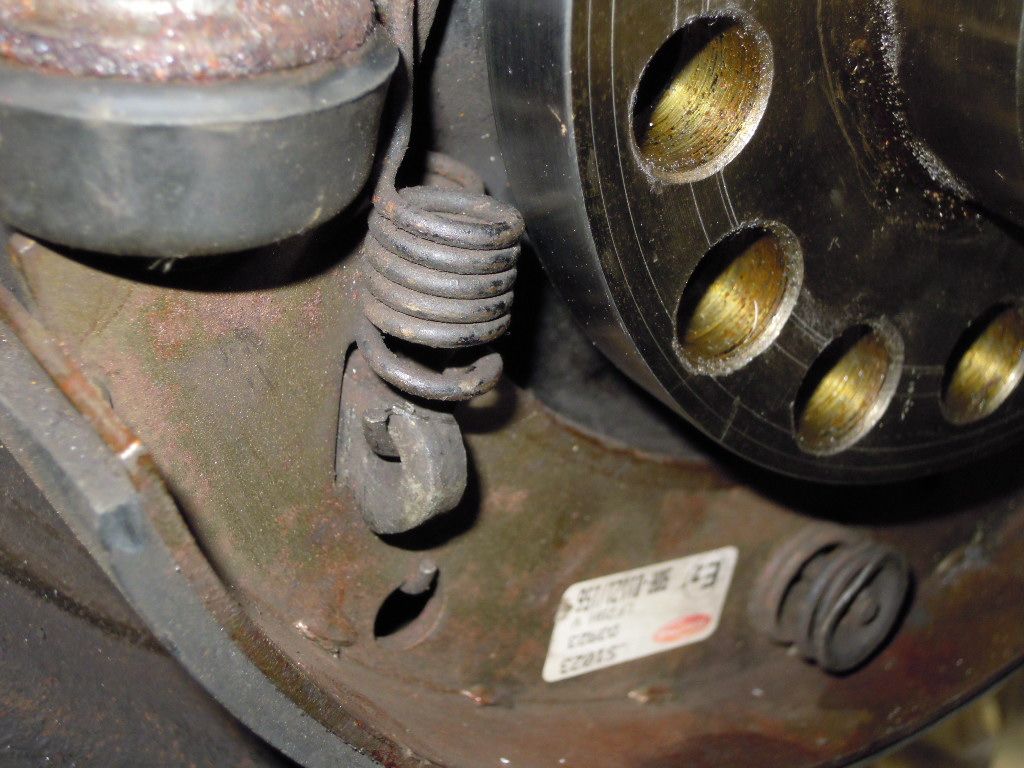

At least 5/8th" clearance for the back of the wheel studs, but I just need to trim a chamfer onto the back of the wheel flange to clear the bottom brake spring. Cant really see it in the pics but there is about 10thou clearance. I'm just worried about the spring vibrating and touching the flange. I fitted the brake assembly with temp bolts and nuts. When the brakes etc are fitted and the bearings pushed on I will have to fit the bearing retainer plate bolts from the rear and use a modified spanner to hold the nuts while I do it all up.

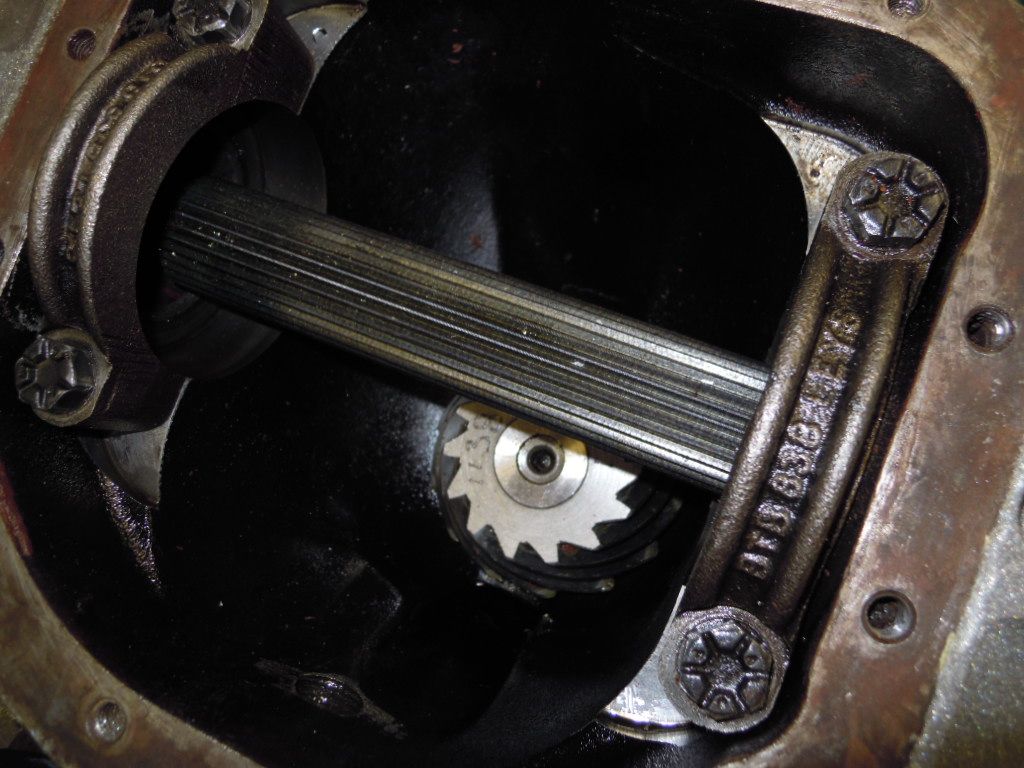

And you can see the shaft will need to be trimmed to size when the final fit is done. I cant do this until I have the spool back from the machine shop though. The splines in the spool are not central, so I'll need to measure and mark the outside of the spool to show where the splines are and then strike two marks onto the diff case so I can fit the shafts without the spool and mark the pints where I need to cut. This will be done on the loose fit bearings. When the shafts are cut (long on drivers side and short on passenger side for my UK car) I can then assemble the brakes etc and press the bearings into place on the shafts in my mates hydraulic press.

So far so good I think ??

-

04-03-2014 01:03 PM #149

-

04-15-2014 02:28 PM #150

Spool now ready for final fitting tests this weekend !!

I have had some issues with machining the hard steel. But i got it figured out in the end. Ring gear drops on and seems to fit nice and flat according to my marking out with the horrid blue stuff which gets everywhere

I have over bored the bolt holes so the cap head screws can be fitted with EN40 washers which we made in the machine shop on Monday from a stock bar that we trimmed, bored and paired in the lathe. This will give the best clamping force I think.

The project it becoming a little fragmented due to various factors. So we are doing small jobs out of sequence between my house, the machine shop and a friends garage. The net result is that all parts are slowly coming together to ensure that this holiday weekend should see the spool fitted and tested for correct mesh of the gears and also to determine the final measurements for the spool bearing side shims. I have enough shims to get me nearly there and I am cutting up feeler gauges and odd offcuts of shim stock to slip in beside the bearings in the casing to make sure I can measure the thickness required for both bearing shims. Once I have this measurement I will order two thick stock MGB shims and get them ground to the correct thickness next week.

I think this is the finished machine work on the spool ????

264Likes

264Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

How much did Santa have to pay for his sleigh? Nothing! It's on the house! .

the Official CHR joke page duel