Thread: Project Special K

-

04-02-2011 12:01 PM #481

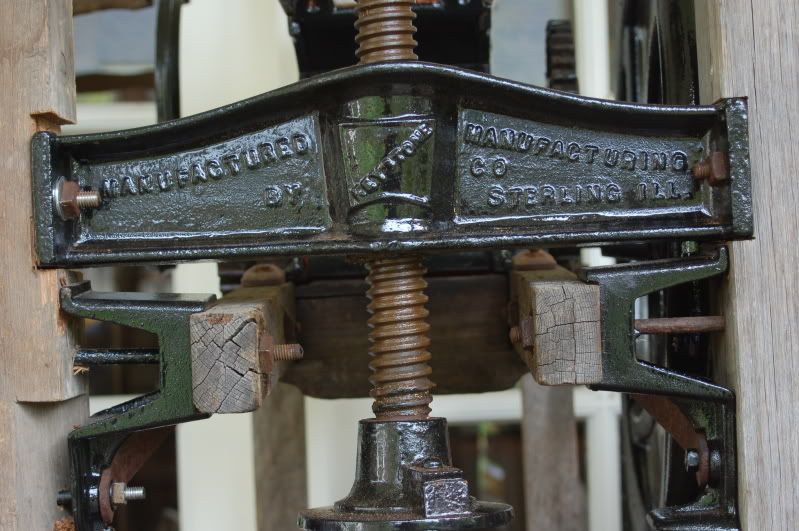

Well now that we have great weather again, I'm finishing a bunch of small projects, to clear way for the truck. I had bought an antique apple press made by Keystone, with a 1875 Patent stamp on it. Last year we used it to make apple cider, but even though we cleaned it as much as possible, the juice still had rust residue in it, from all the cast iron parts. So I decided to take it apart and coated everything cast iron with Por-15. Then the parts that came in contact with the actual juice, I put a enamel coat of a food grade paint over the Por-15 . The paint was hard to find, and only came in "gondola red" which looks like "puke orange " to me, so I left everything out side Black. When I was unassembling the top hopper/crusher, I found that who ever took it apart last had reassembled the housing wrong. As a result the Hopper is now too narrow for the shute under it. So I'll next be making a new hopper out of some cabinet grade plywood, and also will be making the juice shute out of new wood, that can be treated with a food grade clear urethane. Once it is done, we should have some high grade apple juice this summer, which will be made into hard cider too.

While it was apart, I had to make a new main post for the press side of the apple press. One leg is newer made of some nice oak, but the other leg was rotted at the base, which caused problems during pressing last year. It's cool looking at this thing, it was just so well made originally! The fly wheel alone is massive and weighs a ton! Anyway once this is done, I'll be back to the truck!

Last edited by stovens; 04-02-2011 at 12:17 PM.

"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

04-02-2011 12:22 PM #482

Here are some more shots of it. On the post I replaced, I used a piece of recycled lumber from a local guy who specializes in this, and used a teak timber that was part of a door frame recycled from across the world in some tropical village, it just happened to be the right dimensions, and teak is an excellent choice for this sort of thing. If you look closely you can see a dado'd triangular wedge missing from the new post where it married into part of the door frame.

Last edited by stovens; 04-03-2011 at 12:23 PM.

"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

04-02-2011 12:31 PM #483

Here is a before picture with the bad post facing front.

"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

04-02-2011 06:14 PM #484

Steve,

Very cool! I think it needs a sbc and a Lenco

Ken

-

04-03-2011 12:14 PM #485

Ken I'd have to lighten the frame for that! It is funny, the Gondola red looks similar to Chevy Orange to me!

It is funny, the Gondola red looks similar to Chevy Orange to me!

Now a SBF and hopped up C-4 with Ford Blue that's the ticket!

"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

04-24-2011 10:51 AM #486

Well with intermittant rain continuing into our unforseen future, I've been doing woodwork. I made a new bottom tray for the apple press in the above posts, but really wanted to get back to the truck. So yesterday I went to our only hardware store that sells plywood and got some cabinet grade 1/2" plywood to mock out a console and base for my shifter. The original base I made out of sheet metal, beacause that was all I had at the time, and I wanted to practice my welding, but after a lot of thought for down the line interior work, decided to go with a plywood center console to mount the B&M truck shifter to, and also it serves as a tunnel to hide all my wiring, especially since I want to mount my huge Hyw 22 Fuse panel behind the seat, instead of by my left leg while driving!. It's funny the lack of interior space on a truck! The engine bay has tons of space but the cab is relatively small, especially with the stock seat in there. I had read on here about old 80's Fiero seats having speakers in the head rests, and have intertained the idea of putting two bucket seats in there, but for now I think the stock bench is more traditional, so I'll stick with that. Anyway I'll be working on this today, until it's time to visit the Easter Bunny for dinner!

"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

04-30-2011 01:43 AM #487

Well the weather was here, and I finally got back to the truck. I spent the better half of the day drilling and welding, and mounting my shifter and linkage to the old C6. The hardest part was trying to get the linkage aligned in between gears. But as the day wound down I got close enough to give it a try. Fired up the 460, and put her in gear for the first time in several years, she drove into the garage under her own power. The brakes were sticky as was the idle, and the tranny fluid was low, so I didn't push it, but it was so nice not having to push her back in the garage! Now to order a Loker tranny fluid dip stick!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

04-30-2011 02:47 PM #488

-

04-30-2011 04:41 PM #489

Always a banner day the first time a project is able to move under it's own power!!! Congrats!Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

04-30-2011 08:51 PM #490

Yep! It's a great day when you can drive it instead of pushing it!

-

05-01-2011 08:16 AM #491

Just finished reading thru this thread. Very nice.

Its always good to look at different projects.

You've come a long way with that short drive into the garage.

Don't you just love that warm fuzzy feeling?

-

05-01-2011 08:47 AM #492

I'm sooooo jealous.

Wes

You don't have to be crazy to do this...

... but it helps!

-

05-01-2011 11:04 AM #493

Thanks. I planned to rebuild the shifter console out of wood, but put it on hold just to get the linkage work done. Now that everything is fitted in place, I'll pull the nasty rusted metal base out, and make one out of some 3/4" plywood, that should be thick enough for any abuse the shifter gets, and also make it easier to upholster down the road. I have Monday and Tuesday off, so maybe I'll continue on the wood part, and wiring. I'm still oscillating on what to do with the pickup bed floor area. I like wood, but 48's were a weird year, where they had wood under support planks, and a steel plate that mounted on top of the wood for a metal bed. I've never actually seen one redone stock, and I like wood myself, but would really like to find some quarter saw white oak planks for the bed-wood, and make my own custom bed, versus paying upwards of 1000 bucks, for some cheesy poor fitting aftermarket kit, that will require as much fab work as if I did it all myself to begin with! So I'm playing with using a thick plywood as a base mounted to the bed cross supports, and then get some 6-8" wide planks of white oak and secure it to the plywood and frame with metal strips that the used on the stock wood beds. Anyway plenty of time for that later, but any thoughts are helpful ahead of time. I ordered up the fire wall mounted Lokar dipstick, should be here Monday, so I'll get moving on that too! Gotta love summer!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

05-01-2011 01:23 PM #494

Wood to hold a shifter makes me a bit nervous.

Couldn't you cut 1-1/2'' from the width of the metal box and screw your 3/4 ply on both sides of it. You would have the strength of steel welded to the floor and the convenience of plywood for upholstery purposes.

Just a thought.

-

05-01-2011 05:06 PM #495

Heck, just get some 20ga. and whittle away everything that doesn't look like a console!!!! When you're planning the wood for the bed, some of the flooring stores have some really unique stainless trim pieces to use as dividers!Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

379Likes

379Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Thanks guys! One more trip around the sun completed. Lots of blessings and things to be thankful for (like still being able to type this message!!) Here's to us "over 70 guys.." Glenn

HBD Glenn!!