Thread: Hello from an old member

-

01-24-2015 03:51 PM #346

You've got a fantastic crew of friends there, Pel! I REALLY like that EFI manifold on the SBC! It looks very nice, clean and pristine, with the cross over inlet bells. SWEET! Who makes it?Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

01-25-2015 02:32 PM #347

I'll ask him Roger. ....................................................................................

I've asked him now and he says he got the manifold on USA Ebay. Crossover Weber Manifold.

He says the ITB's were made by this guy FOX ENGINEERING CO. - HOME - WEBER EFI REPLACEMENT

-

01-25-2015 02:49 PM #348

The basic news from todays tear down is:

All con rod bearings worn to the copper, except the two that had vapourised and left nothing but a badly damaged journal and two wrecked rods.

All of the crank main bearings show galling marks, but the mains on the crank dont look more than just a little scuffed so they will polish up ok.

The big problem was that the crank was tight to turn even with all of the rods removed. So we removed the main caps as well and it was still tight, but with one loose spot in rotation. So I guess the crank is now bent or distorted in some way ?

Luckily one of the guys on site today had this problem before and he has a machine shop guy that corrected this for him on his engine. Apparently this guy took his crank and made it straight and then re ground it and balanced it as well for not much money. Then my mate had the crank cryo treated by another guy I know at 195 below in the UK. This is Andy at 195 below who cryo treated my original MGB drive shafts a while back. Believe it or not this made them twice as strong??

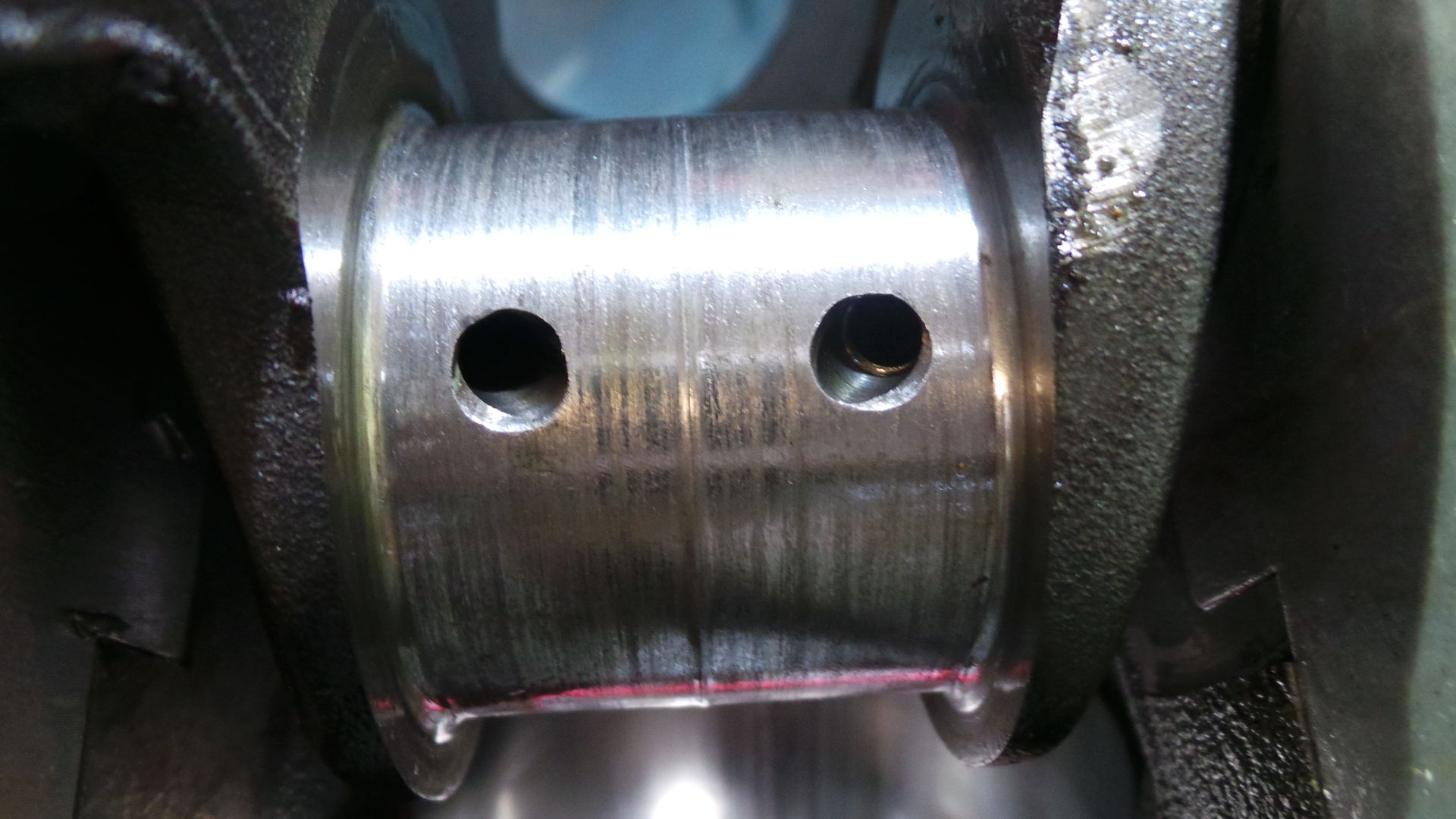

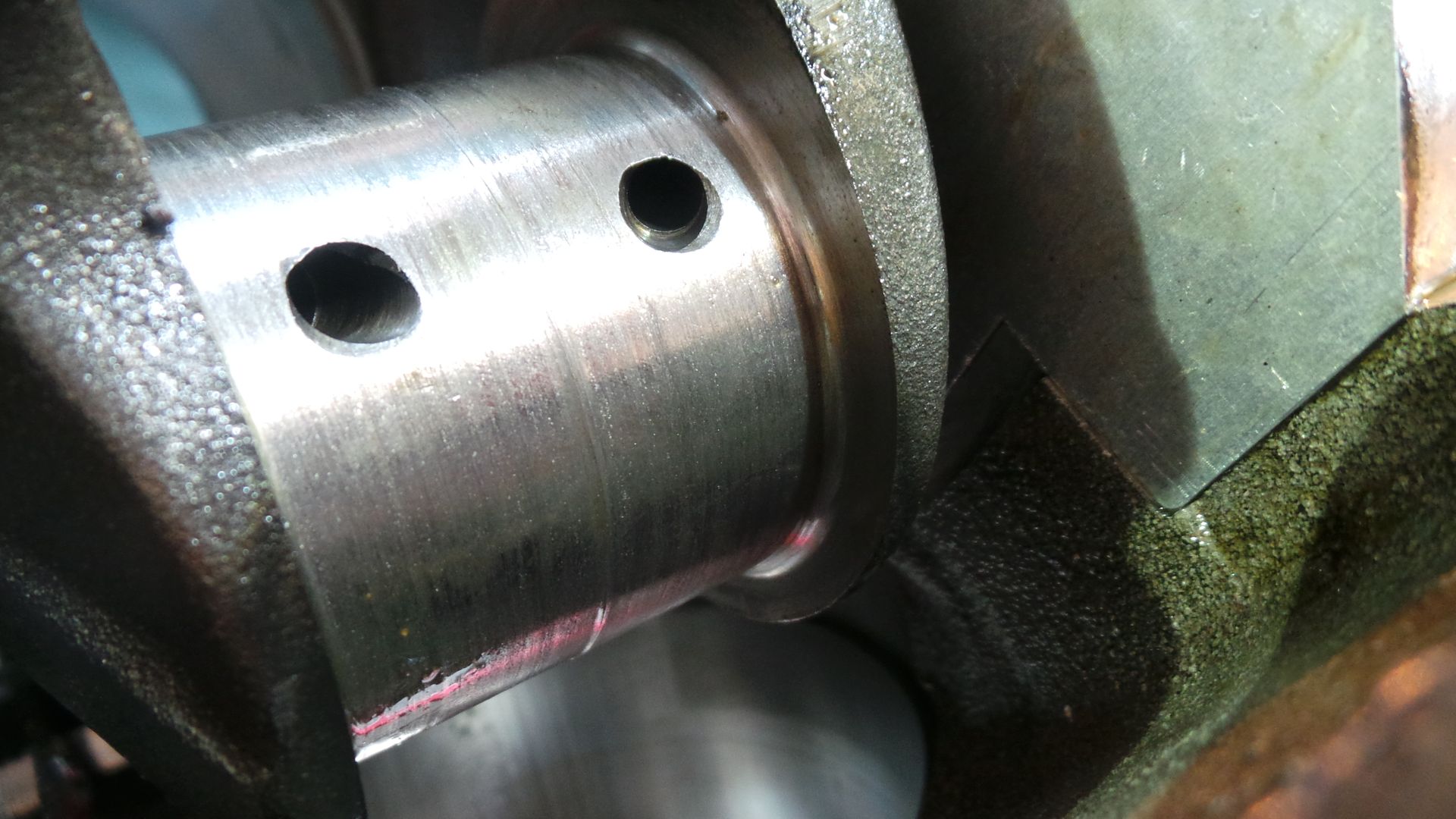

So there may be hope for the old Rover this year. Here is the worst con rod journal from two angles. In the second picture you can see a raised groove between where the shells would have sat

-

01-25-2015 05:39 PM #349

Ouch.. I guess it could be worse somehow?

Perhaps there's a chance to do an offset grind and gain a touch of stroke? I am not familiar with the Rover engine.. but - just thinking out loud here!

Glad to hear that your mates got it out and identified the issues so now the healing can begin.

-

02-06-2015 02:39 PM #350

I hope this link works ??

https://www.facebook.com/video.php?v...81&pnref=story

-

02-07-2015 03:59 AM #351

sadly.. no!

-

02-07-2015 07:16 AM #352

Wow! I guess those strong shots of Happy Gas carry a price! Not doubting, but thinking of the forces required to bend a crank that's secured in the mains - that's some POWER, seems to me.Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

02-07-2015 01:51 PM #353

I'll try to get the video link working guys.

Its just a few seconds showing the crank running on the test rig with a dial gauge on the centre main journal. We didnt need the dial gauge to be honest? The crank is rotating 3mm out of true YIKES !!!

I now have to get a spare crank from a mate to drop it into the block to make sure the block is still straight, which will be lucky I think ?

So while I'm waiting to do more checking I have made a small start on the SBC build. Well, not so much build, but I have just found a really neat set of Mickey Thompson valve covers and a billet alternator bracket

Pel

-

02-07-2015 03:39 PM #354

-

02-07-2015 04:23 PM #355

That one works. Shame about the crank, I'll keep good thoughts that the block is ok.Last edited by 34_40; 02-07-2015 at 04:23 PM. Reason: lernin tospelz

-

02-07-2015 04:35 PM #356

I guess I didn't know that you could bend a casting. I would think that if the block saw enough force to push the limits it would crack vs deform?Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

02-08-2015 07:53 AM #357

Overtighten the intake bolts on a sbf and you can measure the distortion in the base pan rail.

The block needs to be "flexible" or it will crack. I'm certain PEL is beyond the limits but we'll see for sure now!

-

02-08-2015 10:43 AM #358

Last edited by rspears; 02-08-2015 at 11:43 AM.

Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

02-08-2015 12:32 PM #359

I'm hoping for good things with the block

I will try to get off work early tomorrow to go and grab a spare crank so I can drop it in and see if it spins ok ?

If it doesnt I'll take the crank and block to my engine guy so he can check it to see if it can be line bored to make it work.

The block has showed no signs of water leakage or cracking anywhere which may be a good thing ?

Pel

-

02-17-2015 01:52 PM #360

A quick update!

Work has kept me from doing any checking. I have taken Thursday off this week as Gill and I will be going to the theatre to watch War Horse in London. So early on Thursday morning I will be dropping my block to the engine shop for proper checks to be done by my engine guy. I will also be collecting the SBC from him for my mates Slingshot so we can get that back together for the spring so I can run it on track while my buddy recovers from some surgery he is having next month. So at least I'll be on track for some fun this season

Results of the block testing to follow ??

Regards to you guys over there

Pel

264Likes

264Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

How much did Santa have to pay for his sleigh? Nothing! It's on the house! .

the Official CHR joke page duel