-

02-08-2011 10:58 AM #1

2nd shop gathering, metal shaping

We are getting together on the 20th for the 2nd of three wintergatherings at my shop. These gathering are free, any professionals in attendance are requested to refrain from any active self promotion of products or services.

This session will include basic metal shaping by Robert McCartney (metal shaper of the month, All Metalshaping web site), Robert will demo what you can do with basic hand tools, tech will include shrinking, stretching, planishing. Tom Mancuso, an old school metalman, will demo joint leading. John Herold (corvette restorations) will discuss surface prep for paint, inclu different etching & epoxy primers, filler primers etc. I will demo some basic welding with the tig and those interested are asked to bring a shield and they can try thier hand at it. I'll also demo fusion tack weld and butt seam welding without filler as applied to body panels and how to minimize distortion.

I'll open shop around 8am, people show up 9ish for coffee and donuts, the demos begin at 10ish, we'll have a deli style lunch and continue until we feel like going home.

This is all about a bunch of deliquent hot rodders getting together, share some knowledge and have fun doing it. I hope you can make it, my shop is Clarke Co. Speed, Berryville VA, about 15 miles of rt81 near Winchester. Shop phone is 540-955-0479 email is ojh4@verizon.net

We are looking for an ignition guy for the March session.Last edited by ojh; 02-08-2011 at 12:11 PM. Reason: spelling

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

02-09-2011 01:54 PM #2

Sounds like fun and it's nice of you to open your doors to guys like us! Too bad you aren't closer or else I'd be there for every gathering you guys held!www.streamlineautocare.com

If you wan't something done right, then you have to do it yourself!

-

02-09-2011 01:59 PM #3

Wish you could come, check in your area i bet theres plenty of like minded guys and enough talent so you can start your own gatherings.

-

02-09-2011 03:23 PM #4

Maybe next year - we are looking to relocate somewhere near Rocky Mount in Franklin or Bedford County in the next few months (well, maybe. I said that last year too )

)

Dave W

I am now gone from this forum for now - finally have pulled the plug

-

02-10-2011 07:06 AM #5

I am seriously considering joining you guys, maybe with my dad. I know next to nothing about any of that and it sounds like fun What was covered in the first session??

What was covered in the first session??

'35 Ford coupe- LT1/T56, '32 Ford pickup, 70 GTO convertible, 06 GTO

Robert

-

02-10-2011 08:16 PM #6

That is very stand upish to offer anyone some insight to how to work, bend, weld & paint metal at no charge.

WOW ...what a concept - people helping people without a personal goal in mind.

I wish I had the extra time.

KUDOS.

Ratty 46

-

02-11-2011 07:11 AM #7

Thanks for the kind comments guys, i appreciate them.

35fordcoupe, come on up - we really have a great time, not a know-it-all in the bunch. The last session focused on engine assembly, esp cam timing, degreeing, locating tdc, useing dial indicators etc to verify lobe lift, duration, proper opening and closeing etc.

I am personally excited about the metal shaping gathering, i don't know if any of you guys have seen metalshaping but i watched a guy (this was a few years ago and have been hooked ever since) take a chunk of 18ga metal and with a stump, hammers, english wheel he made a front fender for a willys coupe. It took him a couple days but it was perfect down to the headlight opening.

Robert is not going to teach how to do that, he could but the lessons would be lost on us because we don't have the fundamentals. He is teaching the fundamentals. Shrink, stretch and planish. Imagine the old tinsmith, he has some hammers, stump and little else and they would take a flat piece of metal and turn it into a tea pot. You do that by shrink, stretch and planish.

-

02-15-2011 09:54 AM #8

Ojh,

CRUD!!!! I was going to try and make it but just looked at mapquest. It is a nine hour drive one way. That means a total of three days, two round trip and the full day there. I am not going to totally give up on it yet but won't know until later in the week.

EdEd in Jeffersonville, IN

Street Rod Builder / Enthusiast

Journeyman Machinist / Welder / (Ret)

Viet Nam Vet (U.S. Army) USAF (Ret)

Disabled American Veteran

Patriot Guard Rider

Moderator Mortec Forum

-

02-15-2011 12:27 PM #9

Hurst01, i admire your enthieusasm but it is a long way. How about this, if you are in area - anytime - give me a call. I'll set aside what i am doing and we can spend all the time necessary metal shaping and screwing up metal like professionals.

-

02-15-2011 03:08 PM #10

I certainly appreciate that. I am a Journeyman Machinist and Certified Welder. I was Certified with the Air Force in 6 different metals using TIG. I am also certified in oxyaccetylene, MIG and stick. I don't do lap joints on cars, I butt-weld. I can pretty much cut a piece of metal out and weld it in place, change quarters and the like. Problem Is that I suck on shrinking and stretching and mud work. I have a shrinker/stretcher that I use on thin and small stuff but I need to gain some knowledge in other areas, like how to get oil canning out of a door, and shape other areas to suit my needs.

I don't like to use much mud, just a skim coat. I waste 4 times more than I need. I thought it might help to get some ideas on how to straighten some areas that I am not good at, and there are plenty of them.

I saw where you mentioned that someone made a fender from scratch. I saw just a bit of a program on TV a while back where there was a crew of about 5 really sharp metal workers that made a complete body for a 32 Ford Coupe in 5 days, fenders and all. It was straight as an arrow and all the sheet metal was just flat sheets when they started. I was thoroughly impressed. I don't have a clue on how to use an English wheel. I was hoping to learn something.

I am a totally disabled Vet and with all of my problems my years are numbered. I like to think that I have a lot of knowledge but sometimes I see how really "unskilled" I am in some areas.

I was hoping that you would be within 5 hours of me. I would have definitely made it it if that was the case. I was still trying to determine how I could do it but that is a long way and the expense of the travel and lodging tops it off. I can't tell you how disappointed I was when I brought it up on mapquest and it said 8 hours and 56 minutes.

The idea that you are hosting the work shop for the forum members is amazing. I like to see when others share their skills and how-tos and I for one appreciate what you are doing. I have done somewhat the same on welding, but find that most are not really serious about taking the time to learn. They want to do it RIGHT NOW and it does not work that way.

Maybe some day I can get around your way and we can swap a lot of lies.

Ed in Jeffersonville, IN

Street Rod Builder / Enthusiast

Journeyman Machinist / Welder / (Ret)

Viet Nam Vet (U.S. Army) USAF (Ret)

Disabled American Veteran

Patriot Guard Rider

Moderator Mortec Forum

-

02-16-2011 04:31 AM #11

I screwed up and didn't make it to Dutch Comstock's get together this yr.Well maybe I will meet up with them this spring because I have some work I want them to do for me.They are about 2 1/2 hrs away from me.Good Bye

-

02-16-2011 06:52 AM #12

Hurst01, you sound like a pretty talented guy - i bet you'll get a warm welcome at 'All Metalshapers.com'.

1gary, you missed a great metalmeet. I couldn't make it myself but attended Gatormeet just befor Dutchs'. Ben came over from Holland and at that meet thy chopped the top of a 53ish pickup - in 2 days, no body filler!

-

02-21-2011 06:49 AM #13

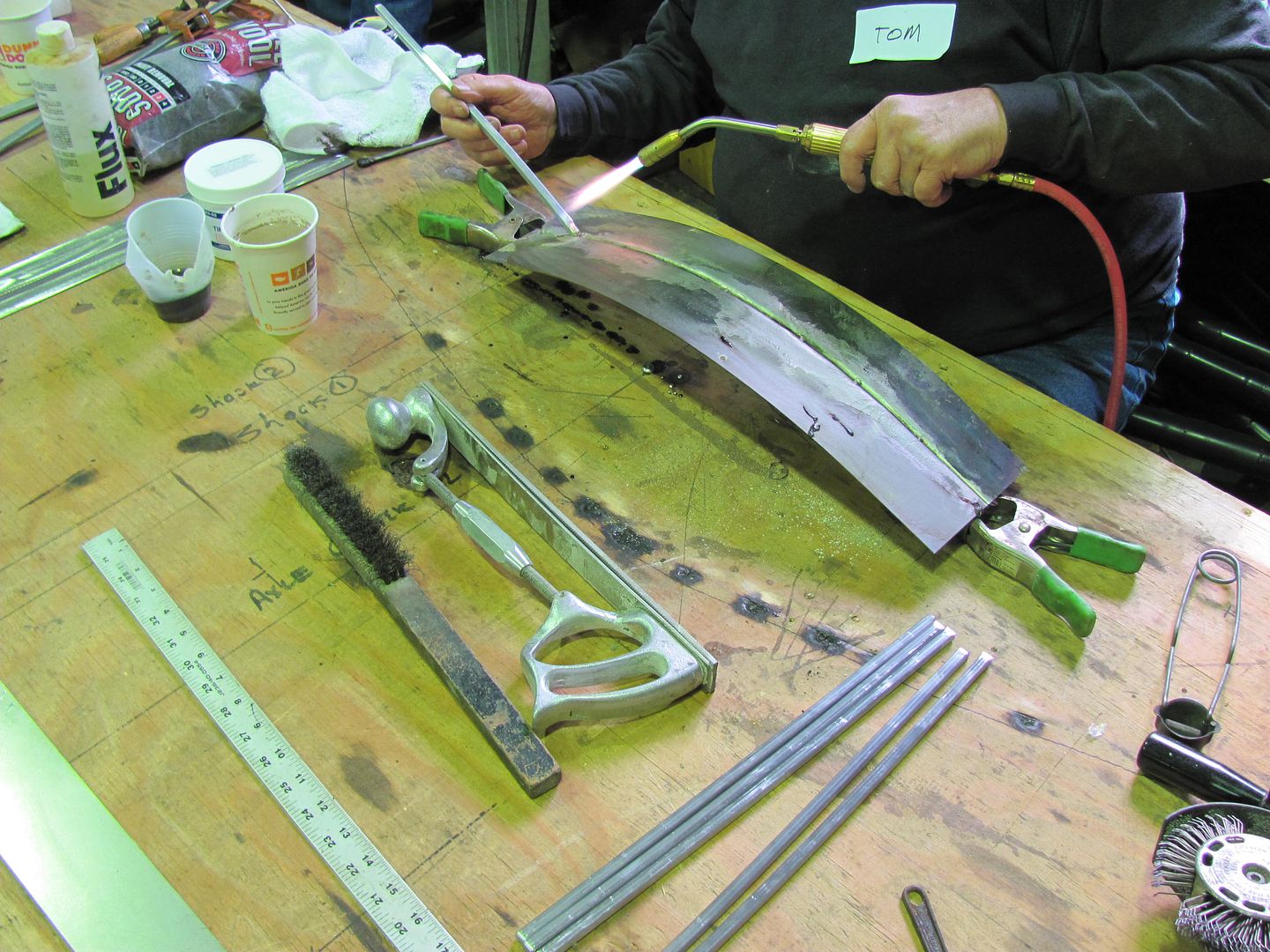

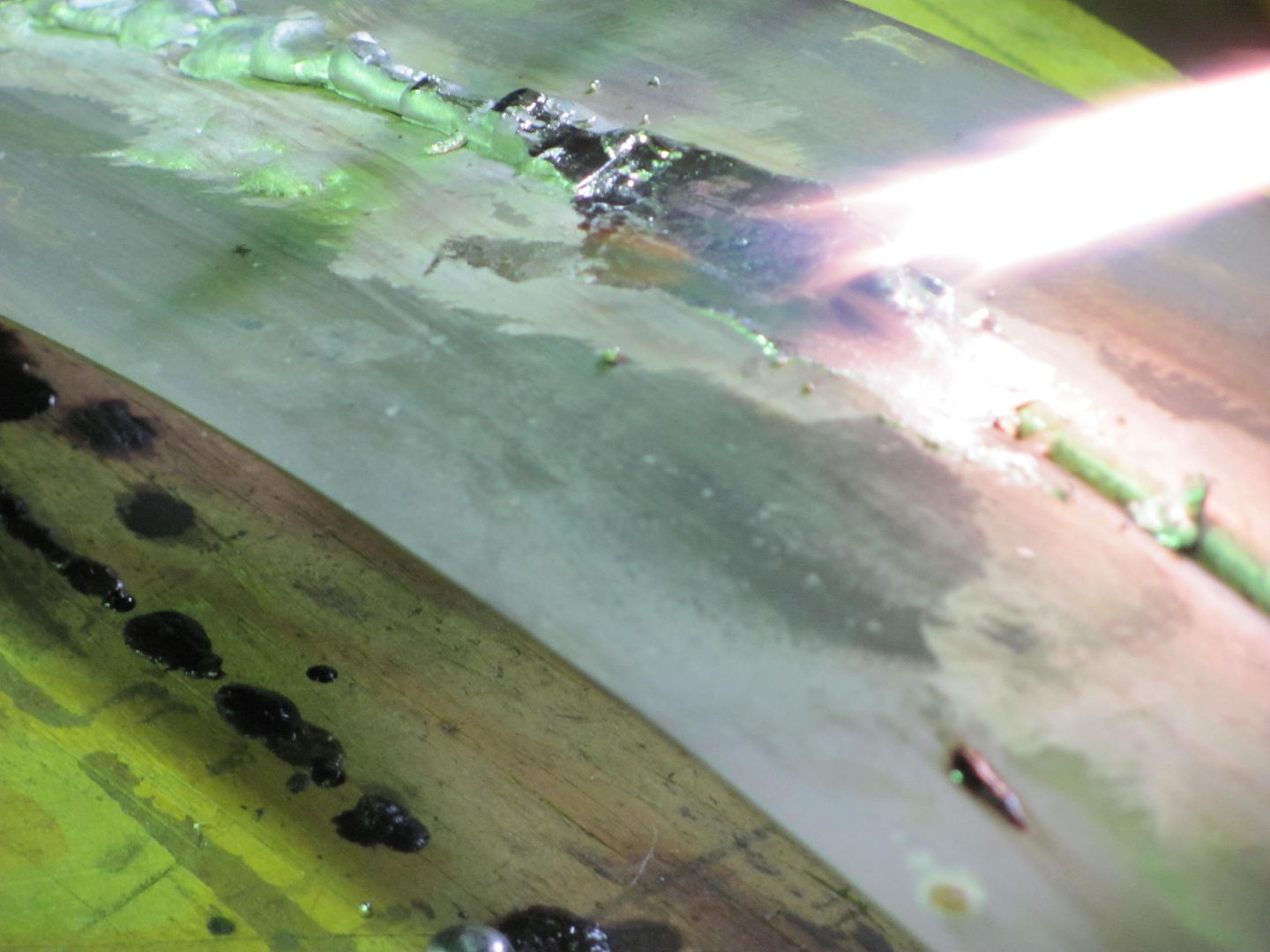

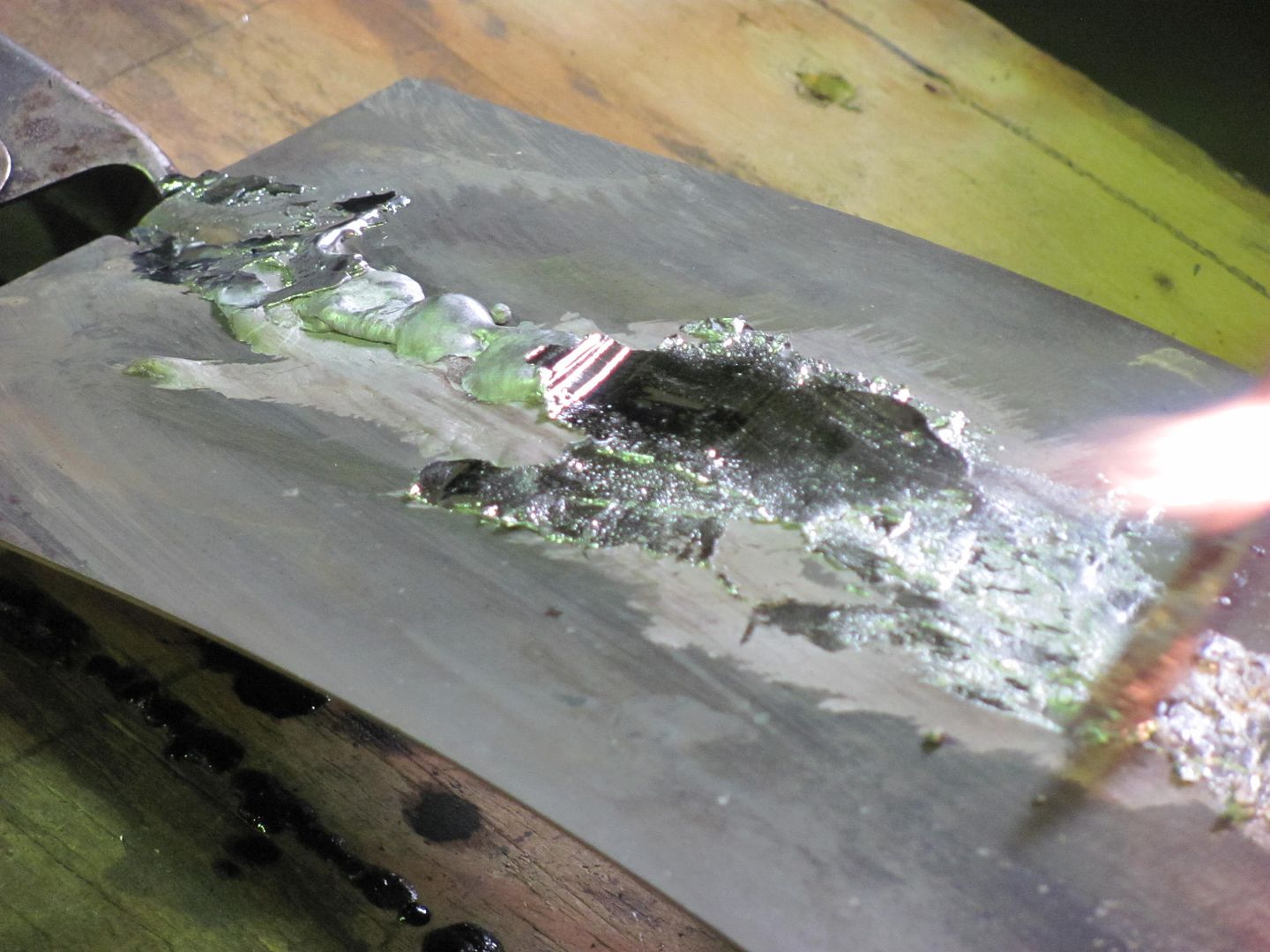

Here's some of the pictures of OJ's meet. Although I got these pictures of Tom doing the lead demo, and Dave doing the shrinking disc demo, I missed getting anything of that guy making metal scraps. But I am supposed to have more emailed to me, so I can post those when I get them.

But I am supposed to have more emailed to me, so I can post those when I get them.

Two flanged panels were tuck shrinked to form a radius. This was to simulate the leading edge of hood halves being welded together and leaded.

Tom using tinning butter on one half and plumbers flux (liquid) with solder on the other, to demonstrate the differences.... The liquid flux tends to get down into cracks better, for a better flow of the body lead.

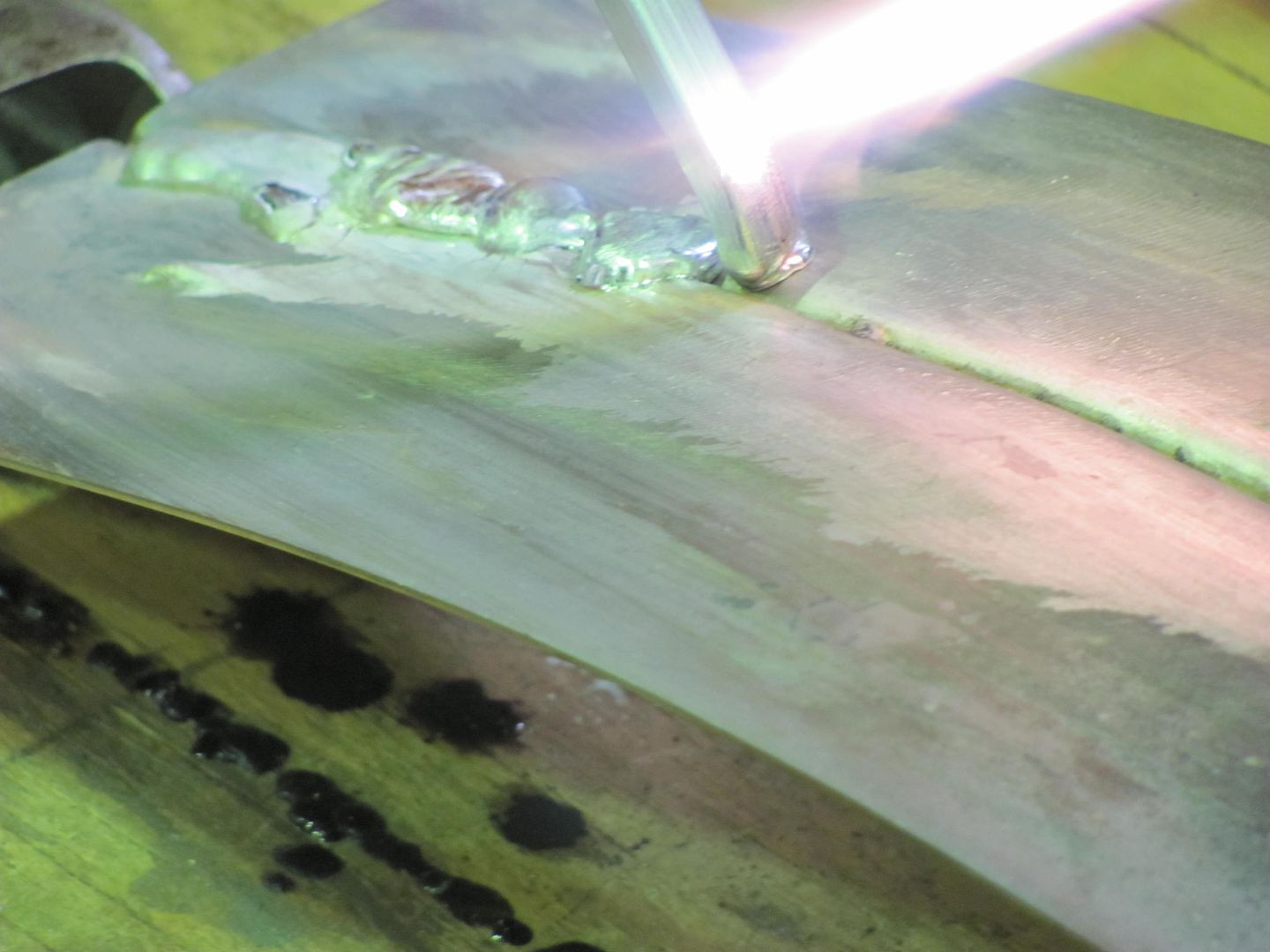

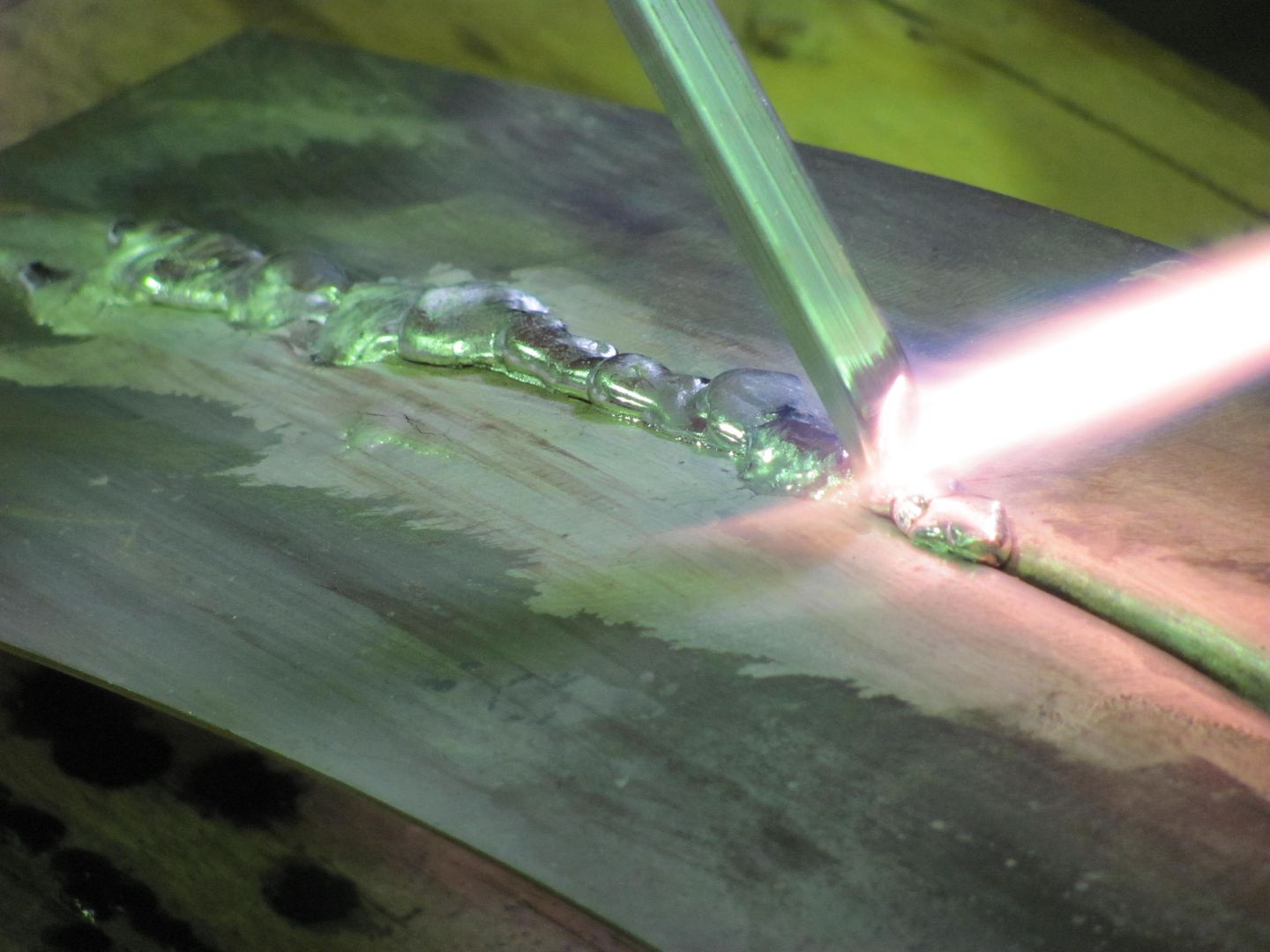

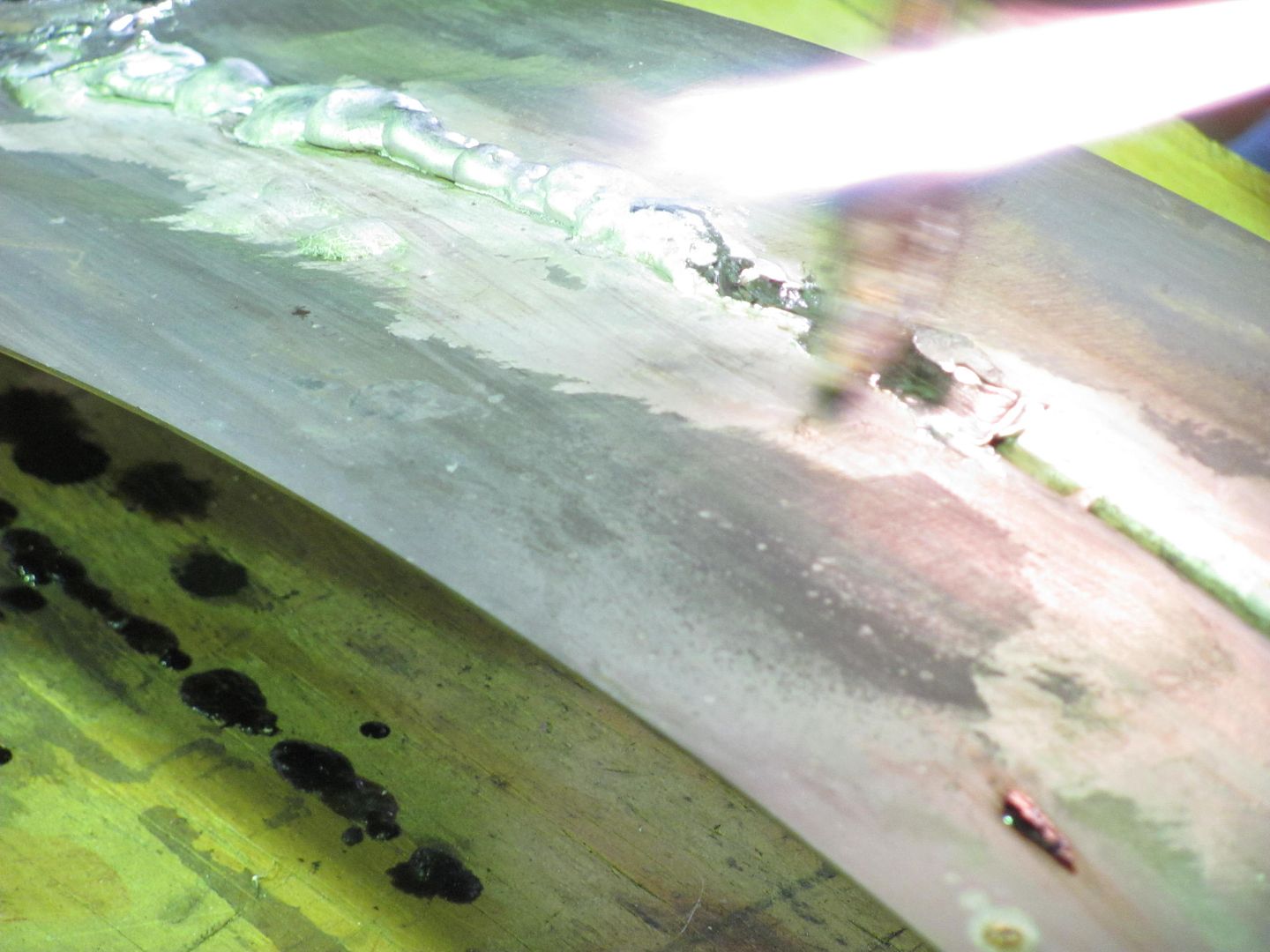

Adding the lead, pushing it into the joint...

Rather than use a wooden paddle and tallow, Tom prefers a vintage soldering iron that uses external heat (the torch in his other hand) It seems to do a better job of managing the heat and the "puddle". Even though he claimed he hasn't leaded anything in ten years, it was like old hat to him.

After our "hood" had a chance to cool, he demonstrated leveling the area with the vixen file.

Our completed sample

I think Tom enjoyed another crack at flowing some lead....

Got some pictures during the break of some of the vintage tin outside....

Back inside for more work on metal, Dave gives a demo using the shrinking disc.

-

02-21-2011 08:54 AM #14

Thanks again OJ! I appreciate you taking the time to open your shop up to everyone. It was hard to pull myself away from a day working on my car, but I knew I'd learn a thing or two that would stick with me for a long time!

'35 Ford coupe- LT1/T56, '32 Ford pickup, 70 GTO convertible, 06 GTO

Robert

-

02-22-2011 09:58 AM #15

It was a great time, nothing quite like watching and listening to a couple master craftsmen - very impressive. It was so good a definative DVD should have been made, i would buy a copy.

One thing i got from it was that there were a lot of younger guys, they were passionate about learning and asked the most questions. I have had these fears that ours was a dying hobby, NSRA is full of greybeards and nobody is coming along to replace them. I get the feeling we'll be in good hands.

And that Chrysler? be sure to invite that guy to any of your events, he makes a killer brownie!

Thanks, oj

Welcome to Club Hot Rod! The premier site for

everything to do with Hot Rod, Customs, Low Riders, Rat Rods, and more.

- » Members from all over the US and the world!

- » Help from all over the world for your questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and hundreds of thousands of posts!

YES! I want to register an account for free right now! p.s.: For registered members this ad will NOT show

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

This website will not be worth anything until if becones SECURE!

Not Secure