Thread: Project Special K

Hybrid View

-

02-05-2009 05:53 AM #1

That would have saved me more times than I would confess....LOL

BradCSome days it's not even worth chewing thru the restraints !

-

02-07-2009 04:34 PM #2

Today was at last sunny! I worked on some pre engine install stuff. The floor shifter has always been mounted to far back to where it would run into the seat so I moved it foward and then welded in a plate to fill the gap in the floor panel. Next I removed the current gas pedal to get ready to install a lokar eliminator pedal. I'm not sure if it will fit comfortably in the space between the steering column and the tranny tunnel, but I tomorrow I'll cut a hole and see how it feels. Anyway it felt good to get back to it.

"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

02-09-2009 04:25 PM #3

Lokar petal went in today. It seemed like it would be easy but took a trip to hardware store for longer screws and several hours later I finally got it in. The hole for the linkage and drilling the screws was the easy part, trying to get them into the base plate under the floor board was a different story. There must be at least three layers of metal in some spots, all kind of tweaking each screw. Anyway it feels good to have it almost done, just need to mount the cable when it comes tomorrow. here is a couple of shots, with a piece of paper propping it up, since it isn't hooked up to the engine. I also cut a few scaps of sheet metal to fill the gaps around the brake petal and steering column.

"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

02-14-2009 10:47 AM #4

Well despite rain, I'm making headway. I got my accelerator linkage and transmission kick down cables from summit, finished installing the accelerator, and have been researching plumbing an air supply to my compressor, purchased a setup from Rapid Air, that includes a water trap, so when I can get at painting the truck, there hopefully be no contaminates to muck it up.

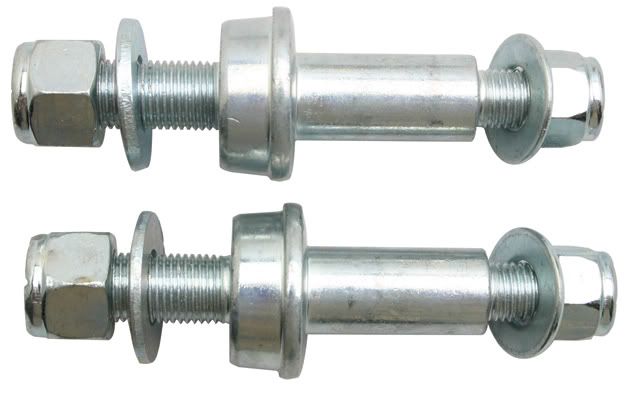

With lots of help from all of you, I feel confident enough to give it a try this spring. I also found some shock mount pins that can bolt to one side of the rear shock mounts on my 9" Ford F100 axle's existing shock mounts(i.e. no cutting and moving) that will allow the shocks to line up with the axle better to where they won't rub againt the frame by the upper mounting bolts! see photo below:

I also have given up on waiting for my friend to weld in the motor mounts( 2 months no return phone calls) and will now do it myself. The mounting kit is pretty straightfoward, and though my welding skills are not the best, the kit is a bolt on and suggests welding in addition for extra strength, but it is not necessary, so bolted and welded by me should be fine!

I'm also wondering about boxing in the frame some more for added strength and wondered if any of you has any idea of what stock to use, and if behind the cab, an x mount above the drive line to the back part of the frame near the differential will be adequate?Last edited by stovens; 02-14-2009 at 10:54 AM.

"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

379Likes

379Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Hated to see that news, he was a good online friend.

We Lost a Good One