Thread: Wiring How To

-

07-06-2009 03:06 PM #1

Wiring How To

I will have to rewire my car and was wondering if anyone created or has a link to a good wiring how to.

I see lots of stories of people wiring incorrectly, making a mess, unsafe, etc. However, I don't see a lot of posts of GOOD wiring jobs.

Hopefully a good wiring how to would have:

How to solder correctly, how to use safety measures like relays and fuses, how to safely protect two wires joined together, etc.

A lot of people say that seeing awful wiring jobs scares people away from trying wiring themselves, but I haven't seen a good how to with pictures and the like. I'd love to tackle the rats nest and connect things correctly, but I need a how to. That's just how I learn. This doesn't seem like something you can just "try out" without keeping safety in mind.

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

07-06-2009 04:09 PM #2

There are a lot of commercially available wiring kits on the market.......some good and some not so good. I've heard good things about Ron Francis' kits and also American Autowire (which I bought for my Son........yet to be installed).

I've always done my own wiring from scratch, but we used a Summit kit that I think is made by Painless for my Son's T bucket. It was NOT painless. All three of us have done a fair amount of wiring (Dan did it professionally on cars and boats for some time) and at times we had to put our heads together to try to figure out what the instructions were saying. In the end we just did it our way, and it worked out.

As for the soldering vs crimp thing, you will get all kinds of opinions, but I crimp. I come out of the marine industry and soldering is a no no on boats as it can create hard spots and brittle wiring. If it is done right I guess it is fine on a car, but good quality crimp terminals are pretty idiot proof IMO.

Another consideration is if your 55 is a stock restoration or a hot rod. If stock you will want the original style harness, but if not stock the sky is the limit. I think as long as you don't go cheap you will be fine with one of the name brand units.

Don

-

07-06-2009 04:21 PM #3

It is certainly acceptable to crimp terminals....the auto factories have been successfully crimping for years. Solder does have its merits but it also has its drawbacks in a vibrating environment.

Regarding crimping, there are two common mistakes that the average person makes by using the "universal" AMP plier type crimper.....too loose a crimp and too heavy of a crimp. We all have seen too loose a crimp since the wire pulls out of the ferrule. If you crimp too tight, the strands of wire are damaged and can break; a few at first and then more.

IF you crimp, invest in a set of semi decent ratchet crimpers. It make the task much easier and you get a positive crimp each time.

Of course, if you are doing WeatherPak or MetriPak terminals, they each have their own crimp tools. You can buy them several places; Del City wiring has them. For just one car, they pay for themselves.

Part of a good crimp and terminal is the wire support to keep the load off of the wire connection. Use tie bases or some device to allow the use of either tie wraps or cable lacing to support the harness....do not let the weight and vibration of the harness (or wire) rest on the terminal junction.

The worst wiring connection is a butt splice that was done with a pair of amp pliers....a failure mode ready to happen.

mike in tucson

-

07-06-2009 04:43 PM #4

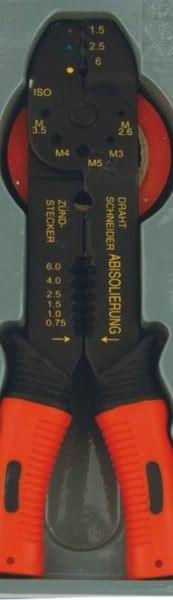

Robot....This is the crimper I have. I used it to install a few CD players. That's about it. I used it for crimp butt connectors. Is that what you were saying NOT to do?

-

07-06-2009 04:46 PM #5

Don....This is for a 36 dodge, not the 55.

The car had a new kit installed. It was just installed incorrectly. The wires are connected to the wrong things even though it states on the wire what to connect it to. I guess I was more or less speaking about how to join/connect the wires correctly.

Past owner, not the guy who actually wired it, said it needs to be rewired, but it comes with a complete 20 circuit wiring harness in the box and that the wiring in the car was new, just not connected to the right things! My first concern is that wires are connected to the proper components and that they are safe. Not necessarily that everything LOOKS beautiful.

You said above, "good quality crimp terminals are pretty idiot proof IMO." Guess I'm asking how to do a good quality crimp terminal.

Here is some of the fun I will have to deal with:

-

07-06-2009 05:13 PM #6

Yep, those are "amp" pliers....dangerous tools.

A good ratchet crimper is under $50.

mike in tucson

-

07-06-2009 05:17 PM #7

If I get a good ratchet crimper, do I still connect the wires the same way with the butt connectors? Or is that looked down upon and viewed as a poor connection?

Also, you might think this is stupid but can you find a random link to what you would consider a good ratchet crimper so I know what you are talking about?

Thanks so much. I really appreciate it.

-

07-06-2009 05:22 PM #8

Everybody has their favorite tools. We've got a bunch of different crimping tools ranging from simple plier types to the racheting ones. Our personal favorite is the simple Channel Lock brand cutter/crimper. Runs about $ 20.00 and does a good job.

Don

-

07-06-2009 05:33 PM #9

Don...thanks! You said above, "good quality crimp terminals are pretty idiot proof IMO." What does a good quality crimp terminal entail? Something I should look for? Something I should NOT do?

-

07-06-2009 07:07 PM #10

Well - here's my two cents.

Klein, in my humble opinion, makes the the best rachet-type crimpers for insulated terminals - they are expensive, but you will never need to buy another set as these will be tools that your grand kids will use.

I also have two sets like the The Channel Locks shown above however; they are for non-insulated terminals - typically copper crimps. In a re-wire, you will use insulated and bare terminals so both types are appropriate.

Regards All,

Glenn"Where the people fear the government you have tyranny. Where the government fears the people you have liberty." John Basil Barnhil

-

07-06-2009 07:09 PM #11

Forgot Klein link:

http://www.ktool.net/servlet/the-285...h-Cycle/Detail

And for what it's worth, butt splices are fine if sized correctly and crimped with with a ratchet crimper."Where the people fear the government you have tyranny. Where the government fears the people you have liberty." John Basil Barnhil

-

07-06-2009 10:25 PM #12

I don't use the automotive grade terminals like you find at Autozone. Working in the marine industry I've come to like Ancor brand wire and terminals. Each strand in the wire is individually tinned, and the ends are a little thicker than the auto grade stuff. You can find these parts at most marine discount stores (any more there is pretty much only West Marine, the others have folded) But if you have a large boat yard kind of place in your town you might check there. Not real cheap, but good stuff. Some even feature built in heat shrink tubing, so after you crimp it you heat it with a heat gun or hair dryer and it will shrink up and seal any moisture out.

I wired my 27 20 years ago with Ancor parts and that car sat in the rain many times. Never had a wiring failure and I could probably still use all of it when I redo the car, but I won't just for GP.

Don

-

07-07-2009 08:20 AM #13

Crimper 101:

The plier-type crimpers DO NOT control the amount of "squish." The amount of crimp is controlled by how far you squeeze...you migh squeeze too much, too little, or just right.

Ratchet crimpers control the amount (or size) of the final crimp so every crimp is the same....ratchet crimpers have several jaw opening diameters so you get the correct diameter. Also, ratchet crimpers have wider jaws so that the crimp area is distributed along the length of the terminal.....cheap amp pliers crimp in a very short area so you usually end up making two crimps on the terminal barrel.

As several guys have said, good crimp tools are expensive but they last forever. We have several thousand dollars in specialized crimp tools.....but a single good set of crimpers can be pretty inexpensive....especially if a connection lets go in the middle of the night.

mike in tucson

-

07-07-2009 08:47 AM #14

Glennsexton wrote:This will only be true if you drill a hole in one of the handles, and then attach a 50 foot lightweight aircraft cable to the handle and the other end to a roof trust or other sturdy garage fixture. My crimpers and other select tools have bad habit of growing legs and taking leave of the premises.Klein, in my humble opinion, makes the the best rachet-type crimpers for insulated terminals - they are expensive, but you will never need to buy another set as these will be tools that your grand kids will use.

Bob

A good friend will come and bail you out of jail....but a true friend will be sitting next to you saying..."Damn....that was fun!

-

07-07-2009 09:01 AM #15

Del City and others, I'm sure, also sell a connector with the solder inside the terminal and a piece of shrink sleeve tube over it. Slip it on the sripped end of the wire and hit it with your heat gun, the solder melts and the shrink sleeve shrinks!!! Works great and holds tight. I use either these or solder type connectors with a QUALITY small tip soldering iron and shrink sleeve over the terminal. Also, don't forget to use a bunch of tie wraps, and anything that has a possibility of being pulled away from it's connection should have a strain relief on it.... On multiple wire looms, I also like to use the waxed string and convuluted tubing over the wires along with plenty of rubber insulated clamps to hold the loom. Takes time and costs a bit more, but quality usually does.......Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

A travel agent was sitting at his desk when he noticed an elderly couple standing outside, gazing longingly at the posters of dream vacations in the shop window. They looked sweet, and honestly, a...

the Official CHR joke page duel