-

03-07-2008 08:16 PM #1

stock suspension and drive set up for strip, vega.

I need to make a cross member for a power glide trans in the 75 vega. At what angle should I set up the engine and trans? Should the block be level with the car sitting level or should the carb pad on the intake be level with the car? This is for the drag strip. Anyone have good links on setup?Friends dont let friends drive fords!

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

03-07-2008 08:28 PM #2

I always set mine up so the carb pad is level...Tough to get an accurate float adjustment if you don't....Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

03-07-2008 08:37 PM #3

If the car raked ,carb pad still level??? Should it move side to side any

Friends dont let friends drive fords!

-

03-07-2008 08:50 PM #4

Don't worry about the rake on the car... I would keep the carb pad parallel with the ground no matter what attitude the truck sits at... \\Don't really follow what you mean by side to side....???? On a drag car, I like to have the engine centered, one angle for the u-joints is plenty, no reason to add a side to side angle to them also.....Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

03-08-2008 07:59 AM #5

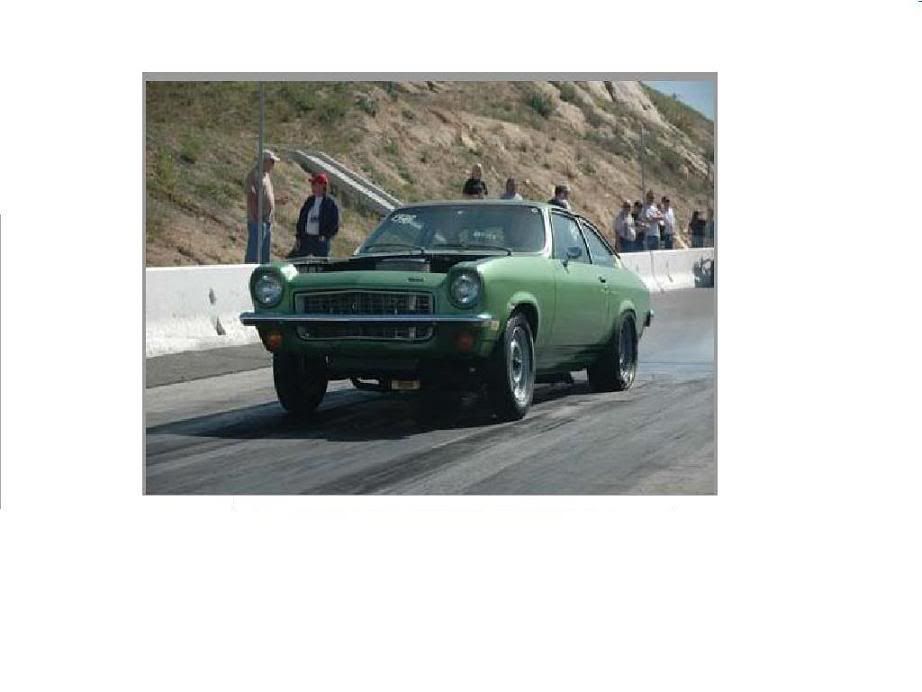

I am trying to set up something like this . This guy is running a 406sbc with track 1 brodix heads and a .640" lift roller cam on nitrous. He is using a ladder bar set up ,he said he lost 2 tenths on his time by switching over tot the ladder bars.

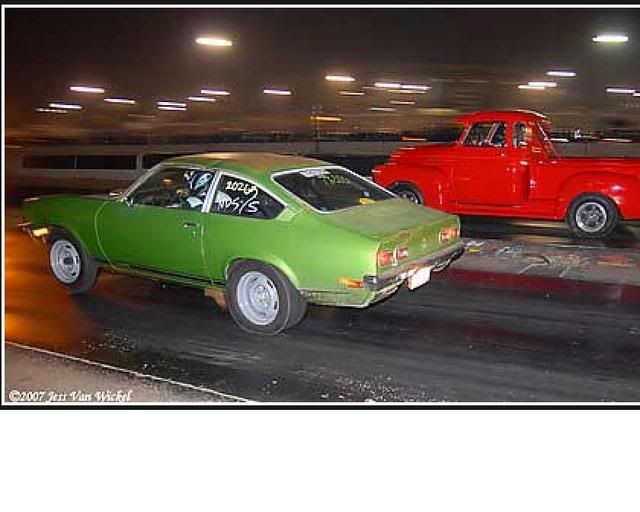

Heres another thats running the stock 4 link with a very small tire. 406 edelbrock heads, 170 shot plate system, th350 3800 stall, 12 bolt with gm posi and 3.73, 26x8.5 MT's, I have a sway bar, airbags in both springs run them both at 25psi. The car leaves extremely hard 1.47 60ft times. It still has the stock upper and lower control arms that have been boxed. The only reason I put the bags in was cause the car was squatting so hard that the pinnion was hitting the floor board. It has went as fast as 6.79 @ 102 in the 8th. I have alot of passes on the car with all the stock suspension and have dialed it down pretty good. The car is in the garage right now, I took it apart to freshen it up and put a bigger solid roller cam in it. If you need any info feel free to ask, I can point you in direction that I should have taken when I first started building the car. He upgraded the motor since then.

I am undecided if I want to stay with the stock suspension or go to a ladder bar set up I know ladder bar would be better than the stock suspension but car would be worth more if i did not cut it up, so I think I am going to stay with the stock suspension.

I know ladder bar would be better than the stock suspension but car would be worth more if i did not cut it up, so I think I am going to stay with the stock suspension.

Last edited by BigTruckDriver; 03-08-2008 at 08:05 AM.

Friends dont let friends drive fords!

-

03-08-2008 08:01 AM #6

double postFriends dont let friends drive fords!

-

03-08-2008 08:08 AM #7

Stock suspension, especially one that is already a 4 link type, can be made to work.... Boxing the bars on the rear is important, gets rid of a lot of the flex in the stamped steel stockers... Use some good urethene bushings, you might also want to drill a small hole through the arm and bushing then install a grease zerk so you can keep everything moving freely and not binding up....same thing on the front end bushings.... Another thing on the front end; use some good lock nuts on the upper a-arm cross shaft and tighten the nuts enough to keep everything in position, but not so much that it compresses the poly bushing and restricts the arms movement....

The stock suspension will probably never hit as hard as an aftermarket 4 link suspension, but it's going to save you a ton of time and money on the build...and not require cutting up the car if that's important to you....Last edited by Dave Severson; 03-08-2008 at 08:10 AM.

Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

03-08-2008 01:16 PM #8

"the car was squatting so hard that the pinnion was hitting the floor board."

Install a pinion snubber.

I'll explain a little about engine angle for the younger readers:

When the factory designed your grocery-getter, they cut the carb mounting surface on a front-down angle so the carb could sit level and the tailshaft of the trans could be lower in the car to provide legroom for passengers. This angle was usually 2 to 3 degrees.

When doing an engine swap, like Dave said, it doesn't matter about the rake on the body. What does matter is the relationship of the crankshaft centerline to the pinion centerline as viewed from the side of the car. You want these centerlines to be PARALLEL to each other. Not pointing at each other necessarily, but parallel with each other like railroad tracks with the car cruising under minimum power. To achieve this, you would usually rotate the differential housing to the point where the crank and pinion centerlines are close to parallel, with the crank centerline at maybe 3 degrees down bubble and the pinion centerline maybe 2 degrees up bubble. This will allow 1 degree of pinion rotation upward under cruise power and the u-joints will be aligned for best power transmission and minimum wear.

Now, the kicker comes in when we begin drag racing the car and the pinion climbs the ring gear violently, upsetting the parallel relationship we had at cruise power. The u-joints are no longer transmitting all the power generated by the motor and in severe cases can break. That's why the rules specify a driveshaft loop (at 13.99 with slicks), to prevent the driveshaft from dropping onto the strip surface or augering up through the floor of the car to injure the driver. (360-degree loop).

So, what do you do? Well, you find a compromise depending on the type of rear suspension you're using. You install the differential housing (pinion) at somewhere between 2 and 8 degrees different angle from the crank centerline so that under extreme power, the u-joints line up parallel. In other words, with a leaf spring car, you might install the pinion at 5 degrees down bubble with the crank centerline at 3 degrees down bubble. This would allow the pinion to climb the ring gear by 8 degrees to line up the u-joints parallel.

You could also install a pinion snubber to limit the pinion rotation and use less differential of installation angle.

Different rear suspension systems will allow more or less pinion rotation. Leaf springs are the worst case scenario, then ladder bars, then 4-links. Dave Morgan lays all this out for easy understanding in his book.

http://www.amazon.com/Door-Slammers-.../dp/0963121707

A little more about engine swaps: It doesn't matter where you install the motor left to right in the car. Oftentimes you have to move it to the passenger side to clear steering or whatever. What does matter if that you install it with the crank centerline PARALLEL with the centerline of the car. Do no point the transmission tailshaft at the pinion unless it just happens that way due to pinion offset in the differential. Some Mopars have been found to have the motor offset to the passenger side by as much as 3 inches. As long as the motor/trans is parallel with the centerline of the car, the angles of the u-joints will cancel each other out and the joints will live a long and happy life.Last edited by techinspector1; 03-08-2008 at 01:21 PM.

-

03-08-2008 02:06 PM #9

I had a 1974 Vega GT with the 140ci / 4 speed . The car had a 6 1/2" ring gear rear end . Turned two of them stock rear ends into Dust . I know your not running the stock rear end But some guys try . The 1976 Vega's went with a bigger rear end and the Torque arm Like the Monza's . The main thing that I want to say is . On the Vega I had it was a clean rust free one . One night when shifting 1st to 2nd I ripped the Lower control arm were it bolts to the uni-body . And this was with a 140ci engine . If you run the stock control arm set up . Reinforce were they mount on the body .

-

03-08-2008 03:44 PM #10

Good point tango. Had a '59 Stude V8 that pulled the front leaf spring mount out of the unibody sheet metal. Too many side-steps on the clutch.

-

03-08-2008 08:51 PM #11

Oh yeah, when you put your frame ties in, I would make the rear mount for them to be the lower A-Arm attach point... I've got it on the 'maro, if I remember I will post up a picture of how I did it.... Anytime you can make an add on to the car to serve two purposes, you'll be saving weight and improving the appearance by not having a lot of extra brackets and tabs hanging all over the car.....Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

03-08-2008 08:53 PM #12

Then it wouldn't be necessary to tell you how poorly my '57 Ford behaved with the shackles flipped and a 312 for power!!!!!! Originally Posted by techinspector1

Originally Posted by techinspector1

Hey, it looked kewl!!!!!

Hey, it looked kewl!!!!!

Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

03-08-2008 11:42 PM #13

Kewl Kemp Daddy-O.

-

03-08-2008 11:55 PM #14

Well, when you're 15 it sure is!!!!!! Originally Posted by techinspector1

Originally Posted by techinspector1

Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

11-29-2014 04:32 PM #15

ok, thanks for the great info.

Life got in the way a little but back on the project

Friends dont let friends drive fords!

Welcome to Club Hot Rod! The premier site for

everything to do with Hot Rod, Customs, Low Riders, Rat Rods, and more.

- » Members from all over the US and the world!

- » Help from all over the world for your questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and hundreds of thousands of posts!

YES! I want to register an account for free right now! p.s.: For registered members this ad will NOT show

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Thanks guys! One more trip around the sun completed. Lots of blessings and things to be thankful for (like still being able to type this message!!) Here's to us "over 70 guys.." Glenn

HBD Glenn!!