Thread: How To: Notching tubing

Threaded View

-

06-28-2006 09:27 AM #1

How To: Notching tubing

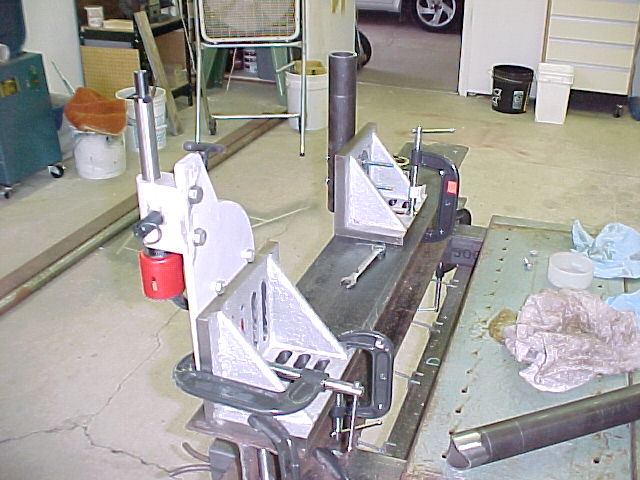

Hey guys, I don't know how many of you do your own cage or chassis work but this how I set up my jigs for notching tubing.

I set all of this up on one of my jig tables but it will work on any bench or table top you have handy.

These pics show my Harbour Freight tubing notcher clamped to a 90* angle plate. This is simple to set up and doesn't require a lot of thought...

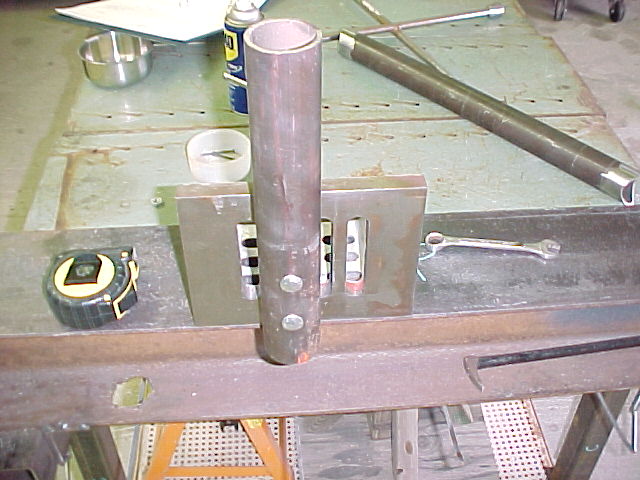

From the backside...

Cutting the first notch is the easy part. No orientation, no length to worry about. Just clamp the tube in the notcher and do the deed.

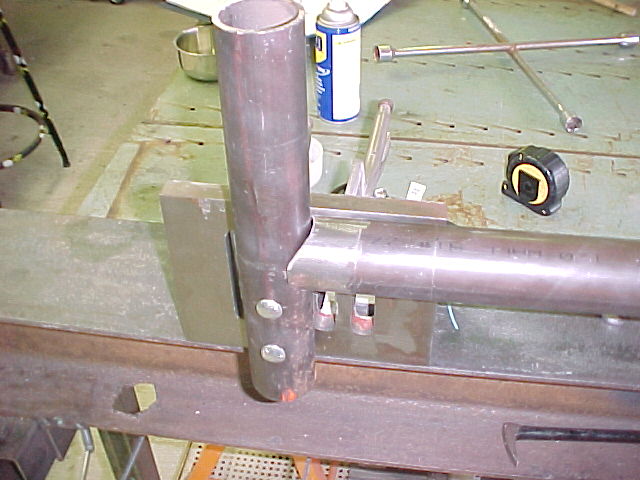

Cutting the second notch is where some planning needs to be done. Getting the LENGTH and the notch ORIENTATION correct is critical to having a usable part versus something to practice welding on...

To do the second notch I bolted a short piece of the mating tubing to another angle plate and use this to nest the "first" notch into while cutting the second notch.

This way I can establish the correct length AND notch orientation in one easy step... Set the tubing length between the outside diameter of the tubing and holesaw, in this case 23 inches, square up the jigs, clamp it all down and cut the second notch. Once it's set up any additional tubes will be identical to the first so measure twice and cut once...

Cutting the second notch...

Thanks for looking

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

I wore a camouflage T-shirt once. The response in the pub was "Oooh, it's a floating head!" .

the Official CHR joke page duel