Thread: Low cost homemade welding tool.

-

06-30-2007 08:34 AM #1

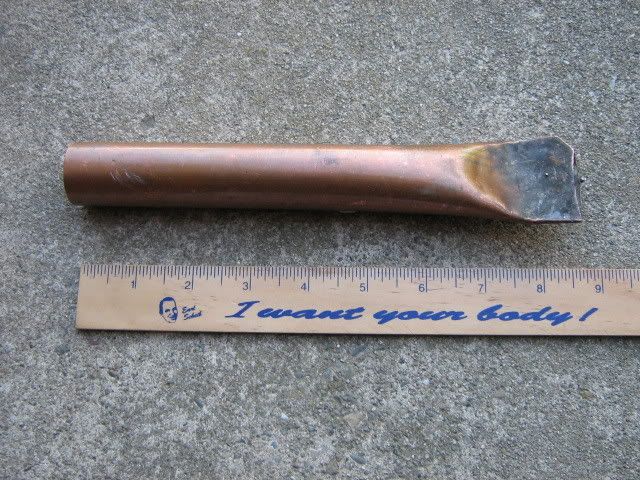

Low cost homemade welding tool.

We have all seen this tip mentioned on the forums, I thought I would put it in the "flesh." Weld won't stick to copper or brass. So, if you had a hole in metal you could temporarily put a piece of copper or brass behind the hole, weld into the edge of the hole with your MIG and literally fill the hole up without the weld falling thru. Remove the copper or brass and the back side will actually be as smooth as the surface of the copper or brass! It is a very neat trick and there are a bunch of tools you can buy for this purpose.

For example, I have a pair of "Vice grip" pliers with the copper backing built onto it. This is a very useful tool and like all tools, you just can't have enough. But it is very limited by the "throat" of the tool. If you have a hole out in the middle of a panel, it is worthless.

One day I found myself needing a copper backing, I walked over to a pile of pipe cut off a piece about 9" long, smashed one end down real good with a hammer and a new tool was born. This is 1" diameter but it could be made from about any size. It has a handle so I can hold it up for a fast weld were even my clamp would have worked. Or I can reach around the back of panels to weld a hole out in the middle. Works like a charm. It was free because I had the pipe sitting there but one quick trip to the hardware store and a few bucks (or less) and you can make one too.

Brian

Last edited by MARTINSR; 06-30-2007 at 08:47 AM.

"Fan of most anything that moves human beings"

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

06-30-2007 08:50 AM #2

I like that one.

I'm surprised in over six years of existence we haven't made a forum for this kind of thing since they pop up every so often. Might get even more if there were a specific section for it.

Okay mods, how about a "Home made tools and neat ideas" forum, either on it's own or under "Shop Talk"?Your Uncle Bob, Senior Geezer Curmudgeon

It's much easier to promise someone a "free" ride on the wagon than to urge them to pull it.

Luck occurs when preparation and opportunity converge.

-

06-30-2007 08:52 AM #3

Cool tip, thanks. I can tell you one thing........pennies don't work. I backed some holes in my T with pennies (thinking they were copper and all) and they turned to white powder that was all over the place. They lit up like a flare.

Next time I'll try tubing.

Don

-

06-30-2007 09:30 AM #4

You know, the problem with the "special forum" for such a thing is just a fraction of the visiters would see it. Even on forums with "tools and stuff" forums I still post stuff like this on the "general" talk or something because way more people see it. I'm a rebel like that. Originally Posted by Bob Parmenter

Originally Posted by Bob Parmenter

Things like this "gets you" thinking about tools, the "correct" thread is viewed when you ARE thinking about tools.

Brian"Fan of most anything that moves human beings"

-

06-30-2007 09:42 AM #5

While there's merit to what you say, I am thinking of it more from a "re-finding" it perspective. Maybe it depends on how a person's "skull hard drive" stores info. I'm just thinking about a guy who's seen something, a few months later is in a situation where he suddenly thinks "hey, I saw something that might work here", and wants to retrieve it. Since the search engine here is pretty specific, if you don't have exactly the right terminology that the original author used, you'll likely never find it. At least with a unique forum you'll have fewer posts to sift through.Your Uncle Bob, Senior Geezer Curmudgeon

It's much easier to promise someone a "free" ride on the wagon than to urge them to pull it.

Luck occurs when preparation and opportunity converge.

-

06-30-2007 09:50 AM #6

Brian,

All you have to be is a member here as well as Hotrodders.com and the Tips and Tricks "mysteriously" appear.

Dave

-

06-30-2007 10:04 AM #7

Now that makes sense! Ok, I got you. Originally Posted by Bob Parmenter

Originally Posted by Bob Parmenter

Dave, I am like the Wolfman....I am everywhere!

Brian"Fan of most anything that moves human beings"

-

06-30-2007 10:54 AM #8

Neat tip. I have used copper tubing to make connectors for large gauge wire such as 3/0, 4/0. I flatten one end, round off the corners a drill two holes. One for the size of the terminal that it's going to be attached to and a smaller one on the angle for feeding solder. I think it makes a better connection than crimping.Ken Thomas

NoT FaDe AwaY and the music didn't die

The simplest road is usually the last one sought

Wild Willie & AA/FA's The greatest show in drag racing

-

06-30-2007 11:06 AM #9

I had to pick on someone today - and you just seemed to be a 'natural' Originally Posted by MARTINSR

Originally Posted by MARTINSR

Dave

-

07-01-2007 01:47 AM #10

I actually have not done it yet but have made the pipe already.

Red

-

07-01-2007 10:34 PM #11

I too have used this trick, (or a variant of it,) I used to have a lot to do with heavy machinery, where a lot of parts (bulldozer blades, digger buckets etc.) are pinned on with pins sometimes up to 3" thick.

Most times, when they break, it's at the hole through the pin where the lynch pin goes.

I used to lay a piece of copper or brass rod across the broken pin where the lynch pin would go and weld over it, then knock the rod out when I'd finished, leaving an accurately placed hole behind.

I'd then run a drill through just to check I hadn't inadvertantly left any lumps or bumps behind, although usually it was pretty clean.

If the rod didn't want to knock out; well 3" of copper or brass is easier to drill through than low hydrogen steel!

It takes a lot of patience to lay just weld after weld down, and waiting for it to cool, but if a replacement part is obsolete, or on the other side of the world, sometimes your options are limited.

johnboyjohnboy

Mountain man. (Retired.)

Some mistakes are too much fun to be made only once.

I don't know everything about anything, and I don't know anything about lots of things.

'47 Ford sedan. 350 -- 350, Jaguar irs + ifs.

'49 Morris Minor. Datsun 1500cc, 5sp manual, Marina front axle, Nissan rear axle.

'51 Ford school bus. Chev 400 ci Vortec 5 sp manual + Gearvendors 2sp, 2000 Chev lwb dually chassis and axles.

'64 A.C. Cobra replica. Ford 429, C6 auto, Torana ifs, Jaguar irs.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Looking good

Stude M5 build