Thread: Hello from an old member

-

05-05-2014 03:19 PM #181

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,297

- Blog Entries

- 1

Sorry to hear about the issues but at least you found them! Do you recheck the torque of the head studs any after you initially torque them and make a certain amount of passes? Just curious, and what materials are your gaskets made from? Your friend's van looks awesome! The front engine dragster looks very nice as well! What's the story with the little convertible?Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

05-05-2014 03:31 PM #182

Hi!

I normally torque the heads down in 3 stages of 50, 60, and 70 ft/lbs in the garage with 30 mins between each torque down. I use VHT copper gasket adhesive as well. This is the first time I have used O ringed heads though. Never had this issue before without O rings. I used to use normal composite head gaskets. But on the last engine I changed to Cometic multi layer steel gaskets and these were fantastic. But I could not use these with the O ringed heads so I gave them to my Son for his V8 Escort project. He has rebuilt his motor 4 times in the last year and re used the Cometic gaskets with no problems.

So I am now using stock Composite head gaskets again. I guess I need to re check head torque from now on.

Which convertible are you talking about ? The Red one or the Blue one ?

Pel

-

05-05-2014 05:55 PM #183

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,297

- Blog Entries

- 1

Pel, if you have O-rings now, retorque them after a heat cycle and they should be alright. On these diesels when we o-ring them, we usually use the OEM gasket and ARP studs. I torque them in 3 stages, and then I fill the cooling system and plug in the block heater over night. Then unplug it and let it completely cool, then recheck the studs. Usually you get a little more on each one. After that it should be fine. We've had good luck doing the heat cycle and rechecking them.

On the question above, I missed the description you gave. Definitely sounds like some cool stuff and that young lady is awesome. I see a lot of young ladys moving out of junior dragsters into super fast drag cars. Pretty dang cool if you ask me!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

05-06-2014 02:45 PM #184

Thanks for that advice

I can re torque before I race next Sunday.

I took off the rockers gear last night and went to the machine shop this afternoon. I explained to my friend that I needed to remove the adjuster stud that I glued in with loctite permanent !!

The trouble is that the stud is so darn hard that I didnt want to try an easy out as I didnt think it would dig in and grip. And if it did, it may just snap off and make things worse. I knew that I could heat the rocker in the oven to soften the loctite, but I had no way of unscrewing it

My good friend looked at it and said "so whats the problem" ? I said, "I need to be able to unscrew the stud but there is no way I can grip it" He said, "just use an allen key" I said, "how the hell can I use an allen key to undo a hard steel stud with no allen socket in the end?" He said, "come with me young Jedi" Ha Ha"!!

He then took me to a machine in the corner of his shop and started to mount my rocker in a clamp? He then fitted what looked like an allen key into a chuck? He then pressed several buttons and twiddled several knobs on this strange machine, which looked like a milling machine ??

What happened next had me watching with my jaw dropped. The table under the chuck was submerged in some green oily stuff as the sides rose up from around the table and this green stuff flooded the rocker. Then the chuck moved down on its own and a sound like a geiger counter came from a speaker unit on the wall. Then magic started happening under the oily fluid as I saw tiny lightning bolts and bubbles rising with puffs of smoke coming from the bubbles as they burst on the surface of the fluid?? OK!! So maybe I'm the only person who has never heard of spark etching

What a fantastic contraption this machine is. I WANT ONE !!

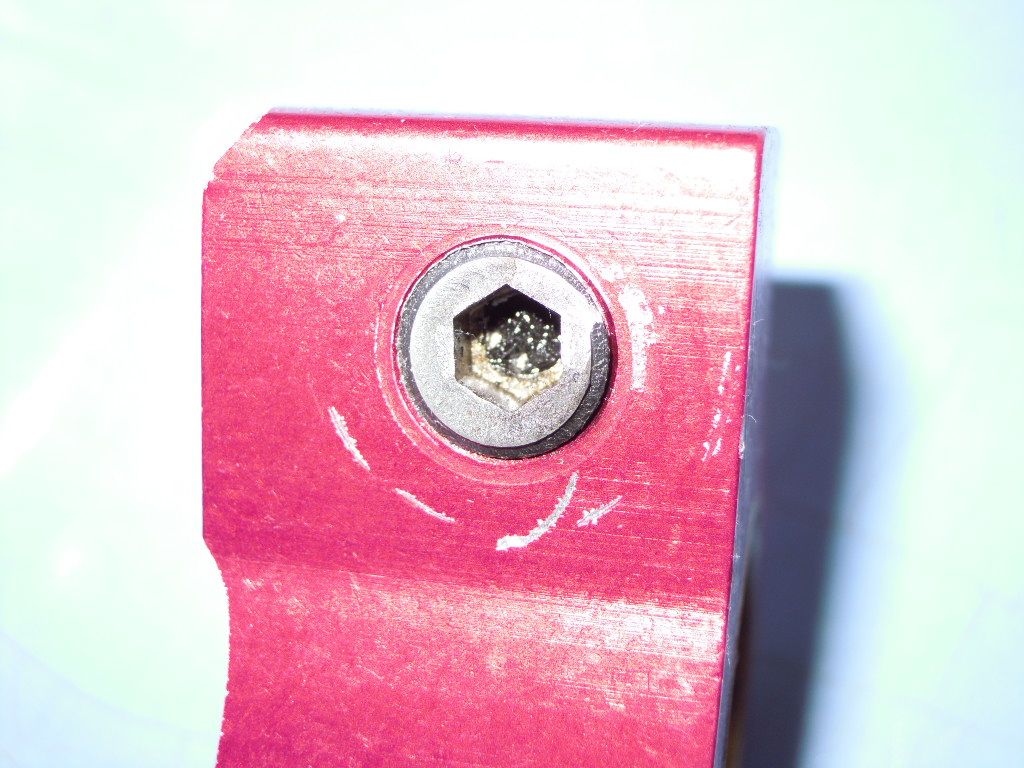

By the time the kettle had boiled and our tea was ready the machine beeped and the magic fluid drained away. Then Geoff unbolted the rocker and this is what I saw....

And this is what I started with !!

Holy Moly!!

Then it was back home to put the rocker in the oven for 20 mins at 220C which allowed me to do this...

HOORAY!!!!

Its 9.20pm here and I'm just back from dropping the rocker through the letter box at the machine shop so Geoff can get busy tomorrow re drilling and tapping to fit a 7/16th unf adjuster from a pro comp chevy rocker. The Kenne Bell adjusters are smaller. My friend with the slingshot has a full spare set of chevy rockers for his engine and he told me to go to his garage and help myself to some spares as he wont need them anytime soon. At least this will get me rolling for the weekend. I have put the word out to my Drag Race buddies and I now have an offer of a used set of KB rockers for very cheap money to put on the shelf. I will only use the pro comp modified rocker for the short term until I can fit a used OEM rocker.

So I can now be out for a grudge race this Sunday I wont win, I never will win against this car. But its fun trying as each time I turn up to race this guy every year I surprise him a little more. He runs a Chevy Monza which is his Drag School car and its very quick. We race on an unused runway at an old airfield. The surface is rough concrete and its a given that you always run at least 1 second slower on slicks than you would run on a prepped Drag Strip. Last year I ran a 10.6 @ 130 something to his 10.3 at 153mph. He toys with me to about 1000 feet and then puts the pedal down just before the finish

I wont win, I never will win against this car. But its fun trying as each time I turn up to race this guy every year I surprise him a little more. He runs a Chevy Monza which is his Drag School car and its very quick. We race on an unused runway at an old airfield. The surface is rough concrete and its a given that you always run at least 1 second slower on slicks than you would run on a prepped Drag Strip. Last year I ran a 10.6 @ 130 something to his 10.3 at 153mph. He toys with me to about 1000 feet and then puts the pedal down just before the finish

I really enjoy this annual race as does Paul who runs the Drag School.

https://www.youtube.com/watch?v=jvrk...iZ--GyG4tfRrjw

-

05-06-2014 03:05 PM #185

Very cool video, reminds me of the drag strip in Ohio Where I flagged many moons ago.Ken Thomas

NoT FaDe AwaY and the music didn't die

The simplest road is usually the last one sought

Wild Willie & AA/FA's The greatest show in drag racing

-

05-06-2014 03:13 PM #186

Its a great place to race. No frills, just plain old RWYB

-

05-06-2014 04:10 PM #187

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,297

- Blog Entries

- 1

Very cool on the sweet machine to cut hex's! And that's a cool race/and track. Thanks for sharing and good luck sir!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

05-07-2014 11:18 AM #188

"So maybe I'm the only person who has never heard of spark etching?"

Add me to the list Pel, That's so cool!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

05-07-2014 01:51 PM #189

Aint it just ???

I now have another technique in the memory bank for any other odd problems.... My mate at the machine shop says he has a friend who does only spark erosion / etching for special projects for F1 race teams. This is his year round living making bespoke parts for the F1 cars

-

05-07-2014 01:57 PM #190

Google CDM, capacitive discharge machining... it's really amazing what electricity and a piece of wire can do.. look it up on youtube also, you can do it at home!

-

05-10-2014 02:49 PM #191

Hooray!!

I have found an engine builder who had a bucket load of used Kenne Bell roller tip rockers on the shelf. So I can store the repaired rocker and fit an original one. Actually the new rocker is already fitted and the heads re torqued and the car is outside on the trailer ready for a 5.30am start to get to the track in the morning. I just need to stop to fill the fuel can and I'm going racing after the 80 mile drive to get there. Having said that it raining here and the wind speed is horrendous. And my barometer is dropping like a stone. So I may have a long tow to the track only to find we sit in rain all day

But thats what we do when racing at this old airfield. They only do 3-4 RWYB days per year so it gets busy. Gates open at 8.30am, but if you are not there by 7.00am latest the queue can be so long that you may not make sign on as the close the book at 200 cars.

-

05-11-2014 03:20 AM #192

Hopin' to hear that you had a good day at the races! Fingers crossed.... 8-)

-

05-11-2014 02:11 PM #193

OH YES!!

It turned out to be great day despite the strong side wind and early rain which dried off by 11am. First pass was ok but blew the tyres off in all 3 gears while struggling to stay straight. 10.6 seconds Second pass I launched at 3/4 pedal for the first 100 feet so i didnt activate the nitrous. When the pedal hit the floor it hooked reasonably well but was wandering quite a bit, 10.4 seconds on that pass

Second pass I launched at 3/4 pedal for the first 100 feet so i didnt activate the nitrous. When the pedal hit the floor it hooked reasonably well but was wandering quite a bit, 10.4 seconds on that pass  Then I had an idea to programme in a 1 second delay on the nitrous so I could launch hard on boost only and thenhave the nitrous ramp in as usual once rolling around 45mph. Bad idea !!!

Then I had an idea to programme in a 1 second delay on the nitrous so I could launch hard on boost only and thenhave the nitrous ramp in as usual once rolling around 45mph. Bad idea !!!

Especially as I dont have my nitrous set to reset the boost ramp when throttle is deactivated. So I hit the gas and spun the tyres right off the line on full boost, then the 1 second delay took me by surprise and spun the tyres harder, so I short shifted to 2nd to see if it would calm down. It didnt, so I backed off the pedal just enough to cut the nitrous and shifted to 3rd. Then when I put my foot in again the tyres let go again and I was wandering quite badly so I pedalled it twice and each time the tyres spun up and I was facing left or right. So I shut it off about 100 feet short of the finish and got myself safe. Quite possibly the most frightening run I have ever done. But the timing ticket was an 11.01 so not too bad at all. Typically on this track your times are 1 second to 1.2 seconds more than running on a prepared Drag Strip. So the numbers are all good from today

Then I put the car on the trailer as I would have been wasting tyres, nitrous and engine if I had done any more passes. So I watched others race for the last 2 hours

-

05-11-2014 05:12 PM #194

Glad to hear you had some passes at least.. Do you not have any "smaller pills"?? Can you not back down the power level on the nitrous?

Or do you prefer it.. "balls to the wall"!! roflmao..

-

05-12-2014 12:05 PM #195

"" Can you not back down the power level on the nitrous? ""

WHAT !!! This aint like dusting crops boy !! (Star Wars folk will understand)

I thought my second pass with the 10.4 and launching half pedal before activating nitrous was good. Hence the idea of adding a 1 second delay on the nitrous hit so I was rolling before it ramped in. I wasnt expecting the launch on boost to hit so hard. I can drop the nitrous down as low as 50hp with my jets. But the nitrous box was at home and I dont like going backwards to suit a poor track so I thought I could do it by reducing the initial hit and bringing the gas in more slowly. It was good fun all the same. Luckily a mate was filming another mate in his AMG and I was next up so I'm on the end of this video. I dropped the tyre pressure by 1psi to see if that might help, but no. Its just an old concrete runway with weeds growing out of the cracks

If the tyres had not started to skip I may have got a clean run. By the time I've launched the slapper bars pretty much lock up the rear springs and the car is sitting on the bump stops, so all my suspension is the tyres at that time, and if they let go I get shaken up inside. You can see the shift light go out well before the finish, so it could have been a good run if I hadnt started to dance to the tune of my slicks (as you can hear in the vid) And yes!! Balls to the Wall every time for me if I can

I'm going to leave that nitrous setup as it is for a run on a proper track next Saturday as it will be interesting to see how it goes?

Regards

Pel

https://www.youtube.com/watch?v=vEMF...ature=youtu.be

264Likes

264Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

You've not been around here for a while, Charlie, but when you were you had GREAT projects!! Happy Birthday!!

Happy Birthday Charlie Fisher!