-

02-24-2011 08:12 AM #31

To expand on the pictures from OJ's event this past weekend, here is an online friendly tech thread on shrinking that should have prefaced the lead demo.

I didn't get as many pictures this past weekend (too many hammers in my hands) so this will be supplemented with some diagrams and previous pictures so we can make a good tech thread. But as a consolation prize, I am told a video made of the event is forthcoming.

Prior to Tom showing the body lead demo, I needed to make some panels for him to work from. We decided that a curved surface, similar to the front end of a 38 Chevy and its hood halves, would be a better fixture for showing the need for flowing lead up a slight incline. I started with two equal sized panels, and bent a flange on the long edge. Then discussed some of the issues faced when shrinking a flange. For demonstration purposes, in the following example we have a 12" long panel with a 1-1/2" wide flange.

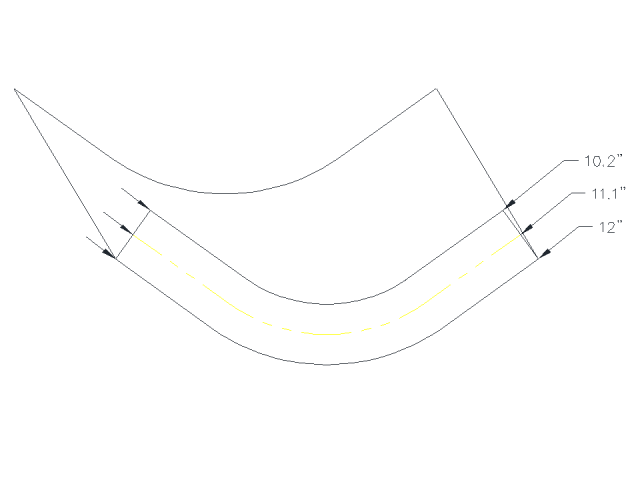

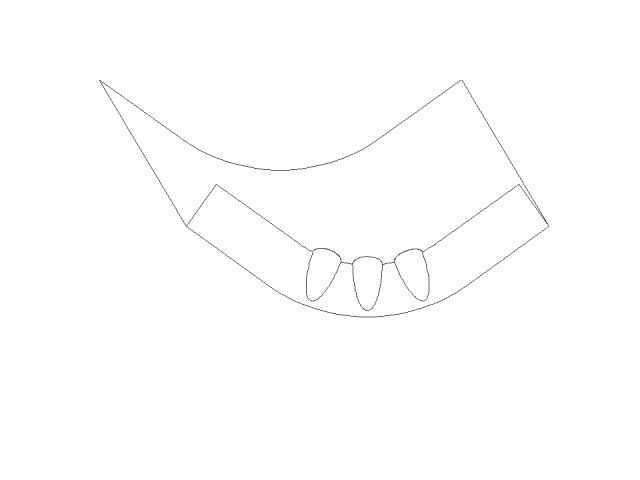

If we were to look at the same panel with a radius, formed by shrinking the flange, we would note dimensions similar to as follows:

....where the 90 degree bend at the flange still retains its 12" length, the centerline of the flange in this case is shortened by almost an inch, and the outer edge of the flange shortened by almost another inch.

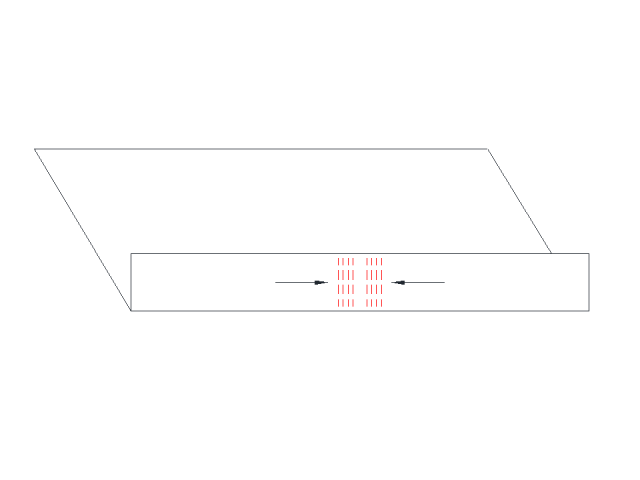

In working with the Lancaster/Eastwood style shrinker-stretcher machines, it is important to note that they are a linear device, the movement they introduce into the metal is in a straight line.

So that once a radius starts to form, and with the shrinking device still moving in a linear fashion, the outer edge of the flange will be put into tension as the centerline shrinks. Anyone who has used these devices will have seen this as the machine starts to lose its effectiveness.

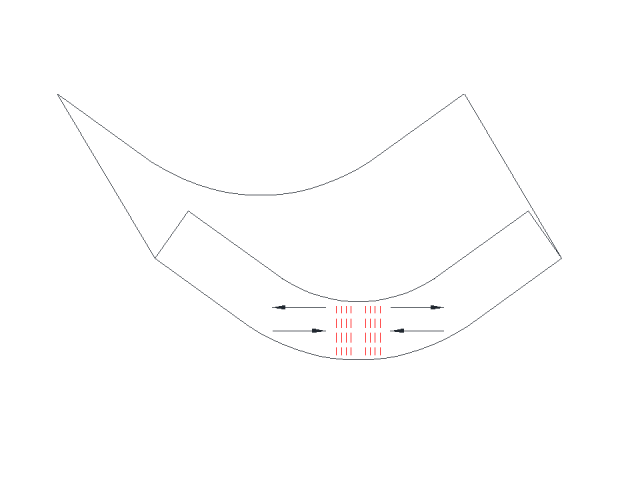

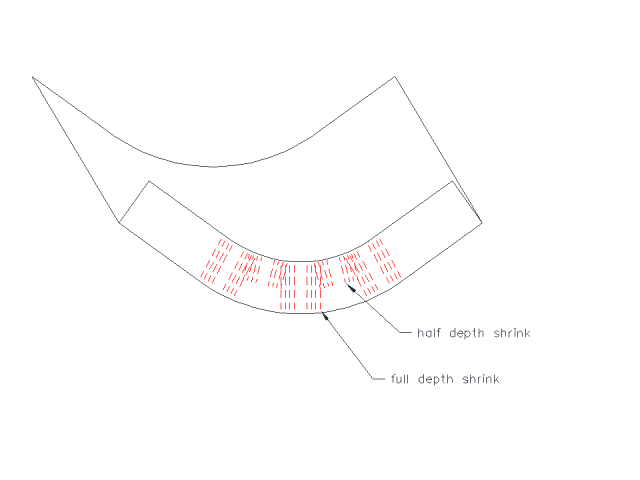

To counter this effect, we need to shrink the outer edge of the flange more than the inner. By simply alternating the depth of the shrink as shown, you can provide more shrink to the outer edge and the device will become more effective.

Another method of shrinking is with the use of tucks. Looking at their shape, the tuck has a wider "gather" at the edge of the flange as compared to the inside bend of the flange, so this eliminates some of the tension issues seen in the mechanical shrinker.

Where the demos this past weekend were supposed to concentrate on using only hand tools so that the participants could readily duplicate the results without the need for a major purchase, we did find the use of the Shrinker a good comparison, and by chance the tuck shrinking did prove to be faster and more effective.

For the tuck shrinking, one can use tucking forks, rounded jaw pliers (by design or modification) or special designed devices. As an example, here is a set of tucking forks I made out of some scrap metal and 5/8 bolts turned down.

And a pair made from needle nose pliers..

Probably the biggest challenge with their use is producing consistent tucks. To produce a flowing, consistent radius, we should start with consistent tucks, both in size and the spacing between them.

I decided to make a pair of tucking pliers out of Vice Grips, as the jaw adjustment on them would prove to give repeatable sized tucks.

We'll start off by finding a pair of vise grips suitable for the job, which in this case means the jaw serrations are starting to wear and round off and won't grip much of anything else. Finish what has started by removing the serrations to produce a nice flat jaw on the bottom, and cut the top one off at about 30 degrees from its original position.

I had some extra long shouldered 3/8 bolts, perfect round stock for the job. Three of them were cut off to 1-1/2" length.

Here's my economy model lathe made by Dewalt...

To set the spacing for the "fingers" the first is clamped in the vise grip jaw, centered.

The outer is placed next to it and then welded down the outside, center finger removed, and then welded down inside. Here we should leave a slight gap of your sheet metal thickness to prevent any binding, which will allow a deeper tuck.

Repeat for opposite side, then weld center finger.

Note in the above picture the 30 degree cut of the upper jaw positions the center finger at an angle compared to the bottom fingers. It is this angle that will help to form the tuck's shape.

Of course I took my favorite anvil along to the meet, here clamped in the vise..

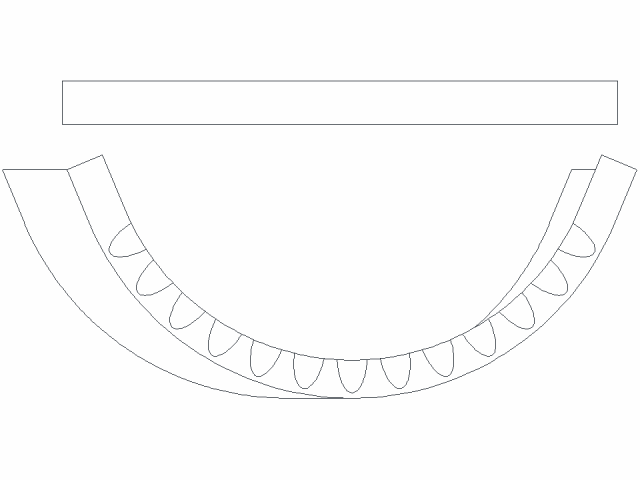

Again our object in this case is consistency, so equally spaced marks are placed on the flange, identical tucks made at each mark, and you can see the consistent radius along the panel.

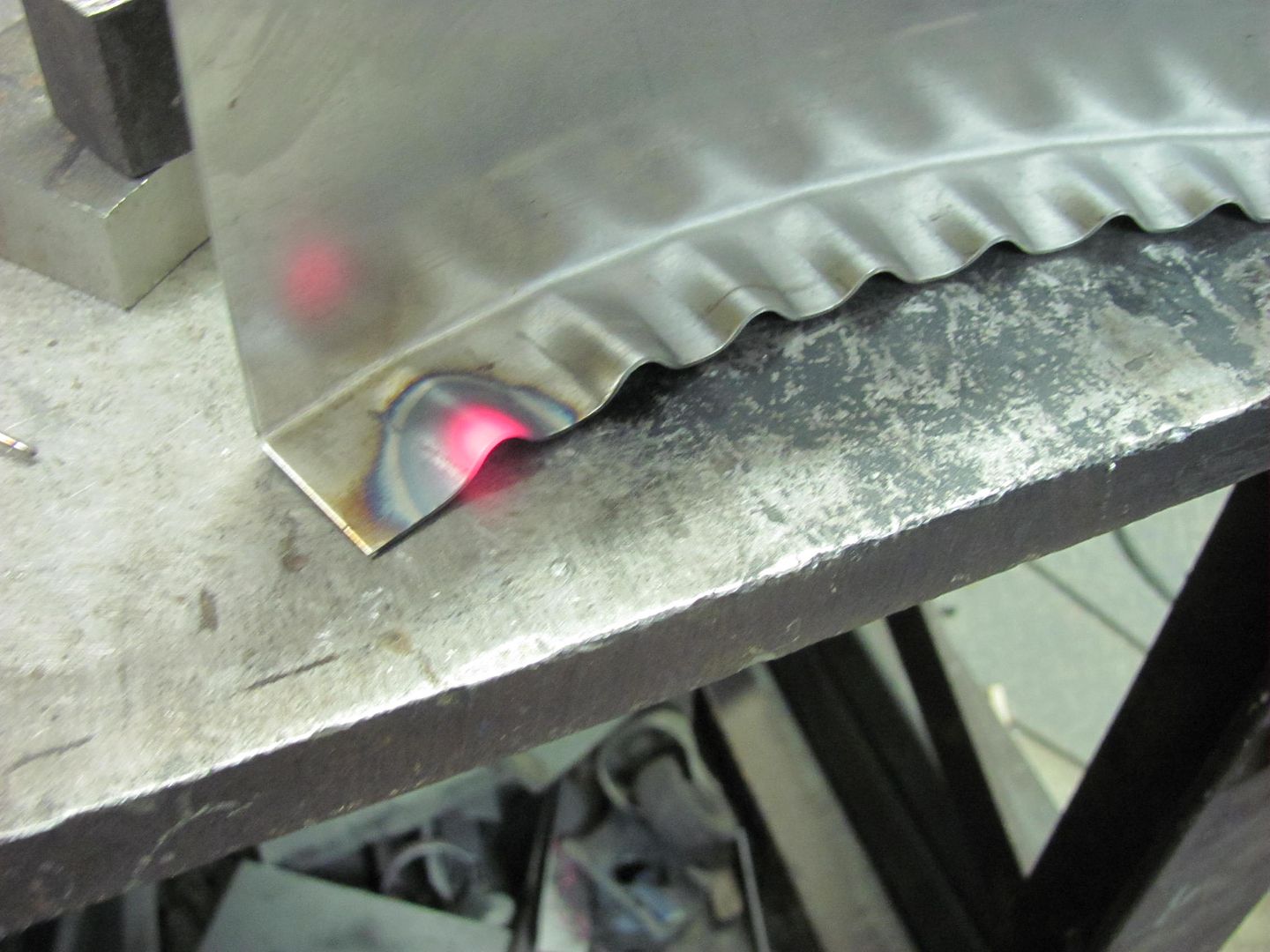

I use a O/A torch to heat the tucks prior to hammering them flat. Others prefer to not use heat, and can capture the tuck and flatten it very effectively without it. I am still working on this proficiency, so in the meantime, I use heat. We're looking for something like this, prior to hammering.

Here OJ assists with torch duties...

Another point to mention is that the hammering action tends to also spread the tuck back apart if not captured effectively. Where the picture above doesn't show it well, a good means of overcoming this would be to clamp a strap of metal across the ends of the newly formed radius prior to hammering, similar to this:

Then the hammering force will be more effective in flattening the tuck back into itself.

Once each piece was completed separately, the flanges were aligned back to back and the two pieces tacked together. Each had an identical radius, for a good fit. Consistency pays off!

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

02-24-2011 11:21 AM #32

And that, my friends, is how it is done! I have many books, been to seminars and purchased videos but this is the best explanation of tuck shrinking i have seen. Thanks for taking the time to post it Robert.

-

02-24-2011 07:49 PM #33

I enjoyed your demos, thanks for posting Robert!

I even made it in a picture..that's me in front of the Impala with the Powerade

'35 Ford coupe- LT1/T56, '32 Ford pickup, 70 GTO convertible, 06 GTO

Robert

Welcome to Club Hot Rod! The premier site for

everything to do with Hot Rod, Customs, Low Riders, Rat Rods, and more.

- » Members from all over the US and the world!

- » Help from all over the world for your questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and hundreds of thousands of posts!

YES! I want to register an account for free right now! p.s.: For registered members this ad will NOT show

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

I check in everyday and some are better than others. I don't think Brent has anything to do with the forum anymore, but I'm not sure. Hopefully as time moves on the forum will get better.

Where is everybody?